-

Posts

5,797 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

Singer 29K72 Patcher Shuttle Carrier Issues

Constabulary replied to Vinculus's topic in Leather Sewing Machines

Check with College Sewing in the UK, they have TOWA made shuttle carrier which seem to be of good quality. I have a small TOWA carrier in my 29K71 and it works fine. This is the large one for the 29K72 https://www.college-sewing.co.uk/82205-SHUTTLE-CARRIER-LG-CAP-SINGER-29K-TOWA Check their 29K parts: https://www.college-sewing.co.uk/Singer29K,29USewingMachineParts But since your 29K72 is in a very good condition I´d rather check the needle / hook timing before you are going to buy a new shuttle carrier.- 18 replies

-

- singer

- singer 29k72

-

(and 4 more)

Tagged with:

-

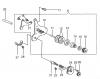

have you solved it? There are several reason why the tension would not release. 1.) The long tension release pin(#20) (goes from from to back inside the machine) is missing. Thats almost impossible but you never know. 2.) The tiny pin (#11) inside the tension unit is missing (pushes against the small bar on the top disc which is installed right behind the tension spring) 3.) The tension unit is not properly installed. It is held by 2 screws one on he front side on the upper end and one thats secures the tension units pin (#21) inside the machine housing. You find the screw (#22) downright inside the machine housing. Its a small one and you may not see it at the 1st look. Loosen both screws and push the tension unit towards the machine housing and tighten both screws. You probably have to readjust the thread regulator spring but that should be mentioned in the machine manual. 4.) In case it all does not help and both pins are present you can slightly adjust the small bar on the release disc (#13) with a screw driver and hammer. Remove the disc and tap the small bar slightly inwards. Not too far otherwise you have a permanent tension release.

-

I´d rather buy a 3200 than a Singer 7. Check the sale section these machines they pop up once in a while. Not sure if I said that before - your bicycle saddles look awesome - makes me think I could use a new cover for my old FIZIK nisene saddle (the old one with red bump corners). Do you remove the old covers first?

-

Speed Reducer With Integrated Bobbin Winder?

Constabulary replied to Constabulary's topic in Leather Sewing Machines

yeah, probably but I could not resist. I´m just thinking about the the position of it . I actually have no use for it but you never know what it will be good for. These reducer thingies are always good to have. -

Just found this thing on Ebay. Seems to be a speed reducer with integrated bobbin winder. I never have seen one of these "machines" before - pretty interesting.

-

Singer 111W 155 Stitch Length

Constabulary replied to David Bruce's topic in Leather Sewing Machines

Machine has no reverse. Always important to check the condition of the timing belt. You will find a 111w153 manual + parts list online. Will not hurt to read the manual before you buy the machine or even print it and take it with you. Looks quite nice - great price also, I would buy it! -

Han Solo Gun Belt

Constabulary replied to tboyce's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Naaa - your on the wrong track - its the DL-44 heavy blaster pistol. This is a secret I only telling on LW.net... Actually the Germans copied the broom handle Mauser from the DL-44 heavy blaster pistol when Marty McFly accidentally dropped into 1896 and lost the gun he previously picked up when he accidentally dropped into.... ah well you for sure remember the year of the great galactic war Or have I mixed up something -

Newbie In Shoes Maker

Constabulary replied to vhoang1102's topic in Shoes, Boots, Sandals and Moccassins

Xin chào - I´m not a shoe maker nor I have such tools but in case you like vintage tools then check Ebay Germany - there are dozens of auctions with tools. Your search words should be "schuhmacher" or "schuster". But please check with the sellers and ask if they would ship to Vietnam before you place a bid. A lot sellers do not ship international. Otherwise you may have some trouble with Ebay sooner or later. -

Operators Manual For Singer 45K76

Constabulary replied to Jwfarms's topic in Leather Sewing Machines

One of the cases where you can´t deny that size matters -

Operators Manual For Singer 45K76

Constabulary replied to Jwfarms's topic in Leather Sewing Machines

Now thats a fly whee / pulley . Machine over all looks not bad - not very much dirt and oil gunk as far as I can tell and all parts seem to be present. Have you sewn with it? Anyway, I´d clean and oil it thorougly and keep it well oiled! EDIT: BTW - what I don´t see is a bobbin winder. -

Reached The End Of My Rope With This

Constabulary replied to Hockeymender's topic in Leather Sewing Machines

Yep - had the same problem with my Jack Servo + 3:1 Speed reducer, always E5 Error. So I kicked out the NPS which I do not need at slow speed - its a nice feature but not that much important to me. Sometimes less technology is better. -

Operators Manual For Singer 45K76

Constabulary replied to Jwfarms's topic in Leather Sewing Machines

Check this thread: http://leatherworker.net/forum/index.php?showtopic=61619 -

Uwe - tell them they are nuts, the "real" puritans are quite cheap: http://www.ebay.com/itm/SEWING-MACHINE-73-E-PURITAN-MAID-BAY-STATE-PRODUCTS-METAL-REAL-MACHINE-WORKS-/111796656073?hash=item1a079997c9:g:WCwAAOSw9N1VvUHU This is a real heavy duty leather stitcher. Look at the mighty foot, must be a needle feed machine, it´s the well know Mod. 73E - I think you agree, right? And its even portable!!! Maybe the predecessor of the Sailrite LS Hokus Pokus

-

ALL 29K PARTS SOLD

-

Adler 69 / Pfaff 335 Binder Options

Constabulary replied to Constabulary's topic in Leather Sewing Machines

I see - well I should have checked the parts lists first. Thats the info I needed. Thanks folks -

Yet I haven´t worked with either machine so I don´t know much about the internal technical details. I know there are dedicated synchronized binder machines of either type. My question is if it possible to convert lets say an Adler 69-373 (or Pfaff 335 equivalent) into synchronized binder machine? I mean do all the machines factorywise already have the synchronizer mechanism thats is probably just covered by the arm cover? Or with other words - can I remove the plain arm cover and replace it with this cover https://www.college-sewing.co.uk/KHB69-ARM-COVER-FOR-BINDING-ADLER-69 and have a synchronized binder machine? I just don´t know and don´t want to waste money.

-

both shuttles and oil cup sold. I have left the 2 needles plates

-

You say a thread brake throws it out of time right? So I would guess either the safety clutch has released or some set screws on the hook driving gears are probably not tightened up properly. If it has the same safety clutch like the Consew 227 or Singer 111 models this Video should give you an idea: Do you have a manual for your machine? Maybe this one helps, it´s from an Consew 227R2 which is about the same as your 2700 I think. http://www.consew.com/Files/112347/PartsBooks/227R-2.pdf

-

- 23 replies

-

- adler 69

- sewing machine table

-

(and 4 more)

Tagged with:

-

Singer 133K - Information Wanted

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Grüße nach Frankfurt! Lucky you - I never have found a 133K8 in Germany, my only luck was the 133K3. Glad you found the manual useful. You can use Sys. 328 (214x1 / 214x2) needles. But you can but the original 216 needles from CollegeSewing in the UK https://www.college-sewing.co.uk/catalog/search.aspx?keywords=216 refine the search in the NEEDLES category. What needles size are you looking for - I may have a few extra. -

Busmc No6 Refurb But Missing Screws

Constabulary replied to Russodges's topic in Leather Sewing Machines

I may have a few from my restoration. All screws have numbers on the head, can you post the numbers please. I´m almost done with my restoration, maybe you are interested in it http://leatherworker.net/forum/index.php?showtopic=62817&page=1 I´d also like to see some pictures of your machine if you don´t mind. -

Well, the few straps I probably would cut with it are worth buying cut to my specs so I think selling it is probably the better deal for me. Some one interested in it $200 incl worldwide shipping? Send me PM.