toxo

Contributing Member-

Posts

2,263 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by toxo

-

Excellent advice Don! For some reason I thought if the needle was down the thread take up would be at the top. I actually looked today and realised that it's not. I'll have a go at your suggestion. Thanks.

-

I heard there was a question of build quality and customer relations. The build quality seems fine but as for the public relations, not so much. After taking my money I heard nothing until I emailed them. was told I would be updated with the info when she had it. Couple of days later I got a call from the driver telling me he was outside my house with a pallet. Later that day I got an email from a different party telling me my press would be delivered tomorrow lol.

-

-

This is essentially what I do Brian. I bury the needle and hold both treads but as I do the first stitch the amount of thread in my hand gets longer and then hopefully it settles down and I can carry on. If, God forbid, I try to backstitch at the start it bunches up and snags. Could I have something 180 degrees out of tune?

-

Thanks Brian. I'll certainly make some changes. I just wanted to be sure that It wasn't just me.

-

My Adler 69 and I have a love/hate relationship. Been going on for a while. I always bury the needle when starting and hold onto both threads but when I start, the thread in my hand grows longer before it settles down and behaves itself and God forbid I do a couple of back stitches at the start when it usually bunches up and ends proceedings. Any ideas guys? I'm almost at the stage where I can rely on all my equipment but this is stopping me from going ahead with confidence.

-

I used a pattern that included holes for hand stitching. When I cut the pattern out I left out the holes because I wanted to machine it. The leather was fairly soft and when I was doing the gusset I found that when I got all the way round the gusset I found the gusset carried on after I wanted it to stop! This is not the first time this has happened and I'm guessing it's the result of having to manhandle the top leather around the corners and so stretching it. Is this a fair assumption or am I missing something? I don't remember reading about this, I guess that all the video posters are playing it safe and only use veg tan which is a lot easier than supple chrome tan. I've learned yet another valuable lesson - Henceforth I will sew from both ends and use more anchors in between. I know a lot of you only use chunky stiff veg tan so probably doesn't apply, but for everyone else, how do you do it?

-

My Durkopp 239 is similar to the 111 and by putting a large handwheel and a servo motor on it I can do a stitch at a time. If you do a search on here I did a thing a while back, maybe a video as well for the cost of around £40 all in.

-

You're more than welcome. Anything else, you know where I am. I forgot to mention that I replaced the arm on the arbor press for a longer one and make sure it's bolted down. The arbor press is much nicer to use if you put a spring on the end of the arm so it's self releasing, even a bunch of rubber bands will do the job. Be sure to keep us up to date with your progress and of course, all the leather craft that comes from it.

-

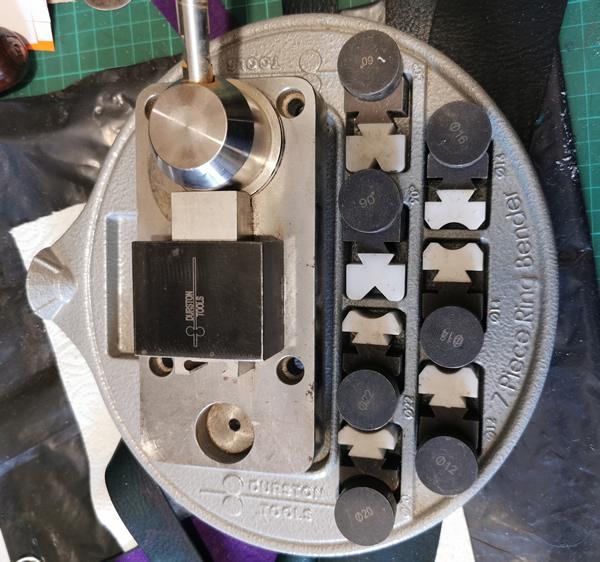

I remember the H Rogers vid. I envy the guy his money, he seems to just buy whatever he needs for his next video. He is a likeable guy though and he tries to inform. That second bender was really expensive IIRC. Here's mine, not the best but it works with some effort. I sometimes (carefully) put a tube over the arm for more leverage even with 2pt r/steel and they are limited. This bit will need to go in a vice if you haven't got it bolted down. This next bit needs some thinking about. If you have the means to hold it together accurately whilst you weld it that's one way to go. I don't A cnc router type set up that cuts the channel in wood/resin for the r/steel to sit in is even better. I don't have that either. I've found the best way for a poor boy to accurately do this stuff is to use wooden formers. You can trace the pattern onto the wood and accurately cut it out (slightly undersize). Bend your r/steel exactly to the pattern and fix it around the outside using screws. The thickness of the wood (decent ply is best) will depend on the size of your r/steel and of course the thickness of the leather you need to cut. R/steel is hard and although you can drill your screw holes, it's not easy and it's time consuming. I use one of these (not cheap but worth it). Even with 2pt steel you need strong hands. At the end of the day you can end up with something that makes it all worthwhile. These are some of my dies. And they make things like these. Good luck.

-

That's similar to the one I use. Paid a lot more for mine. I started out using two steel rods in a strong vice. That stuff he's bending in that video is very thin. Rule steel is hard, 3 point will be hard to DIY so make sure you get 2 point. Forgive me if I'm teaching grandma to suck eggs but if you like I can dig out some pics.

-

Here in the UK there's a company called Partwell I think. They sell in boxes of 1 meter lengths. Don't know if they have anything over there. Can I ask how you process the rule steel?

-

I think I've mentioned this before but it won't hurt to reiterate. Silicone caulking will dilute to the nth degree. Make it so you can paint it on, jobs a good un. Ideal for older tarps etc.

-

Thanks guys. there's a huge difference between one of these and the rest because the rest are in the US. This cost me £1520.00. That includes 20% VAT & delivery. They've even included a free 10mm board for when you use the narrower dies. The others can't get near that. Another reason was I wasn't sure about the difference between the ones that work on linkage and the ones that work on eccentric cams. My engineers brain said the cams would need oiling all the time with the possibility of that part of the cam wearing out. The Lucris is a linkage machine so if anything is gonna wear out it'll just be bolts. I might be talking out of my arse here but that's the way I see it. Can't wait for it to get here. @Rubicon04 I make a lot of the dies myself if they're not too intricate I still have almost a full box of 1 meter 2 point rule steel.

-

Finally bit the bullet and bought one of these. Wiped out half my finances but I need to raise my game. Lucris Hand Press, M A Series III Clicker Press in Scotland, UK from Alpress

-

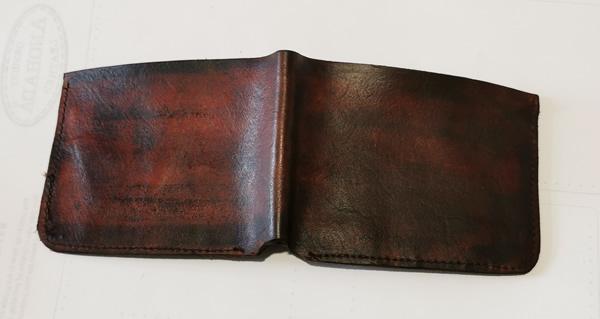

My first wallet

toxo replied to toxo's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks Bill. -

My first wallet

toxo replied to toxo's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks James. -

My first wallet

toxo replied to toxo's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thank you. It means so much when fellow leatherworkers acknowledge your work. -

My first wallet

toxo replied to toxo's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks guys. It's a tad tight due to mistakes but it'll wear in. Started with 1.2 mm V/Tan and got the skiver working well enough to get the first four panels down to 0.6/0.8mm Combination of Feibings dark brown and Norsol saddle tan (different layers) and of course Resolene. Canterbury& District AA has a good river and a few lakes including a trout lake but I generally fish the river. -

My old wallet has been an embarrassment for ages considering I'm a leatherworker so I finally bit the bullet. Nothing special and loads of mistakes but boy have I learned a lot. Was determined to try to machine it. Don't look too closely at the stitching.

-

Thanks for that. Found it on Y/T as well under the guise of the Reliable SewQuiet 6000SM Servo motor. It's going the right way now. Will stick some sponge under the treadle to limit the speed. Getting close now. Realising that tiny adjustments make a big difference.

-

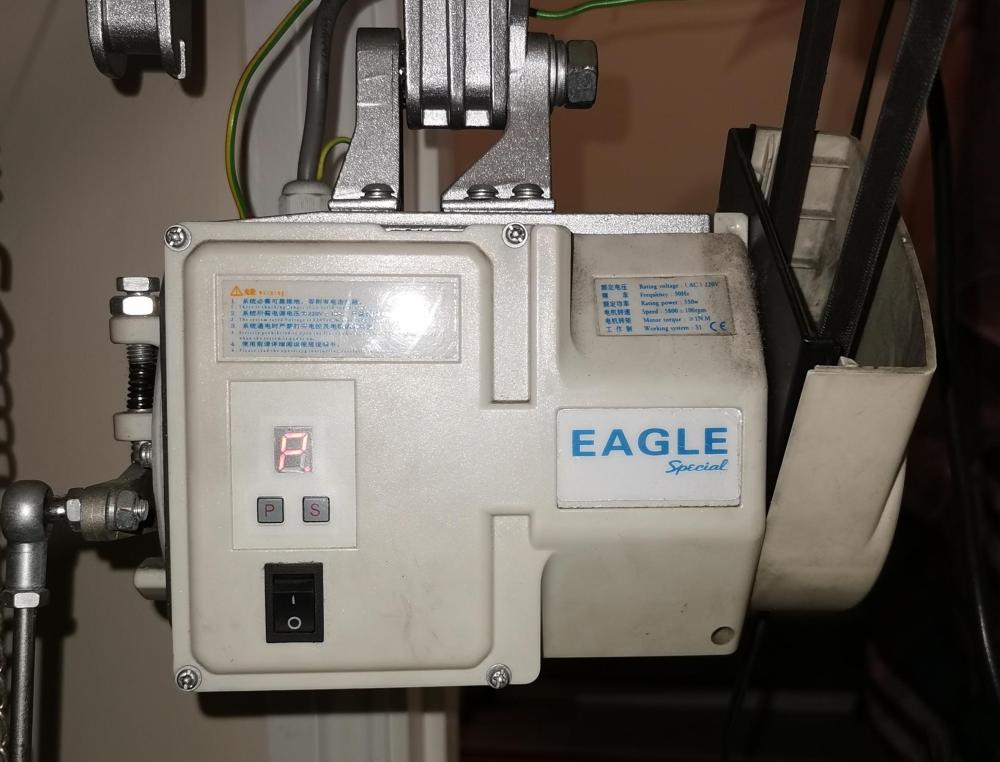

Getting there now. Although it can go really fast I've found the secret is keeping it slow. No waves and much more controllable. Unfortunately whilst trying to slow things down via the motor I've managed to reverse the rotation and can't get it back. It's now running counter clockwise when viewed from the right hand side of the machine. There's a dot on the digits on the motor that wasn't there before. I have the manual for the machine but not the motor. Can someone help me out here. I've obviously not hit the right combination on the buttons thus far. Here's a pic.

-

Looks like I ended up with it.