toxo

Contributing Member-

Posts

2,263 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by toxo

-

This is what attracted me to this sander. Because there's no steel behind the belt there's more leeway when doing curves. there is a selection of belt grits and there's a felt one which I'm thinking will be good for burnishing. Also, the speed is adjustable.

-

Turns out these belts are common on Ebay so I've just ordered the sander. And it turns out that although the compressor was built in Denmark the bolt is an imperial size.

-

Be glad to Bob. Buffer should be here tomorrow. Holding off on the sander til I know where to get the belts. That seller doesn't sell em and doesn't even know the size of the belts. I'll be sorry to pass on that sander cos I like the ones that have no steel behind em and most of the others have really slim belts. Having to really think about my set up cos it's in a small second bedroom but I have everything I need in there. two sewing machines, an 801 skiver and a worktop so plenty of shelves. Just down the hall is a 5ft deep x 3ft wide tool cupboard. Thinking about putting the buffer and sander in there on a sliding shelf but depends on if the mess is controllable, otherwise they can go in the small shed in the garden. Still struggling with the compressor. After buying three socket sets it turns out the bolts are spline or 12 point bolts. I thought I'd cracked it with the last set but the 6mm was too small and the 7mm was too big. Can't find a 6.5mm anywhere. When I eventually get it sorted it'll make a silent airbrush compressor.

-

After my recent house move, although there's still a way to go I'm at the stage where I can start to produce leather stuff. Just finished a motorcycle backrest and about to start on a handbag for his wife. I've decided to invest in a couple of bits of kit to give myself some encouragement. Still trying to refurb the Jun-Air compressor. Not sure how much it's gonna put out but it will at least make an awesome airbrush unit cos it's silent Just bought this - Sealey BB2002 Bench Mounting Buffer/Polisher, 200mm, 550W/230V : Amazon.co.uk: DIY & Tools And as soon as I've found out how easy the belts are to get hold of I'm gonna get one of these. having two grades on one machine will be good I think. - 950W Electric Sanding Machine Belt Sander Double Axis Bench Grinder 220V 6000rpm | eBay My bags are gonna look awesome this year (I hope). Thoughts guys?

-

Welcome from Kent. Posting will give you the oomph to do it again. I run a small workshop down in Gillingham and one of my beginners did this. I lasered the owls which would have been much better with white in the detail but she didn't want to. Good luck. Paul

-

When the stitch is unbalanced and there's a choice to tighten one or loosen the other is there a criteria for which way to go? I'm thinking of maybe too much of one or the other may damage the machine?

-

Didn't know we had a Fb group Matt. I'll go look.

-

Might help if we knew where you are.

-

As per title. They seem to be abundant in the US. Who sells em in the UK?

-

I couldn't find my roll of wire and before I robbed this I thought it might be worth something to someone. I needed a particular colour and it wasn't waxed so I threw this together. Wasn't 100% but that was probably down to the wax. Got me out of a bind and taught me to buy waxed threads.

-

Excellent practical project and very well executed, well done.

-

Is there a reasonably priced leather supplier recommendation

toxo replied to Mulligan31's topic in Suppliers

Might be an idea to tell us where you are. -

Just laid the floor of my new bungalow and now I need to revitalise my leather furniture. This is without doubt the most comfortable furniture I've ever sat on. It not only hugs you but will recline all the way flat on 4 of the chairs so I need to treat it well. Most of it is perfectly fine (has a layer of dust on it in the pic) but there are wear marks on the surface on well used places so before I start experimenting, I thought I'd ask the hive for the benefit of their infinite wisdom. My first thought is a dilute dye mixed with a conditioner just on the wear points, but I'd love to hear from someone with experience.

-

32 hours of tooling

toxo replied to YinTx's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Well done Yin! What a diplomat. Some folks got nothing to do but look for trouble. -

Cut the leather oversize by about half inch either side. Glue all the length leaving 1 inch either side dry. Wrap all the way from top to bottom using low tack masking tape. At this stage the two sides are overlapping. When the glue is dry, using a straight edge cut straight through the middle of the overlap leaving a dead straight line. Of course any tooling will be done when the leather is flat. Simps

-

How surprised was I to find no category for airbrushing or compressors! Anyway, ever since I bought an 801 skiving machine with a purpose made vacuum system and waste bag I've been looking out for a quiet compressor to drive it (the waste system). Thus far I've been using a long air pipe and a noisy 50ltr jobby in the garden but I've just moved into a small 2 bed bungalow with no place at all for a noisy compressor. I learned that the really quiet ones like Jun-Air or Bambi are an arm and a leg to buy so my ears pricked up when an older Jun-Air came up on Ebay for a song. I didn't hold out much hope that it would drive the waste system but at £185 and refurbished I reasoned that if it didn't I could still be spraying leather with a big smile on my face. I ended up getting it for £130 but hold on! This ain't no fairytale. Here it is. I had a mooch around the net and found this Jun-Air 6-4 Quiet Running Compressor - 32 l / min at 8 bar (esska-tech.co.uk) Great joy thinks I. Then it arrived Back down to earth I came. And that wasn't the worst of it. The motor is fine and very quiet but there's no output. Now this is where I'd normally say " If I didn't have bad luck I'd have no kin luck at all", but I don't think this is the case this time. I've been refunded £80 so it stands me in £40. I've shown the damage to Jun-Air and they're sending a replacement for the broken bit gratis, well done Jun-Air and they sent a users manual and spec sheets and parts list and I think I'm gonna enjoy this project so all in all I'm happy.

-

This ^. It's not as if the back of a shoe is a massive curve. Find something roughly the same shape or better yet use the actual shoe with some cling film around it. Mould your leather, let it dry, find something dome shaped (like the tow ball on the car maybe) and tool away.

-

A couple purses

toxo replied to BlackDragon's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Nice job. Well done. -

sporran bag Cossbody Purses

toxo replied to AndyL1's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I make a few cross body bags. These are really nice. Now you've got me wondering if my little laser will do delrin? Well done. -

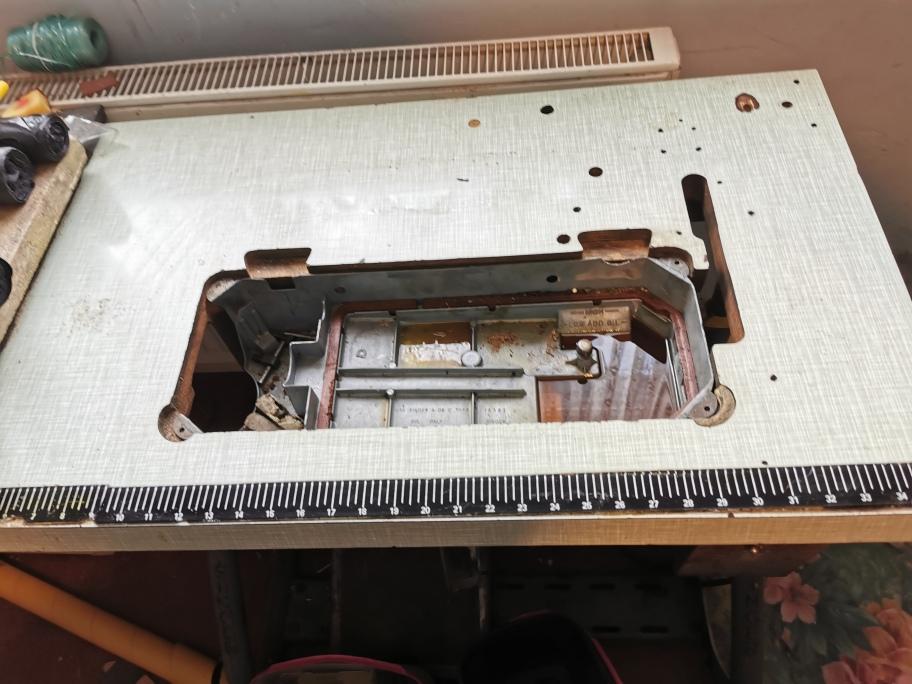

Thought I'd posted these pics before. Anyway, I don't think it's a leather machine and it's much too fast for me. It sits in an oil bath so it will go on forever. The motor on the singer was really noisy so I put new bearings in it and it's nice and quiet now and it's still in situ so won't take much effort to get it up and running. The other motor came off my Durkopp 239 which I think I will be selling soon also, nothing wrong with it, I installed a servo motor.

-

Head, table and motor. Reverse not working. Collect from Gillingham, Kent , UK Also 2nd clutch motor, also free.

-

For those big long hides you won't get a straighter line than a chalk line. You can buy em but any piece of string will do. Just rub along it with some chalk, stretch it tight along the hide and ping it. And if you ever need an absolute 90 degree right angle on a big area use the 3,4,5 method.

-

Interesting cutting style.

-

it also depends on the type of line you're cutting. Straight lines - almost any knife will do as long as it's sharp and used with a strait-edge. If doing a curve I use a knife with a point and raise the butt so I'm just using the point. If you lower the butt the forward edge of the blade will try to straiten out the curve if that makes sense.