-

Posts

1,808 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by hidepounder

-

It does weaken the leather....but just how much strain is going to put on that belt? With a waistline like mine, there is a potential for product failure, otherwise, under normal usage, it's probably not a problem!

-

Bruce, In the spirit of cooperation & fellowship I have decided to share a recently discovered secret. You can now get a full infusion of calories, carbohydrates and cholesteral...2 eggs, bacon, sausage, pancakes and coffee in a real cup....Denny's - $4.99 I mean....why compromise...(or spill while you're driving)?! Bob

-

Rayban...my theory is if you want two pieces held together, why not use the stongest bond possible? So when I sew, it's after I have glued using Barge or Masters cement. Occasionally I'll have a repair item come in that's been glued this way and after removing the stitches, the pieces are still well bonded together with just the glue. So unless you are making something that you want to be able to disassemble easily, I say glue it! Bob

-

Presser feet - getting close to the edge

hidepounder replied to LAPat's topic in Leather Sewing Machines

Pat, I went to a harness set up with my machines. I purchased left only and right only presser feet and also a harness needle foot. All three pieces are very narrow, which allow me to stitch closer than I can with the standard double presser foot. On my machine I can change from a left presser foot to right presser foot, right in the middle of a sewing run, if I need to, without affecting my stitching. If you are just stitchng flat material than you may have no need for these extra pieces, but I think it's easier to sew with a single presser foot holding the work down with the needle foot to the outside near the edge. Remember to leave enough room to allow for edging and burnishing (if you sew first). Another thing I did with my machines was to grind off the toe on the needle foot so that I could actually see the needle penetrate my leather. Again, not something to worry about if you are stitching in a straight line all the time. If your machine didn't come with an edge guide, then you might want to pick up one of those. On some projects you may find it convenient to leave the outside edge oversized or wider than necessary. This allows plenty of surface for your presser feet to walk on. Then, when you're finished sewing you can cut the final edge back as close to the stitching as you need to. I had to teach myself, so these are just some of the tricks I discovered. There are a lot people here who are much more knowledgable than me who I'm sure will jump in here..... Have fun! Bob -

Doesn't look to me like you've forgotten anything! Both pieces look great! I know what it's like to try to start again, I took twenty years off myself. The great news is that there are more sources for tools, patterns, material and references than there ever has been, and most can been found right here on LW! Great job! Bob

-

The cream always rises to the top! Congratulations Darcy and Elton!

-

Thanks for posting this.....I didn't know it was that easy! Bob

-

Sorry I missed you Steve. I was walking down the isle towards Beards booth and he pointed at me and yelled out " thats Hidepounder!" and I got to meet Ian and Terry and a couple of the other members here. It was fun to visit them!

-

Russ, That Platinum 5 horse would look pretty good parked at my barn!!!! Bob PS You probaly know Jim Lovell....he's a good friend. I try to stop by Mack Whites once or twice a year, too.

-

I've noticed there seems to be some concern about rust with regard to stamping tools. I have a number of old tools that were made out of bolts and nails and who knows what and they all accumulate surface rust. This doesn't concern me at all. Most of these old tools develop a patina, rather than surface rust. The ones made of nails seem to rust the worst, I suppose, due to the poor quality of the steel. I just make a few impressions on a piece of scrap and I'm ready to go. As Art said, you could use a little Ballistol (good tip Art, I hadn't thought of that) or you could spray the entire tool with some clear acrylic if you're really worried about it and want them to stay shiney (I would avoid the impression surface). However, I really don't think it's a problem. I have modified a lot of Tandy tools, they rusted, I used them...no big deal. For me, my old rusty handmade tools are sort of point of pride...I know that there aren't any others like them! I just purchased an old veiner from Bob Douglas that was made out of a nail and I bought some of Ellis' new steel tools and can't wait for them to turn dark. When you look at my rack of tools, you won't see much chrome...and I like it that way! Mike I didn't mean to change your subject here...I probably should have stated a new topic...but I noticed the concerns and just charged ahead. Sorry! Just some rambling thoughts.... Bob

-

This is only the second or third time I have seen Tavis' work. I remember how amazed I was the first time I saw his tooling! He's one of the best floral toolers I have EVER seen. He's a master at incorporating old traditional design elements into new style Sheridan patterns...some of this reminds me of F.O. Baird. This is the kind of work I print out and keep in a folder to study for inspiration. When I see work like this, I realize I have so much more to learn. Thanks for posting this Marlon. Bob Park

-

I'm pretty sure Weaver sells 277 in a few colors. Rice probably does too. Art or Ian would know better where to go...... Bob

-

Bruce, I know what you mean...those little treasures one finds from time to time are really gratifying. When you find one you feel like you just won the Lotto! I picked up a CSO twist handle draw gauge on ebay a short while back (I just like those for some reason). It was misrepresented and I got it for about $50 + shipping. It was in terrific condition...just looked bad because of the unsitely patina that was on on it. Douglas sells those gauges for $150 to $200 a piece! BTW, I have a Buchman head knife that I really love. It is very thin and stays SHARP! Rob really bought his tools right! That was one of those great finds! Ben, thanks for Evapo-Rust....hadn't heard of that. Bob

-

Bruce, Thanks for posting the link of old tool makers! That's neat to have. As I browsed quickly through it I discovered the name of William Dodd. Several years ago I sold an old CS Osborne round knife on ebay and threw in a Dodd half round knife that didn't have a handle. I had acquired it somewhere back in the late sixties with a box of old tools. The blade was in perfect condition but I didn't want to spend the money to have a handle made! 150 years old! Just another example of how ignorant I am!!!!! Gotta go.....I'm going to be sick!...but thanks for the site. Bob

-

Rob, Congratulations! You did VERY well! I buy the old tools also. Like Bruce, I have a couple of buffing wheels set up, they have different grades of polishing compound. 99.9% of the tools I buy, polish like new just using the buffing wheels. I use the fine green rouge as a final polish and I use it on the handles as well. I learned this from Bob Douglas who does it professionally. They will polish nicely. Good tools...great buy...I'm envious! Bob

-

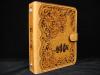

Josh, Here's how I make a notebook or binder. It's made out of three pieces. The front cover, the back cover and the binder. This is constructed completely of new leather. The front and back are 7/8 oz and the binder is 4/5 oz tooling leather. The lining is 2/3 oz. I have not seen a binder which was purchased and then covered with leather. I think that would be an impractical approach (if I interpreted your question correctly). Tool the front, back and binder, sew them together, line them and then install the three ring binder with chicago screws and/or conchos. Obviously, any combination of pockets, etc., can be added to the interior. Hope this answers your question. Bob

-

James, I'm pretty certain he does not have a web site. I think his number is on the front page here. Bob

-

Just got back from the Wickenburg Show! I stayed all day Thursday and Friday...what a great show! There were a slightly fewer vendors this year and a few new ones from last year. All the vendors I talked to said they were really doing well at the show. It was a great place to see new tools! Bob Douglas had a huge number of tools and could hardly keep up with the sales. He had samples of his new French Edgers which will be ready to sell at Sheridan. He is taking orders and it would behoove anyone who is interested to get on the list now! Bob Beard's and Barry King's table were swamped every time I went by. Lonnie from Hackbarth introduced a new line of tool steel tools, Chuck Smith was there with the Old Smoothie line and an assortment of stamping tools he has been working on. Paul at Leather Wranglers had swivel knives spread out all over his table in a wide variety of colors. Wayne Jouresky (sorry I didn't spell your name right Wayne) introduced a few new geometric tools and of course lace maker which is a real gem! Ron was there with his line of edgers and tools also. HideCrafter and Tandy were there of course as well as Thoroughbred Leather, Lee from Herman Oak, Bowden Tree Co and Hansen Silver had about five tables covered with silver. Artisan was there of course...I didn't get to visit with Jerry much. Steve was there with his new line of machines and he was so busy we didn't have a chance to visit much either. There were a lot of other venders there also, I apologize to those who's names I forgot to mention! I was dissappointed in the number of entries in the Billy Wootres swivel knife contest...I know Paul was too...what happened to all you guys who said you were going to enter?! Anyway I submitted three pieces and there were three of four other entries as well. I don't know the results yet of course because the show is still going. Belinda and Norm of Crown King Custom Leather hosted a fantastic party at their shop after the show on Thursday night...served enough barbeque to feed an army! It was a great event and a fantastic opportunity to visit with the vendors and attendees over a cocktail! For those of you who couldn't attend, you missed a great show! I'd tell you all more about, however I seem to be missing a few hours of memory from Thursday and Friday nights...think I'll try to go get rehydrated! Bob

-

Good clean job, Justin! Bob

-

Doug, he should also have told you to remove any knives, sharp objects or anything else that you could use to harm yourself with, from your bench, prior to starting with the Tri-Weave! It's a hard tool to run right, but looks really nice when you do! The Tri-weave on the left is a Hackbarth, the one on the right is a Bob Beard. (photo complete with typical mistakes! ) Bob

-

Another good looking saddle JW! If you want to maintain your sanity, however, don't do a Triweave! Bob

-

CraftTools were designed as entry level tools that enthusiasts could afford to buy. However, even in the 60's, when I first started, professional toolers were using tools other than CraftTools in order to produce high quality work. They were made at home out of nails and bolts or by machinests who produced them in their off time for friends. When Ray Hackarth began making tools, the pro's who could afford to, used them. Nothing has changed today...if you want to produce good work, you need good tools! There comes a time for every tooler, where ones skill level exceeds what CraftTool can produce. Fortunately for all of us, there are a lot of great tool makers out there. Each of them are better at making some tools than others...it's a matter of personal preference. HideCrafters has done a great job of producing an intermediate line of tools, and I'm confident that CraftTool will improve the quality of their tools at some point...but they will still be entry level tools! If your serious about tooling, you need professional quality tools. That's my story and I'm sticking to it! :soapbox: Bob

-

Tooled Snake Belt

hidepounder replied to Casey Jordan's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Casey, that's fantastic! I'm really impressed with the colors too. That came out really well! Bob -

Belt Sander or Block Sander

hidepounder replied to ABC3's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I always sand my edges. I have a sanding belt set up on a grinder that I use for all kind of things. It runs at about 3500 rpm which is too fast for leather, however, I discovered that using the higher speed caused a slight amount of scortching on the edges which enhanced my final finish on the edges. For tight turns I use a small drum sander at 1750 rpm. Occassionally the dremel is real handy. Bob