-

Posts

5,806 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

sewing machine Trouble changing stitch length on Singer 29K58

Constabulary replied to iknowit101's topic in Sewing Leather

Check If the tip of the bell crank lever is worn - this has a biggest effect on the stitch length. Also make sure the stitch length adjuster is correctly assembled. The gib has a notch this notch has to be upwards and the squared piece also has a notch and the notch here has to be downwards. if you have one or both parts the other way around the stitch may be shorter. Just suggestions w/o having seen your machine. -

flip down edge guige - I´m sure the Cowboy dealer have em

-

Help IDing this singer industrial model

Constabulary replied to telcelsmx's topic in Leather Sewing Machines

Singer 107w I would say. -

Sewing canvas

Constabulary replied to T Moore Medicine Hat Saddlery's topic in Leather Sewing Machines

agree for large scale tarps - since he said bedroll I assumed sizes of ground sheets for outdoor / camping or the like -

Parts list for your machine: SINGER 29K51,29k56.pdf

-

Sewing canvas

Constabulary replied to T Moore Medicine Hat Saddlery's topic in Leather Sewing Machines

any triple feed / walking foot upholstery machine will do the job - they usually sew up to 8-9mm material with up to 138 thread - few ca handle 207. Models like Singer 111, 211, Juki 562, 563, Adler 67, 167, Pfaff 145, 545, Consew 206, Durkopp 239 and similar machines. -

There are a few 29 (w/o K) which were made in the US. Singer had factories all over the world, F.I. German machines had a D until 1945 (factory then disassembled by the Russians) D for Deutschland and later from the 1950´s they used a G for Germany (Made in Karlsruhe) US machines either do not have a letter suffix or have W for the former Wheeler and Wilson plant. K suffix is for the Kilbowie, Clydebank, Scotland Singer factory. Lots of history.... You never know what you get from China you may have luck or not - I have ordered all my restoration bits from College Sewing and I´m quite pleased. Their 29K shuttles and shuttle carrier are excellent - made by TOWA in Japan http://www.towa-mfg.co.jp/ Cheap prices are always tempting - most likely I would have ordered from China too but back then these parts where not available directly from China / on Ebay. But as I said before - the parts from CS are good, the only bad 29K part I had was the ball tip spring for the shuttle carrier. But the TOWA shuttle carrier came with a good spring!

-

Not my design - just a DIY I did. The original afaik is from GRABOBBIN. So far I found no better bobbin holder than the magnetic ones. I soon want to make some for different size bobbins as for 132K´s, 29K´s, 45K´s and the like but need some larger router bits... But thats off topic here.

-

Have you noticed the PDF manual I have linked in post # 5 Here it is again: If you can´t download it the problem is probably your "internet device". I can download it to my PC - are you using a cell phone / smartphone? #1 is for adjusting the presser foot hight depending on the material thickness you want to sew. #2 is for adjusting the top thread tension #3 is for locking the revolving handles

-

Isn´t it a bias tape binder? Do you run leather tape through it? If so how thick is the leather tape? Would be nice to see a small video. I guess a right angle binder would be the better choice especially for sewing curved items.

- 34 replies

-

- sewing machine

- binding

-

(and 1 more)

Tagged with:

-

Toledo sewing machines has a nice needle / thread chart: https://www.tolindsewmach.com/thread-chart.html

-

regarding needle - you can use 29x3 / 29x4 (same as 332) - or - 135x16 / 135x17 needles.

-

Not a too bad choice - the 29K5x series is very similar to the later 29K7x series - major difference it the gear box - yours has a fixed horn and "drop out" gear box with very fine teeth pinions - no replacement parts are available for this gear box, the pinions of the 29K7x series DO NOT FIT (so be careful when you remove the gear box for cleaning - do not loose or damage the pinions!!!). Compared with the 29K51 your machine has a slightly narrower horn tip - everything else is the same as on the 29K51. The head is almost the same as from the 29K7x series and almost all parts for the head are available from College Sewing in the UK. Only difference that I recall is that the needle bar driving lever is pinned on your machine - the 29K7x series levers are not pinned... that's at least what I recall. You can get the bobbins from College sewing too: https://www.college-sewing.co.uk/store/Singer29K,29USewingMachineParts If you cannot find a manual you can use the 29K71 manual - you will notice the difference but threading, bobbin winding and so forth are all the same. Singer 29K71, 29K72, 29K73.pdf

-

92 or at max. 138 makes sense. However - I have seen Adler 30-1 setup for 207 thread (they are using the same shuttle as the 29K so no big difference technically) but it depends on the needle plate (needle hole in particular) and if the thread hole in the shuttle is wide enough. BUT 207 really make no sense for these machines because of the very small capacity of the bobbin. These machines are designed for repair work and not for producing leather goods. Prior polyester and nylon cotton and linen thread have been used.

-

Singer 29k71 not sewing, need help!

Constabulary replied to paqman's topic in Leather Sewing Machines

I don´t know how many different Chinese Co´s (re) fabricate parts for the 29K7X models but you "at least" are able to find parts for your machine. It´s no longer the OEM quality you get but you CAN get parts. For older 29K models you almost find nothing but used (worn?) parts. Most likely the new after market 29K parts you can buy nowadays are made to fit the Chinese clone machines and they (probably) have slightly different dimensions than the original British made 29K Singers from the good old days. Nothing beats OEM parts! BTW - the shuttle carrier I bought worked w/o problems only the pinion was tight but it worked. This was my 29K71 experience: this -

Maximum thread size for Singer 211U566A

Constabulary replied to Arenaldiel's topic in Leather Sewing Machines

Most machines of this class can handle size 20 / 138 (with 22 / 140 needle approx) thread but some even size 15 / 207 (with 23 / 160 needle approx) - but depends on how they are setup. -

Adler 669 suppliers/dealers

Constabulary replied to NewYorkerInSydney's topic in Leather Sewing Machines

Check with Sieck.de in Germany - afaik they ship world wide: http://www.sieck.de/maschinen/naehmaschinen/3-fachtransport-naehmaschinen/details/7876/ -

Pfaff 1245 or Adler 067-GK373

Constabulary replied to plinkercases's topic in Leather Sewing Machines

no matter what setup the 67 comes with I would always choose the Pfaff. Adler 67 has an (to me) odd stitch length adjustment, the timing belt is the week part of the 67. Replacing it is a pain. So take a good look at it, if it is old brown timing belt and it is brittle / cracked stay away from it. If I had to choose - I´d always choose the Pfaff (as long as there is no Singer in the game ) !!! -

Spare parts situation for Singer 111 type machines are for sure better than for equivalent Pfaff machines. Its not that you can´t get Pfaff parts but often you have to place special order at a Pfaff dealer and Pfaff parts are often a lot more expensive. That is one of the reasons why I try using only Singer machines though I live in Pfaff-and-Adler-Land. Yet no regret! You won´t find any other machine you find more presser feet for than for Singer 111 based machines. Don´t get me wrong Pfaff machines are for sure top notch machines but they do not sew better than Singers. It always depends on how well a machine is maintained / set up.

-

It easily sews 2-2.5mm veg tan but you have a very limited number of feet available for this machine. Some 141 can use roller foot but depends on how the machine is set up. But on the long view a compound feed / triple feed machine like the 145 or similar would be the better choice.

-

Adler 167 - Timing Belt Replacement

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Honestly - I do not recall. I have an Adler 167 service manual - look if you can get helpful information from it. I atm don´t have the time to cross check it. EDIT: file to big to attach - please send me your email address by PM so I can forward it. -

Reg braking power - I figured (and i only have experience with JACK Servo Motors from College sewing) that the 750W Motors have a harder / stronger brake than the 550W motors. I put a 550W motor on friends a Adler 105 and I have a 750w Motor on my Singer 45D91 (both machines are the same class). The 750w motor makes a bit more noise but when you step off the pedal its a much harder stop compared with the 550W motor. My friends machine does stop but you can see that the needle still makes some way when you step off the pedal (if you know what I mean). These are the servos from College Sewing, they have a separate control box and accelerator unit https://www.college-sewing.co.uk/store/Jack-Servo-Motors The one you show looks like a "budget" servo you find on Ebay for below 100€ - they have a combined control box and accelerator unit! https://www.ebay.de/itm/220V-550W-Brushless-Motor-Servomotor-Nahmotor-Fur-Industrielle-Nahmaschine/273220104265?hash=item3f9d2ff049:g:ii8AAOSwrY9a~jgD Be careful - read the details - these motors (not sure if its the same as the Juki but looks like it is) start at 500 RPM (!!!!) most other Servo Motors start at 200 RPM - that is an important detail I think!

-

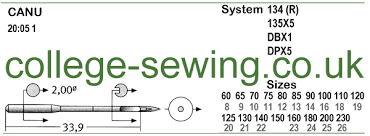

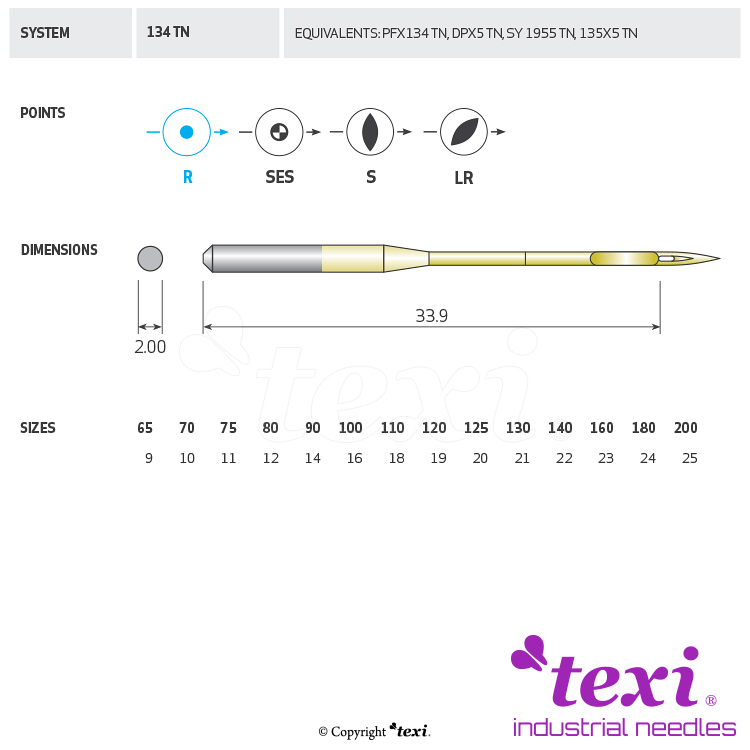

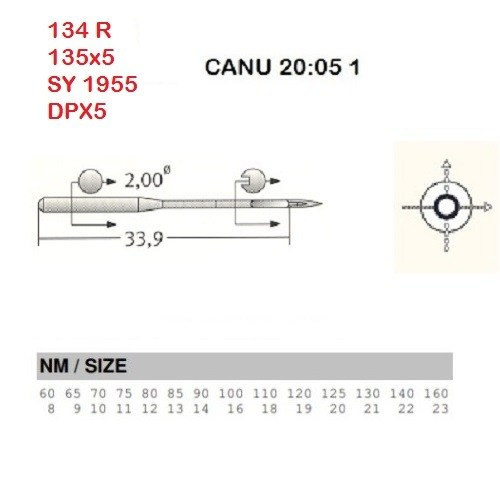

The needles are the same - you may find minor differences among different manufacturers but they all have the same length from top of shank to top of needles eye (as said before - with minor differences) - meaning they are interchangeable. Shank diameter is ~2mmm, length from top of shank to top of needle eye is ~33,9mm Other names for this needle is: DPx134, SY 1995 or even CANU 20:05 1 EDIT:

-

heard some of those folks are out there