-

Posts

2,221 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Uwe

-

Sewing machine manufacturers happily mix fractional, metric, and specialty threads on the same machine. There are also a few places where the metric and fractional systems line up confusingly close. In my threading adventures I've noticed that, depending on tolerances and material, an M5-0.8 is interchangeable with a #10-32 bolt/nut. The #10 bolt diameter is just under 5mm, as are my M5 bolts; and fractional 32/inch thread pitch is 25.4mm/32=.7935mm. A #10-32 bolt often fits nicely into M5-0.8 nut, but a M5-0.8 bolt does not necessarily fit onto a #10-32 threaded hole. I found this out some time ago taking my (assumed made-in-germany metric) mystery bolt to the hardware store to get more, test fitting it nicely into the M5 thread on the test board - yay! So I happily buy a bunch of M5 bolts and when I got home it wouldn't fit into the threaded hole the mystery bolt came from - ugh. Your shouldn't-really-exist M5-1.0 thread looks suspiciously close to a #10-24 on the spec sheet (just under 5mm diameter and 24/inch fractional thread pitch is 25.4mm/24=1.05mm) A short nut with five or so threads is more forgiving than a deeply threaded hole in a machine.

-

Opinions: Smooth Needle Plate,feed Dog Walking Feet

Uwe replied to llucas's topic in Leather Sewing Machines

The promotional brochure for the Durkopp Adler 205 series shows the original smooth parts on page six, in case you want to look up and price some OEM part numbers. -

Opinions: Smooth Needle Plate,feed Dog Walking Feet

Uwe replied to llucas's topic in Leather Sewing Machines

For needle plates this HighTex Throat/Needle Plate page pretty much shows the available options for a Durkopp Adler 205-370 class machine. Hightex is the same as CowBoy, so vendors like Toledo Bob or other banner vendors should be able to get them for you. Some throat plates with the thin slot turn the machine into a needle feed machine (feed dog is removed), which may be just fine for what you're trying to do. For presser feet, a lot of folks on here simply take an existing toothed foot and grind/file off the teeth and then polish it up good to make it as smooth as a baby's bottom. -

I've not seen a parts manuals for the old casting Pfaff 335's. However, the head portion should be mostly identical to the Pfaff 545 for which there are parts manuals available , but they use multiple foot pressure schemes. If you can see the bolt part, you can always go old school and simply measure the diameter with a caliper and count out threads/distance to figure out pitch and find a suitable match. Most tap/die sets also have little thread pitch gauges that are useful to determine pitch. If that fails, a photo with an arrow will go a long way towards mobilizing the resident detectives.

-

It's only a matter of time before I'll own one of these machines. Looks like a nice setup with LOTS of parts. Let me know if you're selling this because you desperately need to get your hands on a Puritan stitcher :-)

-

Perhaps this chart helps: Specifications of historical Thread Standards for sewing machines. I found the chart referenced on an external discussion forum for the practical machinist. A part number is always useful when trying to figure out particulars - can you find the screw you're talking about in a parts diagram for the Pfaff 335? I've used AAASEW.com in the past to research and occasionally order oddball parts and screws. They have a "screws page" that I've used to find things by part number using my browser's find function. Some screws have sizes listed and the 9/64-40 and 11/64-40 sizes seem to pop up more than others.

-

Pfaff 335 Manual For Older Version Needed

Uwe replied to CaroCaro's topic in Leather Sewing Machines

It's quite possible that your binder is set up perfectly fine and it's your tape that's not the right size for the folder. It needs to be pretty much EXACTLY 26mm wide for this folder. You cannot use a 26mm folder with 20mm tape, for example. They make folders in very small increments to fit a specific tape size: It looks like a huge folder attachment - are you sure it's intended for a Pfaff 335? If the tape size is right and the folder is right, perhaps it is supposed to be further to the left, lining up with the inside edge of the outer presser foot and stay in front of the feed dog: Maybe Joe from HockeyMender can chime in - he's the resident expert of Pfaff 335 binding operations. I'm just making slightly educated guesses. -

Pfaff 335 Manual For Older Version Needed

Uwe replied to CaroCaro's topic in Leather Sewing Machines

You should be able to move the binder attachment to the left to adjust the relative stitch line position. Consider the needle position fixed. You need to move the other stuff. The folder part usually has slots to allow left/right movement of the folded tape. Do you have a close-up picture of your setup? -

One of my original plans was to glue some white melamine (formica) sheet to marine plywood before carving it. Turns out finding just the melamine (not a ready-made particleboard countertop) turns out to be even harder than finding phenolic plywood. Oddly enough, there's a Toledo Plywood specialty store practically next door to the Kencraft store and it had a big stack of white melamine sheets. But in the end the phenolic plywood was the better choice for me because it involves considerably less labor (less glueing, clamping, waiting) and the phenolic is a better, ready-made surface in my mind.

-

I don't know exactly what kind of harness feet you are using now so it's hard to judge. A close-up picture of your harness feet would be useful. In general, all the harness feet I've used had tiny footprints (compared to standard feet) which is much more likely to leave impressions on leather (just like high heels on a wood floor.) It's mostly about pounds per square inch, and a tiny footprint is definitely is not your friend if your goal is not to leave an impression. My harness feet had about one-tenth the footprint of regular presser foot and therefore about ten times the pressure per square inch compared to a regular presser foot. Unless you're actually making a horse harness from tough bridle leather or really need to get super close to a buckle or sew along a sliver of an edge, a bigger/wider presser foot combined with a smooth throat plate and feed dog might be a better choice. But you won't know for sure until you try it out. The KH-205M throat plate and feed dog are the smoothest setup I've seen for the Adler 205-370 by a good margin. My standard throat plate has fairly strong serrations and fairly sharp edges (and a few battle scars from the previous owner.) The KH-205M throat plate and feed dog setup is not exactly cheap, but it's really well made and you can return it if it doesn't offer a significantly improvement over your current setup. The KP205LN/RN (or even the standard double-toe) presser feet have big and smooth feet bottoms (compared to harness feet) which again is good for minimizing pressure per square inch and potential markings.

-

The wood supply store in Toledo where I got the phenolic plywood is called Kencraft Company . They ship wood boards in various sizes as well. The helping opportunities pretty much boil down to granting access to the machine for measuring and a couple prototype fittings. The rest happens with me brooding over a computer in CAD programs and beating the various CNC machines into submission to give me what I want. The pictures should tell much of the story regarding engineering concepts and which of several possible attachment options I chose. Finishing the parts and assembly happens in my home workshop. I've considered making kits available with just the parts as they come out of the CNC machines for folks to finish and assemble it themselves, but I'd likely spend more time answering questions and walking folks through the details remotely than doing it myself. Perhaps I'll create a little "making of" video some time to show the steps involved in making these table attachments. The apparent simplicity of the final product may be deceiving. It all seems very obvious and simple when you see the finished product, but the process of getting there often is anything but obvious or simple.

-

The 441 version of the flatbed table attachment is next (and probably last) on my list of table attachment projects. I'll do it in January/February - if I get access to an actual 441 class machine, that is. Anybody in the Detroit area have a Juki 441 or clone for me to take some measurements on and do a couple fit & function tests? (you get to keep one of the prototypes!)

-

Owner & Service Manual For Durkopp Adler 204/205-370

Uwe replied to Uwe's topic in Leather Sewing Machines

Congratulations on your new arrival - you got yourself a great machine for a bargain price! The bobbin spin direction is like this (from manual): Here's a quick little video on how to release the bobbin in a Durkopp Adler 204/205 sewing machine: I'll be working on a series of videos for this machine over the next week or so. A nice threading diagram is in the manual:- 14 replies

-

- manuals

- durkopp adler

-

(and 2 more)

Tagged with:

-

No smell at all from the phenolic resin. It's all cured by the time I get my hands on it and carving it is fine, too. The material is hard to find, actually. Normally it's used to make router tables, jigs, and table saw tops, where you need something very hard and slippery to withstand material being dragged across it all day. I discovered it by chance at my local WoodCraft shop, where it's rather expensive. For my actual production work stock, I ended up driving an hour one way to Toledo where a specialty wood supply store carries this stuff at a more reasonable price and in the sizes I need, albeit in only one color.

-

I just had to try it, I'm like a little boy who can't resist a dare! I carefully turned the wheel by hand and my Consew 225 (twin to a Singer 111) actually sewed 1/8" (3mm) plywood wrapped in 5oz (2mm) oil tan leather without skipping stitch. Who'da thunk? This was sewn with a size 207 bonded polyester using a size 140/22 regular point needle:

-

After searching for "sewing plywood" on youtube, there's a guy sewing plywood on his Pfaff 545, which is essentially identical to the Singer 111. So, depending on how precious your Singer 111 is to you, go for it!

-

I highly doubt a Singer 111 will sew through 4mm of plywood. If it does, not for long. Consider sewing the panel leather material to a softer support material (thin gatorfoam or cardboard etc.) and then glueing the whole affair to the plywood, wrapping the edges. It'l still look it's been sewn right through and be just as durable and rigid in my mind. The only machines I know of that are designed to sew through plywood and similar materials for suitcase, prosthetics and similar applications, are certain Needle & Awl machines. My Puritan advertises being able to sew through plywood and aluminum sheets, and the promo video of the Campbell Lockstitch machines sews right through a copper penny at the one-minute mark. Of course some of these machines may cost more than an old MG car. If you have access to a laser cutter, consider cutting the plywood door panel shape including the stitch holes along the edges right on the laser cutter. I've made templates for hand stitching that way. Then you can just hand sew the leather to the plywood using the pre-cut stitch holes.

-

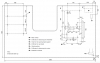

I've come across some dimensioned CAD drawings in various manuals. The attached example of a table with a U-shaped cutout is from a Pfaff 335 manual (the view is of the underside of the table). Interestingly it has no dimensions for the actual cutout (approx. 11" wide and 12" deep) or how far the machine sits from the edge of the cutout. There are no hard rules for the overall shape or size and the actual mounting hole pattern will vary by machine, as TinkerTaylor said (thanks for the shout-out :-) This is as good a starting point as any for making your own table. I had downloaded a manual for an Adler 669 machine simply because it had nice drawings of the table options: I personally really like this convertible option where the left side folds down and out of the way when not in use:

-

I'm finalizing details on my all-new and actually affordable design for a flatbed table attachment for Durkopp Adler 205-370 sewing machines and their copies. Version 1.0 was machined from a big chunk of solid aluminum and cost a small fortune to make. It'll also take off a toe if you drop it on your foot. This version 2.0 uses more affordable, yet extremely durable materials and I'll make a few extras for sale. I discovered phenolic plywood a few weeks ago and love it (say "Phenomenal Phenolic Plywood" ten times really fast, haha!) Anyways, phenolic plywood and stainless steel metal hardware make a great combination for functionality, durability, and good looks - in my mind at least. I'll post proper glamour shots and add it to my ebay store over the weekend. Here are a few preview shots for now:

-

Sorry, I don't know where to get just a shuttle, but I stumbled across this complete Landis 1 machine in Ohio recently on Ebay for $399 with no bids yet: http://r.ebay.com/7RxqOH I'm not an expert in Landis machines, but I have a feeling the shuttle by itself from a dealer will cost about as much as this entire machine. Love the table and pedal setup on this one and you're gonna need a parts machine anyways. I was at Toledo Industrial Sewing Machine earlier this week and I they had one of these in their used showroom, so they may have parts.

-

Here's a DXF export I did earlier today. It'll take some tweaking but it's a good starting point. Let's hope this works: http://uwe.net/CAD/Consew225_v2.dxf

- 181 replies

-

- diy sewing table

- industrial sewing table

-

(and 3 more)

Tagged with:

-

That Singer model number and factory history shure looks messy, after reading up on it a little. According to the Sir Sewalot web page, the W after the model number (as opposed to after the serial number) would indicate the factory in Wittenberge, Germany. Either way, it should be the same machine, just from a different factory. With compound feed and generally nice specs, this machine should work well for sewing leather. I'd check it out in person and sew with it to make sure it works as well as it looks before committing to buy. Sometimes tired old machines with worn-off paint just get a quick paint job to squeeze a few extra bucks out of them. I'm not really sure what the parts supply picture looks like for this model or if it shares components with other, more common machines. If it just looks pretty but doesn't work right, you may have a hard time finding replacement parts. If it looks pretty AND it works well, you should be good for a long time unless you abuse it.

- 14 replies

-

- sewing machine

- sewing

-

(and 2 more)

Tagged with: