Danne

Members-

Posts

772 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by Danne

-

So I use Renia Syntic Total. I start with answering the questions "Why don't you use water based glue instead?" I use water based contact cement for almost everything, except for nylon reinforcement. This glue have three solvents that require respiration protection. Aceton, Ethyl Acetate, Xylene So a regular A1-filter will not work because it's for solvent over 65c, and I sent the MSDS to 3M and asked what filter I should use, and they said 6000-series AXP3-6098 filter, and it should be used with a full face mask. And this make me confused for two reasons. 1. I have checked and those filters fit half masks, but why did they recommend full face mask? Is it because glue is in liquid form and then full face masks are always recommended? (Of course I can't use a full face mask) 2. When I read the spec sheet for AXP3-6098 it say it protects against solvents with a boiling point below 65c (Acetone have a boiling point under 65c (56c) but both ethyl acetate and Xylene have a boiling point over 65c, can someone explain. Did I get wrong information from 3M or what am I missing? Maybe someone here can help me answer these questions?

-

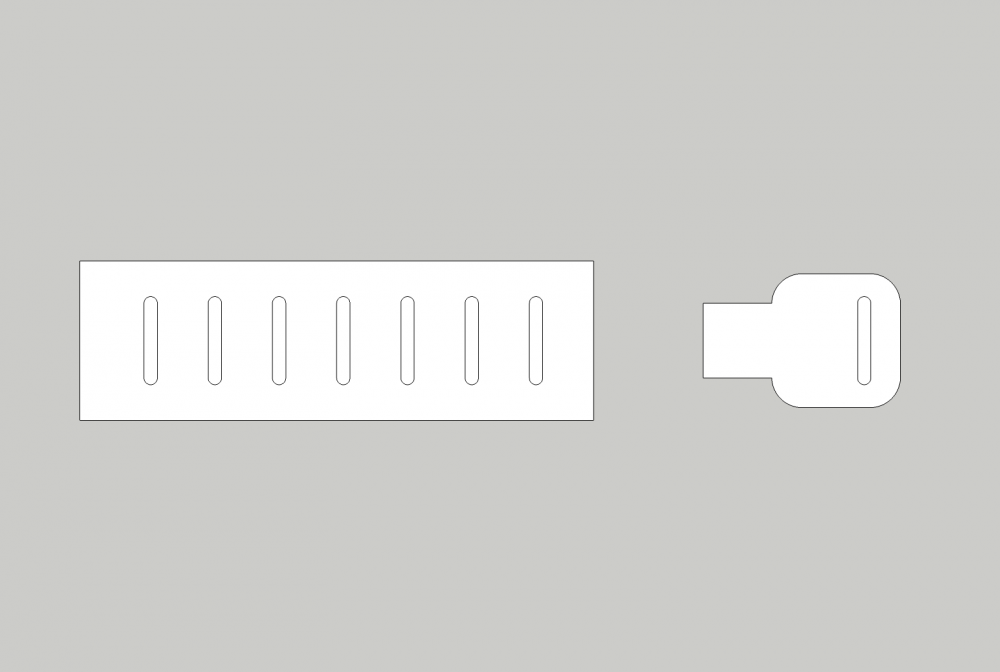

Make templates. If you don't want to do them on the computer, you can use paper and a ruler. Punch holes in your template, and after you aligned your template you push down your hole punch to leave an impression in leather. Remove your template and it's easy to align your hole punch and punch your holes. (Not to scale, because I don't know your dimensions.)

-

Welcome, I also like to make watch straps. I think it's a very good way to become good at attention to details, because small details are very important on watch straps. And also mistakes doesn't cost a lot. The material costs are low. Feel free to dm me, if you are looking for some materials in Europe for watch straps that you can't find.

-

Edge Finishing Problems

Danne replied to DACLAP's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Yes, burnish with water before dyeing edges, this way you push down the fibres on the flesh side (at the transition between edge and flesh) and avoid it bleeding into the flesh. Also consider using a cloth instead for burnishing. (A lot of people prefer canvas, I use a heavier cotton cloth) I rarely burnish edges but I show you two examples. The cognac colored one is painted with oil dye, the black one is just burnished. My method: 1. Sand flat 2. Burnish with water (using a cloth) (3. paint with oil dye) 4. Burnish with Tokonole 5. Sand 800-1200 grit 6. Burnish with Tokonole. 7. Keep sanding and burnish with Tokonole until I feel satisfied. 8. Melt paraffin on the edge and burnish. (Didn't do that on the black strap) -

I make my straps to the correct dimension, or actually -0.5mm to leave room for edge paint, before I stitch. Can you give me some information that might help to understand why your strap deforms. What irons do you use? how thick is the leather? (total thickness of the strap) how far from the edge is the center of your stitch? (LIke where do you scribe with your wing divider or what you use? Also I see someone who could improve just by slowing down a little, and let it take a little bit more time. I see on your back side that you missed to cast the thread on some holes here and there, otherwise stitching looks clean. Ps don't give ut making straps. Keep making them and find something to improve on every strap. Making straps is so good go become good at attention to small details, and the leather cost is law. Also it's super fun to make them (Or I think so :))

-

Yes i've seen that solution too, but if I would do like that on these jars, it would be very messy when I open the lid. Here I can quickly open it up put my glue spreader in the glue and close it. Very quick, and I will update how it works for a little longer time. I will slightly dilute the glue now an then if opened often but with the old seal it became thick very quick.

-

I sharpen my skiving knives with wet and dry sand paper from Mirka on my granite plate. 1000-2500 grit and finish with stropping (Stiff leather with grain side up glued to wood) and green chrome oxide. Skives leather like butter after sharpened.

-

Nubuck or Alcantara is also good choices. I mean there is a reason hyper cars use Alcantara instead if real suede. Don't get me wrong suede can be nice too, but it will wear a lot quicker. But also i'm no leather expert, I have seen those water repellent suedes online, they might be a really good choice.

-

I have very little experience with dye and painting leather. But if you have painted on your leather with an acrylic paint like Angelus, I would say you need an acrylic finisher on top. And Eco-Flo satin shene (Which I guess you use) is an acrylic finisher, if it's good enough for sealing your acrylic paint is something someone else have to answer. Also have a look at the brand of acrylic paint you use, what finish do they sell. If you use Angelus they have a couple of different acrylic finishes. (matte, satin, normal and high gloss)

-

A thin belt without lining will stretch A thin belt in soft leather with lining will stretch (need reinforcement) A stiffer thicker leather like Bridle will work fine without lining.

-

Thanks for the air flow value. I think I will do like in the post I made earlier (see my link) Open the window just slightly and lock it so it's a small gap, take down the roller blind that goes in a channel on the sides, connect the the hose and start the fan. I can't think of another solution, because I have windows that you fold like this:

-

Thank you for this information, I also think the best solution will be to exhaust the fumes/air. Also if I would do this full time eight hours a day, I would need a larger place like a shop/atelier and then I could figure out a better solution if I would use solvent based glues a lot during the days.

-

Interesting. I did a little bit more research about that fume extraction unit (BVX-101) and it seems like the HEPA-filter is not the suitable filter for solvents. But I can't find any data sheet on the filter. (I have looked on the producers website) "For use in light to medium soldering and clean rooms, a 99.997% HEPA / activated carbon gas filtration main filter is recommended. For light duty organic solvent and adhesive applications, a deep bed, activated carbon filter is recommended. In both applications, a dual stage pre-filter is provided to retain the large particles that can reduce filter efficiency and life." I mean "For light duty organic solvent and adhesive applications" that's a vague description, but we see when they answer my mail. I included MSDS when I asked about the product. But as mentioned here in the thread, an exhaust fan that sucks out the fumes out the window will be so much easier, I don't have to think about different filters, replacing filters, and also it will be cheaper. I think I will spend some time thinking about a clean solution for an exhaust fan, in combination with a respirator mask with the correct filter and I certainly don't have to worry, I mean I will only use solvent based glue when making some types of watch straps (thicker padding), flat watch straps and I use a reinforcement that works fine with water based glue.

-

I have the MSDS for all my solvent based glues. But with tests I have probably decided which one I will use. And the hazardous solvents are Xylene, Ethyl acetate and acetone. I have a A1-filter right now but I have to look for something else because acetone have a boiling point below 65c

-

The thing that complicated this is that I live in an apartment, let's say I had my own house, it would be so easy and there would be so many nice solutions. But this really need to be planned well because of space and also me being a perfectionist so I don't like if it doesn't look "clean"

-

But if vented outside then a filter wouldn't be needed?

-

Just a quick google search and the first one I found was 92€ and pre-filter 5-pack 30€ But I wonder how often that hepa filter would need to be replaced. I mean even if I did this professionally full time. And let's say I would make two watch straps/day, we are talking about maybe 10 minutes a day it will be used. Because I think I rarely will use solvent based glue for other than watch straps. I have used reinforcement materials on wallets to give them structure (Vildona) and that material bonds good with Aquilim 315, good enough to leave an edge without stitching? No, but it wouldn't with solvent based glue on that material either, because it's not the glue that separates from the leather, you tear the material in two parts.

-

So I have been trying to find a good solution for storing glue for a while. I have tried those "Ts-boy" but they are not air-tight so glue dries, I can't fit a glue spreader in the opening. I have tried jam jars, which works fine for water based glue. But then I tried these bottles (See my photos) And it works awesome for water based glue, but with solvent based glue it start to dissolve the seal, and the glue dries. So I made a new seal from industrial rubbet mat (Yes I have put it in different solvents, I had it laying in acetone for hours and it doesn't affect the rubber. Unfortunately I don't know where you buy this because I got it from a friend. But an industrial supplier should have it, and they should also have spec sheets for the material so you can see that it works with stronger solvents. Ps. This rubber is also awesome to use as a punching mat for stitching irons. you can barely see the holes, and you can't feel them after.

-

Yes, that's the thing that worry me a little bit too, that I will have to change expensive filters very often. I don't know if it's Hepa certified but it says "HEPA Efficiency: 99.97% at 0.3 micron" And it says it have Hepa filters.

-

What are your thoughts on the BVX-101 I showed? I really like it because my desk space is precious. And also I really like a clean installation where nothing is visible except the extraction hose.

-

I sent a message to the European agent of BVX-101 and asked about the filter for solvents. You can also see some clips on youtube where it's used with the filter for soldering fumes, and it seems like a good solution, because you don't need a hose out your window so you wont be dumping out energy. Here is a photo of the twin unit mounted under a desk, the single unit is smaller though. And I would modify it slightly so I can drill a hole in my desk (because I want my desk against the wall. Those aren't cheap around 600€ + vat + the cost of the desk mount, which you of course can make yourself. I will update you when I get an answer, if I forget you have to remind me.

-

I have a look at it too. Not because it's 12v, installing a single phase 230v fan is easy. But I have a feeling it will be smaller things, and if they do the job as good, that's a good thing.

-

But I think I want something a little bit more powerful. Just did a quick drawing. (Of course the parts will not be red) But with this solution I think I can hide the hose in the bottom drawer when not in use.

-

Yes a good temporary solution until I have solved this, thank you I live in Europe, but have already found similar products that will be suitable. I mean I don't think it needs to be super strong. But I will go for a more powerful fan that I can adjust. A start and stop button on my desk and a potentiometer to adjust the fan, this will be awesome. Really appreciate your idea.