-

Posts

874 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by Rossr

-

Finished this sheath today

Rossr replied to Rossr's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks Nick. This making stuff gets addicting -

I wrapped this sheath up today. Deer skin lined W&C skirting. Geometric stamp and a border stamp. Machine stitched on a needle awl machine. Knife I also made o-1 tool steel, antler and wood handle. Pretty happy with this one not overly fancy but just worked out nice imo. Thoughts as always welcomed Ross

-

Christmas gifts this year.

Rossr replied to CRab's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Looks like you are off to a great start. Keep learning and enjoying Ross -

Most recent knife and sheath

Rossr replied to Rossr's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I do as well. Thanks for the compliment -

Most recent knife and sheath

Rossr replied to Rossr's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I have made a few blades out of damascus. There is for sure some beautiful stuff out there. Regarding the etch. When you grind and polish damascus it get shiny and the pattern isn't distinct . If you catch it in the right light you can see it a bit. My limited understanding is the acid eats away the softer metal and there are some color differences between the different combined steels. So that etch brings out the pattern. Damascus is a combination of different steels forged together and twisted or folded to make a pattern. I'm no expert so dont quote me but that's what I understand I do as well. Thanks for the compliment -

Couple a sheaths off my bench

Rossr replied to Rossr's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks steel hawk. -

Most recent knife and sheath

Rossr replied to Rossr's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks. I think I just like making and learning new things. I just keep trying. Yes that is Damascus. I have never tried to make damascus that's a whole.other set of skills. I think I bought that from Alabama damascus. Its sold as a flat sheet you can then cut shape and in this case I made the bolsters. Lastly I etched it in acid to bring the pattern out. Ross -

Most recent knife and sheath

Rossr replied to Rossr's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Will do and Thanks -

Most recent knife and sheath

Rossr replied to Rossr's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Ok just my thoughts on the opening. When I put the knife in the first time it's usually just a shade damp from stamping. So it sets it open some I let it dry over night . Attached are pics of the opening and side view of this one. In reality I can still easily miss and slice the liner. I sliced a pouch sheath a bit one time no liner just the vegtan when I took my eyes off it as I pushed it in while it was on my belt. So I think my answer is make sure the opening is enough, still needs to be tight though. Then it's a matter of staying vigilant when replacing the blade. In regards to the roled lining stitch. That is tricky I have had it squish too much. I now try to center it best I can which helps. I am also not sure I need to go that high but the welt is up ther so I want a good closure. Remember I am using a needle awl machine so maybe the pressure on the foot causes issues too. I seem to like too finish there rather than start which seems to help but may just be me. On the belt loop the reason the stitch is off I got out on the rolled part and didnt want to run down just that and get both a weaker hold and that squish effect. So I chose to move back in and catch the skirting leather too. Hope that all makes sense Thanks Nick -

Just finished off the sheath today. Just some simple border work and stamped initials. Rolled deer skin lining. Wicket Craig skirting. I got off a bit stitching the belt loop in place but that's just me being critical. Made the knife too. O-1 tool steel. Antler handle in between damascus. I dont make my own damascu but i did shape it etch etc. Hope you all dont mind me continuing to post these up I realize sheaths dont change much just the carving.or tooling on them.

-

Looks great. Really nice work you keep improving!

-

Thanks for the compliment. I wanted the flexibility to move the dividers or add things if and when needed. I know there are some other carving tools I would like to add. So having a movable system gives options. Realistically it will probably not change much but makes me happy knowing it can if I want. Ross

-

Pancake knife sheath

Rossr replied to Rolandranch's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Clean work well executed! I have to give the bat grounding a try. Keep up the great work Ross- 11 replies

-

Got the dividers and inside parts I wanted made. Left me plenty of room.for additional tools down the road and wood blocks projects etc. I like the velcro makes it easy to move things around inside if I want too. Figures I'd share the inside as well thanks for looking folks

-

Appreciate the kind words Thank you

-

Thanks! That just an old wood desk I picked up on the cheap.(I see them listed a lot on craigslist cheap) Some of the tool holders I made some came from buying stamps off ebay etc. The stone o got somewhere I'm not even sure what it is could be thicker but seems to work fine. Yep lacing took a bit as did the carving too but always fun to be down the rabbit hole! Thanks for the kind words Thanks toxo, my son suggested it and it came out well imo

-

I may have went a tad overboard . Thank you Thank you sir

-

Nice carving I like it. What about a wooden shield. Wood would protrude beyond the leather . Glue it on maybe tack it down with decorative furniture tacks around the edge. Maybe lace around the outside too....like the wall hanging thoughts folks had too.

-

Thank you sir!

-

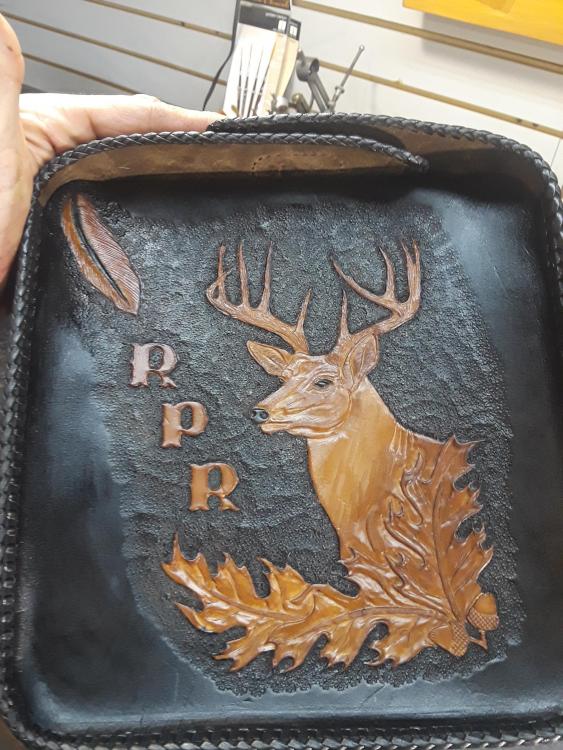

So does anyone else get down a serious rabbit hole? Like you know there are a lot of more pressing matters but hey I need to make this bag like now. I give you my rabbit hole the last few days. I wanted to make a bag to keep some wood carving tools. I play around spoon carving. I'm tired of the gallon zip lock bag. So I keep looking at my books and got flipping through a box of leather magazines and found a 1977 make it with leather article and pattern for a camera bag. I modified it and added velcro for top closure and only used veg tan and tooled the ends. I love the oil tan look but find it almost impossible to glue the liner in place etc. Thankfully sewing still works! The oak leave pattern was in the magazine and is derived from stohlman how to carve leather. The deer and oak leaves is a Jim Linnell design(I hope I did it justice as it's no where near the work Jim has on his website). The feather I messed around myself with, mainly there to cover up a leather blemish but I thought it flowed well. Double loop lace. I stitched two velcro strips inside and will make some dividers and a tool holder . Open to any constructive criticism. This is one of the largest projects I've attempted and overall I'm pleased with the outcome. It's way over kill for some carving tools and some wood blocks. But hey that's why we do this stuff right for the love and joy of it! Happy New year everyone.

-

Knives and Sheaths

Rossr replied to AlexOstacchini's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Yep that's it. I quit knifemaking and sheathwork! Really unique knives and the sheath work too. The carving looks great flows nice and well tooled. I have never seen the rolled brass liner like that it is very unique. I am curious do.you think food will get stuck in there and be an issue.? Or water when cleaning cause a problem? Rust? You should be real proud of those and what stunning gifts Best Ross -

Two New Estwing Hatchet Sheaths

Rossr replied to Vikefan's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Looks like fine work to me. I agree I would rather a loop instead of slots but customer gets what they want! -

Couple a sheaths off my bench

Rossr replied to Rossr's topic in Gun Holsters, Rifle Slings and Knife Sheathes

This debate comes up often . I've had customers want it this way and some the other way. I get the logic of this is wrong for right hand carry. These are both right hand carry. The sharp part towards the back when you slide it in the sheath . The wood handled knife makes it seem like the other way just cause How I laid the knife for the pic. I've never had a problem with it coming undone that way and I prefer opening and closing it this way better. I can still flip.it around thankfully if needed. Ross -

Stuff for a Brother of mine

Rossr replied to Memphis514's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I bet you will have a very happy recipient! Nice work. I cant quite tell on the belt but where it folds over for the buckle did you skive that end down?