-

Posts

1,039 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Big Sioux Saddlery

-

Looking to upgrade to a sewing machine

Big Sioux Saddlery replied to craftsman827's topic in Sewing Leather

That's very interesting, Wiz, I didn't know these were available. I might have to get me a set of those -

Looking to upgrade to a sewing machine

Big Sioux Saddlery replied to craftsman827's topic in Sewing Leather

If you are sewing mostly strap work, a Landis One is better than the clones for doing what you want to do, provided it is a tight machine and adjusted properly. Many of them are nearly worn out but still sew, although you will not get a tight, pretty stitch out of a worn out machine. They are available from time to time, often for LESS than you are looking to spend. You may have to travel to find one. The Landis Ones are not always best for sewing up close to a center bar buckle, or sewing gussets in bags, etc due to the design of the shuttle race. But for flat work, like dog collars, I do think it would work, and work much better sewing up close to spots than any of the clones. It was the only machine I used for at least 15 years. You learn to modify your construction techniques based on your machine's capabilities or shortcomings. I can measure the margin needed for the "One" if you'd like. -

It is very old and I got it from a machinery trader here in SD named Keith Pommer. I assure you I gave a great deal more than $1000. Artisan sells a new splitter, 20" I think for about the same as I gave for mine. Mine just has a hand wheel, I think Artisan's has a servo motor. You can find the old ones here and there if you travel the country.

-

Thor, that is a fantastic idea! Being computer illiterate, it is not within my capabilities to set that up, but it's still a great idea. Of course, once set up, the hard part for me would be keeping it current. Maybe I'd get my kid to do that. . . And the idea of clients visiting the website repeatedly to check on their projects and possibly ordering more products, well that's just a super idea. You get my vote for tip of the day!

- 17 replies

-

- lists

- waiting list

-

(and 1 more)

Tagged with:

-

Looking to upgrade to a sewing machine

Big Sioux Saddlery replied to craftsman827's topic in Sewing Leather

And I'm not saying that you WILL be able to do what you're wanting to do with ANY machine, but the true harness stitchers will come the closest. If you look at the modern "blingy" tack with all the rhinestones and crap, most all the spots have either been set AFTER sewing, or they have a very wide margin, having been sewn on a newer machine. If you're talking about a narrow strap with a row of clincher spots down the center. you may very well NOT find a machine to do what you're wanting without altering the process or the specs of the strap and/or the spots. About as fine as I could go with my Randall was a 5/8" strap with a row of 3/16" spots down the center. I could sew this after the spots were set. Best of luck to you! -

Looking to upgrade to a sewing machine

Big Sioux Saddlery replied to craftsman827's topic in Sewing Leather

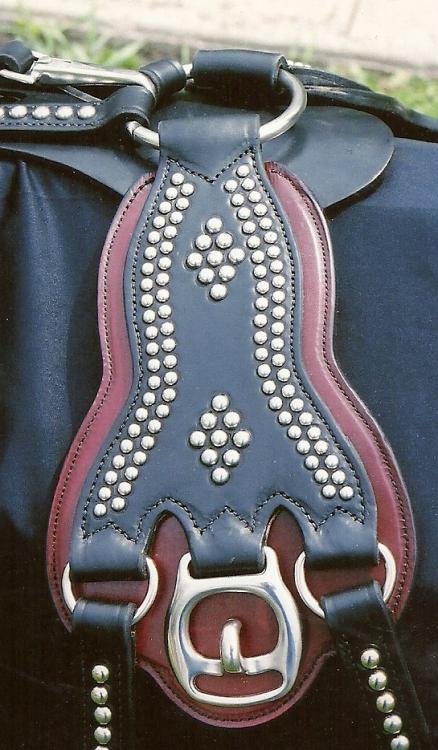

That is true of these other machines having lots of other feet, but the feed mechanism differs from the harness stitchers. The clones require at least an outside foot plus the center toe to feed correctly. I just measured a headstall cheekpiece that I sewed on my Randall. It has spots near the edge that were placed BEFORE sewing. I had less than 1/4" inch sewing margin between the spots and the edge of the leather and I had no problems. Foot marks on leather is part of the game. You rub them out if they occur. And you ALWAYS have to be very careful when sewing close. I know harness makers that have been building harness for decades and will never rise above just common work because they don't strive for perfection. Part of it is their mentality, part of it may be that they have never had the opportunity to look at top end harness. I'm talking about stuff that costs thousands of $ per horse. Inspected closely, one wonders how it's even possible to do some of the things that the maker has done. THAT is what separates common work from superior work. "Very, very careful is part of what gets you there. And no, I am not there yet! There may very well be other machines that will do the job, but I know for a fact that the real true harness stitchers were made to sew close and fine. If a machine has a "triple feed" mechanism (the sewing machine gurus may have to help me out here) they by design require more width of foot (feet) to operate correctly. The harness stitchers are either needle feed or awl feed so the foot can be narrower. I also sew a lot on a Landis One, and while it is a closed needle walking foot/ feed dog machine, It is made to sew pretty close. The harness part shown in the attached picture was sewn on my Landis One. The spots were set before sewing. While I don't know the exact margin and don't have the part to measure as this was years ago, I know it is way less than 3/8" of an inch, and I was sewing through three layers. I always figure on 3/8" when sewing on my Cowboy 4500, which is why I hate it for anything with spots or close work. I love it for a lot of things, but sewing close and doing fine harness work, there are other machines that will perform better. -

Looking to upgrade to a sewing machine

Big Sioux Saddlery replied to craftsman827's topic in Sewing Leather

That is one of my gripes about the new machines like the 441 clones and I suppose the Adlers also. The foot is too wide to sew close to spots when you don't have much of an edge. A traditional harness machine such as a Campbell/Randall would do what you need. They have many different feet and they were made for close and fine work. -

Definition or understanding issues

Big Sioux Saddlery replied to Thor's topic in General Saddlery Discussion

I disagree with the two ply off billet theory. I normally make single ply off billets out of the absolute heaviest skirting or harness leather I have around. I wet it at the fold and preform it so as not to crack there. I also oil them well so aren't so apt to absorb sweat, which would lead to premature failure. What happens when two layers are sewn together is that neither one is heavy enough for the job and one layer breaks down and then you have one light layer holding, and it is sure to follow in short order. The same generally goes for D & S headstalls for hard everyday use. If you use heavy enough stuff to avoid that, then you end up with too much bulk. Personally, I think a long latigo on each side is the strongest and least bulky, but the off billet is easier and faster to change adjustment and people want that convenience. Where people run into problems, is that they don't check their equipment over. Nobody expects the tires on their vehicle to last the life of the vehicle, so check your damn billets once in awhile! You can expect to have to replace them at some point. -

I agree, Bob.

-

-

removing stirrup leathers martha josey saddle

Big Sioux Saddlery replied to cloehorse's topic in How Do I Do That?

Cloe, I'd want to examine the saddle myself to make that decision. Adding fiberglass at this point could make a lump (pressure point), so I'd be tempted to leave it, if when running your hand over the bottom of the bar you don't feel too big of a hole or irregularity. If you do cover it, you will need to do some sanding to feather the edges out to blend. I've done a fair amount of tree repair using fiberglass, and I hate working with it. Even just doing minor repairs to a saddle with a fiberglass cover makes me all itchy for the rest of the day. Good luck to you! -

removing stirrup leathers martha josey saddle

Big Sioux Saddlery replied to cloehorse's topic in How Do I Do That?

I get a few flex tree saddles in for repair. The makers of these love to use tee nuts. I hate, Hate, HATE tee nuts and flex trees. I echo everything Bob Brenner said. Covering the Tee nut with the fiberglass is a new level of stupidity. On the other hand, I've seen Tee nuts floating around loose between the skirts and the tree. Talk about a pressure point! I was thinking about something the other day. Part of what I THINK makes a good saddle a good one is the ease with which it may be disassembled when repair is eventually needed, while still being built in a manner that it doesn't come part UNTIL disassembly is required. And to think that the saddles one builds are built so well that they NEVER will need repair, well that's just arrogance and ignorance. Eventually, all saddles will need to come apart for some sort of maintenance. One of my own personal pet peeves is the use of HUGE steel ring shank nails at every single stage of construction, from the ground seat to installation of the last rosette. On a saddle that hasn't seen oil since it was new (late '70's early 80's) the nails have rusted badly and with the combination of the rust and the leather being dry too long it is impossible to remove some parts without tearing through the leather. I realize the nice slim stainless ring shanks we use now haven't been available for all that long, but some of the nails I find in "better quality saddles" are the next step down from pole barn spikes. It is easy to do more damage than good getting these saddles apart for even simple repairs. So that's something to think about when building one or putting one back together after repair. Think of the guy that has to take the saddle apart next time. It just might be you!! -

I do agree with that Ken. I've never bought from Panhandle. I generally buy only fill-in leather from Weaver as a rule, and I never know what I'm going to get for orders, so retrospectively, if I'd known 6 months ago what I know today, I'd have ordered 9/11 russet harness leather from HO instead of a couple sides at a time from Weaver. But there's been a time when I ordered 6 sides of it from HO and kept it some of it around for years. So sometimes ya just don't know. I just got 15 sides from Wickett a couple weeks ago. And there's been a whole lot of negative feedback about them in the recent past, but I've only had time to open one bundle. I do know I won't buy any more oiled latigo from them. Just tried one sample side of that and I don't like it at all. This may be a discussion for a new thread, but who in the heck has a good latigo for equine applications??

-

I'll tell you why I buy a lot from Weaver. They have a lot. When I started out I thought I was going to be a smart shopper and buy this-n-that from a dozen different places all over the country to get the best deal. The freight kills ya. I have about 3 harness hardware suppliers. Each one of them carries something that the others don't. I do a wide variety of work in my shop, from a custom mini donkey harness to a running W surcingle to custom saddles, plus all associated repair work. And I've thought the thread is very consistent and is the only thread I can run in some of my machines. I've had more trouble with some of the hardware not being consistent. If I can get everything I need in one place on any given order (I'm ordering about every ten days this time of year) I might pay a little more for some items, but I'm in the middle of the country and freight is hellish high no matter who I buy from. If I need a couple fill-in sides of leather and a substantial hardware order, the leather will likely put me over the $1000 mark and I get everything quite a bit cheaper. It wouldn't make me a very smart shopper to save a few bucks per side of leather and get it somewhere else and then pay the top price tier on $700 worth of hardware. Another reason, convenience. Some of my other suppliers are Amish. No phone in the shop, you have to leave a message. Then they call you back and I'm on the phone with a customer so I can't answer. Back and forth we go. Or you mail them a letter. Takes a few days to get there. Takes a week to get the product. If I have the time to wait, no big deal. I don't always have the time to wait. If I call Weaver Mon morning, I'll have that order before the end of the week, I've even had it by Wed, which is unbelievable considering they are in Ohio and I'm in SD. It's typically hassle-free. Not to say that I haven't had issues with Weaver, because I have. But they do try to rectify a situation. When I have a large harness hardware order, consisting of that only, I generally order from a different supplier, But there are a few things that Weaver has that the others don't. I used to buy very little from Weaver, and then they bought out my main harness hardware supplier. I think I shed real tears because I knew that was not a good thing. But, that's the way it goes and I can't do a thing about it. I do think their offering the wholesale status for a one-time fee of $200 is cheesy. That does instantly scream Tandy to me. But it boils down to the fact that I need ALL my suppliers and until I find a better option, I'll likely keep ordering from Weaver. I'm open to suggestions.

-

I guess I have somewhat the same perspective on this as Sonydaze. $1200 doesn't take to long to spend when you start buying hardware and leather. If you're smaller than that, maybe you SHOULDN'T be buying wholesale. When I started out I think there was a $200 minimum first order. Believe me, I scraped to get that $200 together. There has to be a line between legitimate businesses and hobby people trying to buy wholesale. How is it any different than Hermann Oak having a ten side minimum? It's not like Weaver doesn't offer their products at a retail price for those that can't qualify for wholesale. Every other industry in the world operates like that, folks; there's wholesale and there's retail. If you're not in business then you're a consumer and you pay retail. If I want to buy a new pickup (which isn't going to happen for a long time) I have to go through a dealer. I can't just go to Ford Motor Company and say "Hey guys, I want a new $60,000 pickup at wholesale price."

-

Oiling before tooling good/bad?

Big Sioux Saddlery replied to KBCustom's topic in Leatherwork Conversation

Tooling leather is dry by nature. How is it "drier" than what you've had previously that makes you think you should maybe apply oil or conditioner? The only way new leather should crack at all is if it is pretty heavy and bent flesh to flesh hard, like around a buckle, and even then a lot of good leather won't. That's why we wet the fold area before bending, to prevent cracking. In answer to your question, I would absolutely not apply anything except water or your casing solution before tooling.- 4 replies

-

- oiling oils

- tooling

-

(and 2 more)

Tagged with:

-

I haven't ever added a seam to complete a pair of chaps, although I've seen them that way, and it always makes me think "lesser quality". If you choose that route, be very careful where you put the seam, making sure it isn't in a spot that is subject to excessive wear and abrasion or will be uncomfortable to the wearer, such as on the inside of the leg where it would touch the saddle. Chaps are an item that tend to come un-sewed anyway, due to frequent flexing of material and oftentimes, too light of a thread being used. Personally, I would avoid a splice at all costs. I price my chaps high enough to cover all my bases. Trying to build a pair on $100 budget is just cutting it pretty close, IMO. Used to be it was sure feasible, but leather has increased in cost so much, and we have to adjust our expectations accordingly. Many of my chap sides will run over $100 before freight. For an extra tall or big person, I plan on two sides and charge for that extra leather. Years ago, when chap sides started to hover around the $100 mark, a fellow leatherworker said "Boy that's hard to make a pair of chaps work, isn't it?". I just shake my head at that way of thinking. Everything else goes up. A new pickup can cost well over $50,000, 20 years ago they were half that. In the horse industry in particular, for some strange reason, folks tend to think a saddle should cost nearly the same as it did 20 years ago. I believe that is one major reason we're seeing the decline in quality of the production saddles. To remain competitive and profitable, these companies keep cutting costs in material and methods, resulting in an inferior product. Or possibly the reverse is true, people expect to be able to pay the same because the production stuff hasn't gone up at the same rate as everything else, but the reasons are the same. However, I digress. If a splice doesn't bother you, then a 22 ft side may very well work.

-

I always melt the ends of the thread whether sewing leather, beta, biothane or nylon. You will also want to melt any holes that you punch, as well as the cut ends. Be careful, the smoke is said to be toxic and they put warnings right in the packaging. Yet another reason why I much prefer working with leather. There is some labor saved using the synthetics by not having to dye edges and you just unroll the stuff off the roll, very little to no waste, but unless you have a hot knife/punch setup, you will spend a lot of time sealing by hand. I get cranky when I have to make something out of the stuff.

-

I would not chance the one 22 sq ft side for a pair of chaps. I'd ask for two matching sides to have your bases covered. If you run short only having ordered one side, and have to order another, what happens if there isn't one to match it then? It's much easier to have them match them up at the same time in the store than to get one now and one later and hope they match. Total square footage doesn't always tell the whole story. If the side is odd shaped or has some blemishes right in the middle of where you need to cut, you're out of luck. You might be money ahead to order a big hide and then your chances are a lot better. While I like the leather I've gotten from TLG and I like dealing with them, the sides to tend to run small and the yield isn't super. You're paying over $4.50 a ft for that hide, Hide House isn't any higher and they'll have bigger sides. Just make sure to specify when you order. Good luck whatever you decide to do.

-

Yes it is a pain to work with and I despise the stuff. However, it seems to be here to stay. Colt is correct, you have to use a needle two sizes larger than you would for leather. And use a leather point needle, not a nylon point. Even with everything set up right, it is impossible to get a good-looking stitch on that stuff, It is absolutely horrid. Beta is a little less horrid to work with, but nearly as durable as the Biothane.

-

Thank you Dwight. This stuff is NOT my cup of tea. I held out as long as I could, but the demand is so huge right now, and the best thing is that the gal that adds all the stuff I don't like, she does all the marketing. So, this is basically a wholesale gig for me. And that's not all bad:-)

- 10 replies

-

- breastcollar

- tack

- (and 5 more)

-

Are you thinking something like this? The metallic will later be cut into fringe, and conchos and "bling" added. Not by myself however, I just do the leatherwork.

- 10 replies

-

- breastcollar

- tack

- (and 5 more)