-

Posts

2,221 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by Uwe

-

machine for handbags... possible singer153

Uwe replied to beltbuckles's topic in Leather Sewing Machines

Both the Singer 153W103 and the Adler 105 are very nice machine designs, well suited to sewing leather bags. But the two machines are not in the same weight class, meaning there's very little overlap between them in terms of what materials and thread they handle well. The Singer will be good for softer, thin to medium weight leather and lining materials, and up to size 138 thread. The Adler 105 will handle thick, stiff leathers and thick thread up to size 415, but won't be very good at handling thin materials and liners. For $800 that Singer should be in nice condition and in good working order. The Adler 105 is easily worth twice that in good condition. Get both if you can afford it. Parts for the Singer will be much cheaper than parts for the Adler. Working on these machines can be tricky and the learning curve can be steep. It's best to start with a machine that works perfectly - plan to spend some money on having the machines adjusted by a good sewing machine technician. Then you can learn how to do things yourself if you're motivated and mechanically inclined - not everybody is. -

Edge Guide for Consew 225 (and clones)

Uwe replied to KeithHideWorks's topic in Leather Sewing Machines

There's a sweet spot with plain (non-switchable) rare earth magnets - strong enough to stay put, but not so strong as to be dangerous. It's tempting to think that stronger is better. My coworkers experimenting with rare earth magnets for electric motors had warning signs plastered all over their cubicle about the magnets. The truly strong magnets will pinch/remove skin and fleshy parts of your finger in a split second if you handle them wrong. Definitely not for households with kids and pets, either. If you swallow one, you're in deep trouble, if you swallow two an hour apart, you're on the operating table. -

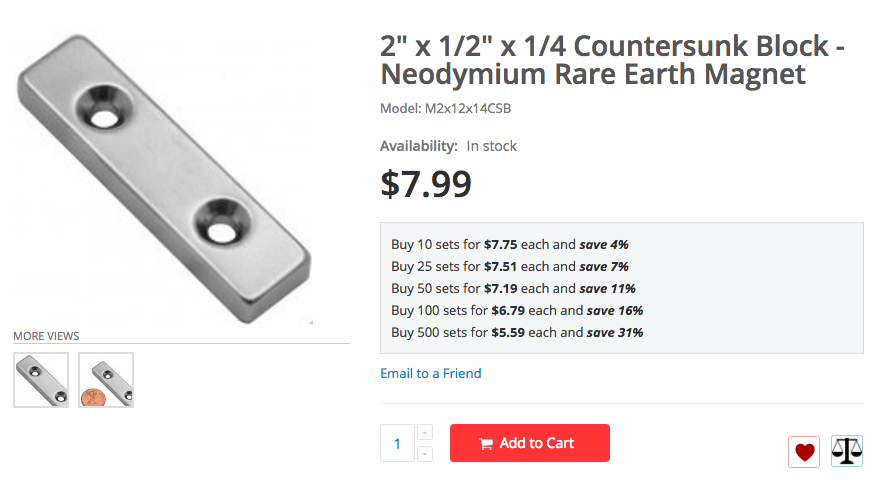

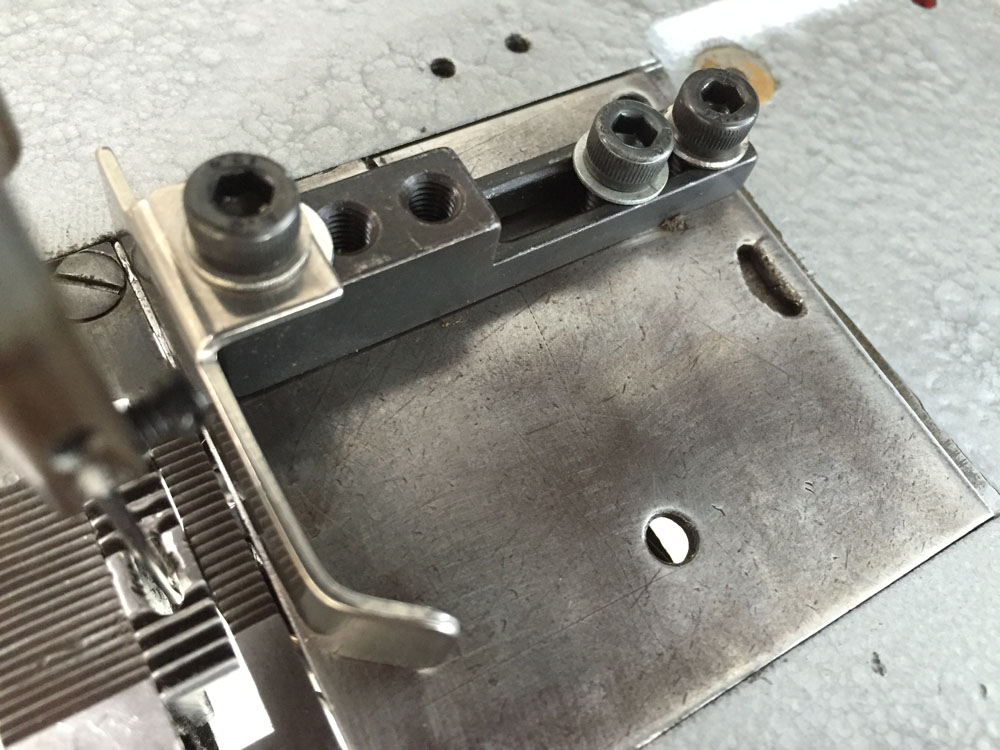

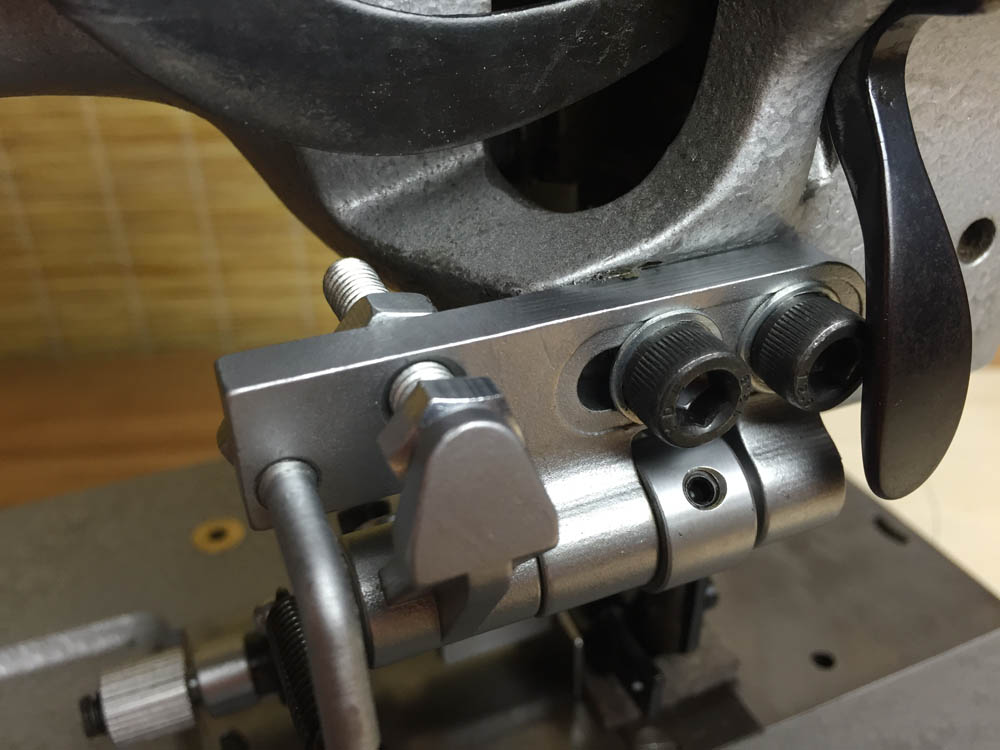

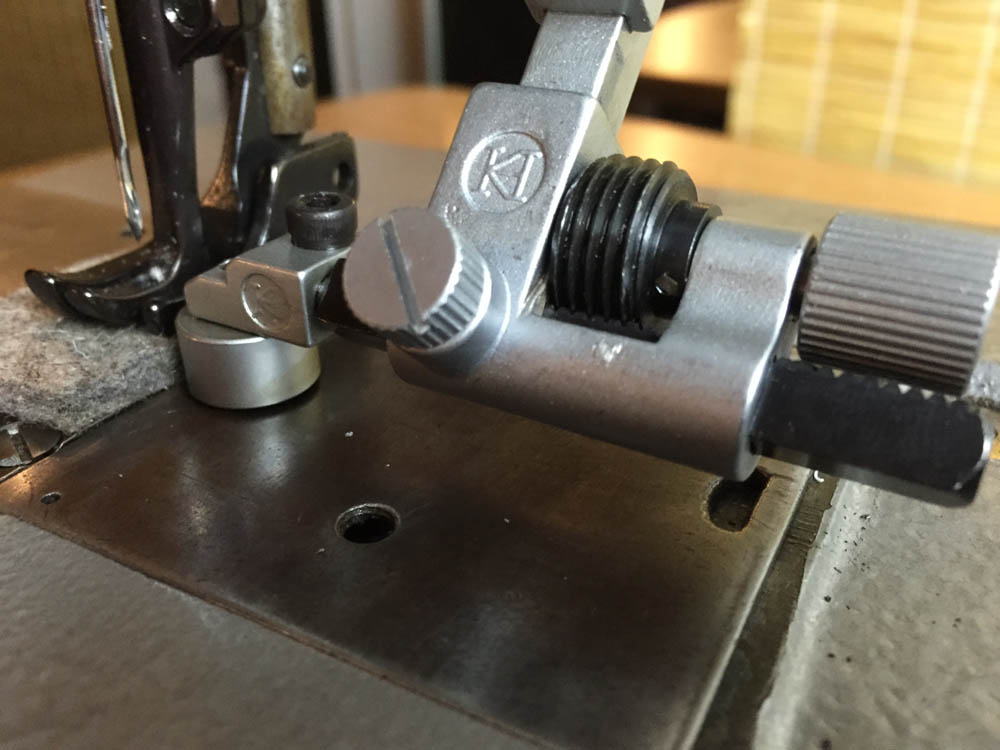

Edge Guide for Consew 225 (and clones)

Uwe replied to KeithHideWorks's topic in Leather Sewing Machines

You have a few options with varying degrees of expense, utility, and installation work involved. A simple, strong rare earth magnet that attaches to the slide plate works for many folks. You can buy a commercial version, or just a plain long bar magnet for around $10. Having holes in the magnet allows for attaching a knob/handle or additional guide bits. I buy magnets from http://www.apexmagents.com You can also make your own edge guide that attaches to the slide plate with screws, like this: The fancy swing down edge guides are nice and versatile, but you have to drill and tap mounting holes on the back of your machine. -

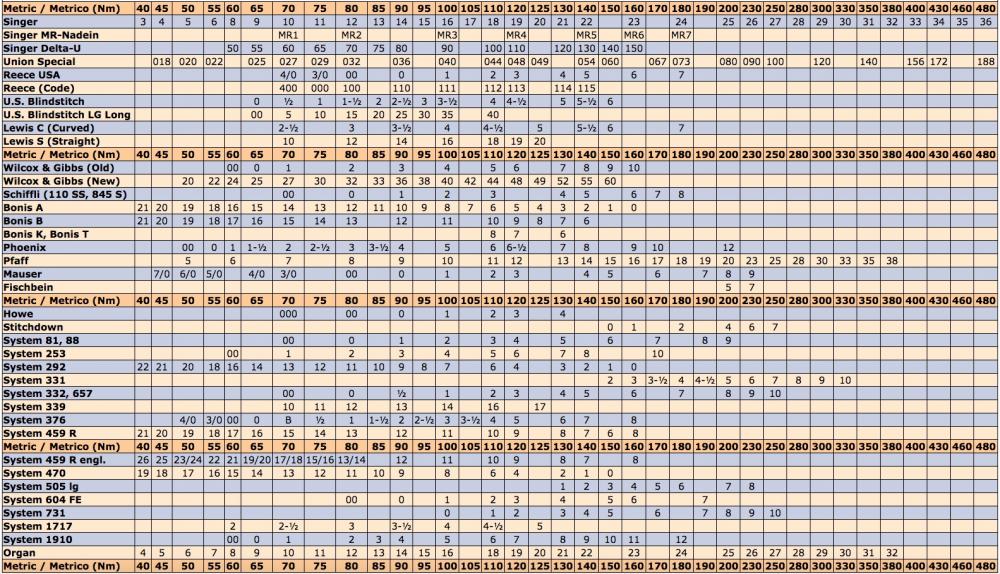

System 331 (Size 10) is indeed a candidate for my mystery needle, according to this Schmetz Needle Size Comparison Chart at Universal Sewing. In the Singer world it would be a size "30". The Singer 7-33 takes a needle 7x5 Size 31 that is one size bigger than mine, at 350 Nm or 3.5 mm thick.

-

The long-arm Adler 220 style machines (also Consew 744, Singer 144) have even bigger bobbins. Those machines run $4-5K used. True monsters. I could barely lift up one end of the machine head high enough to get them off the ground and onto a dolly. Rough bobbin size comparison: Juki 562= 1x Juki 1508= 2x DA 867 (XXL option)= 2.7x Adler 220 = 4.5x

-

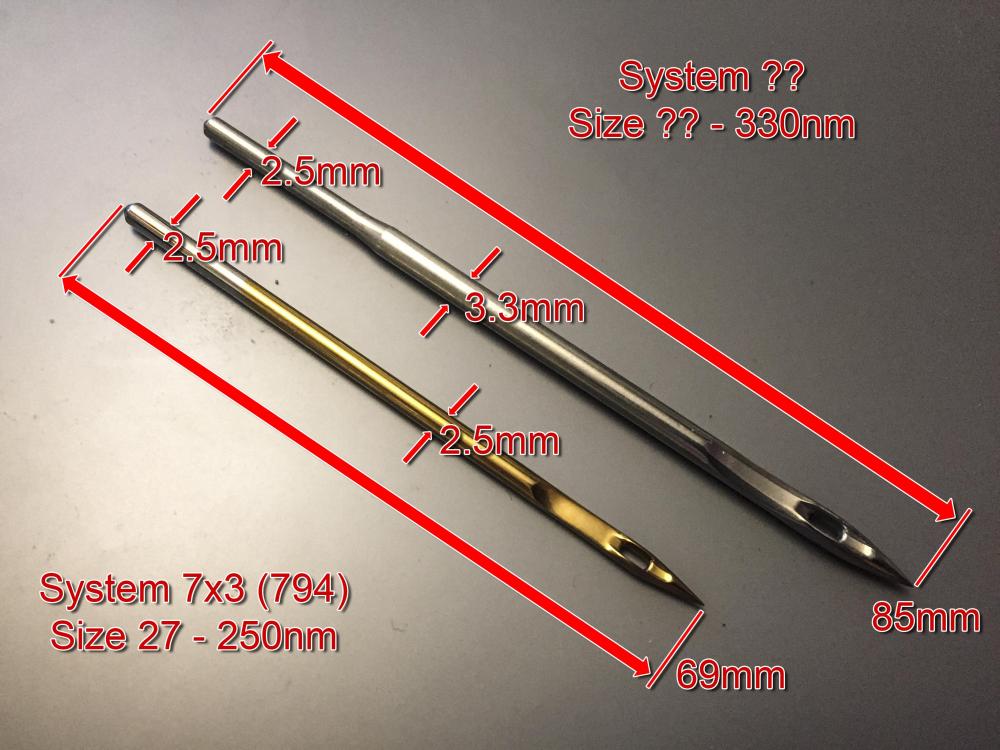

My needle is bigger than yours. I actually managed to find my mystery monster needle where the shank is thinner than the main part of the needle. Here's a picture comparing it to a System 7x3 size 27 needle:

-

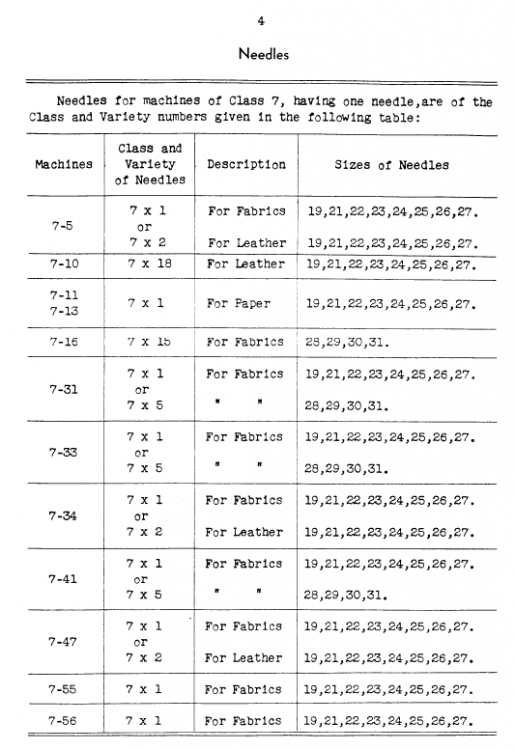

I just looked up my Singer 7-33 manual. It looks to me like fabric needles from size 19-27 belong to system 7x1, and starting with size 28 through 31 the needles belong to system 7x5. I've seen needles where the shank is actually thinner than main part of the needle, perhaps the 7x5 system belong in that category. In most "normal" needle systems the main part of the needle is the same or thinner than the shank, but not thicker.

-

So what are "7x5" needles then? Are they real, mystical creatures, or a typo?

-

Thanks for turning screws for us, Yetibelle! I'm glad you left at least one screw in the machine! Love your vintage ruler, by the way. The Part# 128 description of "Leg Screw" fits better, too.

-

Personally, I think a proper upgrade from the average Juki LU-562 setup would be something like a Durkopp Adler 867. Both machines do essentially the same thing (single needle flatbed for medium weight materials,) but you just know you're not in Kansas anymore the moment you sit down in front of it (or try to lift it out of the table.) I can hook you up. Call me after you explain the situation to your first-born.

-

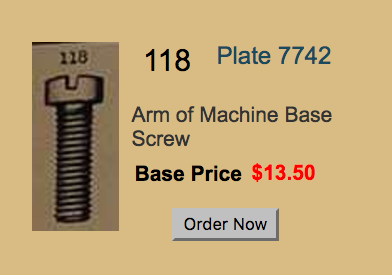

The old 29-4 Parts.pdf manual unfortunately isn't super clear about which part goes where. I think the screw with part number 118 (you know it's an early part with a part number that low) is a good candidate, depending on how you interpret the description of "Arm of Machine Base Screw". The only online price reference to that screw I could find was at http://www.singer29-4.com (which redirects to http://horsenharness.com/singers29-4.html) with a solid price tag of $13.50 per screw (ouch!) Those had better be originals! You want to make sure it's the right one before you order four of them. On the plus side, while researching this I stumbled across a very nice scan of a Singer 29K71/72/73 service and parts manual (Singer 29K.pdf) which has, among other useful info, much more meaningful parts illustrations that indicate parts locations. I was curious if the later versions of the Singer 29 used the same screws for mounting the machine to the base. The Singer 29K71 shows two different kinds of mounting screws on page 41, depending on which type of base it's being attached to. Unfortunately, the base mount screws part number for the 29K71 (Part # 50616) does not appear in the 29-4 parts manual, so the screws are at the very least not identical (not sure about interchangeable)

-

That Ebay listing is an auction, by the way, not a buy-it-now listing. I'd talk to the guy before bidding and find out exactly how he plans to ship it. Many perfectly good machines have been destroyed in transit, especially if they're shipped by people who don't ship sewing machines for a living.

-

@dikman :That black speed-knob-like looking thing is just the main fuse cover, not a remote speed dial knob. Aside from the bobbin size, the built-in bobbin winder and stitch length dial knob is nice, of course. I think $500 for a nice used Juki LU-1508 would actually be a bargain - I've never seen one for that price (I'd probably own it if I had.) The horizontal axis hook Juki DNU-1541 look-alike costs about half of what a Juki LU-1508 costs new. Seeing a used Juki DNU-1541 for $500 used would be more common. The two machines look like twins above the bed and you really have to pay attention to tell the difference (and justify the price difference.) A brand new Juki DNu-1541 head can be had for as little as $1,225 with free shipping in the U.S. I do wonder what exactly makes the Juki LU-1508NH cost twice as much as the Juki DNU-1541S. It can't be just the vertical vs. horizontal axis hook and different feed dog motion. Spot the difference: Juki LU-1508NH: Juki DNU-1541S:

-

Please start a new topic for your Necchi when you get it.

-

Problem with a Singer 112W139 Thread Controller

Uwe replied to tmitch's topic in Leather Sewing Machines

If your thread tension release mechanism is working properly, lifting the presser feet will separate the top thread tension disks and it should be relatively easy to pull out the material (and thread.) -

By the time you get done bringing this machine back from the near-dead and mutilated, you'll have invested well over $1K, approaching the territory of shiny new clones. Loud clicking noises in motors are rarely a good sign. That needle bar repair and mismatched gauge set look pretty bad, indicating the machine had a rough life in the hands of a hack. The seller's "excellent condition" label is far from reality, his use of "sawing machine" is much more accurate.

-

Problem with a Singer 112W139 Thread Controller

Uwe replied to tmitch's topic in Leather Sewing Machines

The best time to pull out your material at the end of a seam is when the thread take-up lever is at the very top. -

That Brother LS3-C51 has come up in a different topic just recently. You may not be the only one contemplating that machine. The Brother LS3-C51 appears to be re-badged Seiko LSC-8B-2 from the looks of it. Seiko makes great machines, sold under several brands. Made-in-Japan is a good thing (but not as good as Made-in-Germany when engineers and well-paid factory workers ruled.) It probably would do just fine for what you're trying to do. But there are no guarantees. I've never touched a Brother LS3-C51 myself - I'm just going by specs and some educated guesses based on similar machines I've worked on. Personally, I'm still rooting the for the Pfaff 345. Take some samples of the materials you're intending to sew and go try it out. It's the best way to get a sense if a machine is comfortable or struggling, or if it's too ugly to have a picture included in the CL ad.

-

New to industrial sewing machines Juki LU-562

Uwe replied to jshep's topic in Leather Sewing Machines

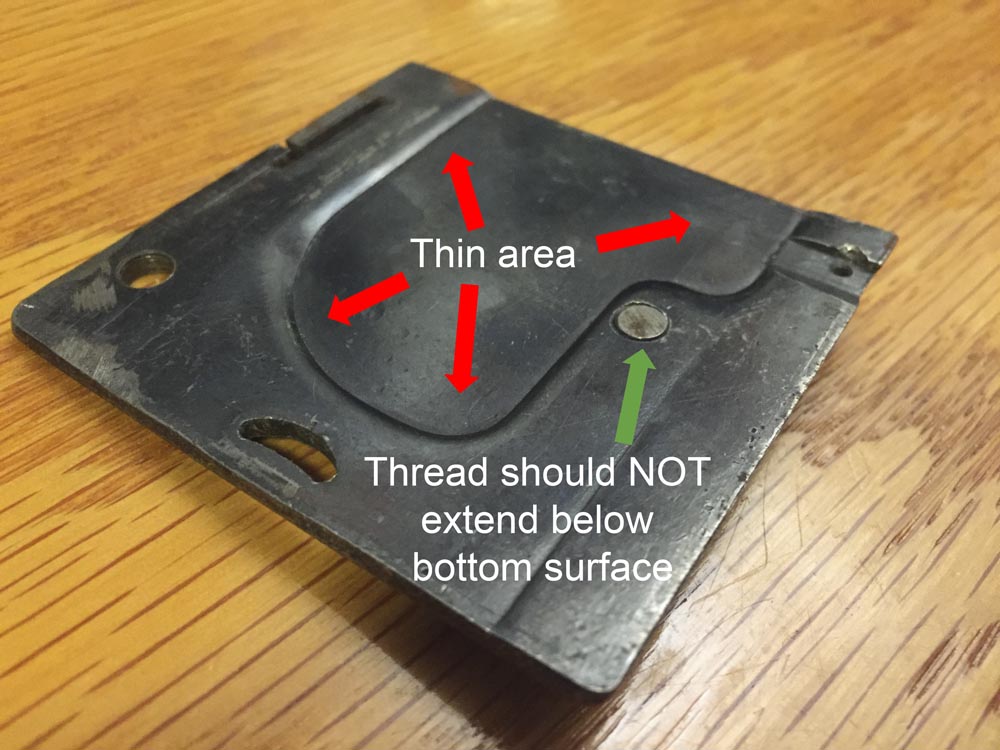

You just need a right slide plate with suitable holes in the right location. The hole in a standard right slide plate for the Juki 562 class is very likely a #10-32 thread. At least several of my slide plates take that size. Luckily most hardware stores carry size #10-32 screws. Most other screws on vintage sewing machines are specialty sizes that you will never find at a normal hardware store. The reality is that many folks "customize" their slide plates by either forcing a different size thread through the hole or drilling and tapping a brand new hole. All of which is fine, really. But there's no way of us knowing exactly what your slide plate is threaded for right now. Many slide plates also have a second thread hole in the top right corner (also threaded for #10-32 on mine) which allows you to lock the slide plate in place to make sure it doesn't move while you're sewing. When you buy additional slide plates, make sure they're the correct "right side" ones. The slide plates for the right have a thinned out area underneath that allows room for the thread and hook to do their thing. The slide plate for the left side are flat (and too thick) on the underside. It's important that the screw thread does NOT extend below the bottom surface of the plate because it may interfere with or damage the hook. Get a screw that is a little too long. Remove the plate and mount the binder and tighten the screw, then cut off the part of the screw that sticks below the bottom surface with a hacksaw/grinder/Dremel and file it nice and flat. Your slide plate won't win any beauty pageants afterwards, but at least it'll work. Here's one example of a plate that has been customized by the previous owner (silver) and a standard, unmodified slide plate (black) Industrious folks who do a lot of binding with different binders have bought multiple slide plates to easily swap out one binder for another, or back to a standard plate without having to fuss with screws and aligning things again. Slide plates are cheap at around $11 each on Ebay, the banner vendors, or from me. -

Yes, they are good for sewing leather - their nearly perfect within a certain range of applications. But sewing heavy leather belts doesn't really fall within the range of applications that these machine are designed for. Squeezing all that engineering into those slim cylinder arms requires some compromises. Machines with larger diameter cylinder arms (e.g. Juki LS-341, Pfaff 345, etc.) have more room to pack larger, more robust mechanics, full four-motion feed dogs and vertical axis hooks with huge bobbins inside those arms. If your "crafts" include gun holsters and horse saddles, you need to step up to the big boys like Juki TSC-441 class machines If your main goal is to sew leather belts and flat crafts like wallets and book covers, then you don't really need (want) a cylinder arm machine. You can buy a cheaper flatbed machine like a Juki LU-563 with better feed dog motion and larger material and thread handling capability (compared to your slim cylinder arm machines, not the big boy above).

-

The two machines you're considering are very close in cylinder arm design and overall capability. Both the Brother LS3-C51 and the Juki DSC-246 are slim cylinder arm machines with horizontal axis hook. Either one is probably a fine machine and you won't notice a great deal of difference in using either beyond the different stitch length adjustment methods. Do some searches on documentation and normal wear parts or accessories like feet, throat plates, feed dogs, hooks, etc. Pick the machine for which you can easily find documentation and affordable parts. Of course the relative condition and price of either machine plays a big role as well.

-

Problem with a Singer 112W139 Thread Controller

Uwe replied to tmitch's topic in Leather Sewing Machines

One side of your stitch lines actually looks pretty evenly balanced. Perhaps your bobbin tensions are adjusted too strong, and not quite evenly balanced. The top thread tension balance off the bottom tension(s). Each bobbin case has a little tension spring to adjust the bobbin thread tension. Those screws are teeny tiny, short, fragile, and have a strong tendency to vanish. I use a screw driver for my eye glasses to adjust the bobbin thread tension screws a quarter turn at a time. Adjust the bobbin tensions so that they're very light, just noticable and about the same when you pull on the thread with just your fingers. -

Hi Sandra, Welcome to Leatherworker.net! Your machine looks very much like a old-casting Pfaff 335, so I think you can use Pfaff 335 parts and accessories. This old-casting Pfaff 335 Manual should get you started on the right path: Pfaff-335-Instruction-Book-Old-Casting-print.pdf The belt on your machine looks too wide. Auto parts store may have the right ones, and some hardware stores carry them too. Look for a "3L xxx" type belt (3L is the width, xxx is the length). For edge guides, you can either get a swing down edge guide like the KG-867 edge guide from Kwok Hing (with a KB-09 adapter bracket, the kit is called KG-1245), or you can use special edge guiding feet like GR-1245. I have these item in my ebay store with nice pictures, just for reference. Check out College Sewing in the U.K. they carry a lot of the same parts that will fit your machine. Your current throat plate/feed dog/presser feet look like they are intended for binding operations. You may want to get a standard gauge set (example: KH-335-R ) and feet (example KP-1245-W) for regular sewing tasks. Kwok Hing makes very good quality parts for Pfaff 335. The original Pfaff parts will be very expensive in comparison. You are also missing a screw on the right that holds the machine to the table. The screws on the right are the important ones, actually, make sure you put bolts/screws in the holes on the right side.

- 7 replies

-

- sewing machines

- accessories

- (and 4 more)

-

Singer 111W155, lack of reverse a major negative?

Uwe replied to MikeC5's topic in Leather Sewing Machines

If you're gonna be all period correct with real horse hair mats for padding, you really should consider sewing with a true vintage sewing machine, and those didn't have reverse back then. Two generations managed to sew without reverse, and they did just fine. -

Bought a Singer 211U567B Need Help With Drip Pan

Uwe replied to Kellen's topic in Leather Sewing Machines

You can order a drip pan online from http://www.singeronline.com/drippan.html for $40. There are subtle differences between various drip pans, especially with the location of the knee lift access hole, so you want to make sure if you spend money, you get one that is designed for the Singer 211 series. I'm sure the usual suspects in the banner ads carry them, too.