-

Posts

5,801 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

150 for a complete gauge set is a bargain even for generic parts. You need a feed bog, throat plate, outside presser foot, inside presser foot and the needle holder with attached needle bar when needle holder and needle bar is 1 piece. Sometime needle bar and needle holder are split parts and you just need the needle holder - depends on what you have installed. When you changed the parts you have to adjust the 2 hook saddles and drive gears and adjust the needle and hook timing. Is it helps - the 145w shares the gauge sets with the Seiko JW-28BL and probably other machines too. Not sure if the Adler 221 has the same gauge set s but I think so. Hope this picture from an old Singer catalogue helps:

-

When I look at the gauge sets at College Sewing you could end up with $500 - $600 for a gauge set incl shipping and tax So depending on your needs, your project and the local market it would probably be cheaper when you buy a lets say used Singer 212 or similar with 3/8 gauge set. Gauge Sets for Singer 212 are dirt cheap - like $25 for a complete set. So maybe that's even an investment for the future. Just an idea w/o knowing what in particular you want to sew with the machine

-

What machines are these and any worth getting?

Constabulary replied to myjtp's topic in Leather Sewing Machines

If I had to choose I´d go with #3 + #5 #1 Singer 241 I guess #2 Juki 5550 I guess #3 Singer 211 #4 Singer 291 or 251 I guess #5 Singer 78 / Consew 128 I guess #6 Singer 31 / 31K I guess -

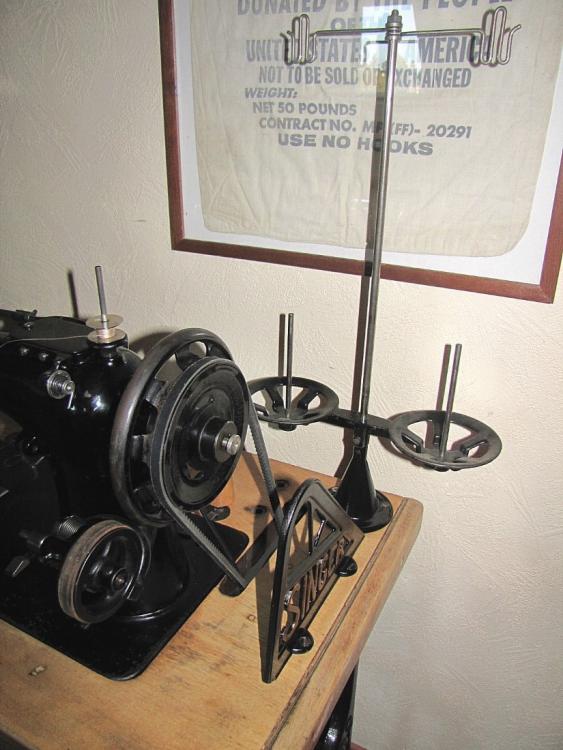

Its a Asian made Singer 29K71 clone with minor differences. Assuming you will buy it used - I´d test sew the machine to see if it suits your needs. I don´t think there are many folks that have long term experience with this brand. It´s just another Asian brand. If you need a manual for testing here it is: Singer 29K71, 29K72, 29K73.pdf

-

sure - same procedure as on any other sewing machine with a belt pulley on the hand wheel. Guessing you have a clutch motor the new servo motor replaces the old clutch motor. You will find dozens of samples here in the forum - just do a quick google search

-

Singer 132K SV 11 -> a 132K6 variant?

Constabulary replied to Constabulary's topic in Leather Sewing Machines

@dikman - thats a secret Singer technology only a few know of - its a self powered machine you can run it with plutonium but I have a hard time finding plutonium - have to check with the Russians . I´m about restoring the old clutch motor which really runs nice and smooth but not sure if I will install it here (but it´s just worth keeping), I think I will go with a JACK servo. Since I want to use the old motor mounting holes (1 left side , 2 right side - so just the other way around as on nowadays motor mounts ) and due to the speed reducer I have to make a extended motor mount to make room for the 2nd V-belt. Something like this... (stolen from Hot Rodders forum) -

Singer 132K SV 11 -> a 132K6 variant?

Constabulary replied to Constabulary's topic in Leather Sewing Machines

-

Singer 132K SV 11 -> a 132K6 variant?

Constabulary replied to Constabulary's topic in Leather Sewing Machines

sooo - my 132K6 setup is almost done Finally found a plate (badly wanted a vintage one) - well rather a complete machine from I which I only needed the plate but the rest is nice too. However for my setup I only needed the plate. I restored a stand earlier this year (see above pictures). Plate was dirty and oily but a lot of paint thinner and sanding made it look nice again - still have a nice vintage look. Plate is really nice quality and also has these nice extensions on either end. This is the "donator" I had to modify the plate to accommodated the larger 132K flat bed + hinges. Some pictures - I don´t think I have to make a lot of words: -

depends on if it has been treated or not. Untreated canvas can be re-dyed. The US military re-dyed a lot of webbing equipment after WWII (or probably late in the war already) from OD#3 (aka khaki) to OD#7 (aka olive green). If the canvas has been thread with stuff like CANVAK (waterproof treatment - feels waxy sometimes) or it is marked MRT (Mildew Resistant Treatment) you cannot dye it or the result will not turn out as expected. I heard sometimes that "light treated" canvas can be pretreated with clear vinegar so it takes the new dye better but I actually never tried this. Usually haversacks (if we are talking about M-1910 or M-1928 haversacks) are untreated. So a general statement is not possible - it depends...

-

Suspended edge guide doesn’t fit right? What to do?

Constabulary replied to myjtp's topic in Leather Sewing Machines

try counter sunk allen screws or extent the mounting points with a piece of flat steel - if you know what I mean. Or even both combined. -

Feed dog making dimple marks on leather

Constabulary replied to thatgriffguy's topic in Sewing Leather

Not knowing what machine you are using but I would first try to reduce the foot pressure. -

what looks like rust could be dried / old oil too. I´d soak the entire machine is hot washing soda solution (if you have a tub of the right size) and and use a brush for cleaning - you will be surprised how much "gunk" is conning off. You have to dry blow the machine with compressed air and oil it afterwards otherwise it starts rusting and seizing up. I did that more than once - worked well for me. If you want to preserve the decals just soak the flat bed - hot soda solution may damage the decals. You probably have already found a Singer 112w manual but I attach it here again - the procedure for replacing the timing belt is mentioned in the manual too. 112W140.pdf

-

I can send you ca PDF copy of the original German manual. Send me a PM with your email address if you are interested. Machine is missing the pre tension / thread guide for the bobbin winder - or maybe it in the drawer. Machine has no reverse - but thats not a too big issue

-

and thats just one sample - I´m pretty sure we eat a lot of stuff we better don´t know of or the food industry / lobbyists makes us belief its "safe" to eat w/o knowing long term issues / side effects. But that`s all off topic

-

A few pictures would be nice - if he has a Singer 97 or probably other nice vintage Singers I would make a trip to Denmark. I haven´t been to Denmark yet so....

-

Have seen this several times on German TV. Meat industry is making larger meat pieces from smaller (scrap) pieces for increasing their profit. Thats nothing new and not too unusual but they don´t make this public of course. I think it´s forbidden on my side of the pond but you never know - meat industry can be "filthy". Few years ago they found horse meat in Bolognese sauce. https://www.google.com/search?source=hp&ei=7JHYW-7mPO6grgTH2Ipg&q=meat+glue&oq=meat+glue&gs_l=psy-ab.12..0j0i22i30k1l9.3362.5629.0.14376.9.9.0.0.0.0.163.1316.0j9.9.0....0...1c.1.64.psy-ab..0.9.1305...0i131k1j0i10k1.0.ycemmyZFKSM Was just an idea in terms of leather

-

This is most likely not a qualified answer - but - has someone ever tried Transglutaminase (so called "meat glue") for gluing leather? Wild idea I know... Just wondering...

-

oops I did it again as the song goes - Singer 29Kxx

Constabulary replied to plinkercases's topic in Leather Sewing Machines

Again - compare numbers - the machines are different. http://www.horsenharness.com/SINGER.html Totally nuts prices for used (probably worn?) parts - thats ridicules. Before you invest in used pinions and parts better look for a different / later model machine. Rebuilding the shuttle area? You mean the inside where the shuttle oscillates? I never heard of that. The shuttle carrier has a spring with a ball tip, that ball tip presses the shuttle against the casting and when the shuttle tip is not too worn and the ball on the spring is fine you most likely just have to adjust the needle holder a bit sideways. As far as I recall the early 29K´s do not have a timing eccentric so the condition of the pinions and racks are essential. The 1st thing I would do (if it is not sewing when cleaned and reassembled) is buying a new quality shuttle (TOWA made) - I don´t know how good or bad the Chinese made shuttles are. Towa shuttles are excellent. Other question - have you pulled out the shuttle carrier with the attached pinion from the top side just as shown in picture #7 / #8? Or have you opened the gear box plate and removed the parts bit by bit? -

oops I did it again as the song goes - Singer 29Kxx

Constabulary replied to plinkercases's topic in Leather Sewing Machines

Sorry but the pinions you would need are not / no longer available as after market parts, the pinions you find on Ebay + so on are for the later model 29K71 - 29K73 but do not fit the the early 29K series (and sometimes they don´t even fit the later machines very well) There were at least 3 different type of pinions for the 29K series - your machines is one of the oldest. Not many parts of the "modern" 29K71 are compatible with your machine - there are a few but not many. Before you order spare parts compare the numbers with the parts list. I guess you already downloaded it, right? You don´t have washing soda (not baking soda) in Canada? Like Arm & Hammer? I´m sure you have that stuff. -

oops I did it again as the song goes - Singer 29Kxx

Constabulary replied to plinkercases's topic in Leather Sewing Machines

try washing soda solution for cleaning of the grime but as always be careful with the decals. -

Either machine 25€ + shipping - shipping costs depend on destination country. I ship worldwide (safely packed) I take paypal 96K40 is sewing and is smooth running - fully gear / shaft driven machine - needs TLC but is functional Singer 25-56 is a hat makers machine, it´s a project machine for restoration - very rare machine

-

Last Weeks! Firesale Landis 12 G $150, Landis Finisher $150

Constabulary replied to Toro's topic in Old/Sold

You have a PM -

Pfaff 138-6 Looking for price and parts help

Constabulary replied to Scoutmom103's topic in Leather Sewing Machines

Lots of rust, even on the hook and presser foot bar. Lots of unusual scratches behind the hook - seems someone tried "something". Often the ZZ mechanism is gummed up on Pfaff 138´s and you need patients to free it (heat gun and oiling until it works again). 20 bucks if you like restoring machines and hunting for spare parts. Better look for a nicer one. -

Singer 45k1 Restoration Decals

Constabulary replied to Parfektionisto's topic in Leather Sewing Machines

I have a 96K with short R SN EB644609 which dates back to 1937 and my 133K3 once also had a short R and that machine was made in 1932. Maybe that helps to narrow down the time frame.