-

Posts

794 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by DonInReno

-

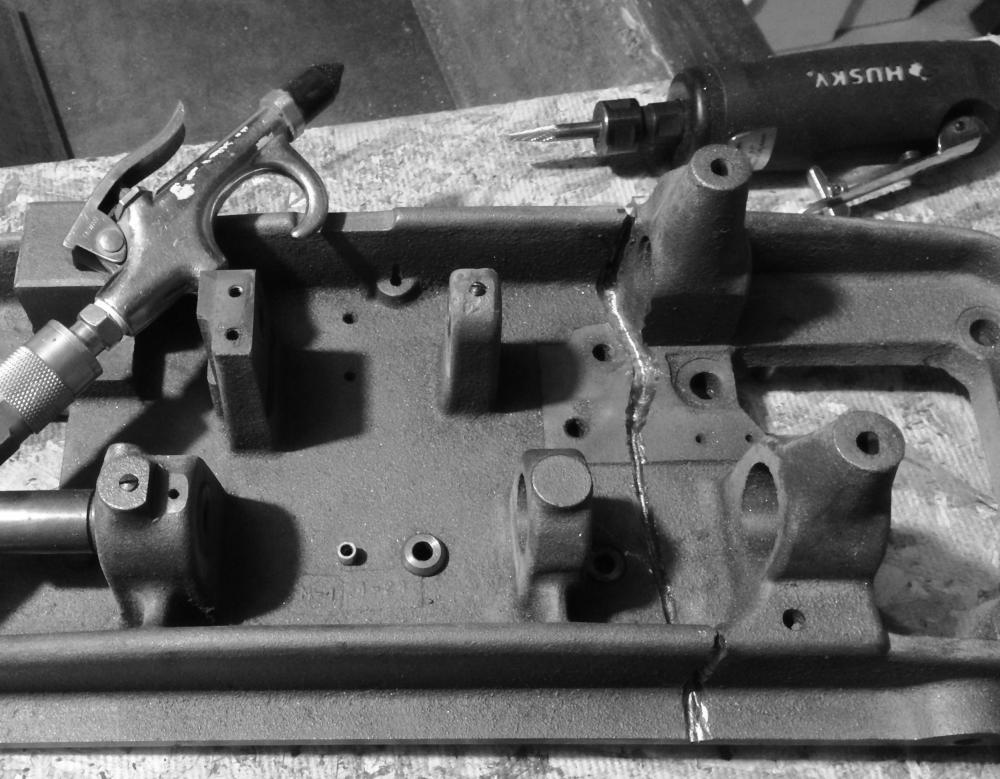

I’m not sure if anyone has an easy crack detection dye or method, but after the visible cracks were gone I was sure the cracks continue but are very fine.... Reading up on crack detection the systems that use strong magnets and fine iron powder got me to thinking and a magnetic base off a dial indicator base seemed to work really well clamped on the other side of the bed from where the grinding was taking place. With the two poles on either side of the crack the crack became the divide and iron fines highlighted It seemed to highlight cracks another 1/16” into the iron from what could be seen without the magnet. I’m more confident I’ve ground down far enough - looking forward to patching it up tomorrow.

-

A huge upgrade is a sailrite monster wheel - it’s a larger hand wheel and comes with a larger belt. Even though it’s a sailrite brand it fits the other clones like yours. Sailrite also has smooth presser feet for leather and a number of other accessories - I’d check out their webpage.

-

At a quick glance this appeared to be a Singer 31-15 and industrial treadle base for very little $$ so I picked it up only to find out it says “Dinger” not “Singer” on the treadle and there isn’t a single Simanco stamp on any of the machine parts! The joke is on me! Lol I thought the Singer tag where a decal should be was a little odd, but that was probably added after clearing customs! Under that green paint is a black machine of unknown origin, although it looks well made - I’m guessing post WW2 Japan when they were copying all sorts of singers? Anyway I’m the only kid on the block with a genuine Dinger!

-

I’ll definitely keep my eyes open for that color! Wow that was quite a break! Seeing some of the machines you and other sewing outfits have patched back together gave me the somewhat misguided confidence to fix the crack in this one! By the time I bought the carbide burr, bronze rod, welding blanket, paint stripper, 6 colors of paint, and all the hours reading up and practicing it would have been cheaper just to toss it in the spare parts bin and buy another! That reminds me to stop by the metal yard and buy some angle to keep it lined up during brazing. Lol

-

I’m getting closer to brazing the crack. The bed was stripped fairly easily. The only hang up was a single set screw in the stitch length gizmo and holy cats was it tight. Giving a good-fitting screw driver bit a hammer smack didn’t do anything to loosen it up. Then the housing the set screw was in was heated to about 200 degrees, but nothing. Then it was heated till the oil started to smoke and nothing. Another smack to the screwdriver bit and it finally unscrewed. Then the lower and upper were separated, paint on the bed was stripped and the crack is being ground out with a carbide burr. The closeup shows how the crack shows up as a fairly dark line - you just have to keep grinding and chasing the line until down below the crack. Luckily it doesn’t go clear through the bed, but about 2/3 to 3/4 the way through. I still have a bit more grinding, but a good quality carbide burr seems to make this job much easier. thats all for now...

-

Just picked up a Consew 206RB-2 for $300

DonInReno replied to myjtp's topic in Leather Sewing Machines

Nice! The cast iron looks right at home on that machine -

What should I look for on a used Juki LU-563?

DonInReno replied to LederMaschinist's topic in Leather Sewing Machines

Juki made a few winners with the 562 and 563 - great machines that you’ll enjoy sewing with. In general for any machine I like to use a strong flashlight and look at every part for signs of cracks, repairs, replacement parts or anything out of place. Like a detective if there’s something out of place look a little deeper. The picture is a hairline crack in a Juki 562 bed. Not all 563’s have reverse. If there’s no reverse lever don’t assume all you need is a replacement lever. The usual wear items that are good to look at are the hook, belt, tension disks, feed dog and presser feet. Does the hook have a nice sharp point and is it properly timed? If it’s a replacement hook don’t assume it will work as good as the original - some poor quality imports may need replacing even if it’s new. Do tension disks have grooves worn in them from thread? Is the belt in good condition or is it oil soaked or have frayed edges with reinforcing wire sticking out? Does it reverse at the same stitch length? The reverse lever should be fairly easy to operate. A stiff reverse may be a sign of a bent shaft under the bed. Does the handwheel rotate smoothly and with very little wobble? If here’s .010” wobble in the handwheel I’d suspect a slightly bent main shaft. Has it been repainted and if so is that hiding anything? Look closely for tell tail signs of repaired cracks or filled holes. Do any guides along the thread path show deep grooving? I like to wiggle things - simply move parts and look for unusual movement. Just a few days ago a loose linkage showed up and was a loose screw and simple to fix. If the hole was stripped or screw was damaged beyond repair it’s not the end of the world, but it does require more work. None of these things in and of themselves are necessarily bad if the price reflects the condition - but they do affect the value and the more you catch the more bargaining leverage is on your side. -

Also there are many rust removers in gel form - even evaporust. Speaking of evaporust, there seems to be a good amount is marketing hype about it - the product literature that claims it attacks rust yet doesn’t dissolve iron is a little hard to swallow since the safety data sheet lists the ph at “2 or 3” It’s a mild acid and does things to metal about like other mild acids do unless there is a magic acid barrier protecting the metal. Don’t get me wrong it’s good stuff, but $20/gal for something in the same ph range as white vinegar seems like $15/gal of marketing. :-)

-

My take on the sailrite clones is pretty neutral. I have one and think for a new machine not used for production, at less than half the price of an industrial it is a great bang for the buck. Need a compact machine for a small apartment - it’s perfect. Need a portable machine or something easy to learn on and it always fills the bill. You will break it if you’re sewing the heaviest things that will fit under the presser foot or if you enjoy hot rodding and regularly breaking needles. Sailrite has upgraded parts that tend to break first and there is a long history backing up the reliability so it’s not really a mystery. More or less by accident I turned over an old Singer and a Japanese singer clone “dressmaker” and was surprised by how similar the parts looked. In fact I’m convinced at least some parts would interchange. Of course these don’t have the walking foot parts, but the lineage of the Thompson and later sailrite machines is firmly rooted in the old all metal domestic machines. This is such a time tested design Ive never known anyone to wear out one of these iron bed domestics. The walking foot and aggressive feed dog does feed canvas quite well. The factory speed reducer and optional monster wheel does a good job of slowing it down and the smallish motor is probably just right since it works, but is less likely to damage parts than a stronger servo. I keep it as my go to for anyone wanting to learn how to sew. It’s just easy to use and not as intimidating to a newbie as something bigger.

-

You can always dampen a cloth in the rust remover of your choice and Saran Wrap it to the machine - it won’t work as fast as submersion, but it’s easy to do. The wd40 won’t help the rust remover since it makes it more difficult for the chemical to actually reach the surface under the rust. Harsh rust removers eat through anything, but one that’s more mild will take a little longer.

-

At two new machines a week that’s....um....multiply little number by number of Friday’s.....Yep you’re on track to have 100 machines by this time next year! That is a nice table. A lot of nylon strapping just doesn’t look correct without a nice stout bar tack - good score!

-

Singer 45k1 Restoration Decals

DonInReno replied to Parfektionisto's topic in Leather Sewing Machines

Very nice restoration! -

Consew 206RB-2 back stitch tangles? Tension or what?

DonInReno replied to myjtp's topic in Leather Sewing Machines

Yes that feed dog has some pretty sharp cuts in it! Lol I second the use of abrasive cord. -

Lot of 12 Singer 78-3 and Consew 28 mix

DonInReno replied to Gregg From Keystone Sewing's topic in Old/Sold

That’s a pretty fair price for a gaggle of walking foot machines - if you were on the left coast at least one of us would snatch them up :-) -

Cowboy 3200 foot impressions.....help needed

DonInReno replied to kyleatherworker's topic in Leather Sewing Machines

Roughly I’m guessing a lighter spring is less than $10? -

Consew 206RB-2 back stitch tangles? Tension or what?

DonInReno replied to myjtp's topic in Leather Sewing Machines

Great idea! I really like this rather than suggesting adding small adjustments until it barely gets the knot in the middle. Becoming comfortable and confident in turning the tension knob is a good basic skill that will benefit new sewers with any sewing adventures down the road. -

Canvas and Leather Sewing Machine

DonInReno replied to YanceyCravat's topic in Leather Sewing Machines

Hi - welcome to the forum! My sewing table is in pieces or I’d invite you over to Reno to try a few flat bed walking foot machines that are great for canvas, and an artisan 3200 that sews 7/8” .... The link to the Artisan 3000 is a good deal if it comes with a variety of presser feet and needle plates - in our neck of the woods there aren’t many 441 clones that show up for that price. You could get that machine and a good used walking foot flat bed machine for less than $2k out of pocket. Yes one of the big machines will sew 138 weight thread very well in canvas - if my big machine is the only one set up I don’t hesitate to hem or repair Carhartts, but, and this is a big but, to be worth a darn both the presser feet and feed dog need to be switched. For something easy like gemming pants it doesn’t matter, but climbing over thick seams in a saddle blanket or panniers would be frustrating without the serrated feet and dog. Likewise sewing leather with the serrated parts rather than the smooth ones will be frustrating as it will mark up the leather unnessesarily. Another source of frustration with repairs and one machine is the switching between thread and needle sizes in addition to having to swap presser feet and feed dog. When a machine sews great with one combination it’s nice to not screw it up swapping back and forth. -

Juki LU-563 - reverse stitch keeps breaking needles

DonInReno replied to Thatone's topic in Leather Sewing Machines

The video is so we can see how the needle, hook and other parts interact - it’s not necessary to catch a needle breaking. -

http://parts.singerco.com/IPinstManuals/112W140.pdf Something to keep in mind as you’re getting used to the new machine is don’t turn any screws to adjust things until you know for certain what the change will do. It’s also ok to only run thread to one needle - just remember to remove the unused bobbin. Guys use all sorts of ways to clean machines - wd-40, tooth brush, q-tips, and toothpicks can clean out anything that’s gunked up, but follow up with regular machine oil for lubrication. One drop of oil everywhere two pieces of metal rub. The rubber belt shouldn’t be left covered in oil or it reduces the lifespan of the belt. Alcohol - either rubbing alcohol or painters alcohol is safe on rubber. Compressed air speeds up a good cleaning. You’ll notice a lot of brownish stuff coming off everywhere - it’s not rust, but rather old dried oil...in time regular cleaning will get all the old stuff off and don’t feel like it all has to come off right away.

-

Great machine! It’s on my wish list. Refinishing advice online ranges from crude yet functional to super detailed show pieces. It might help to decide where along the continuum you want to aim. Many projects here in the archives are full of great advice and show a good range of products and techniques. If you’re interested in a glossy custom paint job some of the best videos are aimed at custom cars and/or musical instruments. The products used are somewhat different, but the techniques are quite similar. Essentially the surface is stripped of all questionable finish, the existing surface is sealed with a primer, additional filler and sand able primer applied, color coats, decals and clear coat. The devil is in the details and starting with the filler coats the entire surface has to be sanded correctly and thoroughly in between subsequent layers. The final color coat is sanded even further so all defects are removed and it’s sanded to 1500 grit or so. Decals applied then clear coats. The final finish gets sanded to be perfectly flat up to 2000 grit or so, then a buffing compound removes smaller scratches. The small automotive sanding blocks and other detail sanding products are perfect for sewing machines.

-

Congrats on the new machine! A big stitcher opens up so many options for cool stuff that everyone should own one at one time or another. Lol Sometimes it’s a choice to pull the top thread down and hand tie to lock the beginning and end for appearance. Other times you may not backstitch starting out if the end of the stitch overlaps the beginning, or if the design covers the beginning with another sewn piece that effectively locks the piece underneath.

-

Hang in there - figuring out problems can be frustrating.

-

The lines of the 132 are such a classic! The catch with this machine is the lack of shipping. I did contact them when it was first listed and the seller would be interested in shipping it if I provided a custom sized shipping crate and took care of the shipping arrangements on my end. The crate is no big deal to build or get to them, but there’s a bit of faith involved having someone actually pack the machine when the shipping damages are on me. Ebay has pretty good buyer protection with respect to shipping damage, so I’m waiting for another 132 the seller will ship or better yet closer to the west coast and I’ll just drive over. :-)

-

4-button servo controller instructions

DonInReno replied to alex11's topic in Leather Sewing Machines

The 16 year old Chinese girls that put it together would get a giggle out of that! Lol