-

Posts

2,221 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by Uwe

-

It's time to launch "Eric's Needle Emporium LLC" to support formerly gouged leathercrafters.

-

A nice, used original will cost about as much as a new clone. Five years from now that nice original will likely be worth just a little bit less if you take care of it; the new clones will drop in value considerably more over that same time period because, well, they're just used clones by then. A used clone is worth perhaps half as much as a used original, at least my book. If the used machines are in good condition and have been properly serviced by the dealer, I'd still vote for the Juki.

-

Buying from a local, reputable dealer is a BIG plus right there, shipping always comes with risk and cost. Typical is a clone manufacturer who enjoys a good reputation and has a significant presence and distribution network in Europe. The Juki LS-341 gets my vote on your list. Aside from the improved quality and resale value of an original, you also enable Juki to advance the state of the art. Otherwise the clone manufacturers won't have anything new to copy ten years from now.

-

So . . . do you have a basement full of Adler 767 machines and other goodies now? That was quite the local opportunity for you there. Auctions of that scale don't happen all that often, at least not in the Detroit area.

-

Regarding needle pricing from the manufacturer's perspective, I had an interesting exchange with a Groz Beckert representative in Atlanta. I had asked about some rare needle system, and he said something along the lines of "Yep, we're the only manufacturer of that needle system worldwide. But we don't charge more for it or gouge people. (pauses to think for moment) In fact we haven't raised needle prices in 25 years - we're crazy!" I guess the manufacturer holds or improves their bottom line by lowering cost of manufacturing, economies of scale, and automation. What happens to pricing after the product leaves the manufacturer greatly depends on the distribution network and how many layers or relay stations there are. Hypothetical price is irrelevant if there's no product to sell or buy. For example, toilet paper is super cheap in price controlled Venezuela - they just don't have any to actually sell. The store shelves are just empty. Even in a free market, if there's no money to be made on the distribution end, nobody will bother to distribute the product, which means you can't buy the product. When I consider how hard it is to actually make a good needle (try making one yourself if you don't believe it's hard to do), I'm thinking $0.30 per needle in small quantities is rather a bargain.

-

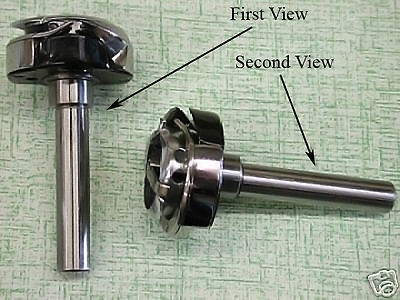

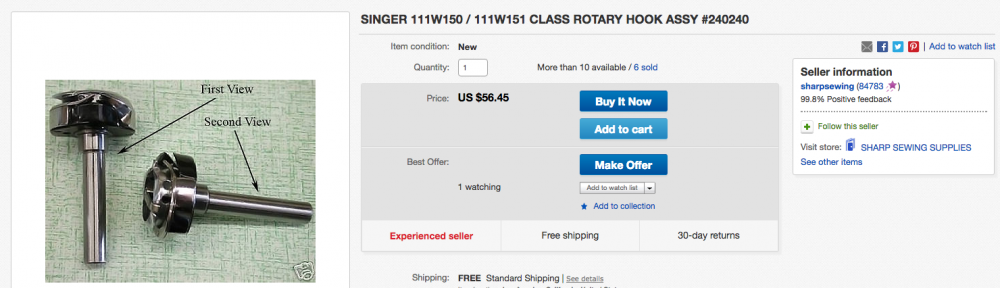

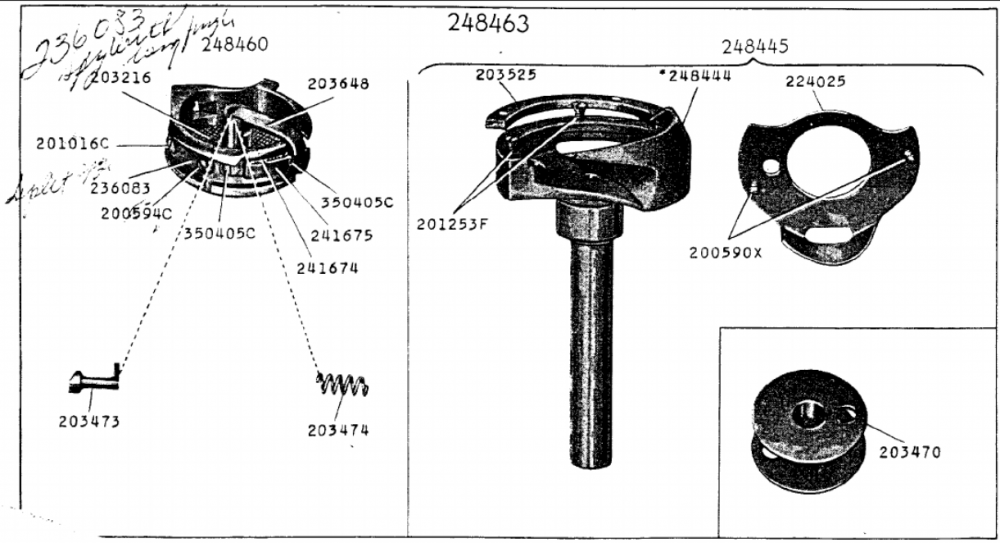

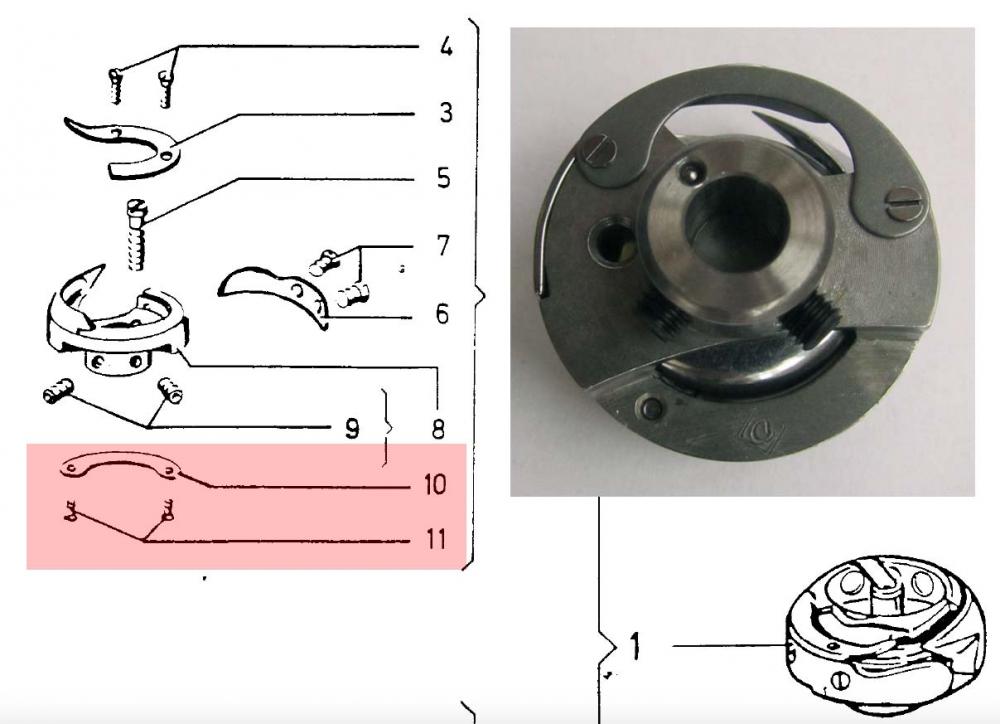

All of the sudden there's a bunch of hook candidates! The Singer 111W151 hook (part number 240240, available from Sharp Sewing on Ebay as of June 2016 for ) looks very promising, too!

-

I saw a Singer 112W140 double needle machine this afternoon that also had a hook with the improved needle guard design. Looks like a good candidate to me, but I'm not sure it would really fit or work on a Consew 225 or Singer 111W155. If anybody has these in their stash, a quick few measurements would be appreciated before I gamble money actually buying one.

-

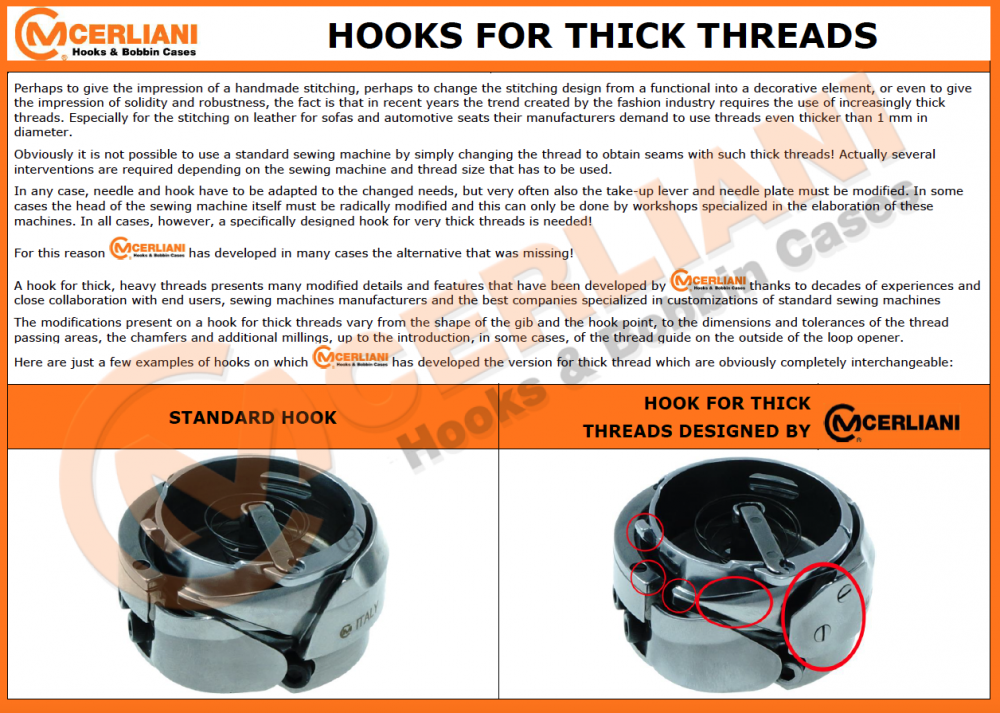

I ordered the cheap HDU-249 from Ebay yesterday just to have it on hand for a closer inspection and to explore. Constabulary, I'm curious about your specific Singer 111G156 setup with the DA hook. Did you do the change-over yourself or did it come that way? Did you have to replace the hook saddle or other parts, or is the hook+shaft a direct drop-in replacement on that machine. Any pictures of that setup would be greatly appreciated! I couldn't find your DA OEM hook on DA's sew24.com parts website. Perhaps I wasn't plugging in the right part numbers. Where do you buy your DA OEM parts? I'm also striking out on a source for the modular shaft that goes with the hook head. The Cerliani website is a treasure trove of hook related information! Hooks like that Hirose hook (HSH1215MM5) you found with the extra deflector are also made by Cerliani. They call it the heavy thread version of that hook.

-

Eric, the shaft diameter of the hook in the Consew measures 9.5mm, the cam measures 12.5mm in diameter. I appreciate the offer of the genuine Singer hook - but hold on to yours for a little while longer. I just picked up a Singer 111W155 in St. Louis last weekend - my first ever genuine boat anchor with a bent main shaft, I think! On the plus side, it has an original Singer hook in it that I'll investigate. That Singer 111W155 boat anchor was fortunately accompanied by a gem of a Pfaff 545C H4N10. It all balances out, I guess. Constabulary, using a Dürkopp 239/241 style hook in a Singer 111 class machine sounds like a very promising path for a "proper" fix and a nice upgrade - I'll have to look into that! Do you have a part number that goes with that Dürkopp hook (and shaft)? HDU249 seems to be the compatible Hirose part number.

-

Surely Ron at Techsew in Montreal ( LW member TechSew Ron) can conjure up some leather needles for the machines he sells.

-

I had also considered putting on a full circular ring on the underside of the hook instead of just a cantilevered tab, but I was worried about covering up the threaded holes, haha! There are spacer shims available (intended for machinists) that would be a perfect match size-wise, available in various thicknesses from several millimeters to 1/10th of a millimeter:

-

Great find! I think you may be onto something here. The Singer 212 hook design has a special hook thread guide "bridge" that get screwed into place. My hook actually has threaded holes on the bottom as you noticed - I didn't know what they were for. It would be NICE if the Singer 212 hook thread guide bridge would fit my hook (it's actually a Hirose HSH-11-55, not a Koban, as I stated earlier). Clearance may be an issue tough - it's super tight. But a screwed-in-place bridge would certainly be more confidence inducing than a glued, cantilevered tab.

-

I appreciate your feedback and honesty Eric. Time will tell if the fix lasts and you may very well be right about it not lasting. But it's not quite same as painted-over bondo on a car to hide evidence of an accident. I'm always upfront with what I do or did to a machine. I'm on good terms with the buyer and we both investigated the problem together. We were delighted when we finally could reproduce the problem to know how it happened, and agreed that it was basically a design flaw. I think he'll appreciate the fix (I even sent him a link to the video) but if the fix doesn't last, I'll install a new hook for him. Alas, with an unmodified hook, we're back to getting thread caught under the hook, which is super annoying. Is this simply an unavoidable design flaw of this class of machines and hooks? The more modern hook designs all seem to have some design element in the hook to minimize or prevent this failure mode. Are there any hooks out there that fit the Singer 111W155 class of machines and don't have this flaw? I bought the Koban hook because I thought they're one of the better brands for hooks. I'd prefer to just install a new hook that doesn't get thread caught on the underside by design, rather than operator skill or luck.

-

So I spent a few hours checking on things that folks had suggested (thanks to all!). Alas, I really could not find any adjustment that was out of spec or one that I could tweak to reliably resolve the problem. The springy-ness of the bonded polyester may exacerbate the problem. Nylon and Cotton may not want to"spring" downward as readily as this polyester thread does. Alas, when sewing for outdoor applications, Polyester is among the few durable choices. I started considering the hook design itself and comparing it other hooks I had on hand. I recently got a Pfaff 545 which has a notably different hook design, that I think makes a big difference for this particular problem. I decided to make a slight modification to the Consew's Kobani hook and add a very thin stainless steel plate that keeps the thread from "falling down" if it goes slack for some reason. Other hook designs have this type of plate and it seemed like a good thing to try. My fix is reversible with simple nail polish remover and in a worst case scenario the hook itself is cheap at around $30 in case we need to go back to square one. I had actually sold the machine a few weeks ago and the new owner, being a novice, ran into trouble quite frequently with this particular issue, causing frustration with an otherwise perfectly good machine. I think the fix is a good one for my particular situation. I'm not suggesting that anybody else should do this. Below is the updated video with footage added at the end to show the fix I decided on. Sorry about the occasional muffled voice. I know I need to step up my microphone game if I am going to be doing more talkies.

-

I Need To Tell You How Much I Hate The Consew Servo Motor...

Uwe replied to JimC's topic in Leather Sewing Machines

I just a got a new modular $200 servo motor from SewPro which is 1100W strong and starts at a low 100 RPM. I have high hopes for it, but haven't installed it yet for testing. I'll report back this coming week after some testing. -

I've had occasional trouble on my Consew 225 with the thread getting caught under the hook. Today I figured how it happens and I can make it happen. What I haven't figured out yet is how to fix it. The machine sews perfectly on a normal run and timing is generally spot-on. But if I happen to stop the machine at the exact wrong moment and touch the hand wheel, it may cause the thread to get caught under the hook. Patient:"Doctor, if I do this it hurts" Doctor: "Don't do that" The "wrong" moment is exactly when the needle exits the material. This may happen occasionally and if turn the handwheel back just a tiny bit to bury the needle again for a turn, trouble ensues. I'm wondering if the design of the new hook is contributing to the problem. The problem happened quite often with the old, original hook, which is why I installed a new hook. Alas, the new hook doesn't prevent the problem entirely. I had messaged with Eric about his problem (before I figured out how to repeat it). The issue may be of general interest, so I'm throwing it up here to crowd source a potential solution and share the fix. Here's the video of the problem:

-

So, does anybody have or know where to find a manual that goes beyond page 8? I'd love to have the whole thing.

-

As for reduced stitch length, sometimes the culprit is actually feed dog timing. If the feed dog doesn't start to come up until after it starts moving backwards or if it goes down before it reaches the very back of its movement, you miss out on part of the full movement it's capable of. The vertical feed dog movement timing should be simple to check and adjust, but I haven't done it yet myself on the 42-5, so I can't offer specifics or pictures right now.

-

My 42-5 has no feed movement when the stitch length lever is at the top. In the bottom position, my feed dog carrier moves about 0.24" front to back, so I should get about 4 stitches per inch (once I order some system 16x63 needles, which are readily available on Ebay and elsewhere.) I'm attaching the manual I had downloaded well before I ever got my 42-5. I saved the file in a folder I had named "Singer 42-5 best Singer flatbed ever?", based on a comment from one of our Australian members. When it finally popped up on CraigsList, I drove three hours one way to pick it up - gotta do these crazy things before I get too old to do them! (I also admit to checking CL before major road trips and picked up a lovely Pfaff 545C H4-N10 in St. Louis last weekend, but that's a different topic) 42_CLASS.pdf

-

Is that piece of leather in your picture only 2-1/4 inches top to bottom? A ruler next to the stitch line would help establish scale. I have a Singer 42-5 that's patiently awaiting its turn for some tender loving care. Parts are hit and miss. Needle bar and presser spring were readily available and cheap, but it took weeks just to get my hands on some bobbins at $12 per bobbin - ouch! I have yet to find a source for throat plates (or throat plate inserts).

-

It seems I've hijacked my own topic! The relative merits of certain sewing machine hacks probably deserves its own topic. I'll check with MJ Foley on actual real-world end-user pricing of the Juki LS-2342 models. The $7-8K ballpark figure is what the Juki guy at the trade show stated for the base model, somewhat hesitantly.

-

I'd recommend holding out for a machine that actually works. If the original owner could not make it work again, chances are slim that you as a novice can. Shipping to Tippman and back again, plus hard-to-guess repair costs makes this machine almost a non-starter regardless of price.

-

The short answer would be "No" I'm afraid. One might be able to modify a standard machine to come close, but I've not seen a commercial machine with the specs you listed. I recently stumbled upon a video by upholstery virtuoso and machine whisperer "Cechaflo" on youtube where he shows how to modify a garment-class vintage flatbed machine to be able to handle thicker needles and thread. The modifications may be similar to make a slim cylinder bed machine deal with thicker thread. I've not attempted any of this, so I can't say how well it might work. You'll be changing tiny bobbins holding just few windings of thick thread all the time, no matter what.

-

One of the most impressive new machines I saw at the trade show in Atlanta last month was the new Juki LS-2342. It's hard to find information online about this machine (even on Juki's website), so I decided to scan in my little sales flyer and share it here. The machine fits size-wise and capability-wise between the LS-1341 and the TSC-441, and may be of interest to leatherworkers with deep pockets - the price is likely around $8K. Here's the brochure for your spec reading entertainment: http://docs.uwe.net/Juki-LS-2342.pdf Juki-LS-2342.pdf

-

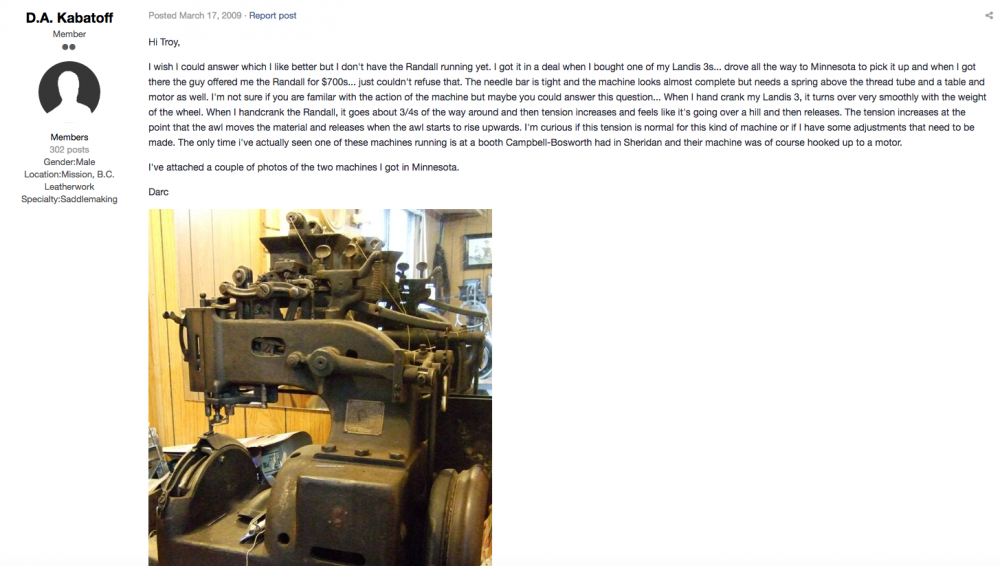

In 2009, a LW member determined a Randall for $700 was a good deal: Here's the part about the Randall, picture looks just like yours.