-

Posts

5,803 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

Please help, advise. Adler 5-6 , plate, presser, feed dog.

Constabulary replied to Szymon's topic in Leather Sewing Machines

Since it is a fix presser foot bar as it seems (no moving back and forth) you can in stall a roller foot. The original roller foot slid directly onto the foot bar and a clamp held it in place so you could adjust is in angle and hight. "The modern" Chinese made roller foot mounts on the squared end of the presser foot bar just as the standard presser foot (in fixed position) BTW - DO NOT buy the roller foot for a Singer 31 they do not fit. You most likely can install needle plate and feed dog of a Singer 45K but feed dog may need a modification. Original Adler parts are VERY expensive. Or a cheap alternative - try GA5-1 parts which are dirt cheap on Ebay - the GA5-1 is based on the Singer 45K and the 45K shares parts with the Adler 5. https://www.ebay.com/itm/142866070102 This is just a fraction of what OEM parts cost and worth giving it a try, I think. I think the feed dog may need a little bit of modification but If I were you I would try it. Just a suggestion EDIT: to give you an idea of what original Adler parts would cost: https://www.ebay.de/sch/i.html?_from=R40&_trksid=m570.l1313&_nkw=adler+5%2C105&_sacat=0 -

Please help, advise. Adler 5-6 , plate, presser, feed dog.

Constabulary replied to Szymon's topic in Leather Sewing Machines

The 5-6 originally was set up for a roller presser foot. Not sure if some one probably altered the casting to make this needle plate fit. So If you don´t mind please post more pictures of the machine especially with removed needle plate. -

well, I´m on the other side of the pond but I remember Mark Rofini is in OR - he is restoring vintage machines too and I often find his website when looking for vintage Singer machines info: http://www.industrialsewmachine.com/

-

It depends on your expectations - you sometimes can find machines like Singer 45K or Adler 5, Adler 105 or the like for a "fair price" but they are for sure not as technically advanced as the CB4500 Wiz has linked too. These machines have been used for decades in the leather trade long before the heavy triple feed machines came out. For me these machines are by far not outdated - though they are not "the hottest shit" in the leather trade but for the above mentioned machines there was a great number of sewing devices and special presser feet for different applications. You will not find these presser feet for most of modern heavy duty compound feed / triple feed stitchers - maybe for the later models of Dürkopp-Adler as they always have supplied special devices for the leather trade but they are $$$ Some will say "but they mark the bottom side of the leather" due to the toothed feed dog - well thats what I mean with expectations - question is does it really bother you or your customers? When I look at the vintage miliary leather equipments or some vintage civilian or miliary holsters then I often see markings on the backside - seems no one bothered that. These markings are usually on the "far side of the moon" - so does it bother? It depends on you and / or the customers I´d say. Markings on the backside especially on the heavier leather equipment usually do not bother I´d say but as mentioned before - it depends. So in my opinion there is nothing wrong with vintage Singer 45K Adler 5, Adler 105 and the like - you just have to look around and watch there market. But most likely for $500 you will not find many heavy duty sewing machines. My 2 cents

-

Just found this making off video for a saddle pad - from min 6:10 on you see the sewing processes and the device / guide I meant. Hope this gives you an idea what kind of machines and sewing devices they are using BTW seems they are using a synchronized binder too - take a close look from min 7:10 on

-

Thats what I wanted to say but that was regarding the 2 needle machine for sewing the double tape top + bottom. I think a long arm machine makes it easier not maneuver large pieces like a saddle pad. Not saying standard machines do not work but the long arm for sure is more comfortable on the long view but for sure depends on the output you have. For outside edge binding a 145 most likely will work fine but you may need a table extension to the left. I think you will end up with at least 2 machines. I´m not a sewing machine professional. This is just what I think what works. I´d check with a dealer (not sure where on the West Coast you are) Thank you

-

Depends on the overall condition - would be nice to see some pictures. I think the 51W shares several parts with other Singer machines - thats the good thing on vintage Singers. So depends on what parts you´re looking for.

- 2 replies

-

- singer 51w

- post bed

- (and 7 more)

-

I know that - My issues started in 2006 when I did massive handwork for several weeks when I put a roof on the garage. Writs and arms hurt so bad I was not able to sleep for a few nights - not much problems during the day but at night it was a horror. Then I got a cortisone shots in each wrist - that cured it for a while but since then I live with it and when it gets really bad again (when I did lots of handwork again) I get C. shots again. And since then it never really stopped. Meanwhile I can live with it because I know when I did a lot of handwork I need a rest for a few days and then it comes down to "sufferable level" but I still feel it. So seems I need the surgery one day... Wondering if the surgery really does the trick - I´ll ask again in a few weeks! Thanks for sharing your experience!

-

for #3: I think the top and bottom tape are sewn with a double needle machine with 2 tape rolls / strands running trough a special application device / devices which guides the bottom tape and top tape. Top tape is running through a presser foot with a flat tubing or you have a attachment which guides the top tape to the presser foot - or both combined. Top tape roll could be mounted on top of the machine. I know there is a tape rack that mounts on the ridge of the machine where the oil port plug is screwed in. And a 2nd device is guiding the bottom tape (tape rack probably mounted underneath the table) and the machine sews them at once - if you know what I mean. You already mentioned Atlanta attachments - I think they can help you with this. A long arm double needle machine probably is what you want for this job. Not sure if a 145 can do this job "professionally" I know College sewing in the UK has some has a lot of sewing devices / folders on their website. Maybe you can put together what you need with their stock item - (I know you are in the US but maybe their stuff gives you some idea - I love browsing their catalog) LW Member ERIC hopefully jumps in here, he for sure knows more on this topic #2 don`t know if there are binder that do the job better that the other, important is that binder and biding material / tape play well together, if the tape is too thick for the binder it will not work properly. I yet haven't used a "fixed" binder (as the one you have linked) but I have used a Pfaff 345 with synchronized binder and currently using a Singer 108w20 for binding it also has a synchronized binder. The synchronized binders work very well and I´m using approx 0.8-1mm thick cotton tape most of the time. Synchronized binder are more versatile I´d say. #1: I have speed reducers on al my active machines - they really make sewing easier when you are not a professional seamstress. I only can recommend the combination of servo motor and speed reducer.

-

Not too expensive I think but depends on the overall condition, motor, accessories, missing parts... I heard there are a few... But I have learned to let go machines. 1st step for a cure? Naaaaa...

-

You for sure have suppliers in the US - this is quite common machine.

-

As we all know - you never can have enough sewing machines Imagine you are in the middle of nowhere and the edge on your mattress rips - Lucky you when you when a mattress binding machine 138 should be possible - manual says up to 22 size needles. But as always you never know how a pre owned machine is setup - just test it. If it is cheap I´d buy it. Very nice and simple machine I really love it. It has no reverse but since it is a binding machine it does not matter (at least for me). An interesting thing on this machine is that it has a constant stitch length, no matter how thick the material is (within it limitations of course) because needle bar guide and feed dog mechanism are on a C shaped frame - meaning needle bar is always straight and has no pivot point as other triple feed machines and feeddog and needle bar are always in a fixed position. But keep in mind, the stitch length is rather short - 7 SPI / 3.6mm. But you can tweak it - I get close to 5mm. You have to play with the settings but don´t ask me for the procedure - I just played around with the information from the manual and not its set. But the numbers on the stitch length dial no longer match the actual stitch length but that does not matter for me. I´m really loving it!

-

I have issues with carpal tunnel as well - both wrists. Sooo - is it better now? They cut the band that goes over the finger nerves, right?

-

Old casting Pfaff 335 (not 335 G) is using the same hook if that helps Not sure where to buy in the US but I usually find everything I need at College sewing in the UK https://www.college-sewing.co.uk/store/Durkopp-Adler-69-Sewing-Machine-Parts

-

Well, there you have it - I would guess this is the original 108WSW36 setup meaning the whole thing w. table and so on... Looks like a Single needle machine - so 2 thread means top and bottom thread I´d say. https://www.youtube.com/watch?v=285XUtTaZjA I think the machine heads are all the same basically - just the application and setup is different. So the specs of the 108w20 / 21 should be similar.

-

Post pictures please You mean double thread ort double needle? Thats a difference. A LW member once sent me pictures of a 108WSV37. Most likely its not setup as it should be (to be an SV) but maybe this gives you an idea. So just from the pictures it looks like a 108w21 (non synchronized binder) just w/o the binder attachments. So maybe the "special" binder (for special applications?) makes it a SV Model. As on most other SV machine it most likely is a standard machine with special / non standard (off the shelf) accessories or probably a pre-production model for testing if the customers wants it... or the like So I would almost assume the 108WSW36 is or was a 108w20 with special application sewing device but that's just a wild guess - some pictures surely would help.

-

halters Raised Nose Piece, Halter Making

Constabulary replied to Silverd's topic in How Do I Do That?

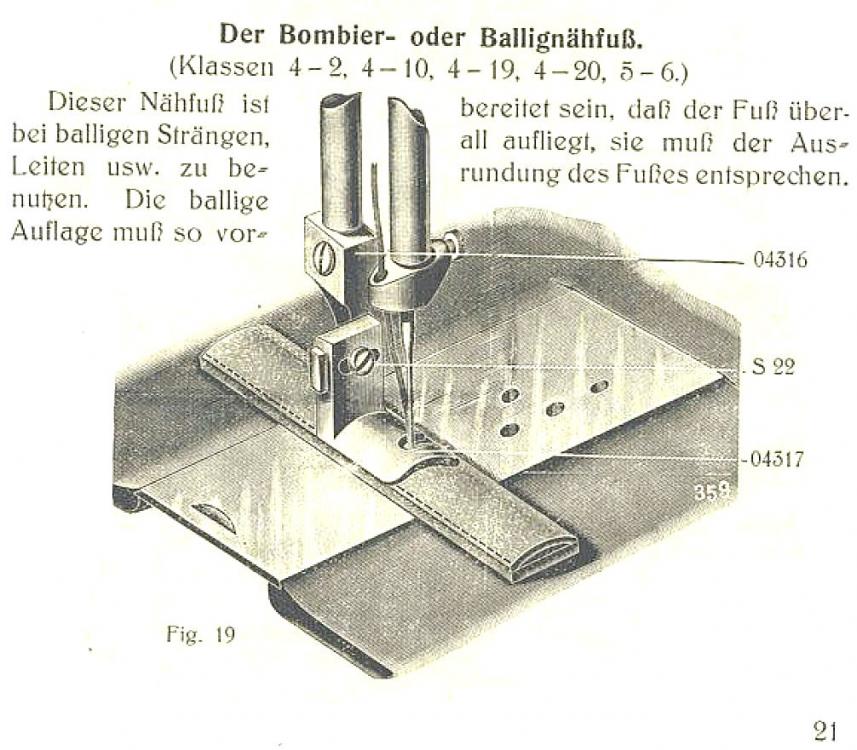

I don´t know the process in particular but in the German leather trade it is called "Bombieren" or "Bombierung" - this has nothing to do with "bombing" - of course. You often find the term Bobierung or Bombiert among male leather belts. Sample: http://www.mabel.de/gurtel/herrengurtel https://shop-hoffnung-berlin.de/index.php?route=information/information&information_id=9 The old Singer 45K and Adler 4 / 5 had a special presser foot for this kind of work I thinks there are belts with and without a padding layer between the top and bottom layer. I think the edges of the inner side of the top layer have been skived a little bit. Hope this helps.- 11 replies

-

- horse

- nose. stitching raised nose straps

-

(and 2 more)

Tagged with:

-

Singer 111 right slide plate fits but is a bit shorter. I would look for a Singer 212 or 112 LEFT side slide plate and shorten it! The left slide plate of the 212 / 112 is longer since the 212 / 112 are double needle machines with 2 hooks so the left slide plate also has the indentation (right word?) on the backside for the hook. for instance: https://www.sewingpartsonline.com/slide-plate-singer-223853.aspx Below picture shows Dürkopp 241 plate and Singer 111 plate (left side) EDIT: I do not have spares - sorry

-

The Dürkopp 241 has several internal parts in common with the Singer 111 as well as the tension unit. I probably have a slide plate if not I can compare with a 111. I´l post the result later

-

Can anyone recognise the model please

Constabulary replied to chrisash's topic in Leather Sewing Machines

well a triple feed machine that takes Singer 111 feet and 7mm stitch length (see knob) for 30 bucks is not too bad - if it is running. Looks a little bit like a 206R - or not? Maybe it is a NECCHI or so.. never seen this before. -

there also SELARIS or FRANKEL stitching wax. Not sure where to get it on the continent but I think a Fiebings dealer should have FRANKELS. But nowadays most folks either use pre waxed thread (linen mostly) or polyester like SERAFIL so the wax pot often left unused.

-

Putting in my worthless 2 cents... There also is an esthetical aspect for using a speed reducer. I personally do not like the large or oversized pulleys (w/o the hand wheel rim) on a sewing machine - I find it kind of ugly - but thats just me. For me, when ever possible, a machine should look like as if it came from the factory. It´s like driving an AMC Pacer - it drives an takes you from A to B but its ugly and you have to look at it day in and day out. If you consider a sewing machine just as a tool for doing a certain job then there nothing wrong with a large pulley on a sewing machine but for me it would not be the way to go / to slow down the machine - just for optical reasons. If it´s all under the table its more "eye friendly " for me Don´t get me wrong - no offense to people who have large pulleys on they machines For instance - this thing would drive me nuts