-

Posts

4,828 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by dikman

-

I reckon a book like that would have some members on here positively salivating.......

-

Need Needles for my Singer 144WSV37

dikman replied to DelNeroDesigns's topic in Leather Sewing Machines

If all your information suggests a particular needle size, but it doesn't fit, my first thought would be that someone has reset the needle bar to take a different size needle. Can you reset the bar for the needles you bought? -

Burnishing Problem Solved - Motorized on the Cheap

dikman replied to cjartist's topic in Leather Machinery

Only negative I can see is that access may be an issue, as most motorised burnishers usually have the wheel hanging over the edge of a table which gives better access for long pieces (belts).- 21 replies

-

- burnisher

- burnishing

-

(and 1 more)

Tagged with:

-

Which servo motor should I buy in Australia?

dikman replied to Carrie88's topic in Leather Sewing Machines

No worries, Brian, only too happy to help. Don't forget you sent me those thread samples, at no charge, when I was first trying to understand thread sizes, types and what would work in my machines. -

I can't comment on the other machines (model numbers would be nice) other than to say Seiko and Adler make some nice machines. I see this one has the binding attachment, if he's going to supply the plain walking feet you want to see it set up first to make sure it has the correct needle plate and replacement cover where that binding plate fits. Also, it looks like it has a clutch motor, you really need to factor in a servo motor if you can as it will be much easier to learn to use.

-

Which servo motor should I buy in Australia?

dikman replied to Carrie88's topic in Leather Sewing Machines

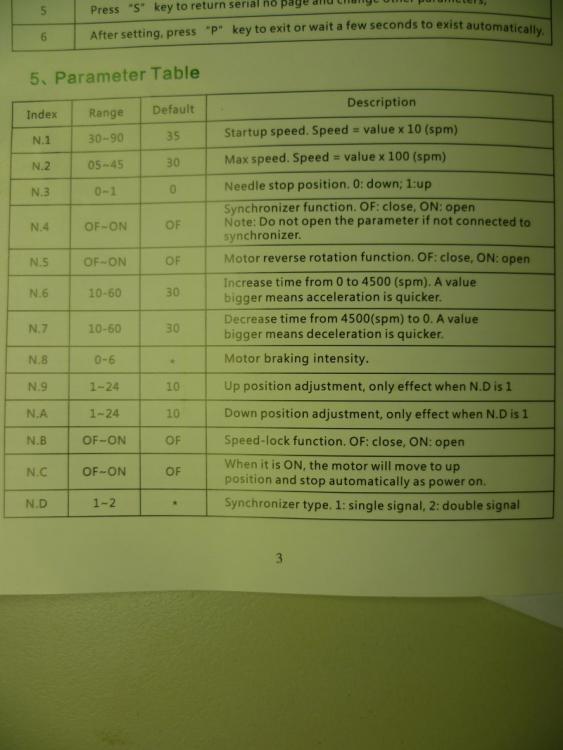

I see what you mean! Doesn't say much for the seller, imo, makes me think he doesn't understand it either. Ok, to get into the adjustment setting, press and hold the P key and turn on the power. It should display SH, which is the first parameter and sets max. speed.(Release the P key when it does). Press P again, which should let you change the settings. Pressing N will increase the value, S will decrease it. Should go up to 5500 rpm, if the seller is right then it's currently set for 1500 rpm.When you've got the right setting press P again, which exits this parameter. I think this means it will then display SH (which is the current parameter). Pressing S should change to the next parameter, SL, lower limit of minimum speed. (Pressing S goes forward, N goes back when searching the parameters). If you press P it will enter this parameter and display the current setting. If you don't want to change it press P to exit it. Once you've changed all that you want to, turn off the power, then turn it back on and you will be back to normal operating with the new settings. I have no idea what some of those parameters are for, obviously some are for the needle positioning system, but as for the others.... I also found a handbook for this motor (well, the controls are the same at least), don't know if you've got it? Anyhow, look at page 10, those three buttons can be used to change settings without getting into the "technician mode". Top one lets you fiddle with the needle position setting, but if you hold it in for at least 3 seconds it will reverse the motor direction!!! The middle button, Speed Mode switch key, lets you change between two speed modes, low speed and non-low speed (that's what it says). I'm guessing that these setting might be governed by the Kp/Ki parameters, but that's only a guess. It will also let you engage soft start mode.Third one is a Speed Setting key, it looks like you can use it to set the speed between min and max (presumably the settings entered via the "technician mode". If I had it with me I might be able to figure out some of those parameters - maybe! Anyhow, hope this helps a bit? Carrie, apologies for digressing slightly in your thread. Link to handbook, wouldn't let me download it. https://www.scribd.com/doc/270478518/Heavy-Duty-Sewing-Machine-Servo-Motor -

Which servo motor should I buy in Australia?

dikman replied to Carrie88's topic in Leather Sewing Machines

Carrie, from what I could find out they're much of a muchness. The housing will change (some are all-in-one, some have separate controls and different control panels) but that's about it. I suppose there may be some quality differences, but how one can tell I don't know. I'm interested in this facebook page too (just out of curiosity). -

Which servo motor should I buy in Australia?

dikman replied to Carrie88's topic in Leather Sewing Machines

Brian, I'll put this in here because it relates to the servo I've mentioned. Mine is a two-button control. The first 5 parameters can be accessed, the rest only change when the needle position synchronizer is fitted and turned on (there are others on the next page but they can't be accessed). The first two are the main ones.N.1 has a range of 10-80 (100-800 spm), N.2 from 1-45 (100-4500 spm). These are the values shown on the display, which are different to those in the book!?! For the two button operation - press "-" until N.O displayed press "+" to select the parameter wanted press "-" to show the value press "+" or "-" to change value, wait for the display to return. Is that what you wanted to know? -

Which servo motor should I buy in Australia?

dikman replied to Carrie88's topic in Leather Sewing Machines

Not sure what those numbers mean, Brian. There are lots of adjustments in the "handbook", but only a couple have any effect. One sets the max. speed and the other sets how slow it goes at startup (or something like that, the book is down in my other shed and it's now dark, cold and wet so I'll have a look tomorrow). I do know that the two settings inter-react somewhat, i.e if you set a high max. speed then the startup is faster. I'll post back tomorrow. -

Doc Holiday Shoulder Holster Pattern Needed

dikman replied to Dwight's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Looks good Dwight. What a complicated bit of strapwork! -

MERNICKLE "WILD BUNCH" 1911 HOLSTER

dikman replied to AA3JW's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Red Cent, did you airbrush that rig? It's certainly very striking in appearance! AA3JW, that last rig definitely shows improvement from the first. Keep at it, you're doing well. -

Which servo motor should I buy in Australia?

dikman replied to Carrie88's topic in Leather Sewing Machines

Ho-hsing are generally considered to be a very good motor. That one doesn't include GST - another $42 - + shipping? This is where I bought mine - https://www.aliexpress.com/store/product/Energy-Saving-Brushless-Servo-Motor-TD-422-550W/1088544_1606343305.html?spm=2114.12010608.0.0.2995e5c0iwbxBR $180 for a 550 watt, for another $30 you can get a 750 watt.Free shipping. It comes with a 75mm pulley but when I bought mine they were offering a 50 mm instead, not sure if they still are. NC, a friend bought a 555 and reckons the servo was brilliant, but the machine didn't suit his needs and it was going to be too much trouble to swap the servo over and try and get it working. You've done well, just out of curiosity what was involved in getting it working on the Consew (in case I come across one at a good price )? -

Which servo motor should I buy in Australia?

dikman replied to Carrie88's topic in Leather Sewing Machines

This was posted in another section - They will be more expensive here (as is everything) because of the logistics involved for people selling them. As mentioned, changing a plug is easy (if you know what you're doing) but I'm sure you could find a friend who does know how if you're not sure. -

Burnishing Problem Solved - Motorized on the Cheap

dikman replied to cjartist's topic in Leather Machinery

Ok, that explains your comment. Sounds like a nice motor if you can get hold of one, good luck with the retirement (I can highly recommend it ).- 21 replies

-

- burnisher

- burnishing

-

(and 1 more)

Tagged with:

-

Machine for mostly canvas, some heavier stuff

dikman replied to mwpdx86's topic in Leather Sewing Machines

I've snapped more than a couple of needles through deflecting and hitting the needle plate, and a couple because the timing was out and they caught down in the bobbin/shuttle area (), haven't tripped a safety clutch yet. Looks like the 1206 can handle slightly heavier thread. One advantage of buying the 1206 is that you'll be getting a new machine, set up properly to start with. -

Machine for mostly canvas, some heavier stuff

dikman replied to mwpdx86's topic in Leather Sewing Machines

That P1206RB that Wiz mentioned looks pretty good for the money, handles up to #207 thread and even includes a servo! -

Machine for mostly canvas, some heavier stuff

dikman replied to mwpdx86's topic in Leather Sewing Machines

I reckon that a flatbed should let you do pretty well all that you want. As for overkill, it's always better to get a machine that is a bit more than what you think you'll need, within reason. -

Burnishing Problem Solved - Motorized on the Cheap

dikman replied to cjartist's topic in Leather Machinery

Actually, unless you've got something completely different on your side of the pond, every grinder that I've come across has had a left-hand thread on one side and a right-hand thread on the other. It is impossible to fit the wrong spindle on the wrong side, so whichever side you use it will always tighten up (unless you some how manage to reverse the motor direction).- 21 replies

-

- burnisher

- burnishing

-

(and 1 more)

Tagged with:

-

Glad you got it sorted. The mechanics of these machines can seem a bit daunting at first, but it's worth spending the time trying to understand the operations of the particular machine that one is using. At least these older machines, for the most part, are simpler than many of the newer ones.

-

Machine for mostly canvas, some heavier stuff

dikman replied to mwpdx86's topic in Leather Sewing Machines

If you can only have one machine then a cylinder arm walking foot would be nice (the ubiquitous Pfaff 335 or clones comes to mind), but the 206RB-5 should suit nicely, particularly if you can fit a servo motor (it will give better slow speed control and be much easier to learn on than a clutch motor). As for the oiling, if you're going to be using it slowly then learn how to manually oil the various parts. It will also help you to understand the machine better. Just curious, what is the "Singer heavy duty" that you have? -

I had the same issue with my 111W117, it looks like the innards are the same. I loosened the screw at the back (photo 1) and adjusted the bar down that the presser foot is attached to (slides in collar in red, photo 2). You may need to adjust the locking collar in yellow, which the presser spring pushes on. Be aware that it is probably going to require a bit of adjusting/readjusting of these screws, in conjunction with the one you've already adjusted, to get it working right. Be careful that the crank arm (above red circle) doesn't bind on the edge of the housing where it goes through the slot. By doing this you will reduce the height under the foot a little. IF you decide to do this and you get in a mess don't blame me, you've been warned!

-

Which screw are you talking about? The screw that adjusts the rocking arm at the back is the usual way of adjusting the feet. The height of the bar holding the foot can also be adjusted from inside, but it can be a bit fiddly because, in my experience, all these adjustments tend to be interlinked.

-

Cheyenne Holsters

dikman replied to Forester's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Very nice work. Did you have any problems feeding the pouch through the loops on the long barrel holster? I'm guessing you had to have it pretty wet. Firearm laws and regulations are certainly bizarre (and usually defy logic). Here in Oz replicas are treated the same as real handguns, which means you have to have a handgun licence to own a replica! -

I just had a look at his website, unfortunately it's all Greek to me! I tried enlarging the photo and it looks to be in very good condition (at least on the outside), If all he means is that the stitch length isn't as long as newer machines then it's nothing to worry about because he's right! You will probably want to factor in changing the feet/feed dog plate, as I mentioned (maybe you can beat him down a bit, based on this?) but if it sews ok then it will be a nice machine to have.

-

Figured it's time to see if this wee beastie will actually work! Foot clearance measured at 3/8", which is what I expected given that it's a 111-class machine. I shoved several layers of veg under the feet and fitted a #22 needle (no thread). It punched through ok, but tended to lift the leather on the upstroke. I couldn't get enough tension on the feet to stop it lifting. It was fine if I reduced the thickness of the leather. Changed to a #18 needle and no problems, went through whatever I could jam under the feet, with no lifting. Fitted a bobbin and some #69 thread and it sewed beautifully.Top tension was off a bit but that didn't matter. Back to the #22 needle and some #138 thread top and bottom. As long as I kept the thickness down a bit it sewed fine. I figured the 22/138 combination is probably pushing it past its design parameters, but the fact it will work if I keep the thickness down is a bonus, as far as I'm concerned. My original intention when I bought it was just to use it to pre-punch leather when handstitching, but the fact it sews is great, considering what I had to do to make it into an "ordinary" machine. Not bad for $150 .