Danne

Members-

Posts

772 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by Danne

-

I use sandpaper from Mirka up to 2500 grit and strop with green chrome oxide. And to be honest I don't think it's harder to sharpen the cheap Aliexpress knife compared to my Japanese skiving knives. Have you tried Olfa black max blades for snap-off blade knives? they get dull quite fast but they are razor sharp.

-

Yes, I agree. There is a difference between buying high quality tools and cheap tools. Like if you buy something from Ksblade, all their tools are good quality tools. Not all tools from Aliexpress are good tools. But if someone have a very limited budget and ask for advice there are cheap tools that will do the job. I sometimes get contacted by beginners who ask what tools they should buy and they link to some amazon kit. I usually ask them what they plan to do and recommend some tools from leathercrafttools.com (I have some tools from them and Goodsjapan which sell a lot of the same brands) and i'm happy with those tools. Do I want to upgrade things like my skiving knives from Kyoshin Elle? Yes, I want some tools from Okada, mostly because they are nice. And if I would do this professionally I think I will get a better edge retention on his skiving knives. But there are also things that take time. I like both my irons from Ksblade and Kevinlee's premium. But I don't really need them. In most cases I use them as pricking irons and open the holes with a reshaped awl, so I could use cheaper pricking irons with tapered prongs. Those irons wouldn't be suitable for me when I started this craft because I had no clue how to reshape and sharpen my awls or how to use them with consistent results, and punching European pricking irons with a large taper on the prongs would result in quite large holes. (For my taste to large hole for the thinner thread I prefer)

-

Newbie query on lining billfold and making ID pocket

Danne replied to PhilDimashq's topic in How Do I Do That?

You wrote "this time I've made the "arms" about 2 mm longer than I want. Then I've skived that 2 mm on the bottom of the T arms, and I'm overlapping each pocket by 2mm." I usually overlap the "ears" around 3-4mm, then the overlap get a "flatter" angle. And if I overlap 3mm, I start skiving the pocket ear 4mm from the edge. And before I rough and glue the pocket in place I use a distance piece (Glued to thicker card paper) and shape the overlapping area with a bone folder (pushing it down a little bit) The most common used product from Alran is Chevre sully (I don't think it's on the website) and the second most popular is Liege Main. The weight of Sully is around 1.2-1.3mm and it can be worth buying from somewhere where you can get splitting. https://www.rmleathersupply.com/ have splitting, but since you live in Ireland, maybe you should have a look in Uk (I don't think there are any import duties yet) MarcusGear have Lowick goat, and also Perlinger Noblessa (But Noblessa hides are quite large) If you ask him I think he can split it (At least I know he have splitting service for some products) Or you can use leatherthinning.co.uk. https://www.marcusgear.co.uk/leather-goods/ Also keep in mind when you are buying directly from tanneries (MarcusGear is not a tannery) I would recommend you to buy a little bit more, most tanneries wont appreciate you buying one skin. I also send you a dm about some alternatives. -

Before someone gets upset, I will start with clarify a couple of things. 1. I don't see myself as a professional leathercrafter, i'm a self taught hobbyist and my results are not perfect, but I will say after a lot of practice my skiving and stitching skills are on a decent level. 2. I have also blamed my tools, my inconsistent skiving was because I needed a better skiving knife (Even though I had a Kyoshin Elle knife which is a really good knife) and when I bought my Ksblade pricking/stitching irons, I had to admit to myself that the reason for my inconsistent stitching isn't because of my stitching irons, I need to practice more. 3. Are there benefits with more expensive tools? Yes, for example a really cheap skiving knife often have very bad edge retention, and if you can afford it I would recommend you to buy a slightly better skiving knife, because you will have to constantly sharpen those cheaper ones. The more expensive pricking irons are often easier to work with and polished and sharp and make smaller holes. The more expensive ones is often easier to punch through thicker leather, and when you make holes in really thin leather for example a watch strap it's easier to get a nice stitch line with small slim holes. So you are starting this craft and you aren't happy with your results, your budget was low so you bought the absolute cheapest tools you could find, and you think it will get better once you can afford better tools, the answer is no. If you can't get a decent result with cheap tools, you will not get better result with the more expensive tools. (Of course this doesn't apply to all tools. Here in my example I will talk about skiving knives and stitching irons. Here I have tools from Aliexpress. The price is around: Stitching irons: ~ 5usd Skiving knife: ~ 2usd So I start with the skiving knife. Here is a card pocket I skived with this skiving knife, and believe me it does a much better job than the most expensive knife you can find if it's an expensive knife you can't get really sharp. But once you learn to sharpen your knife, of course it's nice with a good quality tool that keep it's edge sharp longer. Here is a crafter on Instagram https://www.instagram.com/mamaleathergoods/ who use cheap Aliexpress irons and stitching looks really clean. A couple of final words. You don't need a lot of money to work with leather and make nice things. You can buy cheap tools, some cheap tools are really bad, other do the job. If you decide to spend a little bit more money it's still a good idea to not buy the most expensive tools, as an example buying Ksblade, Sinabrooks, Kevinlee premium irons before you know if you want Japanese or European style irons is not a good idea. Is it convenient with an expensive electric creaser? yes, but manual Wuta creasers will do a really nice job, even though it requires some practice for correct temperature if you need to heat it over an alcohol lamp. And depending on where you live (where you can't buy leather with splitting) you might want to save that money for a skiving machine instead and learn to split leather for wallets and watch straps and other small leather goods. And of course if you have done this for a while and know what tools you like, and you can afford it expensive and sometimes handmade tools have it's benefits. First it's fun to buy tools Crafting with high quality tools feels good. But what I wanna say is that you don't NEED those tools to get a good result. But keep in mind not all cheap tools will do the job, Tandy is a good example, they have a lot of tools that are more or less useless. (Even though it seems like they have started to sell some better quality tools also. (I haven't tried them, because I will never buy anything from them again since they ripped me off on some tools I bought like a useless hole punch set.

-

I see a lot of people who struggle with skiving, and have problems getting a good clean result. I have been there too, i'm not an expert on skiving, but I think my skiving is quite good. There are a couple of things I think is important. 1. A sharp knife, it should cut VERY easy through your leather. 2. Using a sawing motion and not trying to push the knife through the edge. (3.) This is my opinion, I find it a lot easier to skive with the bevel down, that way I get a "fulcrum point" and if I need to skive feather thin, I can do it in two skives.

-

Latest card holder

Danne replied to Danne's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thank you. -

Latest card holder

Danne replied to Danne's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thank you blue duck. But not perfect. But finally I will be there or close to at least -

I have no experience with tooling but I asked a crafter on Instagram (Can't remember who it was but I saved the photo) what reinforcement this is. And he told me it's tape he use when tooling.

-

Latest card holder

Danne replied to Danne's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Yes the card pockets are 0.9mm. If I had access to a band knife splitter so I could split myself I would make them slightly thinner and fully lined. Probably around 0.4+0.3mm (And no skiving on the edges of the pockets) but instead skive some parts of the "base" of the card sections. (Under the cards) Construction can be hard. Where to skive, and how much and still keep the product durable? and one construction might work with one type of leather but not with another leather. -

Newbie query on lining billfold and making ID pocket

Danne replied to PhilDimashq's topic in How Do I Do That?

My exterior is 2.5oz, and card pockets slightly under 2.5oz. Also keep in mind that my card holder (I think you are referring to my last brown card holder) is skived, both the exterior lining is skived under card sections, and the top layer of the card sections are skived at the exterior edges, and also some skiving on the card pockets (outside of the stitching) so my edge thickness is around 2mm. If I would make the same card holder with veg tan interior the edges would be slightly thicker because I wouldn't skive the card pockets because from my experience they risk breaking the stitch that overlap the edge instead of stretching a little bit like chevre does. In my opinion you need thinner leather to be able to line your wallets. (An option if you choose not to line them, is to burnish the flesh side with tokonole) Also when/if you start to line your wallets you will either have to glue your folded parts in a curve or you will get a lot of "creases" where the wallets folds. So I would recommend you playing around with small test pieces that you fold to see how it looks. How much it creases depends on the type of leather and the leather weights used, and of course how tight the fold is. Ps. I'm a self taught hobbyist, and this is based on what i've learned from wallets i've made earlier and have been used for 2-3 years by friends and myself. -

Latest card holder

Danne replied to Danne's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thank you. -

Latest card holder

Danne replied to Danne's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thank you Thank you Thank you, It's 0.5mm and 0.9mm (Everything is lined except card pockets) -

Latest card holder

Danne replied to Danne's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thank you Thank you YinTx -

I have done this card holder in the same color combinations and shared here before. But trying to improve my finish so keep making it. Exterior leather: Tärnsjö 9368 Interior: Alran Sully dark brown. Thread: Meisi Xiange Twist #30 ML001 Edge paint: Fenice

-

A question out of curiosity, i'm looking to buy a used Fortuna or FAV. Is the reason you are looking for a used spare part because new ones are super expensive, or is it because they are not available anymore for that machine? The reason I ask is because it might be worth for me to compare spare parts prices between Fortuna and FAV before I buy a machine. If you haven't even looked for a new spare part (or maybe used from a supplier) I would ask both http://www.sieck.de/ and http://www.fortuna-service.com/

-

It's interesting how different we all are. I find that stitching is the absolutely hardest part with this craft. Sure stitching stiffer thicker veg tan with a decent result was relatively easy to learn. But when things start to become thin, and combinations with different temper on leather, I find that I use a lot of different angles and tension, and sometimes the result is good, other times I can't get it as I like. But of course I get better and better the more I practice. But still if I for example compare with skiving edges, I find skiving edges with consistent results super easy compared to stitching.

-

Looks like some old irons I bought from Aliexpress (A lot cheaper) and they do the job. Regarding Ksblade, an alternative is Kevinlee's premium irons. (I have both Ksblade and Kevinlee) I have some Japenese style irons too, but I prefer the European style. Kevinlee's irons make awesome holes. Ksblade is a little easier to align, and Kevin's irons is a little top heavy. But his irons is very good value for you money. https://www.kevinleathertools.com/products/kl-french-style-pricking-iron-1

-

So, I have decided it's time to buy a skiving machine. Since I have limited space I can't buy a larger machine with exhaust. I included a drawing of my plan for my new work area. I will mount the skiving machine directly onto my table to the left of the cabinet (Dimensions not exact here it will be a little bit more table space to the left of the cabinet) And I will do a diy-solution for the exhaust. Probably 3d-print a connector for a vacuum cleaner. I have a couple of questions. 1. I plan to buy a Fortuna SM50 or a FAV2 (Depends of what I find) I know I can add a second motor to the FAV2 machine, but can I do the same to SM50? (I can't find a manual for that machine, or photos so I can see if it's possible) A second motor will of course be so I can run the bell knife at full speed all the time. 2. A general question. If you just like me work with both softer leather (like chevre sully) and stiffer veg tan, and you want to increase the gap slightly between the presser feet and the bell knife when skiving/splitting veg tan. How do you do this the best way practically. Because when you sharpen the knife at one position, let's say you have a small gap for softer leather, and increase the gap for stiffer leather, you want to move the bell knife back to it's "original position" before you sharpen the next time again, or you will have to reshape a new bevel on the knife everytime. My thoughts. two different thickness of paper? (Now I don't know the perfect distance for different types of leather, but let's say 0.2mm is suitable for softer chrome tan, and 0.5mm for veg tan. Then I have two pieces of paper so I can adjust for veg tan, and adjust it back to thin leather and not having to do a lot of reshaping of the knife when sharpening the next time. 3. Which feed roll would be most suitable for me when using softer chrome/combination tanned and stiffer veg tan (Will rarely skive/split thicker leather than 1.5mm) and split down to around 0.5mm for lined card pockets keeper lining on watch straps and such (Yes I know it requires some practice for a good result) Emery fina grain? Emery medium grain? or Vulkollan? Or do I need different feed wheels for different leather? I'm sorry if I explained this bad, if you don't understand how I mean just ask, and I try to explain better. If you have any other advice in the choice of machines or accessories like sharpening stones, feed wheels and such please share.

-

I pre-punch the exterior, then I open the holes with an awl after assembled.

-

Make sure to hammer down your edges really good, and also let it cure before sanding. I have no problem with this and I use both water based and solvent based contact cement. Here is a burnished edge on two layers of leather (bad photo) but no visible glue line. I can't remember if I used water based or solvent based glue on this one. With natural veg tan without dye on edges you will of course see a little transition between layers. But when I look at your photo I see "gaps"

- 10 replies

-

Maybe start with something simple like a card case? Everything I do is fully lined and my templates would be hard to explain to someone else. But a while ago I made a simple card case template for someone. Use leather around 1-1.2mm To avoid seeing the top pocket through the bottom pocket, it can be good to skive the edges. It doesn't have to be perfect since it won't be visible. A safety beveler will work fine if you don't feel comfortable using a skiving knife. (This is A4, i'm not sure if it's possible to print in letter size, if not just tell me, and I make one in letter size. Edit: I didn't really explain the distance piece. Glue it to some thicker card paper, and you can use it to align the distance for the top pocket from the edge. Scribe a line where you need to roughen your leather grain for glue, and also use it when you assemble your pocket so it's the correct distance from the top. 2card.pdf2card_template.pdf

-

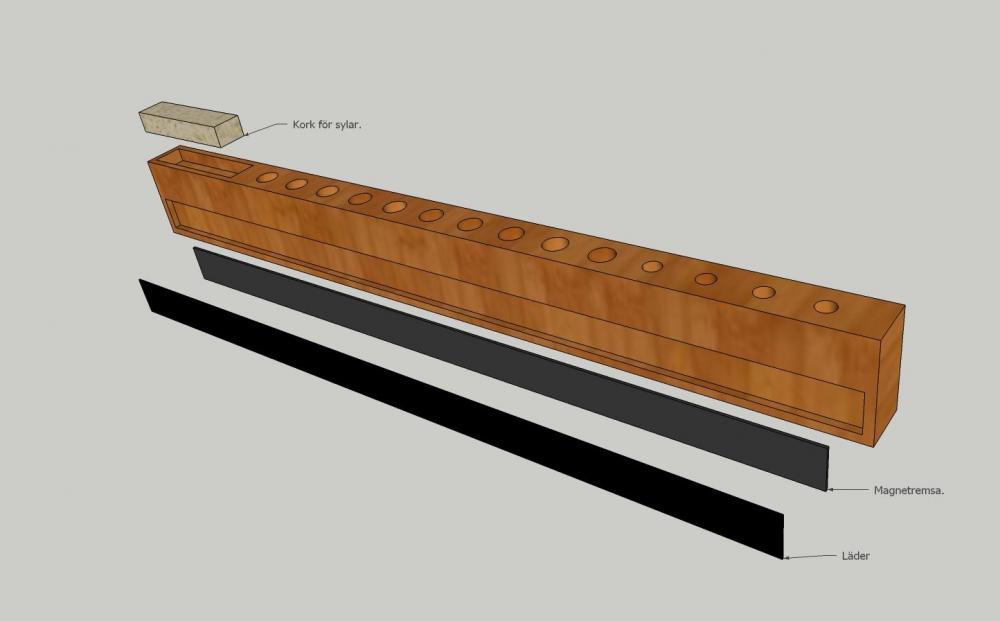

This is the work area I have now. And this photo is not new so there are even more tools. This is a quick drawing of the style of tool holder, but it's not finished yet. I will make it longer and add more holes for more types of tools. Translation from top to bottom (It's in Swedish) Cork for awls, magnet strip, leather. This is my plan, and I will need to find good solutions for storing most things on the wall, maybe a shelf for glue jars, electric creaser, everything I can do to free up space to work on. (To the left of the cabinet I will mount a skiving machine) And to the left in the photo is leather storage (Card paper rolls, I think they are used to cast concrete, and are available in a lot of different dimensions so seems to be perfect for leather storage)

-

I like your storage solution. For me the important part is to get some of my most used tools away from my bench and up on the wall because my work area is very limited- but yes I agree with you, it's also good to have a storage solution that allows new tools tools. I have made some drawings of a wall tool holder with both holes for tools like edge bevelers, hole punches, awls and such. But also a hidden magnet behind leather for skiving knives and other tools. I just need to buy some woodworking tools. I got away with using a handheld drill and a plastic miter saw box for making my stitching pony, but now I need some more tools like a handheld router, some good wood drills (have access to a drillpress) and a decent quality chisel set. To not go more off-topic here. I can show photos in dm of my storage solution plans. And more ideas for wall storage is also welcome of course. So if you feel like discussing it more just dm me

-

Yes, please update me when you have tried them. I'm not looking for "fancy" nice looking tools, I just want them to do the job. And also plan to build a storage solution in wood for tools.

-

That kit with punches look nice. Regarding round hole punches, i've also heard good things about this one from Kevinlee. https://www.kevinleathertools.com/products/hexagonal-handle-black-round-holeunch-set-14cs