-

Posts

308 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Wedgetail

-

Custom Dual Strap Satchel

Wedgetail replied to David Bruce's topic in Satchels, Luggage and Briefcases

Nicely done! Classic design, done well.- 15 replies

-

- satchel

- leather bag

-

(and 4 more)

Tagged with:

-

Look great! It is always satisfying when you make functional tools for yourself that suit your needs perfectly

- 16 replies

-

- stitching pony

- box jig

-

(and 1 more)

Tagged with:

-

Good call @fredk, i was watching that in my video and thinking exactly the same thing. Would be a good improvement. @leathersmyth I'd like to see a photo of that! I have a train line at the end of my street with a bunch of track laying around waiting for disposal. (It has been removed, replaced with new track, and waiting to be collected for like 3 years) @veedub3 thanks! I hope it helps

-

G'day guys, I have been tinkering away in my workshop again and had a simple idea about how to make a basic long anvil to get into all those hard to reach places on your leatherworking projects for hole punching and rivet setting. I made this one using scrap and some basic clamps I had laying around... Enjoy, and I hope you learn something! And if you get a chance, check out some of my other videos and subscribe to my channel.

-

Notebook cover

Wedgetail replied to Bolanca's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Cool! I like it -

Agree depends what you are looking for, and where you are. But yes, veg tan here is rediculously expensive... australia tax. I like Adelaide Saddlery and Leather for hardware. Birdsall for leather, and kangaroo skins Packer leather for kangaroo is better, I hear, but not so good for bovine. Tandy.... well... if they actually manage to send you the right thing, or have it in stock, then they are OK (if not mildly extortionate). You can get lots of good stuff from leffler leather, and they are the aussie distributor for claytons, but I'll let you draw your own conclusions about their prices...

-

Life or death is of no consequence. Accept that, accept your utter insignificance in the universe, accept that there is no good or bad but merely what is or is not, and you will find happiness in the smallest of things and enjoy life for what it is; because you will know that none of it matters anyway, and you are truly free. ... Bit of a nihilist. Clearly not a religious either... But you know, to each their own.

-

My makers mark is just an eagle with no words. I put it on the tongue end of the belt. (Where it adds to the aesthetic) Don't want my logo? Don't buy my stuff. Now... if it's a custom order, I'll ask where they want the logo. Most of the time they're happy to have it displayed prominently.

-

Casual Weekender

Wedgetail replied to venator's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Nice one! Well done mate. -

Chicago screws, Aka screw posts, aka posts with screws. Tandy, buckleguy, saddlery trade suppliers, and you may find them at craft stores too... or book binding suppliers, it is very common to use screw posts in that business. But all in small volume... means more $$$. For my 2c, it pays to buy more in bulk and have a bunch of these in different colours and sizes on hand... trust me there is nothing worse than having to place a whole order where the shipping price is 10x more than the item, after already going out if your way hunting around town just because you need one 3.5mm brass screwpost and all you can find is 5mm nickel plated... #lessonslearned.

-

I would be envious... but really this reads as follows: Man works hard, cashes in on the fruits of his labour. Well deserved I reckon.

-

40W Chinese Laser - Engrave and Cut Leather - Discuss

Wedgetail replied to Billy Hell's topic in 3D Printers and Lasers

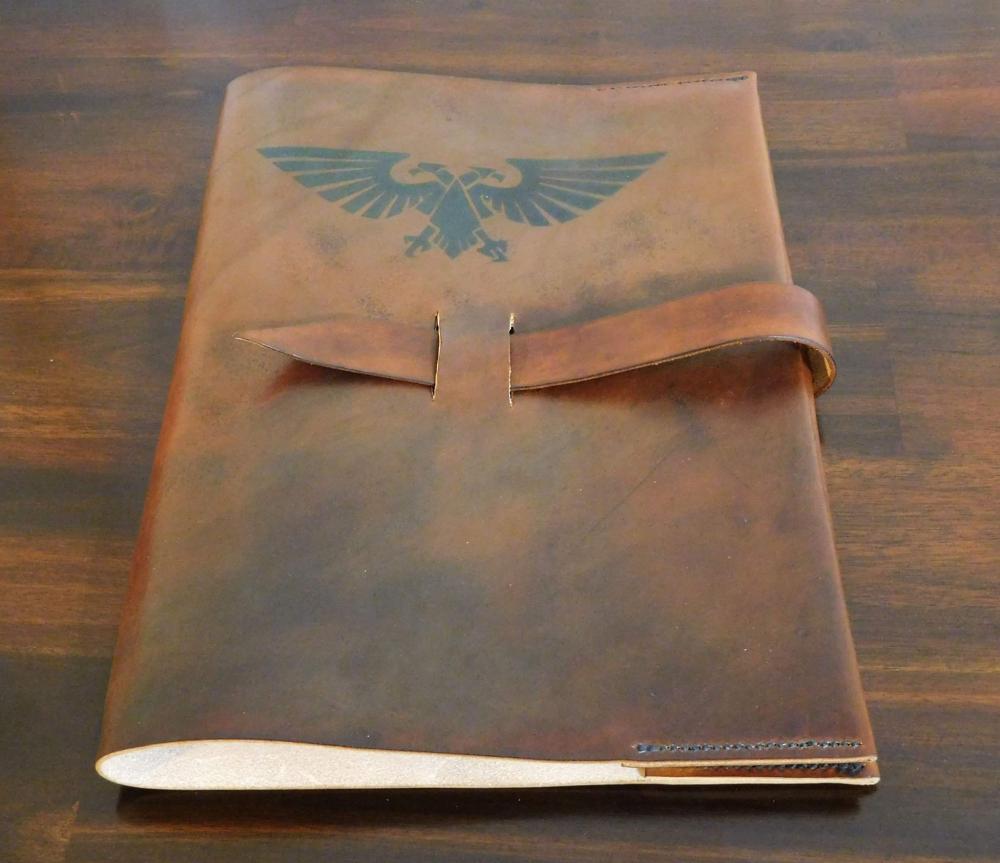

Examples of stencil dyed custom orders. The crow silhoette on a coffee sleeve was one of the first I tried. The book and cover were for fellow wargamers. Even the words on that bookmark are stencil cut using the laser and then sprayed on with dye... just need to find a font with bridges to each of the voids... like e's amd p's for example... pretty damned durable, and really cool. Anyway, just some ideas. -

40W Chinese Laser - Engrave and Cut Leather - Discuss

Wedgetail replied to Billy Hell's topic in 3D Printers and Lasers

-

40W Chinese Laser - Engrave and Cut Leather - Discuss

Wedgetail replied to Billy Hell's topic in 3D Printers and Lasers

Oh yeah, it has totally paid for itself. I have used it to engrave nameplates, and things like coffee sleeves with logos and names. People looooooove personalisation. I charge a few bucks extra for it too, but more than anything it helps make a sale. I'll post some examples. I also make all my small parts templates. Everything from wallet backs and T pockets, to rounds, and I just finished some designs for belt end templates in various sizes for one of the members here who lives nearby (just need to get back to the shed to cut them). I also use it to cut stencils for spraying dye with my airbrush... I'll post some examples on that too. It's by no means perfect, but all in all, I would buy again: any day of the week. -

40W Chinese Laser - Engrave and Cut Leather - Discuss

Wedgetail replied to Billy Hell's topic in 3D Printers and Lasers

Yeah cool, I bought the laser from ebay. In Aussie dollars, it was bang on $500 delivered to my door. 1 aud currently buys around 75c USA. The only extras I bought are the earth cable adapter for the power outlet, a bucket, and a zip tie that is serving as a compression clamp. I haven't bothered replacing the fan yet but my shed is well ventilated... in all, probably $20 worth of stuff. Maybe 50 if you use an in-line extractor fan and upgrade the pipe too. The unit is pretty big, and you won't want to move it around much, so I built a little desk for it with a sheet of plywood and 4 off the shelf legs. -

40W Chinese Laser - Engrave and Cut Leather - Discuss

Wedgetail replied to Billy Hell's topic in 3D Printers and Lasers

Ok this thread is pretty big and I'm on a train so I'll give you some of my experiences with my K40 laser I bought from ebay. Wiring was fine inside the unit Earthing, it tells you to connect a wire to a ground probe... screw that. In Australia we have 3 prong power sockets. The bottom one is an earth. I connected the earth wire to a specially designed cable that has an earth wire running to the male end of a lead. It also has a female one on the back of it and operates like a double adapter. Just plugged that into the power outlet. Done. The pump works fine, but just any old aquarium pump will work fine if you wanted to replace it. It is dangerous from the perspective that you typically have an open water container next to an electrical outlet and equipment (in my case, the pump is in a bucket on the floor. But the hose isn't long, so you don't get much reach, which means it'll usually be right beside the laser.... which becomes a serious hazard when the hose pops off the pump and water starts spraying all over the place (i.e "power board")like a fountain... I recommend using a compression clamp to hold the hose in place. Also, use only demineralised water. Otherwise you'll get mineral buildup in the laser and tubes. I pour mine into the bucket, operate the machine, and then funnel it back into the container to avoid evaporation loss of my demineralised water. The fan is junk. Mine died early, and even when it worked it didn't do much. It also has a stupid way of fitting it, including a rectangular attachment to a round fan... which leaves everything pretty open and the smoke escapes. I sealed it with duct tape. Done. The laser is dangerous when in operation, so always keep the lid closed and wear safety gear if necessary. Aligning the mirrors sucked. Took me a long time, but once done holds its own. The rails appear to be sliiiiightly out of square on my unit. Not enough to worry about, but cutting a large acrylic template it was off by about 1-2mm I removed the lense and turned it upside down, because it wasn't cutting well, now it cuts better. For software: have a look at K40 whisperer. I just switched to it, and it seems really great. I think they may support mac? Not sure though... k40 whisperer does some cool stuff, like enabling you to run cut, vector engrave, and raster engrave using different colours in your design file. It will also run with any DXF file, so you can download draftsight for free and make all the things you need, and feed them straight to the laser. MASSIVE improvement, and no need to touch Corel draw... Now lets talk about cutting and engraving. 3mm extruded acrylic: loves it. 3mm cast acrylic: nope. Thin stuff like pigskin or kangaroo, or leather around 1.5mm (3-4oz): no problem. I have not tried much thicker than that since I first got it and worked out most of the kinks. I will have a go next I'm in the shop and let you know. But as a general rule: the bigger it is, the more power, the more charring... but I'm still learning. Engraving, is good. I use mine for doing initials mostly, and sometimes cool logos and things. It's pretty fun. But you are basically vaporising the leather, and that leaves soot behind. Cleaning it out is easy enough, but then it gets soot all over your leather. So, if you plan doing cutting or engraving with natural veg tan, I'd recommend using something like frisket film, or any other low adhesive contact film to protect your work surface... which will vary in success depending on the patterns you are engraving! The smell... oh the smell... it's horrible. BUT it dissipates over time. The leather itself will smell pretty bad for a bit. Less so when you clean it and apply finishes. If I missed anything, or if you want to know more, or if you want me to try something, let me know! Just in time... train is pulling in at my station -

What do you do with small leather scraps?

Wedgetail replied to 2SSophie's topic in Leatherwork Conversation

Nice, hair barrettes too. Not first in my mind, since I am pretty much balding =p -

What do you do with small leather scraps?

Wedgetail replied to 2SSophie's topic in Leatherwork Conversation

Oh, add glove snaps and make them into headphone (earbud) holders... same technique would work for cable ties to tidy up the cables at the back of your TV. -

What do you do with small leather scraps?

Wedgetail replied to 2SSophie's topic in Leatherwork Conversation

Couple of ideas... not that I bother woth some of them. Use a large hole punch to turn them into leather washers for saddlers rivets on larger projects. Use them for testing dye Use them under your leather for hole punching into and save your tools and cutting mat. Mix them in a blender, add epoxy, compress, and turn them into micarta... sounds like a fun experiment. For slightly larger bits, make lacing from them. Make name plates to sew onto finished products... you can use a little benchtop laser to etch them. Create tags from them you can add your makers mark to, and attach them with lace for presentation of your finished products. Wrap them around clamp jaws to protect your leather projects. Key fobs Test knife sharpness Test skiving techniques Practice stitching, and test new stitching chisel/thread combinations Cut them into uniform shapes, add tarzans grip double sided tape, and stick to furniture legs to protect your flooring. ... that's all I could come up with on the spot. -

Also, looking at other fixed prong buckles, those prongs are likely to have a bend to them so that when they are inserted they don't pull out under tension. Edit: after watching the video, that's exactly what they do! Lol

-

It's a double fixed prong buckle... I can't find one like it, though can find plenty of single fixed prong buckles. Not with that little pull bit on the end though. Best bet? Find a mate who can bend and weld small parts.

-

How to make a press for moulding leather pouches and such

Wedgetail replied to RockyAussie's topic in How Do I Do That?

It's commonly called the Australia tax. How does it work? Let's do the math. Take the price of something overseas, in its local currency. Add the shipping cost to get it here from international (measured in kidneys), including any import duties and taxes (at least GST applicable, which is 10%) Convert it from the local currency to AUD (currently about US $0.75)... so multiply base cost + import tax + shipping by 1.25 Add a minimum markup of 20% Then add another 20% to total that for the Australia tax... which is an extra gouge at the price because it costs too much and takes too long for someone to get just one of that thing from overseas. Then add GST, which is a government tax of 10% charged on to the end customer. Australia tax... It's how we go from $12 per sqft leather to $29 at some (actually quite popular) suppliers here.- 74 replies

-

- moulding leather press

- handcuff pouch

-

(and 1 more)

Tagged with:

-

How to make a press for moulding leather pouches and such

Wedgetail replied to RockyAussie's topic in How Do I Do That?

Sending you a PM Brian.- 74 replies

-

- moulding leather press

- handcuff pouch

-

(and 1 more)

Tagged with: