-

Posts

5,806 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

Help! I'm reaching the end of my tether!

Constabulary replied to Cymro29k3's topic in Leather Sewing Machines

the foot lift lever is an early "push down" lever - modern lever do not fit. I only have seen this once - let me check if I find more pictures... you can ask a welder if he could weld a piece of metal on it to endlong the lever. EDIT: I once restored a 29K3 with push down lever. This it how it looks when correctly installed - sorry no other picture I recall it was a bit odd to install it but I do not recall what the problem was. So it could well be that your lever is the correct one - just broken. -

Help! I'm reaching the end of my tether!

Constabulary replied to Cymro29k3's topic in Leather Sewing Machines

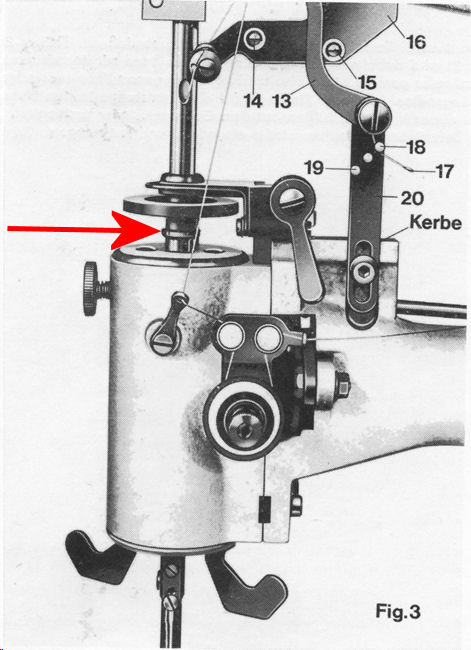

@ Yetibelle When I look at your pictures it seems there is a wrong part on your machine - the "vibrating presser lifting lever" appears to be too long. I guess its from a different / earlier 29K model. See big red arrow I added. Or it is just the angle... not sure... -

Help! I'm reaching the end of my tether!

Constabulary replied to Cymro29k3's topic in Leather Sewing Machines

As I said almost all head parts are interchangeable (with head I mean the "cylinder" cast iron part which is attached with 4 screws to the body - not speaking of the machine body or gear box). Difference that I recall between K51 and K71 head is that the lifting lever on the K51 is pinned whereas the K71 is just clamped and the lifting lever adjusting lever is a bit different. You sometimes have to read a bit between the lines when it comes to 29K patchers... Reg. unavailable parts - the gear box parts (racks, pinions) of the 29K5x are no longer available - their pinions are a lot smaller (29K patchers had at least 3 different size gear box pinions - depending on the subclass). But I know someone who is planing to make new pinions for the 29K5x machines but that may still take some time... I fortunately have a few spare pinions for the 29K5x series but they are not for sale. The 29K patcher series have changed a lot over the years (or decades). If you want to buy a 29K patcher I would recommend the later models 29K70 - 29K73 because all parts are available (aftermarket made in China), followed by the 29K6x series (gear box parts are the same and just very minor difference in the overall parts compared to the 29K7x series) then followed by the 29K5x series because the "head parts" are almost identical with the 29K7x series. Other than that I would not really recommend buying a 29K model except it is really cheap and you do not have much expectations. But as always it depends on the overall condition... An early 29K can be nice too but it´s all about the wear parts - JFTC you need some - maybe - one day... This is just my opinion based on the availability of parts for a long term use of the machines. -

Help! I'm reaching the end of my tether!

Constabulary replied to Cymro29k3's topic in Leather Sewing Machines

29K3 has the leaf spring on the backside, the internal helical spring came out with the 29K5x series and all later 29K machines have this helical spring too and most of the head parts of the 29K5x and later ("up to date") 29K models are interchangeable. -

Help! I'm reaching the end of my tether!

Constabulary replied to Cymro29k3's topic in Leather Sewing Machines

I understood it the way that the feeding is the main problem at the moment not the loop forming / stitch building Yetibelle - yours looks like a 29K51 - the 29K3 is a bit different -

Help! I'm reaching the end of my tether!

Constabulary replied to Cymro29k3's topic in Leather Sewing Machines

Hard to tell w/o sitting in front of it and watching the stitch cycle. Well - when cranking the machine - in the moment the presser foot moves back (for making a new stitch) and touches the needle plate the needle bar should be in its lowest position and should start rising. If this is not the case it "could be" that the pulley cam is in wrong position on the top shaft. Beside that - I guess you have the stitch length adjuster on the longest stitch right? Make sure the stitch length adjuster is correctly assembled. The squared frame and the gib have a "wedge" which have to be in a positioned correctly. The wedges give the presser foot bar space for its movement (feeding). Also make sure foot lift mechanism on the backside is correctly assembled and foot pressure is adjusted as low as possible. Position of the foot lift slider on the leaf spring is also important. I would like to see a pictures of the backside if you don´t mind. BTW - very special color -

identify this old singer machine

Constabulary replied to Carlosveiga's topic in Leather Sewing Machines

Singer 18 - left stand version of the Singer 17. If it has no tag compare the parts list of the class 18 machines. The details will lead you to the subclass I guess. -

You may need a heavier spring (old spring became weak over the time) and / or thicker brake pad or roughen the surface. Thats what comes to my mind first. Maybe to thick clutch pad material - maybe sand it down a bit... Hard to tell from a distance.

-

Documentation for vintage equipment/machines

Constabulary replied to LeatherworkingNovice's topic in Resources

Holy crap - these are nice manuals You "Singer patcher idjits" out there - check the PDF in particular the BOOK 4 section regarding Singer 29K series patchers. I never expected to see an Army manual for Singer patchers - very cool find -

Try a round point needle. It´s no that round point only can sew fabric. Thin leather often works fine with a round point needles. Or try S Point or DI Point needles See attachment - maybe it helps a bit finding the right needle SCHMETZ-14215_Leaflet-Schneidspitzen_GB-pdf.pdf

-

No dealer in Canada for pedestal stands? if you can´t find one modify a bench grinder stand.

-

What should I look out for when buying a Durkopp 291?

Constabulary replied to MrBurns's topic in Leather Sewing Machines

I know those "technical" sewing machines are tempting to buy but these machines are meant to run in a industrial environments having a sewing machine technician checking them when ever needed. For sure interesting to have all the bell and whistles but often enough they cause problems due to their age and you barely find someone who is still be able to deal with motors like EFKA Vario Stop or Quick Rotan and the like. I have tried it twice and both motors went to the junk yard. If those motors have issues in my opinion it is really not worth the time and money. However - if everything is well tuned and running - then why not But personally I´m a low tech fan - I like machines I can repair with a "hammer and a nail". I (personally) would remove the entire motor and replace it with a new servo motor and maybe a speed reducer. I think on the long view this is a more trouble free solution. Beside that - 291 are for sure excellent machines but as you said parts are $$$ and hard to find. College sewing in the UK have some parts and I´m sure most DA dealers can supply you with parts. Hooks and presser feet are extremely expensive. My 2 cents -

NO LONGER AVAILABLE - PLEASE DELETE

-

The JUKI 563 is based on the Singer 111 - pretty much a well proven machine / machines series (for decades!). It´s same with all sewing machines - you can have trouble with a poorly adjusted new $1500 machine and you can have fun with a used well adjusted $500 machine everything in between is possible no matter if new or used. The best bet is to test sew the machine (no matter if new or used) with the needle thread and material you want to work with. The Singer 111 type machines (like Juki 563 and some others) are very well technically documented - especially here in the forum. Tons of information / videos on trouble shouting and so forth. I think you can´t go wrong with it if it is as you described but as I said before you never know until you have test sewn it.

-

This is what I did to lower the foot pedal bar when I installed 2" casters. The pedal bar is custom and originally belonged to a different stand.

-

Pearson question re LH shuttle plate

Constabulary replied to plinkercases's topic in Leather Sewing Machines

-

Pearson question re LH shuttle plate

Constabulary replied to plinkercases's topic in Leather Sewing Machines

I´ll post pictures later. During the restoration I have replaced mine with a NOS one and it has not seen much use since then. -

halters Raised Nose Piece, Halter Making

Constabulary replied to Silverd's topic in How Do I Do That?

okay so then it most likely is the slider that you have fixed too far right and / or in an odd angle and it is hanging on the casting - move the slider a bit to the left and check again I think thats it.- 11 replies

-

- horse

- nose. stitching raised nose straps

-

(and 2 more)

Tagged with:

-

Adler 105 with extras on CL in MD

Constabulary replied to SilverForgeStudio's topic in Leather Sewing Machines

Yes, 105-65 with needle feed and bottom feed! -

halters Raised Nose Piece, Halter Making

Constabulary replied to Silverd's topic in How Do I Do That?

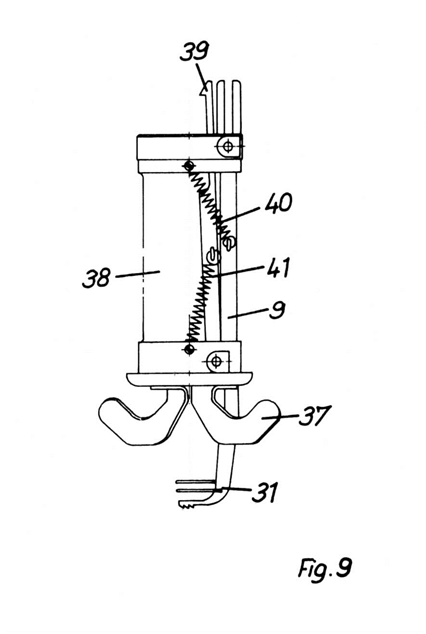

1.) I´d try is increasing the foot pressure. 2.) I´d check if the "hook nose end" #39 is hanging on the lower rim (see red arrow in 2nd picture) of the needle bar bushing if not this could be the problem. 3.) I´d check if the internal spring #41 is in place Hope this helps- 11 replies

-

- horse

- nose. stitching raised nose straps

-

(and 2 more)

Tagged with:

-

Who uses a Pearson #6

Constabulary replied to T Moore Medicine Hat Saddlery's topic in Leather Sewing Machines

I´m pretty sure it could (technically) but the largest needle you can find at most dealers is is 230 metric. Some may have larger needles but you barely find them on the "free market" meaning the WWW. -

Machine Choice Heavier Than A Juki 1541S

Constabulary replied to stickandtin's topic in Leather Sewing Machines

To my best knowledge - the large hook Juki / Seiko machines have a different hook saddles than the Singer 111 type machines - take a look at the parts lists. Changing the hook saddles is a lot of work (removing lower shaft, changing the saddle but back together everything and retime the machine...). That for sure costs good number of $$$ and time. -

Singer 95k51 hinges.. machine side?

Constabulary replied to plinkercases's topic in Leather Sewing Machines

as always - it would be good to see pictures, Singer used different type of hinges. -

The best synthetic thread I have used sofar is AMAN SERFIL / Synton (same thread AFAIK just renamed once) it runs so smoooth through any of my machines, love it! Other than that I like Gruschwitz GETAFIL P very much (I´m using 11/4 of this therad) - hellufa strong thread. I have not much use for such a strong thread however - it´s great! GRUSCHWITZ has some "technical threads" you might be interested in but I don´t know who supplies it / if it is supplied in the US. https://www.gruschwitz.com/en/products/standard-products.html

-

Consew 206RB rotary hook diameter request.

Constabulary replied to LederMaschinist's topic in Leather Sewing Machines

Wild idea I know but yours is wild too - how is this. put a good quality tight cardan joint on the hook drive shaft + a support bushing (if needed and you have enough space) and then you only alter the front bushing. Cardan has to be real tight otherwise if could affect the timing I guess. Ya know what I mean? Have to admit I don´t know how the 206 looks on the underside... Maybe it´s just an early morning brain fart EDIT Or is it what Bob mean with an angle? Then I better shut up