-

Posts

722 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by rickybobby

-

Judge And Sig Pro Holster Pattern

rickybobby replied to glockanator's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Just my .02 cents, The more complicated a customer makes your job the more difficult the whole experience will become. It seems that once you start to accommodate someone something out of the ordinary, the more time it costs YOU! Pass on the job and do your normal orders, if you don't have any, use the time to market yourself and your business. -

When Did Y'all Make The Switch?

rickybobby replied to glockanator's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Switch as soon as you have your patterns all "dialed in". You will be amazed how much easier better leather is to work with, your edges will look better and your molding will as well. If tooling one the casing process and burnishing effects you have been reading about but can never quite master will "appear". It was not always operator error that things did not happen like you wanted them to after following all the right steps. sometimes it was just poor quality leather. I have been buying from Roger Fulmer of RJF leather (a sponsor here on LW.net) it has been some of the finest consistency and least waste of any place else I have bought leather. The worst part of these hides is better than most hides at our Tandy leather store (N. Phoenix location) Also you can buy it pre dyed saving an entire step for some belts and holster projects. Saddle soap it, oil or condition, do the edges, seal it and done! Hope this helps, -

Welcome Bob! Very nice work!

-

Dale Harwood - The Art Of Saddle Making

rickybobby replied to Newfman's topic in General Saddlery Discussion

Bill Gomer DVD's show you pattern making as well and would be a good addition to your library. I have not seen the Harwood or Watt DVD's yet but hope too. I have seen one other makers vid. and really did not get much out of it at all (just like his chap vid) well, some people can teach and others just collect your money. -

I am ready for a clicker! How do I get the info for the discount? I didn't see anything about it on their website? I'm calling them monday! This would be so cool ! Rick

-

Another Horsehide Holster

rickybobby replied to Colt Hammerless's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Nice job! and great design! -

This is where I get mine... E-Z SALES & MANUFACTURING, INC. 1432 West 166th Street • Gardena, CA 90247 (310) 327-0343 • (800) 767-0346 • Fax (310) 327-1159 E-MAIL: sales@ezsalesinc.com They have many sizes and styles

-

Made A Few Pouches For My Leathermans

rickybobby replied to JME1979's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Very nice work! My leatherman case looks like heck! You have inspired me to put that on the list of things to do! -

Bob Klenda has some great patterns on his site. Just download the order form and mail it to him with a check or money order. (they are pretty low tech there) but they are great patterns!! http://www.klendasaddlery.com/patterns.htm

-

You can order from the company direct. http://www.dotfasteners.com/pull_the_dot.html I think there is a minimum of 100 each I would order from them but I am looking at maybe 50 each ( in Black) Would you want to split an order? I think Springfield Leather has them and you can buy a couple there (no minimum)

-

pm sent to be put on "list"

-

Nice job! I don't think the stitching is bad! Really nice, I am unsure what the small d ring is for? It looks kinda cool but is there a reason?

-

Some New Stuff

rickybobby replied to Josh Ashman's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Nice work on all of them! I like the cool angle that the "spike" holster follows the knife! -

I just pull the excess to the underside of the project and start new a couple stitches back. This is what I consider "commercially acceptable" If it is truly a "custom" item, with a custom price, I will use a new bobbin. There is another method and that is to separate the layers, pull the thread to the inside, tie it off then start the stitch in the same hole, finish the project and go back and pull the starting thread in that hole and reglue the layers together. It is a P.I.T.A. but it can salvage a "custom" piece. Rick

-

Nice work on your first pieces! Welcome to the forum, glad you "delurked" and came out of hiding! Rick

-

Very nice watch straps!! Welcome to the forum!! Rick

-

Sixer, Stop!! Get your machine and some scrap leather, clear your mind, the machine is your friend! Some very basic steps here, glue a couple pieces of leather together like it was a holster. Sand your edges smooth so you can mark a stitch line. #1 I make my stitch line the thickness of the holster or belt. It is easy to remember and only once in a while do I deviate. It just works for me and looks ok. #2 Put the leather under the presser foot, line up the needle with your stitch line. #3 Pull 6 or 7 inches of thread out of the upper and lower and hold it taunt BEHIND the holster for the first few stitches. (this keeps everything from balling up) #4 SLOW, set your machine to very slow speed prior to doing any of this. #5 Ease your turns while sewing. A little at a time, preferably while the needle is in the leather make the turn, this takes time and a little rhythm that will come to you. #6 When finishing, before pulling the project out from the machine, make sure the needle has gone ALL THE WAY UP AND HAS JUST STARTED DOWN ABOUT 1/4 INCH. This allows the bottom thread to release from the shuttle hook and pull out of the bobbin smoothly. Also make sure the foot is in the UP position this releases thread tension so you can pull some thread out to remove the project from the machine. I have found that many people that have just bought a machine do not know #6 information. I have shown a few people this and it helped clear some confusion up. After that it is just practice. Put your hand sewing stuff away and spend a couple hours with your machine, it will enhance your leather working skills!! Ferg had a good idea about you tube, I have not looked but I bet there is some great info and basic starter sewing videos on there! Hope this helps, Rick

-

Problems With Tippman Boss

rickybobby replied to EasternOregonLeather's topic in Leather Sewing Machines

HI, Sorry to hear about the trouble you have had with your Boss. I had one, used it most everyday, sewed holsters in 7/8 oz, lots of belts (makes my arm hurt just thinking of it!) saddle parts in excess of 14oz when put together. I never had those parts break. Now I did find that it works best when I kept it lubed. I used bearing grease in gear parts and kept everything else oiled. Maybe this will help keep it going for you, Rick -

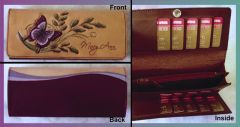

Ladies purse with 16 card slots.

rickybobby commented on Anet du Toit's gallery image in Our Leatherwork Galleries

-

Sewing Holsters With A Machine

rickybobby replied to Sixer's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Sixer, You might check this thread out. there are some online videos by Ronnie at Techsew. I have not seen them yet but you might check them out http://leatherworker.net/forum/index.php?showtopic=37805&st=0 Rick -

Learning About The Sewing Machine You Just Bought

rickybobby replied to rickybobby's topic in Leather Sewing Machines

Steve, Looking at your face when there are sewing machine troubles is a comfort! The rest of the time, welllll ??? lol!! Steve I know you go out of your way to be accessible to your clients as well, you are one of two in the business that believes that customer service is important! I have had first hand experience with yours and it is outstanding. I have not seen the DVD, I think that it is a great idea, just like Ron from TechSew that have YouTube videos on such topics. Maybe all the bases are covered by you guys but, maybe there is a need for some "hands on" in person (beginning) sewing lessons? Any and all thoughts are considered here, and appreciated. Remember this is for folks pretty new to machines or with little or no experience. Rick -

Learning About The Sewing Machine You Just Bought

rickybobby replied to rickybobby's topic in Leather Sewing Machines

Ron, Good to see that some of these questions have a place to get answered. Now some new users can get some questions answered. I know you are one of two distributors that someone can rely on to answer their phone calls! Rick -

Learning About The Sewing Machine You Just Bought

rickybobby replied to rickybobby's topic in Leather Sewing Machines

You could be the official Sponsor!! We can have the class in the "TechSew Stadium" If there are any questions that you get that you cannot fix over the phone is the information that a class like this is for. Beginning users (for leather) and the difficulties that they are having. There are some things that we learn on our own and take a while that if we were shown in the first week of using a machine, a lot of wasted time and leather could be avoided. As well as phone calls to you guys. What would be the top 5 questions that beginners have to you that can only be helped in person (showing someone on a machine)? -

Sewing Holsters With A Machine

rickybobby replied to Sixer's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I would tighten the foot presser tension some and see if that helps keep the leather "down", dropping the stitches on sewing curves may be from how you are executing the turn. If you are making "jerking" motions while moving the holster (and the needle is not on the up stroke) it may miss the bobbin hook (skipping the stitch). Use some scrap leather and practice the curve. The machine works fine on straight lines so I would say it is something in your movements on the curves. A slow but deliberate movement in guiding your work is the best. I say we all go over to Lukes house, I have never been to Memphis!