-

Posts

2,221 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Uwe

-

Adjusting stitch length Singer 153W103 alternate method

Uwe replied to Lindy's topic in Leather Sewing Machines

The adjustment screw won't work unless it has something inside that hollow main shaft to press against. You'll have to slide a suitable rod inside the shaft AND find an adjustment screw. Screw sizes on old sewing machines are notoriously difficult to determine (especially if the screw is missing) and often impossible to find in a store. I'd be tempted to try and replace the shoulder bolt+nut that goes through both parts (just above the "0" marks) with a regular bolt+nut. A suitable regular bolt+nut may allow you to clamp the two parts together and fix them in various positions to change stitch length. Cumbersome, but workable. -

Adjusting stitch length Singer 153W103 alternate method

Uwe replied to Lindy's topic in Leather Sewing Machines

Here's a video I made some time ago when the same question had come up on another Singer 153 machine that had a non-functional stitch length knob. -

Telling us what YOU found out about that machine in terms of pictures, documentation, specs, is a great way to get the ball rolling. Specific questions help, too. We occasionally suffer from let-me-google-that-for-you fatigue.

-

Designs like the SInger 111W drive the feed dog motion from the lower shaft, so in that case the upper and lower shaft need to be synchronized. That's where you'll find those shaft synchronization marks. The Adler 67 design drives feed dog motions (lift and feed) directly from the upper shaft, so no synchronization between upper and lower shaft is required. The lower shaft only drives the hook (and optional thread cutting cam). The hook itself can be freely adjusted on its own. The cone/bevel gears on the other hand usually do have factory marks on them that indicate which teeth should mesh. Watch out for them if separate the cone/bevel gears. The gears may still work but may be noisy and wear more quickly if they're not properly meshed.

-

You have my sympathies dealing with this abomination of a user interface on a servo motor. Here's the manual for the two-digit display model - good luck: http://www.consew.com/Files/112347/InstructionManuals/CSM1000.pdf 500 RPM may well be the slowest this motor can spin. The initial running-on syndrome may have to do with the position sensor - especially if the actual position sensor is missing. The controller logic will keep spinning the motor after the pedal is released to wait for the signal that the handwheel is in the right position. If there is no signal (because the sensor is missing) the controller logic will give up after a few turns, and perhaps record the position sensor as missing, so it won't try again until you cycle power. There's usually a setting that tells the controller whether the position sensor is installed or not - make sure that setting reflects reality. Installing a speed reducer pulley may also cause problems on some motors if the reduction is too strong. Some control logic systems only allow for certain number of motor revolutions to reach the desired handwheel position. The controller may give up before that position is reached, even if the position sensor is installed correctly.

-

Post some picture before you start taking things apart. If you're unsure whether you have a clutch motor or a servo motor, I'd recommend taking a step back and evaluate before you start digging in. General rule: don't turn a screw unless you know what it does (unless you can afford the machine to be down for a week or two while you figure out what went wrong.)

-

You can move the speed reducer pulley toward the back. There's a bit of science/geometry to installing motors and speed reducers. Tilting back of the machine is part of it. When installed just right the tilting works like it does without the speed reducer. Essentially, when you draw an imaginary line through the hand wheel and the hinge pivot, the center of the connecting pulley (speed reducer or motor) needs to be slightly towards the back of that line. Otherwise you have to overcome increased tension at first when tilting the machine back. There's nothing you can do about the position of the hand wheel and hinge pivot, so the only thing you can adjust is the position of the pulley. Here's a quick diagram that hopefully illustrates the concept. Green pulley (or motor) position is good, red position is trouble when tilting the machine back. The graphic exaggerates a little. Pulley on that line or slightly behind is fine. In the red pulley position the distance between hand wheel and pulley (and thus belt tension) increases at first, then decreases as you tilt the machine back. In the green position, the distance between hand wheel and pulley only decreases (reducing belt tension) as you tilt the machine back.

- 24 replies

-

- quick-release

- qick release

-

(and 1 more)

Tagged with:

-

When you manually back-tack you slightly raise the feet to turn the material around 180˚. What they mean is that thread tension should not release when you lift the feet only slightly for that purpose. Some chain stitch designs are technically incapable of sewing in reverse (and it's not a question of reversing material transport like with lockstitch machines.)This has to do with how the thread loops/triangles underneath are formed. On some chains stitch designs the chain can only form if the material moves in one direction.

- 4 replies

-

- union special

- union special 63900 a

-

(and 1 more)

Tagged with:

-

Is it a good choice? Seiko CH8B cylinder bed

Uwe replied to Ehgreen's topic in Leather Sewing Machines

Yes, "441" is shorthand for a class of machines that includes the original Juki TSC-441 and the many copies, clones, and close variations of that design. -

Is it a good choice? Seiko CH8B cylinder bed

Uwe replied to Ehgreen's topic in Leather Sewing Machines

That flatbed table sure is bigger than mine! Seiko makes good machines. A good used original (Juki,Seiko,Adler,Pfaff,etc.) is worth as much as a new clone - and will likely hold its value better, at least in my book. The 441 is the more popular design, more people have experience with it, and you may have an easier time finding help, parts, and accessories for it. Most people cannot tell if a stitch line was made on an original or a clone, but some people find working with originals more enjoyable and rewarding. -

I recommend ordering bobbins by part number. Don't trust the "Fits XYZ machines" statements (your bobbins "fit" but they're not right.) Get some original Juki bobbins to do your machine justice - how much can they cost, really?

-

Sounds like your bobbin basket got forcefully rotated out of position and jammed up pretty well. If the bobbin basket rotates out of position, the needle will surely find an early demise. Normally that bobbin basket will only properly lock into place in exactly one position. If it's not inserted properly and the latch key that keeps the basket from rotating is not properly engaged in the matching cutout, the basket may spin out of place and bind up. I made a video that hopefully will illustrate what I'm trying to say:

-

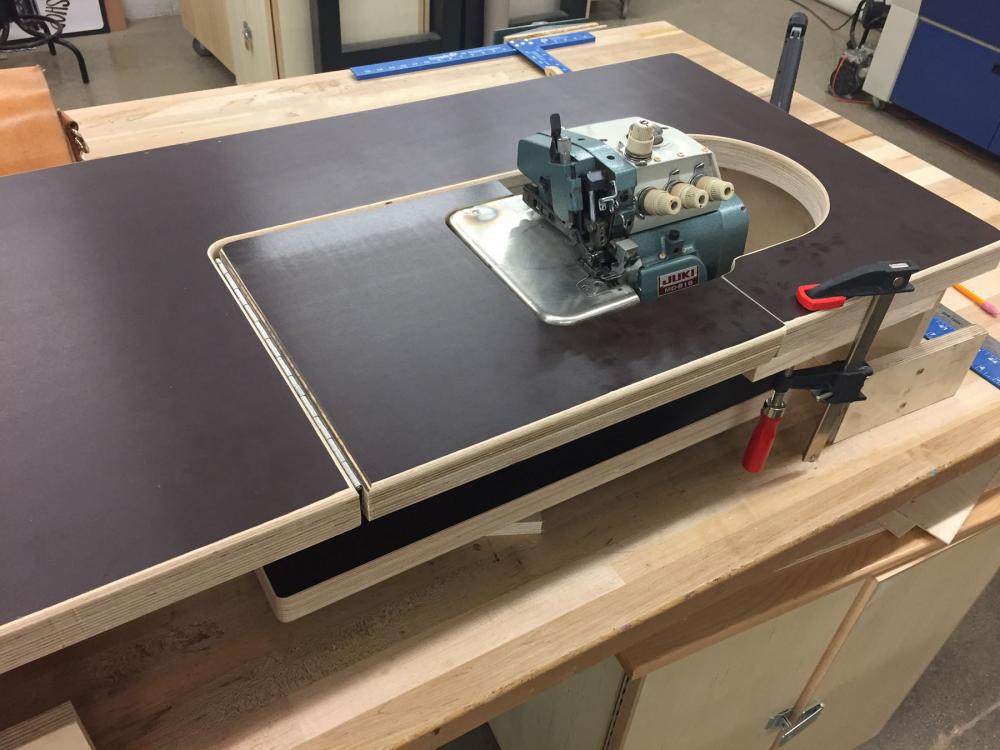

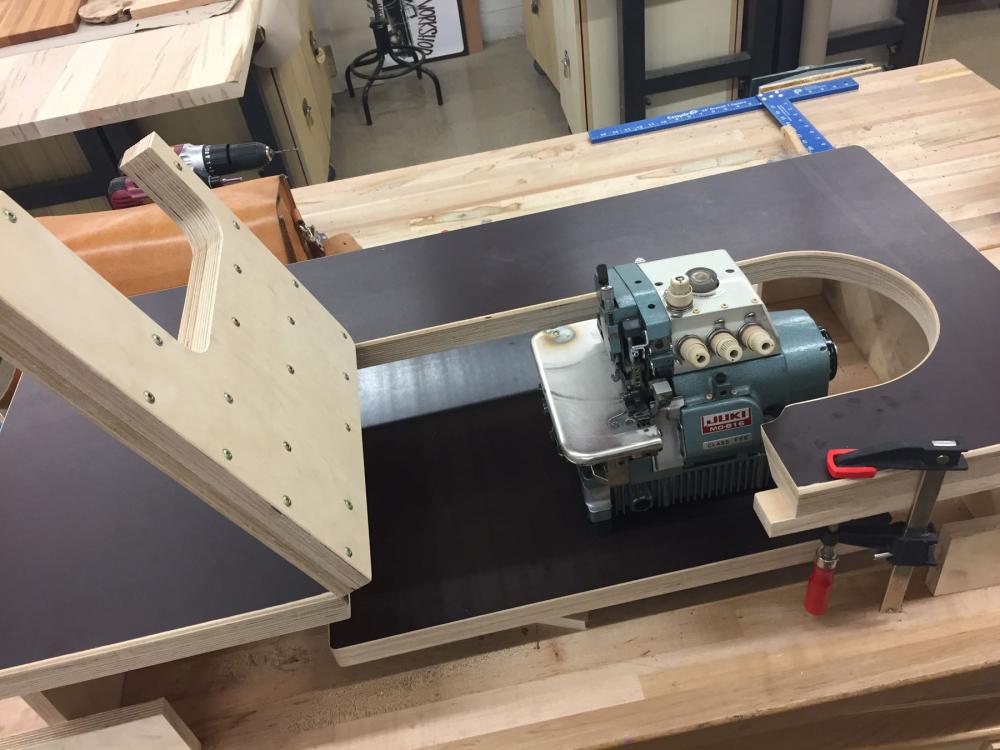

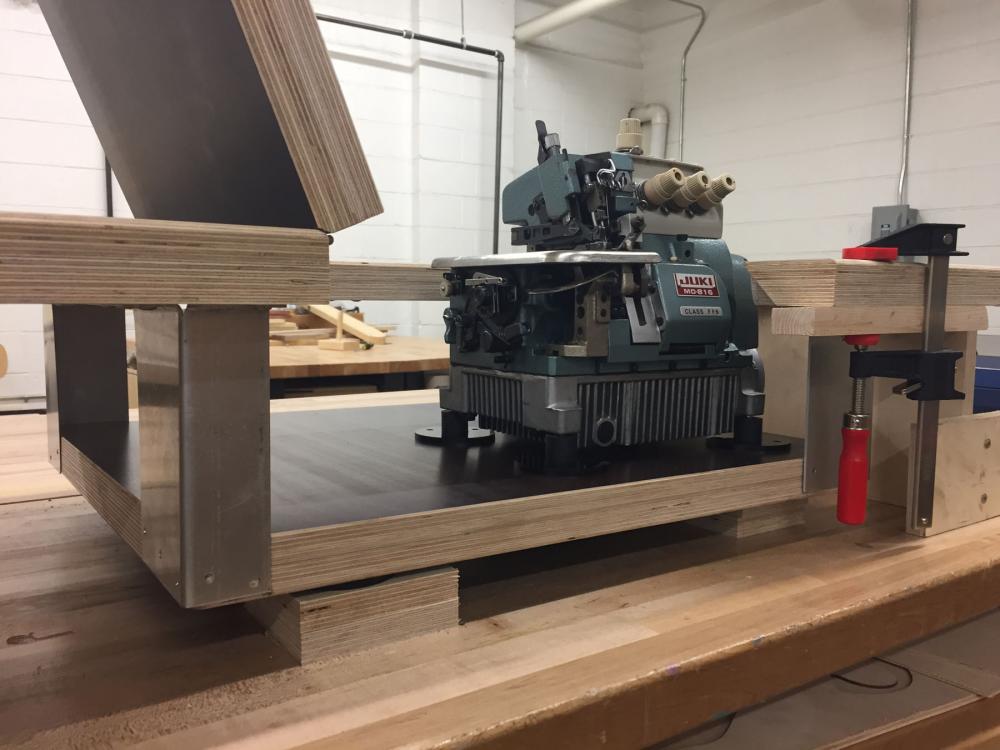

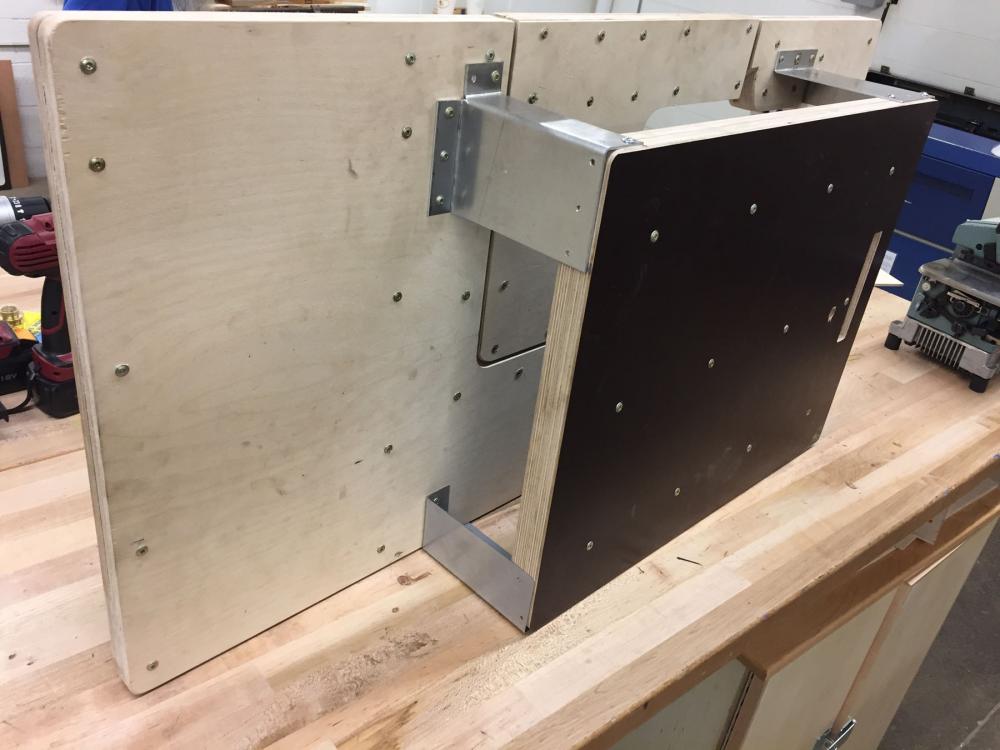

The phenolic plywood does not lend itself to glueing because nothing sticks to that slick coating. So screws it is, and lots of them. Makes for a very solid table top, though.

- 181 replies

-

- diy sewing table

- industrial sewing table

-

(and 3 more)

Tagged with:

-

I built a table for a sunken 5-thread Juki MO-816 serger for a client. Not precisely a leather machine, but a rather challenging table to build. The tabletop and suspended shelf are made of two layers of 3/4" plywood, phenolic and baltic birch plywood, screwed together. The black laser-cut acrylic rings on the suspended shelf keep the machine's rubber feet in place to keep the machine from wandering as you sew.

- 181 replies

-

- diy sewing table

- industrial sewing table

-

(and 3 more)

Tagged with:

-

Just for the record and to keep rumors from spreading, the CB3200 is NOT a clone of the Adler 205. The CB-3200 is a well-loved mutt that incorporates some elements of the Juki TSC-441 design along with other design elements of undetermined lineage. No Adler 205 plans were harmed in the making of the CB3200. The barrel hook may be interchangeable, but that's about it.

-

Then a proper motorized sewing machine should appear to be a bargain, not "crazy expensive."

-

Pfaff 337-734/01 Documents Seach

Uwe replied to geiercustomleather's topic in Leather Sewing Machines

Good old Dixie Sewing Machine to the rescue! A website design that predates Google/Facebook/MySpace and hasn't been changed since, but with a treasure trove of manuals. Hard to believe, yet fitting, that Pfaff uses them as their go-to online resource. I've been there many times and have downloaded entire sections of manual because that website may disappear at any time without notice, along with all those manuals. I actually had those file hiding on my own archive. Thanks for sharing the links for future inquiring minds! -

Pfaff 337-734/01 Documents Seach

Uwe replied to geiercustomleather's topic in Leather Sewing Machines

Can you please share the Pfaff 337 PDF manual(s) here ? One of the administrators (green username like @Northmount ) can help if the file is too large. Just the link to the PDF would be great, too, if its public. -

I'd recommend making a day trip to Keystone Sewing (LW member @Gregg From Keystone Sewing ) in Philadelphia. Having somebody available local-ish for advice, parts and service can make a huge difference. Being able to see and try out a machine in person with your sample materials is a big deal. Online info generally doesn't tell the whole story. I also think the kind of machine you probably want for shoe work is a dual driven wheel setup. Some of those machines belong to a class of clones that often have "9910" in the model number. This is the Highlead GC24618 (HG9910) in Gregg's shop. Once your shoes sell like Jimmy Choo, then you can afford a proper modern machine like the Pfaff 1591:

-

That speed reducer box alone sells for close to $180, so you got yourself a good deal. It looks very much like a Consew 206RB-? to me. Exactly which model level 1/2/3/4/5, I can't quite tell. With a little luck ,it's a re-badged Seiko STH-8BLD. If so it'll say Seiko all over the place on the inside. Most people in north America refer to that hook as a horizontal axis hook, using the orientation of the hook's axis to classify. Elsewhere in the world they use the hook's plane of rotation as the reference, which is indeed vertical. I'm just now reading a book from the 50's where the German author constantly uses phrases like "horizontaler Greifer (vertical hook)", in order not to confuse "die Amerikaner." I generally add the word "axis," as in "horizontal axis hook" to remove any ambiguity and avoid repeated "your horizontal is my vertical" elaborations.

-

You should totally buy a machine from a local store if you can. They'll be happy to provide service and parts. The early Consew 206RB-5 and previous 206RB-1/2/3/4 models were Seiko machines. Later, Consew quietly switched the 206RB-5 to a Chinese clone supplier.

-

Seiko CW-8B (Consew 227R) "Oil Reservoir" and oiling?

Uwe replied to gr8legs's topic in Leather Sewing Machines

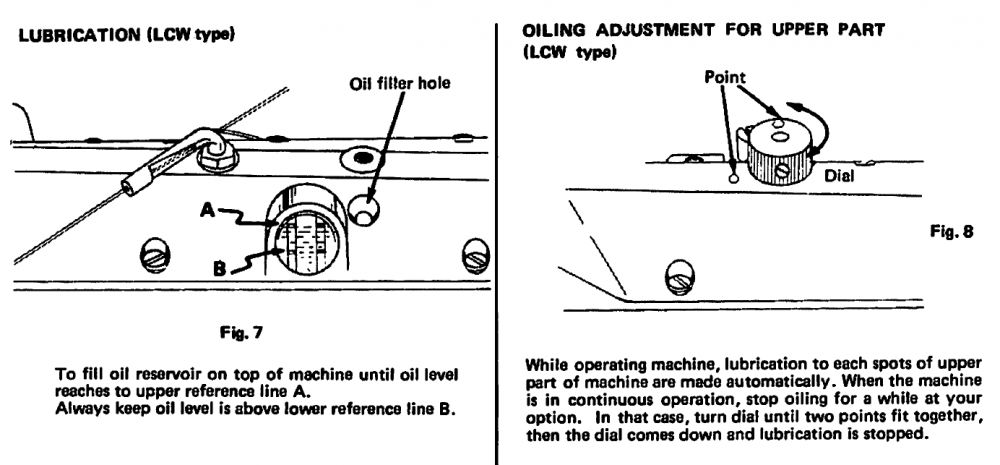

My Seiko CW, LCW, NCW Operator's Guide (Seiko CW, LCW, NCW Operator’s Guide.pdf) covers multiple machines. The oil reservoir segments only apply to the LCW version, which, as @brmax already pointed out, actually does have an oil reservoir. The CW version does not have an oil reservoir. Here's the segment talking about the oil reservoir on the LCW: -

All in the list except the Consew 206RB design have vertical axis hooks. If there's a rectangular slide cover plate to the right of the feet, then it has a vertical axis hook.

-

This may be an uphill and loosing battle. Remote crowd sourced support, being new to sewing, dealing with a mystery machine that has experts guessing at the most basic information is not an ideal combination. I predict lots of frustration all around. Post some detailed photos (good luck figuring that out on this forum) of the machine including any markings or brand stamps you can find on it or on parts inside or under the machine. Your only real hope may be to find out who actually manufactured the machine and what the original model is. Consew doesn't manufacture machines, they only put their label on machines made by others (Seiko etc.) - and obfuscate documentation to render it nearly useless. If you can find out the original make and model, you have a chance. Otherwise, you may be better off starting with a different machine.