-

Posts

193 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by trash treasure

-

Well, since you weren't impressed much by the info (sorry everyone, about the repeat chart image, btw), there's not much more I can say. If you knew all this stuff already, then you should have said so, in your original post. I, for one, wasn't assuming anything, except that you didn't know what thread to use for sewing a tow strap. I guess that mistakenly lead me to to the conclusion that you did not have experience sewing them - Hence my lame attempt at possibly useful info - Obviously, my bad. BTW - I Never read your posts about machine purchase - So many people ask about that, I guess I just glazed over it. Good luck with learning to use it.

-

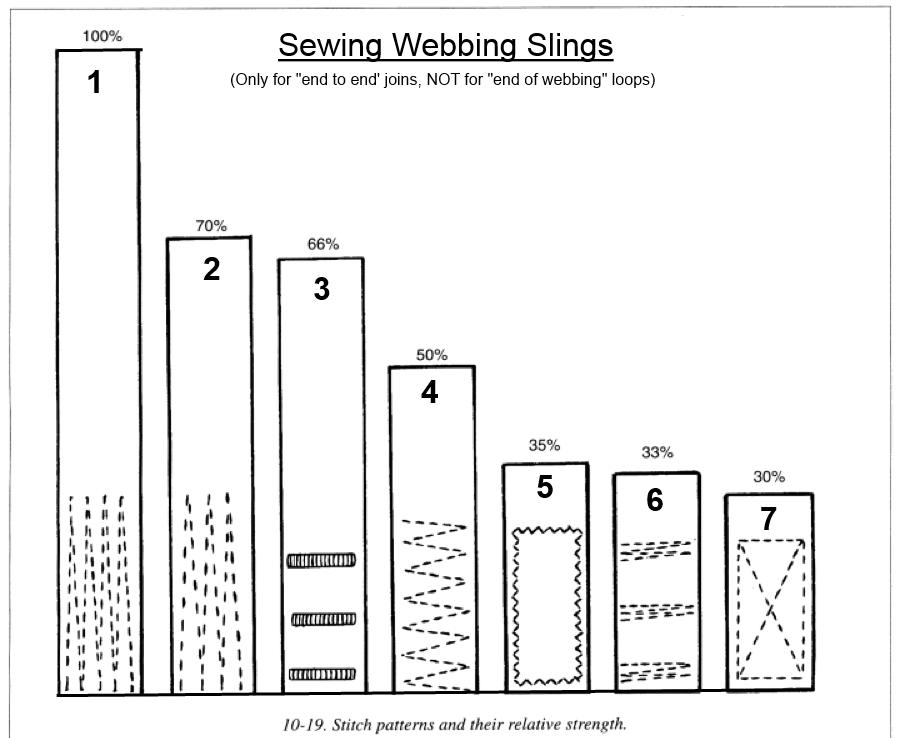

Since we're on this subject, here's some basic info you might find useful. Some years ago, Sailrite did some testing of various stitch patterns, to try and determine relative breaking strengths : https://www.sailrite.com/How-to-Sew-Webbing-Loops And here's a little chart sewing some of the stitch patterns used for this stuff - I understand that it's now mostly accepted that stitching more or less in line with the pull direction is strongest, with maybe some cross stitching at the ends. In any case, I'm NOT recommending that you sell, or even give away, any straps you make, unless you get them tested and certified. If you make them for your own use, then use a lot of heavy thread, in one of the stronger stitch patterns, and GLUE the lap before sewing (Contact cement, super seam stick, etc) - They won't break at the stitching if you do it right. BUT, if you're not used to this kind of heavy duty sewing, and don't have a machine capable of using heavy thread, you should probably just pass on this type of stuff.

-

I believe nylon is technically stronger than polyester, but has less UV resistance. For something like a lift or tow strap, that won't be left out, probably nylon.

-

As far as the thread goes, that may not be the problem here. I mentioned it, as something to check, when all else fails :~) We've gone through a lot of thread in our shop, and I only remember one spool that was bad that way. It was supposedly bonded polyester, but obviously poor quality, as it fed through the tensions weirdly - Not much to do about this kind of thing, except to try and buy good quality.

-

Looks like it would be a decent, medium capacity, Taiwan made walking foot - Modeled on Singer 111, but updated w. reverse and large bobbin. Interesting - It supposedly has an automatic oiler - I guess maybe the oil cup on the top of the arm gravity feeds the hook. If it's in good shape, it will do just fine for upholstery. If it comes with a clutch motor, and you're not used to that, there's quite a learning curve. Whether the price is good, depends on the condition. At the very least, you'll probably want to put a 45mm pulley on the clutch motor to slow it down, or better yet, change it out for a servo motor. Since you don't have a photo, here's the factory info : http://www.chikon.com.tw/ck-563.htm

-

We had a cone of bad thread once, that would cause that - Uneven thickness, I guess.

-

2 buttons, so probably 111w155 - A good machine, if you don't mind no reverse.

-

Sergers with automatic thread tensioning

trash treasure replied to unionattic's topic in Leather Sewing Machines

No expert here, but if you're talking about a computerized machine, and then if it's truly automatic, it monitors the fabric thickness and stitch pattern, and adjusts accordingly - All done through the miracle of electronics, with sensors telling solenoids what to do. There are some machines like that, that require the user to adjust the tension within a certain range, and then the machine compensates a little - Those would really be semi-automatic. And it's not just sergers - Other kinds of machines can have the feature, also . All this stuff is the reason I buy older machines - I wouldn't begin to know how to service one of these modern marvels, and I can't afford to pay someone else to do it. -

It would seem to me, that it's the interaction of the feed dog with the inner foot, that determines the tracking. So that's where I would look. You might try some different feet, and feed dogs - Aftermarket parts combinations, on a clone machine, might offer all kinds of possibilities ........ Some good, some not-so-good.

-

Number plate on Consew 206RB machine?

trash treasure replied to Texxut's topic in Leather Sewing Machines

It looks like a serial # -

Reverse Pedal on a Post Bed?

trash treasure replied to shoemaker4's topic in Leather Sewing Machines

That would work ! -

Adler 104-VNS2 Presser Foot Height?

trash treasure replied to metallurgynerd's topic in Leather Sewing Machines

I would just lower the feet to the standard on-the-deck position - That would have been the way it came from the factory. But that's just me - YMMV. Nice looking machine, BTW - Much nicer than the ones I usually find :~) -

What's the best sewing machine?

trash treasure replied to ariannacraig's topic in Leather Sewing Machines

Here's one, although I doubt the price would appeal to a "value buyer" - I believe the model has been made by Consew, and re-badged and sold under other names, for some years now, so maybe you could find a used one : https://atlaslevy.3dcartstores.com/Consew-146RB-Zig-Zag-Walking-Foot-Sewing-Machine-Head-Only_p_1128.html -

Grease for Gears in Gearboxes

trash treasure replied to Scoutmom103's topic in Leather Sewing Machines

This is absolutely right - Please do not think to use any kind "gear oil" in a sewing machine gear case - They are NOT sealed like that, and all you will do is make a mess! What works for a bush hog, is NOT what's needed in a sewing machine. Either use some kind light grease, that will stick to the gears, or just take the gear case off, and oil regularly. One grease I've found that works pretty well, if you go the grease route, is "Super Lube" synthetic grease - It's a clear grease, with no smell, and it seems to hang on the gears fine : https://www.amazon.com/Super-Lube-21030-Synthetic-Grease/dp/B000XBH9HI/ref=sr_1_3?crid=102Q4WNC2JWML&keywords=super%2Blube%2Bgrease&qid=1658919014&sprefix=super%2Blube%2Bgrease%2Caps%2C938&sr=8-3&th=1- 28 replies

-

- grease

- industrial sewing machine

-

(and 1 more)

Tagged with:

-

Which Adler Heavy Duty Flatbed..?

trash treasure replied to TheMackinaw's topic in Leather Sewing Machines

Adler 167 and 267 use a larger size bobbin that the 67. -

OK - First get the needle and foot out of the way please, and you also might have to remove the the bobbin case opener finger - Remember approximately where it's set, so you can get it back in the right place. Take some needle-nose pliers, and see if you can grab the edge of the bobbin basket - It's really hard steel, so you won't harm it. The thing is, it only lifts out in one position, and you have to hold it still while you turn the hook race, until it will come out. So hold the basket, while turning the hand wheel. Wiggle the hand wheel back and forth, until it comes out - Don't force it, and when it gets to the right place it will pop out easily. It's a feel sort of thing - you'll know when it's going to lift out. I've done this so many times, I can do it in my sleep almost - But be patient, and it will come out. Maybe someone else will chime in and describe this better, but anyway, that's how I do it.

-

Oops - I see that RockyAussie was asking about the steel screws - I thought he meant the aluminum parts ........

-

The handwheel looks to be aluminum - I think he said he might anodize the parts, which is an electrolytic process used for aluminum. You can use dye in the process, and create many colors, that way.

-

Did you do the machine work on the handwheel? If so - Very nice work.

-

I'm sure it can sew leather - It looks like it's a compound feed. It's just that most people wouldn't need a long arm machine like that to sew most leather goods. If you do need it to reach the middle of large pieces, then it might be just the thing :~)

-

The original greased pig sewing machine!

trash treasure replied to Flatcapper's topic in Leather Sewing Machines

I winced when I read this - I feel bad for your machine, but I'm very glad there were no serious injuries. I hope you won't take this as "hind sight", but maybe the following description of machine lifting might help others in the future - I'm sure it isn't an original idea, btw. I'm not a large or very strong individual, but I've dealt with various kinds of machinery (including sewing machines), my whole life, and so had to learn ways of safely lifting and moving heavy (sometimes VERY heavy) objects. What we (My wife and I) do with any sewing machine too heavy for one person to easily lift, is what I've come to call the "cannibal" method - We hold a length of metal pipe ( I use a piece of aluminum pipe, but a piece of 1" EMT, etc. would work), maybe 6' long or so, over the machine arm, and wrap strong rope or nylon strap (ratchet strap is fine) over and around the pipe and under the machine arm, several times, spreading the wraps out so the machine is balanced - Secure the wraps, squat down, get your shoulders under the pipe, and lift away. We've easily and safely lifted sewing machines, one even weighing north of 200 lbs, like this, carried them up/down stairs, off trailers, etc. , and moved them quite a distance sometimes. Anyway, I hope this might help someone avoid problems. -

Pfaff 145 H3 Squeaking Handwheel

trash treasure replied to ethereal's topic in Leather Sewing Machines

If you got that machine for $500, complete with a servo motor AND a speed reducer, you got a REAL good deal! I'd check the belt alignments, to make sure they're all running straight. A belt running on a pulley at a sideways angle can cause the noise you describe, as will a belt running too loose. And make sure you've oiled everything in the machine powertrain - Both above and below the bed. The manual should show the oiling points. -

Old factory sewing machine stand, or not?

trash treasure replied to trash treasure's topic in Leather Sewing Machines

Thank you ! I was sure I was right, but the guy didn't believe me that it was a re-purposed sewing machine table -

This was posted on another forum, I follow - A guy there, from Germany, posted photos of a small antique metal lathe he just bought. He says the table it came with is original to the lathe, but I think it's an old line shaft sewing factory table - Anyone have an opinion ?