Sonydaze

Members-

Posts

310 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Sonydaze

-

The way your picture looks, to correct the bottom base for the die would move it further out of alignment. It may well be that the holes in the casting were not properly aligned.... difficult to fix. I really doubt that a different set of dies will make any difference. Don't keep a press that is a problem to use. The object of buying a press is to make setting various hardware fast, easy and consistent. I hope they have not been asking you to pay return shipping. For manual presses, I prefer kick presses like this http://www.atlaslevy.com/Foot-PressKick-Press--Snap-Rivet-machine_p_4506.html If set up properly, they will perfectly set snaps, rivets or whatever consistantly for thousands of times. This is why they are very commonly used in Asian factories. Used ones can often be found. There are also double ones that can be setup with the dies for both parts of snaps.

-

The two dies should be close to lining up to each other. In your picture, the bottom die appears to be tilted. The part it fits into is painted continuously on the left but has a gap on the right. I would want another press that they have actually set up and tested.

-

Since it is a new thread, that could be the problem. As far as the machine, I would try in a new needle (suggested size 14 or 16 for #46 thread). I would also turn the inside presser foot so it is not so close to the needle.

-

I would check the end of the needle to make sure it is not burred as well as the hole through the lower feed dog. A deflection can burr both. The timing being out a bit or too large of a gap between the needle and the hook could also cause this. I can't see the end of the needle, but a round point vs. a leather needle will sew better on webbing.

-

I don't know the insert dimensions for a United Carr M369 press but getting adapters made so you can use more common sized dies is an option to consider. I have a mishmash of different dies and several different presses. I turned steel adapters to make them work together.

-

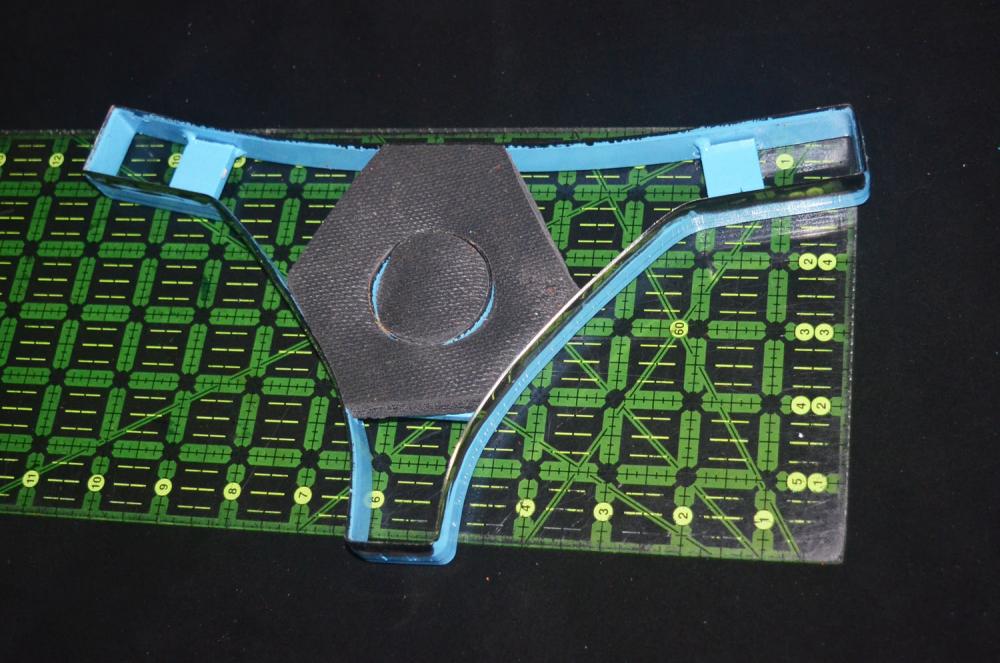

Here is a die I recently had made by Economy Die Makers. This one is made with 3/4" cutting rule and cost C$94.00 (approx US$72.00) It has done about 200 clicks so far and works great.

-

Gunnarson, I hear you. I choked on the price of the Tormek system for a long time, but it has proven to be worthwhile. As it greatly shortened the time I spend sharpening as well as sharp tools are more efficient than working with sorta sharp ones. Sharpening for me was frustrating, some days I was the sharpening master, other days I felt like I could make a dull edge worse, with Tormek's jigs it is relatively easy to get a consistent good edge. Btw I have no affiliation with Tormek other than owning one.

-

I didn't have much success with sharpening scissors until I got my Tormek. It does a decent job.

-

Tandy snaps are poor quality which is a good part of the problem. Both Weaver Leather and Ohio Travelbag have decent snaps (as well as many other suppliers). I think Ohio Travelbag offers more than one length of posts on their snaps. Using a press with dies will consistently give you better results, especially if the leather is a bit thick for the post height. If you are setting snaps frequently, a press is a good investment to consider. If you are using hand tools, I agree with the previous posts about hitting with several taps are the way to get better results.

-

SOLD to a good home.

-

Your needle might be too small for the thread you are using. Try a larger needle and see if the the fraying goes away.

-

Tell me about your "Hot Box"

Sonydaze replied to Dwight's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Several years ago I built a drying box for drying freshly painted wood handles in the winter time. It is a plywood box about 18" x 24" x 24" high with a drop on lid. Low in the back, I cut a hole to slide a ceramic cube heater half way through the plywood and duct taped it in place. At the top, I drilled four 1 1/2" holes to allow good circulation. The ceramic heater is thermostatically controlled so I have excellent heat control. This is pretty simple to make, not expensive and should work great for drying leather. -

Cutting sole bend on a band saw works well, so I think a hand jig saw would work. Although it will likely take awhile. Sand the edges to clean them up.

-

Skiving Machine Ripping Leather, please help !

Sonydaze replied to SonderingSusan's topic in How Do I Do That?

Mine would very likely be polished with use by now, but polishing the feet did help with feeding when I was going though my teething problems with figuring out how to sharpen/adjust the skiver. The Chinese makers will never be accused of over finessing their products. Regarding the other feet, I use the straight presser foot frequently. We use the drum skiver a lot to skive/bevel the buckle fold over area on straps. After skiving the strap ends we change to the straight presser foot to bevel the end of the straps. Setup is a bit concise but you can bevel the ends as fast as you can feed them. It is faster and does a cleaner bevel than a knife type skiver (as well as re-sharpening is easy peasy)- 30 replies

-

- skiving mavine

- rip

-

(and 1 more)

Tagged with:

-

I bought my Consew skiver from Atlas Levy years ago. They are good with parts. so I would think that they could help you. http://www.atlaslevy.com/

-

Skiving Machine Ripping Leather, please help !

Sonydaze replied to SonderingSusan's topic in How Do I Do That?

You shouldn't need to push the grinding wheel over with your hand. See my picture...the leaver on the far right goes to the lower position to drive the grind stone. The knurled knob, that I put the arrow over, turns counterclockwise to engage the grindstone to the drum. Turn it slowly until you get sparks, I like to lightly engage it. When finished sharpening, turn the knob clockwise so it doesn't quite touch the drum and move the lever back to the top position. One other thing that I found helpful is I polished the contact areas of my presser feet to a mirror finish, the topside of the leather slides under them easier.- 30 replies

-

- skiving mavine

- rip

-

(and 1 more)

Tagged with:

-

We hot emboss our logo into most everything we make as do some embossing to personalize items. Most of what we use is various chrome tan leather. I think getting consistent results from a handheld stamp would be a challenge, especially if you can't control the temperature of the stamp. I agree with the previous posts... a clean impression comes from a combination of temperature, pressure and duration. We get our magnesium dies made 1/4" deep (by Sterling Marking Products https://www.sterling.ca/graphics.cfm). The deeper dies tend to give a cleaner imprint. Also as a suggestion, emboss as soon as practical in the process of making something. If you get a bad imprint you will have less labour invested in the piece. It is also a good idea to do a few test impressions on scraps before doing the real thing.

-

Thanks for the chuckle!

-

Zlatko (the owner of Economy Dies) is an old school, European die maker. He prefers that you make templates and snail mail them to him....back comes great dies. heh heh... I would think most people that know the difference between an .ai file or a .dxf can handle minor currency exchange?

-

I use Economy Die Makers. http://www.economydiemakers.com/

-

Skiving Machine Ripping Leather, please help !

Sonydaze replied to SonderingSusan's topic in How Do I Do That?

If this fixes it, don't feel bad, I think almost everyone with a drum skiver has learned this the hard way. I have yet to see a machine with a good instruction manual.- 30 replies

-

- skiving mavine

- rip

-

(and 1 more)

Tagged with:

-

Skiving Machine Ripping Leather, please help !

Sonydaze replied to SonderingSusan's topic in How Do I Do That?

I'm presuming that you have a drum skiver. The cutting edge of the drum needs to be advanced to very close to the presser foot and then sharpened. If you have not advanced/sharpened the cutting drum frequently, you likely have to do a long grind to get the bevel on the drum back to how it should be. Properly adjusted and very sharp, we can skive the edges of upholstery leather. It doesn't work perfectly all the time, but we get the job done.- 30 replies

-

- skiving mavine

- rip

-

(and 1 more)

Tagged with:

-

The brush is probably stuck in the hardened glue in the bottom. You can try solvents if you can get them inside? Putting a bit of Vaseline on threads and edges where lids meet is a good thing.

-

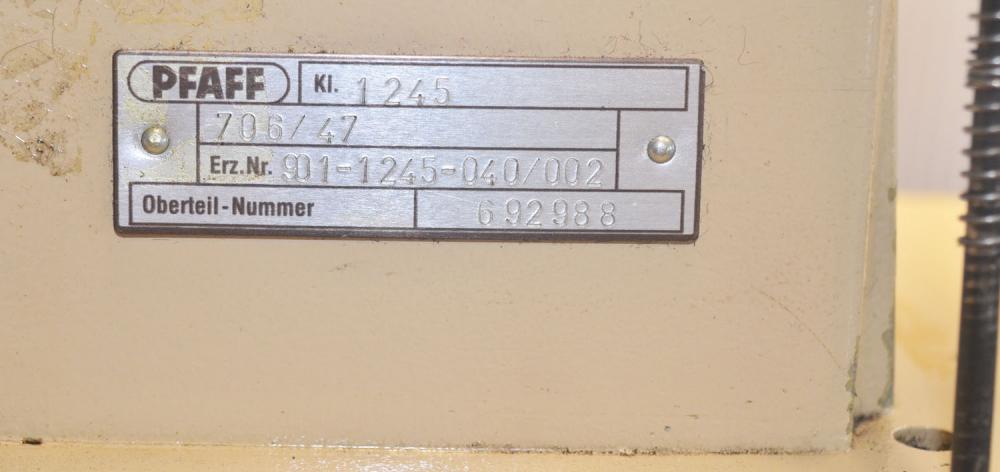

Pfaff Model 1245 (head only). This is a unison feed machine, great for leather and canvas etc up to 3/8" thick. It appears to be in good condition other than the top thread guides. Price US$375 Shipping extra. I will pack the head in a crate. Payment by PayPal.

-

We use 60mm rotary cutters for probably 90% of our leather cutting. Great for straight lines and okay for mild curves. For square corners we roll close then finish the corner with an utility knife.