-

Posts

2,221 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by Uwe

-

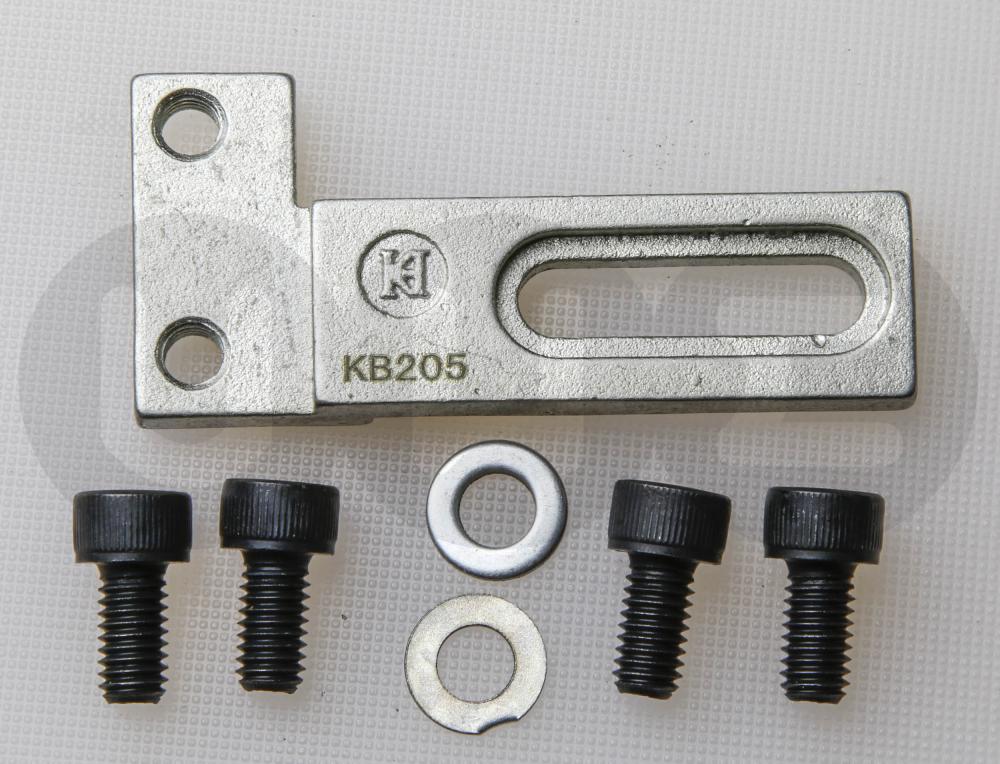

The best way to find out for sure is to just try it out. I do have the KG-867 guides and KB-205 brackets on hand, in case you want to try that one first. I can mail you a set for testing today, just PM me your mailing address (I'm leaving for a road trip at noon). If you can wait a few weeks, I can add a KG-967 guide to my next Kwok Hing order and let you borrow it for testing. You'll probably have a hard time finding the KG-967 guide at retailers in the wild, and establishing a direct order line with KH is not always simple.

-

The KB205 bracket might work then. It comes with standard M6 screws. PM me if you want try one out, I have a few KB205 brackets on hand and can send you a sample for testing. The Cowboy brand 441 machines (CB4500) don't have a flat surface where the mounting holes need to be (it's a curved recess instead), complicating things a bit. Kwok Hing also makes a long version of the swing down guide called KG967. It has a 20mm longer arm than the KG867.

-

The leather type knife-edged needles will generally cut thread or fabric just as well as leather. I'd just finish the seam off by hand. You have to do something by hand anyway to pull the top thread ends to the bottom and secure them. It probably takes less time to finish the seam by hand, than to redo the entire stitch line because it cut a previously stitched thread every so often. Then you can claim "hand finished seams" and charge more money .

-

The KB205 adapter bracket for Kwok Hing guides may actually work on a Cobra, or at least be a good starting point for a custom bracket. While the Adler 205 is a totally different design, the general dimensions are not that far off from a 441. I had contemplated drilling holes and installing a swing down edge guide on my 441, but never got around to it. If the vertically aligned holes are already there, it may be worth a shot.

-

My crystal ball is all foggy this morning. I need pictures!

-

Open the bobbin cover and turn it over by hand very slowly and just observe what's going on. Most of the time it'll be obvious what is causing the thread to fray, either rubbing against something or running over a sharp edge or whatever. Does the thread get frayed before it ever gets to the eye of the needle? Running and snapping the feet dry like you did will surely cause some sharp metal edges somewhere. Sending the head back for repair on the dealer's dime seems excessive at this point and risk more damage than it may fix. Figure out how to take a close-up video of the hook movement with thread and leather like the one posted above, except focus on the hook instead of the thread stand in the background (usually done by touching and holding the area on your smart phone screen that you want to be in focus until the focus locks.) Get a $10 phone holder (a scotch tape dispenser works nicely in a pinch) and put the phone on a stable surface. Horizontal video rocks.

-

Can you post a close-up picture of the machine's back side showing the hole locations? You may need an adapter bracket (hopefully it would be included). Either way, the manual foot lift lever tends to get in the way of the swing-down guide on the 441 class machines. If you do what Al Bane did in his video (remove the ball on the lever), you're losing the gravity-operated foot lift release because the weight of manual lever no longer pulls down enough. Swing-down edge guides on a 441 class machine are a compromise, not an elegant solution.

-

Don't run it under motor power until you figure this out. Chances are, that some part is touching something it shouldn't touch during the stitch cycle. If the part that is supposed to move stops moving, oftentimes something else start moving (or breaking) to compensate. Take the belt off the hand wheel, remove the thread, lift the presser feet and slowly turn it over by hand towards you. Take note of any tightness or increased resistance - then check moving parts at the point in the cycle. Double check your feed dog movement to make sure it doesn't touch the front or back of the throat plate (or underneath). Also check the foot lift linkage where it goes from outside to inside on the back of the head - sometimes that linkage arm touches the casting/housing after an adjustment, causing a bind.

-

I'm thankful that Juki (and Durkopp Adler, Pfaff etc.) care enough to actually produce manuals in multiple languages. I translated technical (car) manuals to finance college in the U.S. and it's HARD work. Ignoring a language you don't know is super easy by comparison.

-

Tech specs, needles and thread range, availability of manuals are important details most people ask about before they buy a machine. Bob's your guy.

-

Leather armor just needs to look convincing at a renaissance fair, it doesn't need to be functional - nobody's going around whacking people with sharp swords or axes like in Game Of Thrones. You don't really need to sew shoe sole leather to make convincing looking leather armour. A used medium duty cylinder arm walking foot machine is still your best bet for coming even close to $1K, I think. A $2K budget would open of the field of candidates considerably and include some post bed and heavy duty cylinder arm candidates.

-

So that's what it was - I thought I had felt a disturbance in the Force.

-

Any dealer who's going to that length to accommodate your decision making process is worth serious consideration. I'm not aware of Juki making a table attachment for the LS-341. You can always build your own. I make table attachments for Pfaff 335, Durkopp Adler 69 and Durkopp Adler 205. Juki TSC-441 and Juki LS-341 are next on my to-do list for table attachments.

-

Many of the usual suspects like Juki LU-562 or LU-563, Adler 67, Singer 111W155, Consew 225/226, etc. can often be found for under a grand and they're a BIG step up from the Sailrites. If you need to sew three-dimensional things like bags, armor, codpieces. a cylinder arm machine is desirable, but those usually run more than a grand for the nice walking foot ones.

-

Where to buy a quality machine with a Efka servo?

Uwe replied to ruinbliss's topic in Leather Sewing Machines

Last comments from me on the video topic, I promise. Most people have no clue what Flash and HTML5 even is, let alone have a sense of the effort and Infrastructure involved to make systems like Siri/Cortana/Alexa work at all. The average mobile phone has likely 100 times the compute power it took to get us to the moon. I film most of my HD videos on my iPhone and it's just plain amazing what it can do. Expecting the average leatherworker to set up up their own site for video hosting is unrealistic. Heck, most people in the industrial sewing machine business struggle with basic email! Watching Youtube videos on a mobile device or a Mac is seriously low risk. -

Where to buy a quality machine with a Efka servo?

Uwe replied to ruinbliss's topic in Leather Sewing Machines

Just upload videos to youtube and avoid all these system specific issues. That's one of the reasons youtube is so popular - it just works on nearly every device. Mark the video "unlisted" if you only want close, personal friends to know you take vertical videos. -

Where to buy a quality machine with a Efka servo?

Uwe replied to ruinbliss's topic in Leather Sewing Machines

It's hard to make suggestions without knowing what physical limitations we need to consider. Some systems can be adapted with hand controls for folks who can't operate a foot pedal. If manual dexterity is limited, certain controls can be shifted to leg/foot actuators, to allow for one-handed operation, etc. It boils down to finding somebody who's willing to put together a workstation customized for your needs. Any outfit that will only drop boxes at your doorstep is not really a good candidate. Once you find somebody local to put it all together, have them help you choose the pieces based on your intended use. Efka motors are great for many applications, but they may not be a good choice for what you're trying to do. -

Some needle systems are close enough in size to make them work with a minor tweak. Your needles are WAY too short. No wonder your needle's eye is too high. There's really no way you can make those short needles work in that machine - if you just lower the needle bar, it will likely hit the presser feet. Wait for your 135x16 needles to come in. College Sewing in the UK may have better delivery times than some Ebay sellers.

-

My 135x16 needles are 44.19mm long butt-to-tip. All needles in that 135x16 system should be exactly the same length and only vary in thickness, and shape of the tip. Normally, needle systems are defined in terms of distance from butt to the eye of the needle as one key metric. Usually one adjusts the needle bar height AFTER setting the hook timing position. Get the hook to point at the needle at exactly the right "time", i.e. when the needle has risen a precise distance (check manual) from its bottom dead center position as you turn the wheel towards you. THEN you adjust the needle bar to make the eye of the needle sit a precise distance below the tip of the hook (setting it so the hook points at just below the mid-point of the needle's scarf is a usually good approximation.)

-

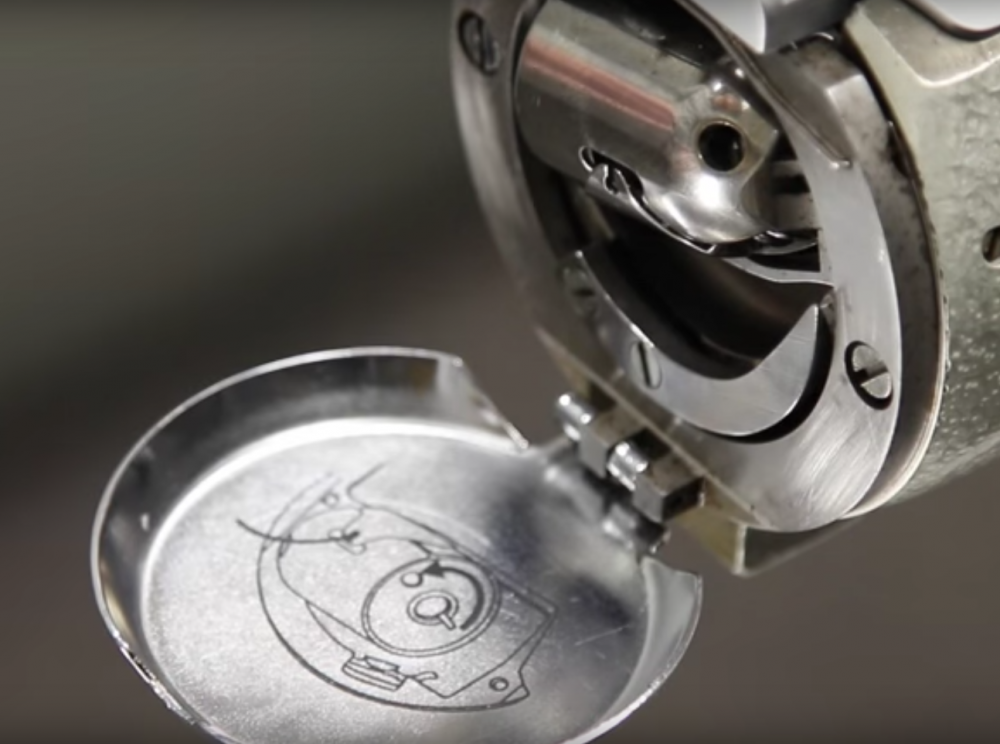

I made a video some time ago that shows the underside of a loop-pickup on a vertical axis hook machine. It may help visualize what's going on down there.

-

Perhaps I'm missing something. I've been wondering for a while now why I keep coming across variations of "A good time to stop and turn the material is when the needle has come back up a little bit." Even Al Bane says something to that effect in one of his videos. That guideline just goes against my understanding of the stitch cycle. Generally, folks stop to make a turn while the needle is buried in the material because it provides a good pivot point. In that situation it seems to me that the only really BAD time to stop and turn is when the needle has come back up a little bit, the thread is still busy forming a loop but the hook has not yet caught that loop. Thou shalt not mess with the loop, in commandment speak. So why do so many folks recommend to stop and turn the material exactly during that most vulnerable period? Is it the thrill of playing Russian roulette with skipped stitches? In my mind, a good time to stop and turn the material is either: A.) While the needle is still going down OR B.) AFTER the needle has come back up again far enough so that the hook has had a chance to positively catch the loop. I really am curious about the reasoning behind the common recommendation and I'd love to hear from others.

-

I'm guessing the bobbin case wasn't seated properly inside the hook and came loose. There's a second dimple just above the big one. The needle should never be anywhere those spots. When you insert the bobbin case on a horizontal axis bobbin, make SURE it snaps into place. You have to pull up the little tab to hold the bobbin case (this also hold the bobbin inside the case) then insert the bobbin case into the hook and let go of the tab. You should feel and and hear it "snap" into place. If the bobbin case comes loose and starts to rotate while you're sewing, all manner of bad, expensive things will happen.

-

That'll do it! Time to get out the dremel tool or get a new bobbin basket.

-

The standard LU-562 and L-563 do have reverse, but both machines were also manufactured in special "-3" subclass versions, as in Juki LU-562-3 and LU-563-3 (or LU-563 Subclass 3) . The "-3" subclasses lack the reverse mechanism, which allows for greater forward stitch length.

-

Nice work! I'm a big fan of putting instructions and information right where you need it. My label maker gets lots of use. One of the first things I do when I start working on a new machine is make a needle system and size range label and stick it on the machine. The other thing I often need a reminder of is which way to insert the bobbin. I made a graphic and lasered it right on the inside of my bobbin cover of my Adler 205 (a clear sticker would work just as well in that spot, but I have access to a CNC laser and I really wanted to try out the metal marking fluid). I think I'll start lasering bobbin threading graphics onto the hook slide cover plates of my flatbed machines. The advantage of laser etching bare metal is that it doesn't wear off.