Danne

Members-

Posts

772 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Danne

-

I buy from Meisi https://www.meisithreads.com/waxed-linen-threads I live in Europe, but it was rather quick (Except customs in that suck here) Shipping was 4-5 days + customs. Here you have a couple of colors in Us (YueFung is the same thread) Be careful Meisi manufactured AmyRoke thread before, but I'm quite certain they changed supplier. https://www.blackmountainsleather.com/collections/waxed-linen-threads/products/waxed-linen-thread-0-35mm-yue-fung-brand You can also use Fil Au Chinois 832 (0.43mm) Around the same price but larger spools.

-

I bought the same stitching hole punches and they make small holes and I liked them. I also bought edge bevelers from Kyoshin Elle, which I would recommend you to do, even though they cost a little more. (I still use mine with good results) https://leathercrafttools.com/item?id=3688

-

Burnishing & the magic in saddle soap glycerin bar?

Danne replied to GRod's topic in How Do I Do That?

Yes it's a big misconception that you need all those expensive tools and materials to do a good job. I saw a guy from Russia a while ago, he made nice watch straps and guess what he used as an edge beveler? A flat-head screwdriver with a groove. Personally I really like tools and I have to restrain myself from buying all those nice tools :D -

Burnishing & the magic in saddle soap glycerin bar?

Danne replied to GRod's topic in How Do I Do That?

Now I'm not the correct person to answer any questions here, since my experience with burnishing is very limited (except burnishing edge paint with paraffin/bees wax) But have you tried Tokonole? I personally like that more than saddle soap. -

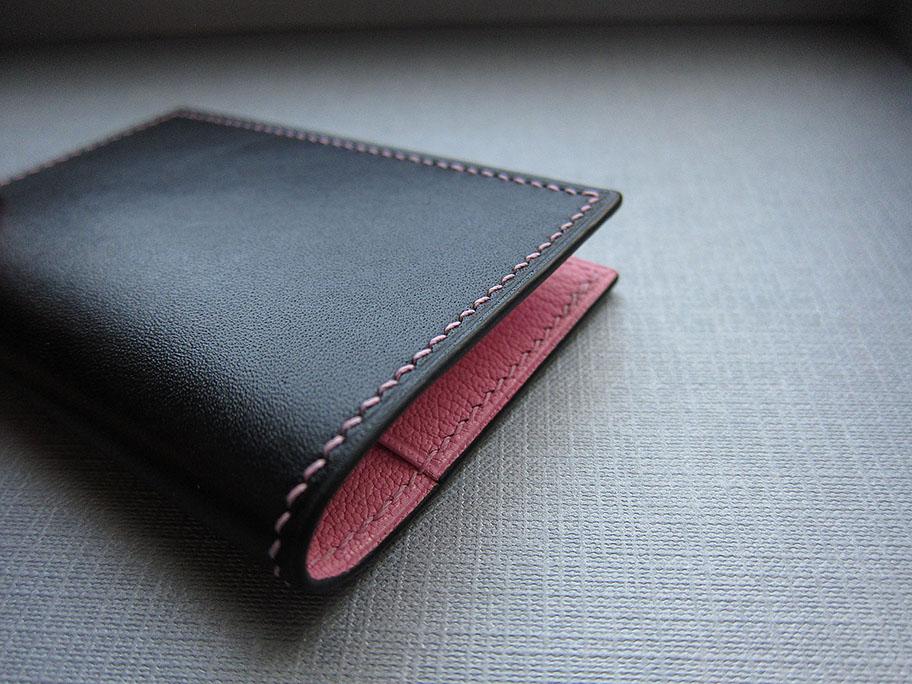

Business card holder and watch strap

Danne replied to Danne's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

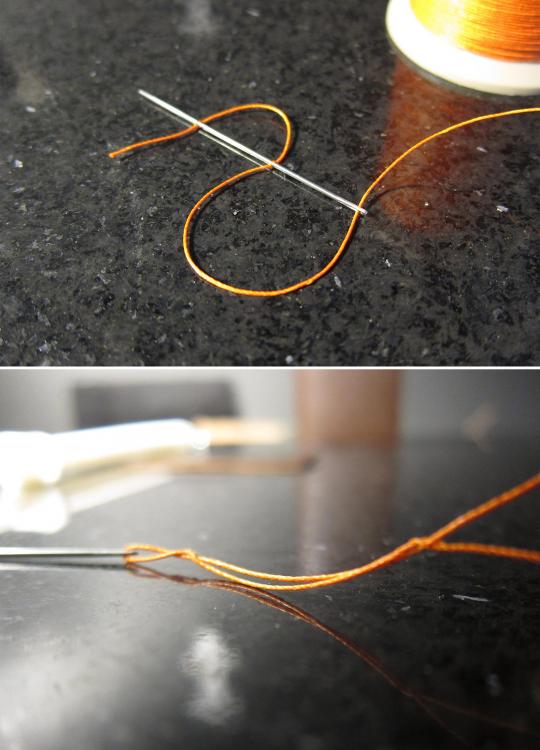

Outside leather (black) is 1mm. Lining 0.5mm pockets 0.5+0.5mm I send them to a company who split it for me. I'm looking for a Bell knife skiving machine, with which I can split smaller pieces myself for watch straps and wallets. I use water-based glue on everything on this card holder (Renia Aquilim 315) You can use it as a "wet bond" (glue on one side and attach) or as a contact cement where you put glue on both sides and wait until clear/tacky. On the outer piece I "wet bonded" since it's not glued in the middle, if you look carefully on my fourth picture you see it's not glued in the middle. (But glued around a curve) I also use solvent based contact cement when I glue reinforcement to watch straps. Card pockets are lined and skived down to around 0.6-0.7 (just before I reach the glue line) (See picture on skiving) Personally, I wouldn't skive veg tan pockets like this, I don't know if they have enough tensile strength. From my experience, I and some friends have used my wallets with this construction without a problem. (See the picture of my 2 years old wallet pockets) Regarding stitching straight. For example on this wallet, I pre-punched the outer section (black veg tan) before gluing the lining. And when assembled I used an awl. If you prefer to punch after everything is assembled it's a better choice to punch from the inside since the skived pocket edges make it hard to punch from outside. Keep in mind this is my amateur thoughts -

Business card holder and watch strap

Danne replied to Danne's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks, appreciated. Since I started with leathercraft a couple of years ago, I've always wanted to do watch straps and wallets, unfortunately, there is very little information out there if you want to do thinner leather goods. If you do a thicker watch strap, wallet, card case. There are no "rules" regarding construction. If it looks good it is good If you do a slim watch strap (like around 1mm at the lugs) it will stretch over time and leave a gap. (Needs reinforcement) I wish I could study a couple of weeks at either Peter Nitz or Shiang, it would be the first time in school you want short lunch breaks :D -

Business card holder and watch strap

Danne replied to Danne's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Yes I use a creaser from Regad. On this project I used FN2-iron. Do you need an electric creaser for good results? No I have seen very good results with Wuta manual creasers (You heat over an alcohol lamp) For a lot of people you have a budget for leatherworking tools. If I had to choose between spending the money on an electric creaser or save the money for a bell knife skiving machine I would choose a skiving machine. I'm looking for a skiving machine right now and it's certainly a more "important" tool. Maybe not so much if you live in Us where you can buy smaller amounts of leather with splitting service, but here in Europe it's a very good tool for smaller things like watch straps and wallets. -

Business card holder and watch strap

Danne replied to Danne's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thank you. Leather is dyed from tannery. I plan on dye some leather myself soon. Trying to do some nice dyeing effects. -

In my price list from Cmdachong I don't have his new creaser (The one pictured here) But I don't think his price is that high. Because it's more expensive than a twin machine from Regad with two handles. Don't get me wrong here. Your tool looks like it has a decent price from what you get. I have a single machine and I don't need a twin machine. I think there are two reasons you want twin machine. Either because it's comfortable (No need the switch irons when doing a project) or if you use one iron for straight sections and one around corners. (Like FN2 and FN2MCR ) Personally, I use regular irons around corners, which works really good with a little bit of practice.

- 12 replies

-

- electric leather creaser

- diy tool

-

(and 2 more)

Tagged with:

-

No, but people seem happy with their machines.

- 12 replies

-

- electric leather creaser

- diy tool

-

(and 2 more)

Tagged with:

-

https://www.instagram.com/cmdachong/ He has released a new machine now. I have his older product list and price list. dm me with your mail and I can send it.

- 12 replies

-

- electric leather creaser

- diy tool

-

(and 2 more)

Tagged with:

-

Looks lite a nice solution. But the cost for a Regad with five irons is not $1100 Around 730 usd for a Regad with five irons + shipping from Mando (Prices a year old so maybe a little more) Or a twin machine with two handles and five irons from Cmdachong 400usd. (Also a year old prices)

- 12 replies

-

- electric leather creaser

- diy tool

-

(and 2 more)

Tagged with:

-

HELP how do I split 6 inch wide pieces of leather

Danne replied to jennifer1962's topic in How Do I Do That?

You have four different alternatives here (Depending on the thickness you want) 1. Crank splitter At least 1000 euro. With a sharp blade you can split veg tan down to 0.5mm 2. Skiving machine Around 1000euro for a Chinese machine. The primary use for this machine is to thin down edges, but you can split leather in sections, but it requires practice. 3. Band knife splitter. A used old machine 2-3000euro (Requires VERY good mechanical skills, since they are very finicky) A new machine is around 12000euro. 4. Send leather to someone who split it for you and you can get it as thin as you want. (Depending on accessories to the machine, but at least down to 0.5mm) With the width, you are going to split I think #4 is the best affordable solution. Where are you located? -

Where to find extremely thin leather?

Danne replied to hatrabbit's topic in Leatherwork Conversation

https://districtleathersupply.com/collections/leather?sort_by=price-ascending They split to your required thickness. -

I never tried edge paint on oily/waxy leathers. Maybe you need to use adhesion promoter?

- 13 replies

-

- fenice

- edge paint

-

(and 1 more)

Tagged with:

-

It depends on the choice of creaser and leather. But with the FN-creaser I get a nicer transition between the edge and top layer if I creaser after the first layer of paint. Give it a try and share what you think.

- 13 replies

-

- fenice

- edge paint

-

(and 1 more)

Tagged with:

-

Even if it's difficult to burnish, wouldn't some beeswax or Tokonole at least seal the edge from moisture? Or you can paint them. I have no experience with waxy/oily leathers. But there are products out there, like adhesion promoters and such.

-

If you bought a refurbished machine, it would be nice at first, but soon you would probably discover you need to learn how everything works, all those small important adjustments you need to do. A new Camoga like the Camoga Compact have automatic knife trend setting. Easy to replace knife, and switch between roll/bar. But I’m sure the build quality is not like the old machines.

-

"I've spent about 5-6% the cost of a new machine on this one." Wow, sounds like you made a really good deal. Regarding splitting with a skiving machine. As I said I have no experience there either. But I have seen people split leather with good results. (Softer leather like chevre sully or alligator and such.) I have seen different types of presser feet, some have slightly rounded edges. I would really appreciate the pdf-manuals you have. I really hope you get this machine into full working condition.

-

My guess is that prongs have a flat surface where it’s screwed. But It’s very small screws. I didn’t have a small enough tool at home otherwise I would have been able to answer both if it’s a flat surface and if loctite is used.

-

I have 3mm/9spi and I'm really happy with them. But I just made an order from KevinLee 10+11SPI Ksblade don't sell 11SPI so I thought I try KevinLee. If I remember correct they don't share which steel they use. But my tools stay sharp, and I haven't heard from anyone that their prongs get bent. If you need to change prongs you have to send your tool to Ksblade. I bought 2,5,10 prong I don't use the 5 prong that often so in case I would need to replace a prong I could "borrow" one from my 5 prong, and get that replaced. This way I'm not without irons the time it take to ship it back and forth. It's probably easy to change a prong. Maybe they use some loctite on the crew (if so you may need heat to loosen it.)