brmax

Members-

Posts

1,027 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by brmax

-

Overwhelmed by leather Sewing machines

brmax replied to Starwind0's topic in Leather Sewing Machines

If your considering leather work, the machine and you will require a speed reducer unit on a sew machine, no matter if a servo is used. There are discussions on many ways to accomplish this “requirement” but just kindly accept the tip. I am seriously promoting your traveling to a few places with machines. I think everyone here would guide you to standing in front of a few machines, especially setup for leather, which is a bit heavier and focused on projects requiring slow operations at times. Maybe pre travel, we can all better help select between a flat bed or a cylinder type machine as your last postings. In any case some how getting your hands on some thread will surely help determine needs. But projects discussed in some other forums may help decide a direction when viewing others project photos. Good day Floyd -

Setting feed dog gap side & front to back. Pfaff 145

brmax replied to Devo's topic in Leather Sewing Machines

Seem to recall the front to back feed dog adjustment is definitely part of the “timing” adjustment in a procedure step. On many machines this is relative to a stitch length setting also. Typically the needle plate has its taper head screws, so are self aligning. If Im picking up what your saying. Therefore feed dog side clearance can be tedious but secondary as the top plate is not usually adjustable on flat tops. So with this Im understanding your shaft adjustment toward a side. But I don't know that particular machines procedure, so good luck, I will say a 145 manual though is a good option to find. Hope something in this has bearing. Have a good day Floyd -

Silverd: its a bit like mentioned in the prior postings, both are in the upholstery class. Many in canvas as I use them, they have a bit newer design in some ways. As in the way the feed mechanism rotates; a more square if ya will. In any case the Juki 1508 is a “Top” load bobbin. Where as the Juki 1541 is in laymen term a “ Side “ load bobbin, so in short order learning to load from underneath left and above your left knee. Its as said learned in short order and not at all an issue. They are both superb machines from Japan and both copied through out the world. I suppose for a reason. In any event they both are most likely lite for the present discussion, regards to the current project photos posted. Its a struggle to select a machine, but one will be forced to select projects best suited to the machine no matter what the operator wants. And thats funny And Im still struggling to conform good day Floyd

-

Overwhelmed by leather Sewing machines

brmax replied to Starwind0's topic in Leather Sewing Machines

Its always a benefit these days checking some youtube videos. I would suggest popcorn and searching: machine sewing leather wallets. Then filtering so to see some using 92 size threads. As typical dress wallets are likely using 69 threads, or some even less or thinner thread. I had mentioned it before and consider it important, thats using different color thread if one needs to highlight the thread. Versus using bigger thread, when strength is not needed. Good day Floyd -

Overwhelmed by leather Sewing machines

brmax replied to Starwind0's topic in Leather Sewing Machines

There are some great replies in the post above, and a spot on reply particularly mentioning two or another machine to do the other work. Welcome to the hunt that many of us find part of the fun. In all this fun and your present projects, you need or want a machine. These “machine” sewing threads that are optional for us only fit certain size machines no matter what. It would benefit you to pick only one to use per machine, honestly at this stage its a tip! Having a bit of help sorting these sizes can be extremely helpful, though sometimes seem brutally honest. Especially when we think we can use one machine for many projects. Its tough but really is a benefit, and thats finding your budget no matter what.. followed by thread size. This now is an automatic what and what cannot be your projects. Have a good day Floyd -

The Juki TSC-441U factory manuals complete

brmax replied to Louiesdad's topic in Leather Sewing Machines

A Big thanks to ya Floyd -

Congrats on your new machine, I have never purchased a brand new machine either. So Answering your last part first; no its not necessary to use with either thread types. It in my opinion it can be considered as more a cooling lubricant enabling a faster production sew, without the thread melting from heat. If later on a need for parts, one of the dealers frequenting the site can be a big help, some are in ad banners above if you have them turned on or available. Im not sure how that works, my screen shows them all the time. I mention that as a photo could help because who knows what brand these extra pieces are. Have a good day Floyd

-

If you have ten of these, Its positive I will learn something here in the post. I thought if signing on I may see a photo, as the part where you mention setting tension so no threads peaking through other side, threw me off. In any case can you mention your stitch length or setting and possibly thread size with needle size, this helps set it up a bit more for some team help if ya will. Also can you help us and explain if you or your techs ran through any pre checks of say hook to needle position, and at what stitch length setting or any regular ones you all do. Good day Floyd

-

Leather Machine Company experience

brmax replied to WolfteverGunleather's topic in Leather Sewing Machines

I personally received excellent up front phone assistance from the Leather Machine company. With guidance to and from a tech in the shop; Tonys help on a Cobra class 4 of mine several years ago. They in short order put my questions in the shop with the clear description I gave them, and what I thought would be required. I was happy with the response in that, I didn't need to purchase what was considered. Rather an adjustment not known to me and not in my manual. They didn't ask what serial no., or when I purchased this. As I truly don't think it mattered, obviously. But I purchase this machine used in the middle of the Illinois cornfields from some good people. In any case I was corrected in I didn't need to buy a different special thickness part. Only to follow this particular procedure that was explained thoroughly and smartly. This tech call took what to me seemed a short time maybe 15 minutes max and only once! The internet has changed many things, including websites and their ease of changing things on sites. So sometimes reverting to the ole actual talking can be beneficial. This seemed to be where they shined. * I appreciate the consistent help around this Leatherworker forum, for which I have benefited tremendously. Thank you all! Have a good day there Floyd ps: i appreciate talking to all the folks at a business, but I can relate my usual questions to the techs much better. I don't talk long so blunt, smart tech questions need clear sharp attention. -

Consew 756R (Seiko CH-8B) - Going back to 794H Needles???

brmax replied to Smooooth's topic in Leather Sewing Machines

In one of my opinions I will say yes, with regards to the machine has been sewing great. With that its great to remove the cover plate and feed dog. Using this for your option to view the hook to needle alignment with its position. I cannot say what distance of needle lift past bottom center your machine is needed for spec.. good day Floyd -

Please give your opinion on my sewing machine purchase

brmax replied to Louiesdad's topic in Leather Sewing Machines

We really might be talking two distinctly different needs with regards to leather and canvas heavy tarps. Can you help with your 90% of the time tarp weight and a thread you want or need, appreciate it. With that I do understand the brief need of cylinder arm requirement! in canvas work. In all this branding hoopla, I understand kgg. Theres just know way we can give holidays and benefits as we do, with the added hr, we have as a nation worked up to. Though these first brands mentioned weather copied early or late have proven themselves. It doesn't come overnight, as any professional learns, and then gets relied on for. Whats this you say! Its getting the task done under stress in situations with restrictions and being able to use experience ( yes experience matters ) to finalize the assigned or commissioned product goal on time. Hey its Friday See ya later man Floyd no offense intended: i run a cobra and juki but many sewing factories in china run Juki and DA -

I would look further into your leads as of now, I think your onto a good lead. If its in the continental 48 and uses paypal. They work pretty good for the buyer as I understand. But I haven't had an issue. In any case, each brand name has its professional record to establish. So here we mention Juki. Im not sure how many factories are now! and have been filled for the last thirty years with other than Juki. I will easily say the Europeans I guess to use many Durkopp Adlers, while some other parts of the world use Seiko. These names have obviously, metaphorically very big shoulders, in that they have proven themselves daily!!! In factories throughout the world. So when they have newer designs we should look to them. Additionally I always keep an eye out for their equipment in the succession for any interest. Im happy with ebay, if theres an option elsewhere still using a payment option as pay pal all the better and great. I believe they stick to the sale as I understand, as long as one sticks with them. There are some articles on tips using these on the site here, regarding transfer of responsibility. Other than buying new from a dealer, I found myself when using online, my sense of security needed to have adequate insurance coverage on such a shipped item. This is seldom seen on person to person ebay types, as the standard is minimal coverage amount. Fyi, meaning up the coverage is likely required when above a 100$ So, if you can do it, pick the newest design in the industry, second opinion is the newest in a branded name. With this machine foundation no matter ones time on it, we can base a consistency and reputation. Knowing we all have to start somewhere, Experience Matters, Testing and performance results are to be respected. Lets not sit that tested reputation of machinery aside so dam easily. Have a god day Floyd

-

Tippmann Aerostitch II still available?

brmax replied to DavidMillsSaddlery's topic in Leather Sewing Machines

Would it be an advantage if one had no electric! If this is the deal. To obtain and use the standard head from a Cobra or Cowboy with! the present pulley or modify a larger pulley ( solely for hand wheeling ) I honestly know this would be my path to leather stitching enlightenment, if’n I was in the deep woods or elsewhere with no electric. Then again, I'm not sure why I would be choosing that situation, and any sew machine. I mean my list of items is incomplete. Just sayin if I was just a road runner, I am positive a generator for even minimal other usage would be on top of a list. I guess in serious supposing, of all these possible situations, this I still know. As an old mechanic, Im not getting rid of the wheel! And all it has help in our times. Now being a positive person, and team player I consider if a person was in space a wheel is less important, ? so with that a new proposed article for popular mechanics. All in good humor have a good day everyone Floyd -

What's up with this thread I was given?

brmax replied to williaty's topic in Leather Sewing Machines

Just curious, what color is the plastic spool. Particularly for the red Good day Floyd -

Totally understand! In the same task, I have my biggest problem twisting the thread in order to get it to the left side of the bobbin case lever in a loop fashion going towards the needle side. What a pain, sometimes a pencil can help as the angle seems to help my frustrations sometimes. As mentioned though holding the bobbin is a required and great benefit. It seems once I get the thread past the bobbin case opening lever, I can just give it a slight pull towards the rear 11 clock hook position. You can then feel it get into position, for next hook task to bring it up top. I guess it gets to be a habit and fortunately we forget about it. Good day Floyd

-

Are industrial machine tables a universal fit?

brmax replied to pgb123's topic in Leather Sewing Machines

Are you considering a formica type material top laminate. Just curious, in any case the wood recommendation is to be pretty thick for your best outcome. As that big of a rectangle does put a sway in the tops. An other tip is some machines need the v-belt slot very close, and many remove the part between the two holes. I would keep that area between the machine and v-belt if by all means possible. For what its worth I think 3 sheets of 3/4” plywood or particle board is minimum. As your familiar with the router a slight! Gap between the machine and top edge is helpful, as when tilting the requirement width is a bit more. I would suggest a 1/16”- 3/32”. Hey thanks for sharing your project, and keep us posted. Floyd -

Good video guides for learning about Sewing Machines?

brmax replied to JC2019's topic in Leather Sewing Machines

In my opinion, a key point that you and all face is thread size. The products we used regularly have found a standard to use, say blu jeans, coats and suits. With this to remind us of tested and proven types and sizes, we have a good base to consider. In some leather projects we can and should pick our priority. Doing this painful task we find standards of thread used in proven ways. All this hot air leads the conversation to machines were designed to use a certain range of thread, and tuned for a specific! This sounds simple and is. What is not obvious is the machines inner workings are designed to punch holes and pull/tension on these threads we choose. Some of the machine names are old and have proven themselves, some 24/7 with a factory operator who many times could be piece work paid, these operators do have a speed and its usually the machines top. These are the machines to consider for heavier duty rated sewing. Good day Floyd -

The class 4 cobra and the cowboy 4500 both have options on packages! In that they offer many or most all the feet options along with other handy items “if” you need them. These are not cheap but consider your work. I believe the standard on the class 4 is the center foot and a left presser foot, as your setting looking at the machine during sewing. As you probably been seeing premium packages with many other options. This I also believe is the same for the others like the 4500 in that hd grade machine, and which there is getting to be several, newer and older. In any case enjoy the hunt, and do look around there are plenty used in new shape in my opinion. Just takes a good eye and tough patience Good day Floyd

-

Are industrial machine tables a universal fit?

brmax replied to pgb123's topic in Leather Sewing Machines

Many times hidden, but in the manuals I have seen these cutout measurements with a small scaled picture. This may be best asking one of the machine sales guys on the site banners. I know they typically have tops, and do the machine “ routing” of the proper spec. They likely have so many templates they have to hunt for the particular model. I found my self changing to new style tilt/mounts, so this is just another something to look and value the condition. Good day Floyd -

Juki dnu 1541s bent bobbin winding tention

brmax replied to rhdiv's topic in Leather Sewing Machines

I agree with the others, and for sure I would remove the mount to straighten it. Even though it is double secured with screws, I would say its to fragile an area if trying to bend the mount. Have a good day Floyd -

Kobe 1541S alternating lift height adjustment

brmax replied to plinkercases's topic in Leather Sewing Machines

Thanks Gregg for the photo! I found another manual this procedure is in, though its been hidden as I stuffed it in a sleeve folder in the binder. Its called; Juki instruction manual #no.05 and with a series number 29349503. this has all the languages and its clearly a great manual in actual operator sense, better than a lot. In that aspect I totaly recommend it. In any case I hadn't looked at it well enough but this adjustment, its in there! On page 28. Instruction no. 19. This description is much much more normal, I believe or it is for me anyway. ( i dont need as big of a sign ) But this manual here its not the quality of that engineers manual that is linked with a big thanks to dikman. I have that one printed and in binders for each of the 41, seems handy and I write down what and any dimension i used in each step in adj. specs. Maybe a slight issue in ocd ness, yet its a record. Have a good day everyone Floyd ps: -

You may have to make a longer video, especially showing your transmission to the machine head, that sounds interesting. I understand your idea of speed control, then using some existing pulley transmission system. Although some more views or photos of all this is really required. It can sure help me understand better, your reason the servo is not slow enough or the control is not, and requiring a constant other setting. As this control part is something many of us have had to address in several ways. Good day Floyd

-

Kobe 1541S alternating lift height adjustment

brmax replied to plinkercases's topic in Leather Sewing Machines

I understand, mine don't either. I sure wished, but in any case that specific adjustment for us both on standard styles will be pictured on top of page 10 and its written adj. procedure adjacent page. The adjustments now for the walk and presser foot ( equal ) are listed as mentioned pictured on page 12 of the Juki manual and written on the adjacent page. It does as you can notice have a separate designation photo for machines with automatic thread trimmer. Mine doesn't so the photo left is relevant to me. Many times reminding ourselves the stitch knob positioned correctly for these adjustments is critical. They many times require different settings for different steps in these adjustments. Have a good day Floyd -

Kobe 1541S alternating lift height adjustment

brmax replied to plinkercases's topic in Leather Sewing Machines

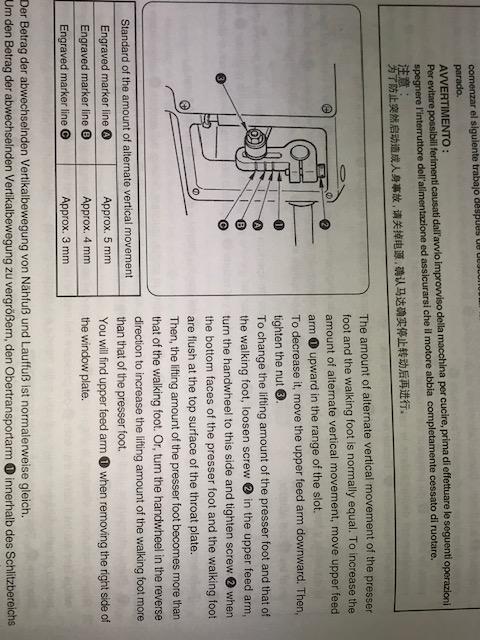

Heres a step from the link that can help. I think the picture is at top of page 12 in the manual linked, and corresponding to this copied text below. Pretty sure this works. It does and did on each of my 4 Jukis Good luck on your mission (2) Alternate momentum 1. Set the stitch dial to “0”. 2. Turn the handwheel to make sure that the amount of alternate vertical movement of walking foot 1 and presser foot 2 is almost equal. 3. When the amount is not equal, loosen setscrew 3 in the top feed rear arm and adjust so that the amount should be equal. Adjust the amount almost to A = B. TM When the amount of alternate vertical movement of the walking foot is larger than that of the presser foot : 1) Loosen setscrew 3 in the top feed rear arm in the state that walking foot 1 is raised a little, press walking foot 1 to the feed dog. 2) Re-tighten the setscrew and turn the handwheel to make sure of the amount of the amount of alternate vertical movement of the walking foot and the presser foot. Adjust the vertical stroke of the walking foot so that it is larger than that of the presser foot in accordance with the sewing products. TM Sewing sponge material or the like TM Sewing material with overlapped sections When the alternative vertical strokes of the walking foot and presser foot are considerably different TM The stitch pitch is different from the value set by the dial. TM Decrease the number of revolution of the motor a little since the feed efficiency is decreased. -

Kobe 1541S alternating lift height adjustment

brmax replied to plinkercases's topic in Leather Sewing Machines

It maybe benefit to check pages 12 & 13 in that manual, carefully. I found it a best practice to look over each step in the manual, particularly as they many times work upon the other, so following an order seems to be correct, Good day Floyd