-

Posts

5,976 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by fredk

-

I use a wood-workers awl to punch into the cap, which sometimes raises the edge then I wiggle in a small pair of wire side cutters and snip the rivet post.

- 12 replies

-

- how to remove rivets

- rivet removale

- (and 2 more)

-

Two short-shank double headed ready rivets, and cover the rivet heads inside the holster with a thin piece of leather if necessary

-

Can you get a replacement needle bar easy enough?

-

Leather smell, storage smell, mildew smell?

fredk replied to Redbeeerd's topic in Leatherwork Conversation

Go to a hardware store to find oxalic acid, or to your local pub and ask what they use for cleaning down the serving tops of the counter bars. This is often sold as 'Bar-Keeper's Friend' for cleaning bar tops. Although not a lot of pubs/bars actually use it. Another source is your local beekeepers; they might use it for disinfecting bee hive parts -

Both 'scratch' awls work fine. I have several of both and they do work well for poking holes in leather up to about 3mm thick. I have several as 1. I have them left over from teaching kit 2. I have numerous work benches and a couple of transportable work kits in which I keep them

-

The ring is a thimble ring

-

Several ways to tackle a plain breast plate. I'd suggest you get or make a buck to form the leather over. An old shop mannequin, or a few planks nailed together. The size of your torso plus an extra 1 or 2 inches in girth. Wet mould a piece of 4mm or thicker veg tan over it. Tack/nail the leather to the buck, then when its fully dry cut out the shapes for the arms and neck and trim the bottom edge. If you want a breast ridge down the centre add a strip of wood to the buck for that The back piece can be made in the same way

-

1851 Colt Conversion Holsters

fredk replied to JWheeler331's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thems shure do look nice -

From leather bottle making to castrating beeves what a load of bollocks! Just joking. Some of the words we use for livestock come from old Anglo-Saxon, some from Norman-French, and in the US some from Spanish-Indo When I see the bullocks being gathered in a field, getting ready for the slaughter houses, I think; thats a lot of burgers and a lot of leather, I wonder where that goes

-

Are you trying to make a plain breast & back plate or articulated?

-

Duck Tote for Brother in Laws

fredk replied to ArkieNewbie's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Excellent -

In English English we call them bullocks

-

A selection of iron nails for making holes. A penny nail will make a slot for lacing

-

Oddly, despite it being Kindle and Amazon, that book is not available to me. I can't use kindle anyways, my eBook is a Kobo, not compatible

-

To me, its a gamble; how much do you want the splitter and how much can you afford to loose? I no longer gamble, but when I did I set my limit, what I could afford to loose, about £1 per week. Sometimes I won, most-times I lost I've taken the gamble on machinery or cars, sometimes I've won, sometimes I've lost; but I went in with my eyes open and knowing I could loose, but just my limit

-

I wonder how they get away with using bitumen in bottles and cups For the last 25 years or so bitumen is only allowed to be used in agriculture by licensed users, eg arborists. Its forbidden for other uses UK 'nanny' state laws

-

I've been following this Sometimes the old saying 'if its too good to be true then it is' often holds true But sometimes, bargains can be had, people just want rid of things, they need either the space or just get rid of an ex's garbage In the plastic modelling world over here we often come across a modeller's 'stash' being sold off very cheaply because his/her ex or widow just wants rid of it all And I'm reminded of a sale a very long time ago; a lady near where I lived sold a low-mileage, almost new, part customized, Roll Royce car for £1. Why? it needed a new interior, or the interior well cleaned, because her husband had blown his head off inside the car. She wanted the car gone Check everything out carefully and go with gut instinct

-

It was 21 years ago and I knew nothing about leather (I still don't! ) so I'm trying to remember I was using the rawhide from chews to edge Viking shields. After soaking and unrolling and allowing the rawhide to dry a bit I sliced off the thicker parts. In slices about 2" wide. These were laced or nailed to the shield edges. Almost all the rawhide was no more that about 1.5mm thick, the thinnest parts which I considered waste was no more than about 1mm thick, a lot of it thinner. I realised that the strips of very thin rawhide could be used, the width could do a baby shoe sole and the vamp made in two or three pieces. I was working the rawhide slightly wet. I think, just by constant working of the rawhide in my hands it became more flexible. Certainly the soles dried relatively stiff but the vamps had more flexibility. It certainly was not as soft as the turn-shoes. But if you check out baby shoes in a shoe shop you'll find them very stiff. They are more for protection and for getting baby used to wearing shoes. As baby grows and needs more flexible shoes then the turn-shoes are worn

-

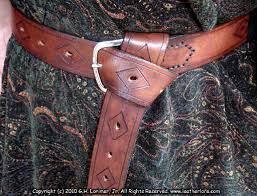

The turn-shoes were all chrome tan upholstery leather, vamp & sole The rawhide shoes were different ones; both uppers and soles. Made for babies who were yet to walk or do much walking. I don't know if I still have the patterns for them They kinda looked like these, with the sole laced to the vamp, a strap over the top to pull tight and a small buckle. After construction the shoes were given several coats of Resolene to seal them. #1 favourite dottir started with these then went on to the turn-shoes All these were made at the start of my leathercrafting years. With either of these shoes, they don't very much shaping as children's feet are still forming. The shoes just need to be very flexible

-

Ps. Make them out of rawhide Get some big dog chews*, soak them, open them up, flatten them then make the shoes I've made items out of rawhide this way as rawhide is not available here *if its safe for a dog to eat it'll be safe for a toddler (maybe)

-

When my #1 favorite dottir was a toddler and we as a family did medieval shows I made her slipper shoes from upholstery grade chrome tan leather. They were in the turn-shoes style of making. She had a new pair just about every 6 months, from age about 1 to 6. I think I still have all her sole patterns somewhere; I'm just too lazy to have a good clear-out Now, whilst she never sat and chewed them she liked them and even when she was of school age she used to change into them after school. She said they were the most comfortable shoes she had A few years ago I made some small valet trays in veg tan. Dyed and sealed. At that time I was having a problem with sealing the dyed finish, so I really worked on these. After sealing they were soaked in warm water, in cold water, they got a good saturated wash with alcohol and then with acetone. No dye came off at all. A month after the trays were given out one of the recipients told me, as a funny story, that her 3 y/o grandson had sucked on her tray and came away with a red mouth. I never thought of testing with a toddler's saliva!

-

-

The best you can do with that is to pre-construction clamp each piece between two pieces of wood, so the edge is very, very close to the wood, like 1/2 or 1mm, then rub some soft beeswax along the leather edge

-

Copydex