-

Posts

5,801 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

Singer 45k1 Restoration Decals

Constabulary replied to Parfektionisto's topic in Leather Sewing Machines

WOW - thats a really nice restoration!!!! How did you apply the decals w/o flaking? I tried it once and it did not work very well. I guess you used this micro scale decal film stuff, right? Which have you used? -

I like the Singer 307G2, Singer 107w / 143w Series along with 20U and 457 because you find a good range of needle plates feed dogs and presser feet for different applications. Other brands probably share these parts with Singer but I don´t know the "who is who of ZZ clone machines". Never underestimate the range of accessories that is available for certain machines!!! The availability of accessories and parts made me a huge vintage Singer fan. For the above Singers you find some nice broader feed dogs,and needle plates + presser feet and also "diamond / checkered" feed dogs with less aggressive teeth. BTW - the above machines all share the same feed dogs and needle plates but presser feet differ (guess how I know) 107w can also be fitted as straight and ZZ binder machine (maybe possible with the 20U too but I`m not sure). You also find blank presser feet for making a custom foot for the 107w, 143w, 457 - just in case... Other than that Pfaff 138 is great - IMO nicer than the predecessor 238.

-

singer patcher on battleship Scharnhorst

Constabulary replied to chrisash's topic in Leather Sewing Machines

you can also tell by thread regulator on the tip of the arm lever Well, Singer made sewing machines for the German Wehrmacht too. So a Singer patcher would not be too unusual. The German made Singer Patchers where marked 29D instead od 29K. Here is a war time Singer add saying Singer made special sewing machines for the apparel industry for the Wehrmacht. I think that was because they had a wide range of special sewing machines no one else made back then - just a guess. However just as most manufacturers back them (like Dürkopp and so forth) Singer in Wittenberge also delivered "non sewing machine materials" to the munitions / armament industry. -

45K´s are the heavier machines, they have much more weight on the flywheel so a lot more punch. The machine was listed at least twice - no one bid - what shame.

-

singer patcher on battleship Scharnhorst

Constabulary replied to chrisash's topic in Leather Sewing Machines

Adler patchers actually Nice Video! -

sample for a DIY speed reducer:

-

Aaron Martin has 2 samples of BUSMC / Pearson bobbin winders on his site - maybe they give you an idea how to make them: https://www.aaronmartin.com/product.php?catview=137

-

Singer 29 take needle head apart

Constabulary replied to chrisash's topic in Leather Sewing Machines

I have done this a few times and never needed a video or instruction nor I have written down an order or the like - all parts just fit on one spot - not much you can do wrong and there is nothing that can go out of time. Just start and take some pictures when you have removed a part. Only thing I want to point out is that the pins go out from back to front. -

Same thing with other leather sewing machines - F.I. you seldom find Singer 45K with its accessories (meaning different presser feet and sewing devices that belonged to certain machines depending on their subclasses.) it´s often enough just the machine you find. I have been hunting for a presser foot adapter for the sideways adjustable 45K presser feet I have but never have seen one for sell. I was about making one... Just recently I found one in a lot of vintage Phoenix sewing machine prats - totally different machine, the adapter does not even fit for Phoenix machines. I just looked at the picture and spotted this freakin adapter buried under several other parts (which I don´t need ) and I was just 75% sure it could be "the one"- I bought it and had luck. You have to spend time (and money) when you need certain parts for certain vintage machines. Best sample is LW member EVO160 who is looking for 45K parts for years just to complete his (2 I guess) 45K´s he is restoring. I found some for him, some came from LW member UWE and LW member Jimi, I know he bought a cast iron stand from Great Britain and he even reproduced a cast iron piece for the stand... I´m really looking forward to seeing his finished projects - especially the accessories he collected. Vintage sewing machiens really can be an addiction but - hell - it´s fun to keep them alive.

-

https://www.ebay.com/itm/123417296542 Looks like a good deal - lots of spare parts included

-

-

smartass mode on: uuuuhm - for sewing? - smartass mode off. It´s no too unsual to run a patcher with a clutch motor. Adler even had a clutch motor mount for their caliber 30 machines - will look for pictures...

-

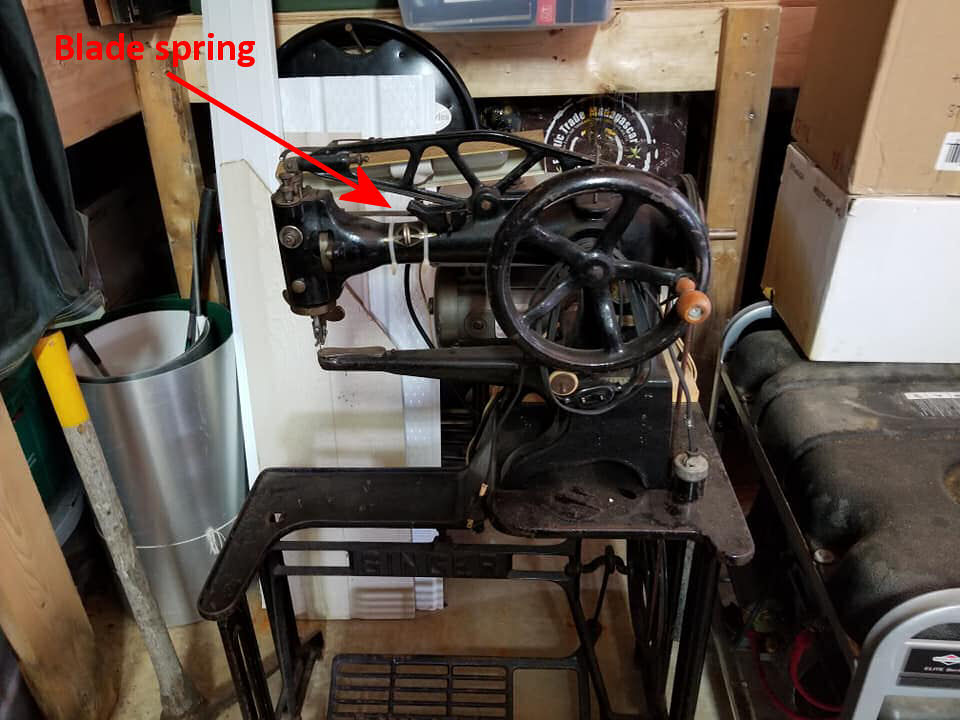

Not a 29K51 - 53 - it has a blade spring on the back side - the 29K5x subclass have helical presser foot spring it the head and no blade springs on the backside. I guess its an earlier 29K3 / K4 or the like. But its the later type treadle base.

-

Pfaff 335 17b h2L stitch problems

Constabulary replied to libbysstitches's topic in Leather Sewing Machines

Your pictures are too big most likely. I think you have to reduce the file size.- 18 replies

-

- pfaff 335b

- stitch length

-

(and 1 more)

Tagged with:

-

Holy smokes - I never have seen a 105 like this Seems to have triple feed. It looks to me like a binder machine or special application machine. But I doubt you will get THIS machine for 500€ or so. We don´t know how either machine is set up. It is well possible that "off the shelf" machines have been modified. Only 1 picture or just a class and subclass cannot tell how a machine is actually set up. Especially not w/o seeing good pictures. Honestly - go to the dealer and talk to them and test the machine, this is better than any advice. Don´t take the machine home and then find out - test it - a good dealer allows you to test machines.

-

I doubt it is a 105 at all its rather an Adler 5 (predecessor of the 105). Dont trust the tag - if it has one. I even doubt that there ever has been a 373 subclass. 373 usually goes with Adler 67, 167 and the like but not with Adler 5 or 105. The Adler 105 looks different. It seems to have a jump foot system but the picture doe not tell the whole story. Do you have a side view of full front view? Foot lift usually is 12mm -14mm but when possible go and test it before you buy it. You never know if a vintage machine has been modified or not. If you need a German manual for the Adler 5 send me a PM and I can email you one.

-

Pfaff 335 17b h2L stitch problems

Constabulary replied to libbysstitches's topic in Leather Sewing Machines

Have you sewn with the machine before the transport - meaning are you sure it had a longer stitch length before? It could also be possible that the throat plate (actually the length of the cut out where the feed dog moves back and forth in) or the stitch length lever limits the stitch length (same here - the cut out in the dial / scale where the stitch length lever goes up and down in could limit the stitch length) so it´s not necessarily a technical problem it could be a general setup problem. Pictures of your machine would be helpful.- 18 replies

-

- pfaff 335b

- stitch length

-

(and 1 more)

Tagged with:

-

this rather sounds like a tension problem or do I get you wrong? I´d lower the top tension or increase the bottom tension. Not sure what the feed dog has to do with this?

-

this may help you:

-

Adler 5 A 25 - Operating Manual & Help Needed

Constabulary replied to CeeCee's topic in Leather Sewing Machines

Don´t know if you get a notification when you receive a PM - so please check your PM´s -

Machine Timing - best order of adjustment

Constabulary replied to ZigZag's topic in Leather Sewing Machines

so when you have the 211 manual you have everything you need for adjustments. The manual gives you the order. -

singer 111G156 needle bar rock frame play

Constabulary replied to davemac2's topic in Leather Sewing Machines

This angled piece probably needs adjustment (see red arrow in my picture). Just loosen the screw push the angled piece toward the rock frame and tighten the screw again. I would do the same with screw # 20347AL and the stud # 2484237. -

it could well be that the tip of bell crank lever (see parts list) is worn or you have assembled the stitch length adjuster the wrong way - or both. Reg. stitch length adjuster: The gib the set screw is pushing against has a small wedge this wedged has to be upwards. The squared frame also has a wedge this has to be downwards. Hope you know what I mean - some pictures. The wedges give the presser foot bar room for it´s movement. See PDF attachment for the manual / parts list. 29k71-71-73 Service Manual and Parts List.pdf

-

I have got a good lot of used and some NOS 29K patcher parts. Send me a message with what you are looking for and I check what I have or probably can give hints for alternative parts.

-

I´m also wondering if there is a setup with speed reducer that makes the NP work. Trial & Error science - I love it... go on please

.thumb.jpg.a76e1fbf7a7b5be70792d404a2a439c4.jpg)

.thumb.jpg.a3c3cf3ae9875ba0b0ae295d479e1be7.jpg)

.thumb.jpg.96477f3490413b73eeb4df75f4f354d5.jpg)

.thumb.jpg.e3e9110750076e9374212bba277bd790.jpg)

.thumb.jpg.86824a5c7fc2714db1f9045d02b3ad0e.jpg)

.thumb.jpg.33a396a4d6670dd1c3b41ef55566eefc.jpg)