-

Posts

2,221 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Uwe

-

I recommend the original Juki part. When you compare the two versions side by side, the difference are quite obvious. One key difference is the that the top section of the vertical flat slide part is machined to be thinner than the rest of the metal stock. I think it makes a difference and allows for smoother movement and more pin-pushing action. ABC Sewing Machines sells the Genuine Juki part for $7.33, which in my mind is trivial compared to the effort it takes to install it. It may take a week or two to get them (I ordered a bunch of them). MJ Foley has them too for about the same price (and they include the Pin that goes inside the machine.) All my parts from both ABC and MJ Foley arrived in boxes, unharmed. The parts worked perfectly on all my Juki and Juki clone machines. I installed one of these on my Consew 225 today. It took a fair amount of fiddling/filing/polishing to make it work on the Consew (the vertical sliding part was a tad too wide for the Consew mate). But now even my Consew 225 is a happy thread tension releaser.

- 20 replies

-

- tacsew t1563

- juki lu-563

- (and 6 more)

-

Looking at the Efka AB60A Manual it appears you are out of luck. It boils down to "Thou shalt not use this setup without the positioner" unless I'm missing something.

-

The EPS is more of control box thing. The DC1600 is really the motor, which is often combined with the AB60D control box. The manual for the AB60D boggles the mind with nearly 300 parameters you can set. I glanced at it hoping to find some position sensor on/off parameter, but no such luck. My vintage Viking 6570 still has the best needle position control interface I've seen - a simple three-position switch with Up/Off/Down settings.

-

I didn't know, actually, but I'm a tenacious Googler with occasional insomnia. I really thought that the "Kochs Adlernähmaschinen Werke AG" wording on my Chandler 67 machine label was mangled German introduced by some dyslexic contractor who printed the stickers. In my mind the old company name was just poor German no matter how I looked at it. What it actually means is "The factories owned by Koch that make the ADLER branded sewing machines, Inc." What I always thought it meant was "The sewing machine factories founded by Kochs and Adler, Inc." No wonder they eventually changed their name. "Ford's Model-A-Cars Factories, Inc." doesn't exactly roll off the tongue, either.

- 11 replies

-

A wiggly feed dog will cause problems, no doubt.

-

That Juki-In-A-Box is indeed a nice and compact setup! I hadn't seen that one before.

-

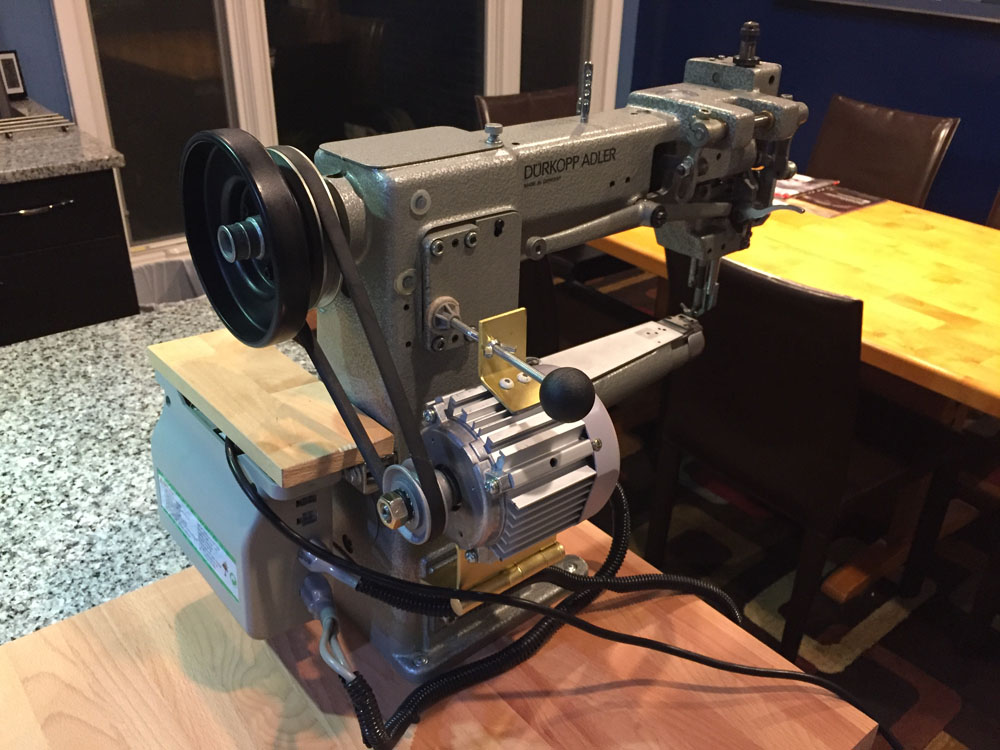

I got my FamilySew clone of the Sailrite to work and it's okay, but compared to a Juki class machine it just seems crude, weak, and noisy. I think I'm going to make a NYC-apartment-sized portable tabletop setup for my Juki class machines, similar to this concept mock-up pictured below. Weight will be a few pounds higher (just invite that friendly bodybuilding neighbor over for a protein shake), cost will be similar to a new high-end Sailrite, but machine and stitch quality will be significantly better. You'd loose the knee-lift, but then the Sailrite type machines don't have that, either.

-

Used Fortuna skiving machines similar to yours have recently sold on ebay for $400-$800. Older machines are often hard to price because the condition is hard to judge, and the price difference between a "works" and "needs work" machine can easily be a factor of three or four. Brand new aftermarket Consew brand skivers of the same class sell for around $700 for the head. Fortuna brand machines are the originals and may hold their value a little better. Fortuna machines are represented in the U.S. exclusively by PIMA (Premium Industrial Machines of America), based in Alpharetta, Georgia. The company used to be called Pfaff Industrial of America, but they can't use that name anymore after Pfaff changed ownership. The Fortuna product page of their website: http://pfaff-industrial.us/browse-by-application/skiving/fortuna-skiving-splitting/ They should also know about authorized service centers around the country.

-

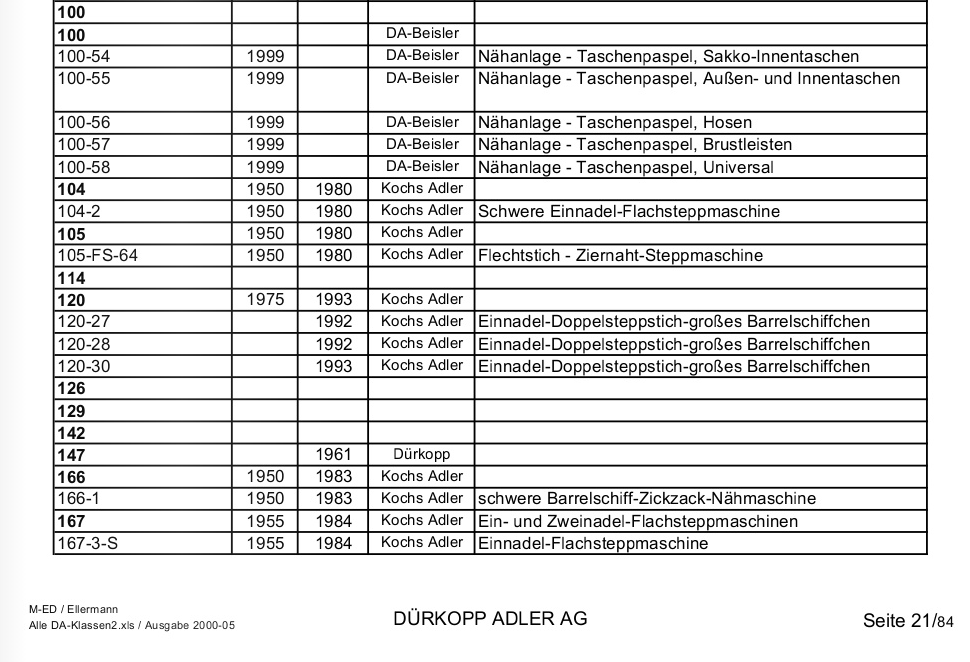

Not exactly pre-war, but old nonetheless. According to this DA historical production document from the year 2000, the 105 class of machines was produced from 1950 through 1980. The 205 series started life in 1979 (and was discontinued in 2014/15). The company changed legal entities from "Kochs Adlernähmaschinen Werke AG" to "Kochs Adler AG" in 1971. I suspect (but haven't seen real proof) that the year 1971 also coincides with the change in logo and script from "ADLER" with eagle logo to plain "adler". So "ADLER" and eagle-logo would indicate pre-1971.

- 11 replies

-

-

I have a few tape folders in my eBay store (http://r.ebay.com/qwHY3m). PM me if you don't want to use eBay. For some reason few people/vendors carry the tape folders, I'm not really sure why. Joe is the binding expert, though.

-

I know little about the TuffSew brand and they may actually be of poor quality. At the same time I'm suspicious of a discussion forum on the Sailrite company website where somebody just happens to ask about the quality of a direct competitor brand. It's like logging into a die-hard Chevrolet forum and asking about the latest Ford truck. Nothing good will be said.

-

My Juki LU-563-3 is ready to go to market. This is the Subclass 3 version of the LU-563 machine, which offers longer stitch length and thicker thread capacity, but lacks reverse. It has an entirely new thread tension system front to back, and I installed a brand new hook that is the "extra heavy thread" version. In real life, this probably means you can sew size 207 thread. Alas, not a single spool of 207 thread was to be found in my stash to verify. It was not entirely happy sewing size 277 Nylon thread, but I'll keep experimenting a little to see if it will do 277 reliably. Of course it sews size 138 thread without any trouble just like the standard version. I was able to get the stitch length to max out at around 8.5mm, or 3 stitches/inch. The spec sheet for LU-563 Subclass 3 machine says this version is capable of 10mm long stitches (2.5 stitches/inch). If anybody knows how to dial that in, please contact me. My local Detroit CL ad is here: http://detroit.craigslist.org/wyn/bfd/5576277761.html I can ship the head for $150 within the continental U.S. in a custom wooden crate. I'm not shipping tables, sorry. I made a promo/demo video for this machine:

-

The operator of the trouble machine may stop the machine more often than the others. Every time you stop the machine, there's a slight chance of a skipped stitch, depending on exactly when in the stitch cycle you stop the machine (that brief moment right after the needle starts to rise again, when the thread loop is forming but the hook has not yet caught the loop is the worst time to stop the machine in terms of potential skipped stitches). Pull up a chair and observe that operator and machine for a while - you may see a pattern that contributes to the problem. If the machine's Efka motors have needle positioners that stop in the down position, perhaps that machine's programmed down position has a slightly higher chance of a skipped stitch. If they're using huge spools of top thread, the trouble machine's cone of thread may be a little more lumpy/sticky/rough/brittle than the others and occasionally tug at just the wrong time.

-

Gravitational waves. That machine is clearly a gravitational wave detector that senses when a gravitational wave, generated by a supernova in a distant galaxy, causes a distortion in times-space and deflects the thread loop away from the hook. I see a nobel prize in your future.

-

Those portable Sailrite class machines apparently have a foot lift of 3/8" and they're designed to sew up to 1/4" according to the spec sheets. So they may not be super good candidates for your intended work, but they'd be a big step up from your home machine (and if you find yourself on a boat in the middle of the atlantic with a ripped sail, they're absolutely perfect.) Even full size industrial walking foot machines will start to moan and complain with material thickness approaching 1/2".

-

To my knowledge, the only portable flatbed machines that come even close to what you're trying to do are the sailrite ultrafeed class of machines (http://www.sailrite.com/), made by various manufacturers in the $400-$800 price range. Whether or not any of them can actually sew 5/8" with good results, I'm not certain. I actually have two of these types of machines (clones, not sailrite) that I haven't even tried out yet. Perhaps I'll give them a whirl tomorrow and see what they can do. I'm not actually planning on using them, they came in a package deal along with another machine I bought for keeps. They'll be up for sale as soon as I can make sure they actually work.

-

People's definition of compound feed varies, to some it just means more than one mode of material transport. When people in the LW forums say compound feed, they generally mean triple feed, or unison feed. It means the material is moved by three methods at the same time: 1. Bottom feed dog 2. Upper presser foot 3. Needle However, every possible combination of the three methods exists in some machine. In your machine's design it looks like the needle does NOT help move the material - it just goes down and up to make the stitch while the material is stationary. Then the material is moved while the needle is up. That's not bad thing, mind you, but most people who sew leather want the triple feed mode of moving multiple layers of material. Here's a video of how I think your machine works. Of course I may be wrong, and it wouldn't be the first time, either.

- 11 replies

-

It looks a lot like the machines described in this brochure: http://www.duerkopp-adler.com/commons/download/download-text-attachments/Vintage_Leaflets_Adler/Leaflets_Adler_class_105.pdf Yours is dated earlier based on the logo and typeface - I'm guessing 30's or 40's. Not exactly sure when they stopped using the "ADLER" and went to "adler", but I have a feeling that "adler" is a post-war change.

- 11 replies

-

A close-up of that type plate you're pointing at on the front would be very helpful. Also a close-up of the throat plate and feed dog with raised presser foot and picture of the backside to determine what type of feed mechanism this machine has. It looks like it has top feed (perhaps adjustable to create pucker/stretch for moccasin type work?), it likely also has bottom feed, but the needle plate hole indicates no needle feed.

- 11 replies

-

I took in a handful of project machines over the last few months and will be putting them up for sale as I finish working on them. First one out of the gates is a Juki LU-562 (next up are a Juki LU-563-3 and an Adler 67-GA373.) I took apart the head for a proper cleaning and to replace the thread tension release guide. It also has new presser feet, feed dog, bobbin cover plate, and assorted new screws. The paint shows some wear but mechanically the machine is in fine working condition, adjusted to factory specs with perfect reverse stitching, and ready to provide decades of reliable service in caring hands. I'm located near Detroit, Michigan. The machine head by itself is $600. I can ship the head for $150 within the continental U.S. in a custom-made wooden shipping crate. The machine is also listed on my Detroit Area Craigslist: https://detroit.craigslist.org/wyn/bfd/5573798856.html I made a sewing demo/promo video for this Juki LU-562 machine. The video also includes some glamour close-up stills at the end:

-

New Dürkopp Adler 969 And 967 H Type Machines For X Heavy Work

Uwe replied to Trox's topic in Leather Sewing Machines

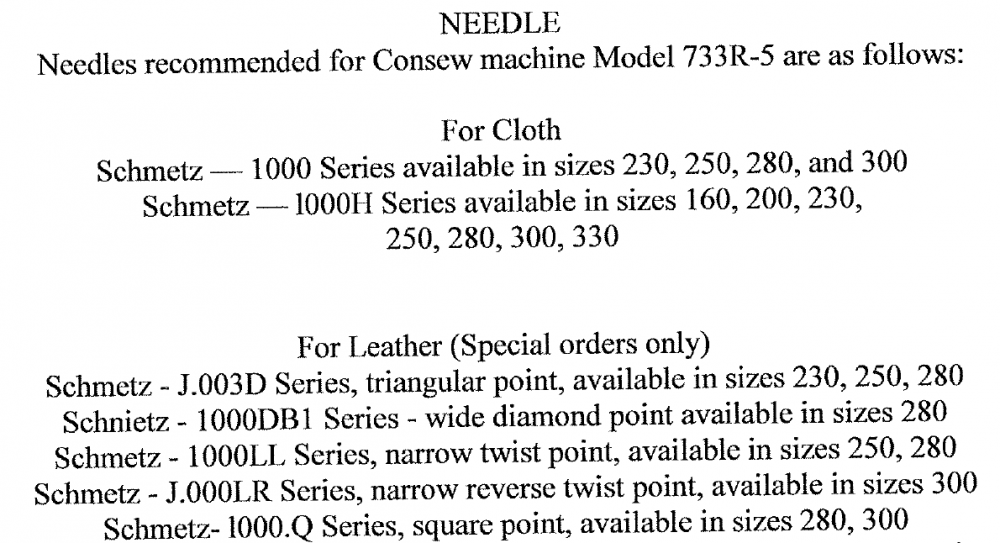

I'm only repeating what the Schmetz sales person told me at their booth earlier today. He was going by memory, and who knows what production runs they actually have nowadays. I came across one other reference for the 1000 needles in a Consew brochure for their 733 series machine. Special order may mean that you have to buy a couple thousand needles at a time to make it worth their while to fire up the production line.- 79 replies

-

- 967 h type

- 969 h type

-

(and 1 more)

Tagged with:

-

I posted the following in another thread with the same question a little while ago: The Durkopp Adler H-Type machines can use both system 794 and system 1000 Needles. The system 1000 Needles are only made by Schmetz as of right now. The 1000H versions are the fabric point needles. They have only one leather point version, the 1000Q, which has a square tip with four cutting edges for leather work. They are only available in sizes 250, 280, and 300. The 1000 series has slightly shorter shank and thus a longer shaft, to allow for maximum material thickness without the thicker shank part penetrating the material. All this is what the folks at the Durkopp Adler, Schmetz, and Groetz Beckerts stand just told me a few minutes ago. I just happen to be at the TexProcess sewing machinery trade show in Atlanta. They also said the System 794 needles are a much better choice for leatherwork because of the large number of leather point versions that are available in that needle system, from both Schmetz and Groetz Beckert.

-

New Dürkopp Adler 969 And 967 H Type Machines For X Heavy Work

Uwe replied to Trox's topic in Leather Sewing Machines

The Durkopp Adler H-Type machines can use both system 794 and system 1000 Needles. The system 1000 Needles are only made by Schmetz as of right now. The 1000H versions are the fabric point needles. They have only one leather point version, the 1000Q, which has a square tip with four cutting edges for leather work. They are only available in sizes 250, 280, and 300. The 1000 series has slightly shorter shank and thus a longer shaft, to allow for maximum material thickness without the thicker shank part penetrating the material. All this is what the folks at the Durkopp Adler, Schmetz, and Groetz Beckerts stand just told me a few minutes ago. I just happen to be at the TexProcess sewing machinery trade show in Atlanta. They also said the System 794 needles are a much better choice for leatherwork because of the large number of leather point versions that are available in that needle system, from both Schmetz and Groetz Beckert.- 79 replies

-

- 967 h type

- 969 h type

-

(and 1 more)

Tagged with: