-

Posts

2,372 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by immiketoo

-

Honestly thats the one I use least. Cant really find a use for it.

-

Lets talk about WOW factor in leatherwork.

immiketoo replied to immiketoo's topic in Leatherwork Conversation

Lol...I hate excuse makers. -

Thats a trim knife designed by a friend of mine. Crazy sharp and very useful.

-

IT works for me. Not sure why it wont for you. The first file is a MOV which is apple. The difference is the shape. The offset handle makes long running cuts easy and rocking it down allows tight corners to be cut with ease. I can cut quarter sized circles all day long and if I really want to go tight, flip it over and go for it.

-

Any spirit dye will work just fine out of the bottle, but I like to thin them for a variety of reasons. Those include having greater control over the shades of color I want, saving material by using less of it and reducing the possibility of excess dyestuffs piling up on the surface of the leather when spraying. To cover areas to resist dye, you need liquid latex. Its brush on and requires careful application so you don't miss any areas. Two coats is best and you have to be careful you don't smear the dyestuffs that accumulate on top of it onto your project when you remove the latex. The wont dry on the latex or absorb so its best to spray away from the latex to minimize the build up.

- 3 replies

-

- airbrushing

- air brushing

-

(and 2 more)

Tagged with:

-

Congrats chief! I retired a few years ago and do leather full time now. I also appreciate a good dobro, although my national is not a lap version like yours. Enjoy your time!

-

When I first started, I went to Tandy bought the basic kit, and about 1000 dollars worth of other stuff in the first few months of my leather career. It didn't take long for me to learn about pro tools, high quality leather, custom knives and a certified tool whore was born. In my first two years, I probably spent 20 grand on associated tools, machines, leather and supplies. I found out that I had a liking for swivel knives and black crack. Fast forward to a few years later. Met a girl here, fell in love and moved to Greece where the lifestyle is decidedly less materialistic and consumerism based. In reality, its the economy, but it shed new light. As did meeting a few of my mentors who have a more minimalist approach to leather working. As I finally fell into my "style," I realized that I have little need for most of the stuff I bought along the way. What's the point? I hope that I can help you avoid spending a lot of unnecessary cash at the beginning of your career and to help you focus what you do spend on high quality tools that will last a lifetime. So, what do I find to be essential. These are MY opinions based on trying nearly everything on the market and your mileage may vary. High quality bevelers. Of all my tools, beveler get 90 percent of the work. I probably have 50 different bevelers, and I use most of them all the time. Stainless steel, tool steel, steep, standard and figure all are in my stable. A top level round knife. Yes you can use a craft knife for most things, but there's a reason the round knife has been used for thousands of years. Skimping on cutting tools is an exercise in frustration and a good tool can ease your workload tremendously. A good maul. For tooling, I find a maul to be the weapon of choice. It took me a while to find the size I like but my main one is 17 oz. I have a 12 and a 24 that see occasional use, but I could get by with only the 17. I also have a BMFM thats about 8 lbs for bag punches. Essential IMO. One good swivel knife. Two is nice if you have specialty blades and don't feel like switching blades, but I could get by with one. The perfect SK blade. This will depend on your style of carving, but a top blade by a pro maker will outperform nearly any kit blade and give you years of love and affection. Blade choice will also partially dictate the style of your carving, at least until you decide consciously you want to do it differently. Granite tooling surface. Stop buying one inch thick tooling surfaces. Look at a surface plate. They're solid, heavy, smooth and they make your tooling more crisp, reduce noise and generally last longer. Old headstones are fine too, if you can find/lift one. Sharstools.com sells a wide variety of sizes of surface plate for reasonable money especially if you go with B grade which is FINE for leatherwork. Edgers. Buy good ones. They will change your life. Barry King, Ron's Tools, old refurbished Gomph etc. The box of unused crappy edgers is my shame. Lights. Good lighting is essential, especially if you're a little older. Dazor or OTT light both make great lights for the desktop and good room lighting is essential for other tasks. Student desk lamps generally suck, and the color of the light isn't good. Look for daylight bulbs if you use standard lights. Work surfaces. Old kitchen tables are fine, but the lack solidity and the height can be uncomfortable. Work benches are usually taller and allow more work options. I like to sit while tooling and stand for most other tasks. Talk benches allow this. Work area. The bigger the better, unless you're extremely good at modulizing(?) your work space. I have a single spare room at the moment and its filled with stuff. I have to change configurations to change tasks whether its cutting, sewing, painting, tooling or whatever. Ideally I'll have separate stations for each task. NEVER put dye on your cutting or tooling surfaces if you can help it. Nothing hurts worse than that rogue blue streak on your freshly tooled project that is supposed to remain natural. Don't mix metal and cutting surfaces. If you work with metal, it should be away from your leather, tooling and cutting areas. Spots on leather and the lovely crunch of metal killing the edge of you're awesome round knife sucks. Been there, done that. Buying vs Making: I think its awesome that some people can make their own stuff. Whether its tools, benches or whatever, here's the deal. I don't have a lot of power tools. For me to make my own anything, the cost of buying tools to make tools is stupid. I will just buy the tool and be done with it. However, if you are handy, use it. Make an amazing work area. Shape your own bevelers, or make the SK you can't find anywhere else. Make tool racks and other fine things. Then call me, I'll probably need them. What are your thoughts? Did I miss anything? Probably. Chime in!

-

Center bottom and upper right. I have two. Of all of them, the french is the most used.

-

Buy a 3 inch thick surface plate from Shars tools or woodcraft. They are smoother, heavier and all around better then cutouts and they dampen noise and vibes better too. I think you can get a small one for under 50 bucks.

-

Try this one... D725451A-4489-45EF-B392-D36B92D34D51.mp4

-

I agree with that wholeheartedly. Back then, there was no way of knowing what I would have gravitated toward. In fact, it was so wide open that any of the sets of tools I have could have been THE set.

-

A little taste of what a sharp knife can do. 10 oz strap. D725451A-4489-45EF-B392-D36B92D34D51.MOV

-

I use my Knip french for 99 percent of my cutting. I would sell all my other knives before I got rid of my french model. In fact, I'd fight you for it if it came to that. I have a few mor ethan Mutt has too, so that's saying something

-

Honestly, I bought most of this in my first two or three years. Now, I have more than I'll ever use and its just jewelry really. Nice to show off. I could survive with only two of them. The same goes for most of my tool racks. I could keep about a dozen or so and probably never need another one. I was young and foolish.

-

That’s why I have this many knives...every damned time.

-

Lets talk about WOW factor in leatherwork.

immiketoo replied to immiketoo's topic in Leatherwork Conversation

This is called satisficing. A term coined in the police management world where doing just enough to be an acceptable job. It has no negative connotations, and often, I will stop work on a particular project at a point where I know I could do better, but the price agreed upon for the item doesn't allow for more work. Sometimes, though I do just the opposite. Put WAY more time in than I was paid for to make it perfect or as close as I can get to perfect. Weird. Anyway, flaws or no, if the customer is happy, that is what matters. -

I would say that Maybe I should say cut correctly bevel the right amount? There are infinite combinations of this that will work, as long as you find what works for you.

-

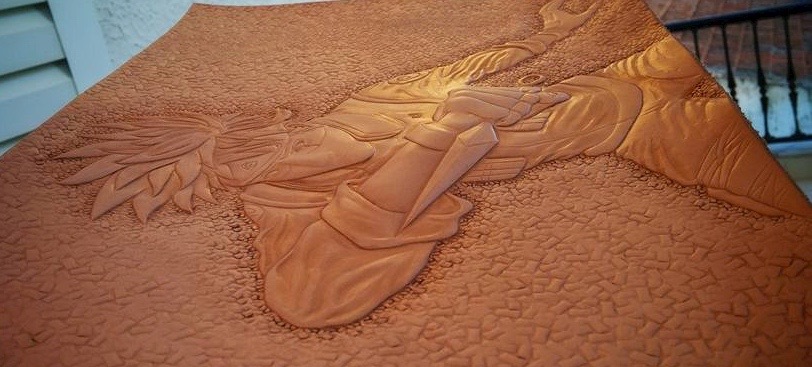

Custom armguard for injury.

immiketoo replied to immiketoo's topic in Collars, Cuffs, Leashes and Leads

Thank you, I appreciate that! Now if I could get the rest of my work to the same level, I'd be pretty good! -

Certain colors are worse than others. Browns and red should be fine. Blue/green/purple are the worst with USMC black being the king of rub off. I use sheep fleece but in bigger sizes to facilitate buffing. As mentioned earlier, letting it dry completely helps tons.

-

I have two desktop OTT lights on my bench, and they provide more than enough light to work. At 48 years old, my eyes are starting to need the bright light and I like them. My only complaint is that they don't stay where you put them anymore. The heads sag a little, but not so much that I can't use them.

-

Retail Shop Front Vs Workshop/unit

immiketoo replied to Handstitched's topic in Leatherwork Conversation

Mmmmm...meat pies. And beer. -

Punch the inside curves with a round hole punch and then the rest with your knife. Easy peasy.

-

The ones you linked are far better looking in my opinion.

-

Lets talk about WOW factor in leatherwork.

immiketoo replied to immiketoo's topic in Leatherwork Conversation

I try to be a well rounded leatherworker. I want my construction to stand out as much as I want the decoration and edges and finish to stand out. Recently, I saw a well renowned master post something for an upcoming class where the stitching looked like my first year attempts. I think its imperative that all aspects of your piece are at an acceptable level before I offer something to the public. That being said, there are pieces out there I charged money for that I cringe just thinking about. I guess its the journey, right?