-

Posts

1,642 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by garypl

-

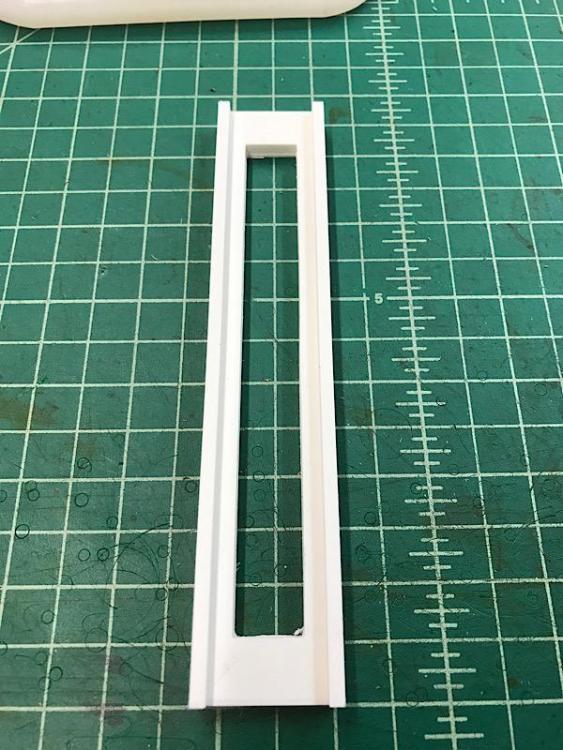

Thanks Brian and Arturo! Here is an STL file for the 1" guide. I am printing a 1.25" guide now to confirm everything fits and will post the file soon. Gary 1 in Belt template.stl

-

Been making collars for a friend’s dog rescue group and decided to 3D print a simple guide to align 1/2” stamps centered in the collar. The guide fits over a 1” strap and the stamps can then be moved closer to each other without getting off kilter. I stamp the first letter, then remove the stamp and position the next stamp so the edge of the stamp is barely touching the previous impression. Looks better with less space between the letters. Will print a guide for 1-1/4” next If anyone is interested I will be glad to share the stl or gcode files. Gary

-

Feibings dye question

garypl replied to DaveP's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

I never apply oil dyes to wet leather - only dry. Water based dyes should not be a problem on damp leather. Gary -

Very nice work! Gary

-

Thanks Bob - I am going to order a LW knife as soon as I make up my mind which one!

-

Another beautiful piece of work Ryan! Gary

-

Thanks Ferg! I will try one of the LW knives. I have an LW swivel knife that is my favorite, so I thought his round knives should be good quality. Gary

-

Anyone have comments on the round knives sold by Leather Wranglers? I would like to buy a knife similar in quality to one of Terry’s knives

-

I spoke with Terry about 2 months ago to check status of the two knives I ordered over a year before and he said he would be working on my order very soon. Guess that won’t happen now. Other than losing a loved one, losing your property in a fire has to be about the worst thing that can happen to anyone. I wish Terry all the best, really nice and talented gentleman.

-

I suggest spray adhesive and sew the edges with leather folded over the fabric. Brushing contact cement on a cotton handkerchief will be an exercise in frustration. Ask me how I know

-

Dual SA Cowboy Rig

garypl replied to MLGilbert's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Nice job! -

Very First Knife Sheath

garypl replied to SLP's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Very nice sheath! What did you use to stitch it? Gary- 10 replies

-

- knife sheath

- knife

- (and 4 more)

-

Call Bob Kovar at Toledo Sewing - 419-380-8540 - I believe they are @$200.

-

It mounts right where the servo motor mounts and the servo motor is moved to the bottom of the speed reducer. Might have to get a different belt, but it’s very easy to install.

-

First attempt at making a mold and didn’t know how strong the outer frame should be. Turns out it seems plenty strong - maybe I will make the next one a bit thinner. Takes me only a couple of minutes to level the bed using a piece of paper as a feeler gauge.

-

Thanks Chris - I have not had a chance to download Cura yet, but it will be a rainy weekend here in Georgia, so will try it out tomorrow! Gary

-

Great feedback, thank you everyone! Chris, I am using the Creality slicer that came with the printer. I will download Cura as I have heard many good comments about it. Using Tinkercad to create projects for now. Downloaded Fusion 360, but have not taken the time to learn it yet. Right now I’m just printing a lot of small items to update the printer itself, but what I plan to do is convert many of the patterns I have on card stock to plastic templates that will be sturdier and easier to use!

-

I think if I adjust the settings it will come out finer. Actually, the inside is much smother than the top. I molded a piece of leather and there are no markings where it squeezed between the two pieces. Just printed a small wrench to release pressure on my Harbor Freight hydraulic press so I don’t have to use the lever that pumps the ram up and down. I’m having too much fun printing stuff - need to start leather projects! Gary

-

Printed my first mold forms today for a small case I make for trap machine controllers. Took about 8 hours total time to print both parts. Tested it with some 2-3 oz bridle and it worked great! Outer frame feels very rigid - made it with PLA at 25% fill - maybe overkill?

-

Chris - thanks for the tips! I have started using Tinkercad and I will check out the Fusion360 program. Just printed a filament guide and end cap for my printer. Will post projects as I make progress. Gary

-

I made the plunge and bought an Ender 3D printer and assembled it today. My first print job was a cable clamp to hold one of the cables in place. I am looking forward to using it to make forms for molding, templates and jigs to help with my leather projects! Gary

-

I’ve been using an 8 ton press from HF for small clicker dies - works great. Think I paid $75 for it on sale. Gary

-

Why don’t you put your stitch line in 3/16” and after stitching trim or sand it back to 1/8”? Gary

-

I think this would be a bad idea. Likely to get moldy when it’s hot and humid. Gary

-

I will try to get over to my friend’s house in the next week to take pictures of stamps he has left. He is in the hospital now, so might take a few days to get the pics. Gary