-

Posts

794 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by DonInReno

-

Lol - I was pretty tired the day this was posted...lucky to have spelled Singer correctly :-)

-

Filson Factory Auction Dozens of 211W151 Starting at $20

DonInReno replied to JJN's topic in Leather Sewing Machines

Eric, thanks for the background info on these machines and the facilities! Your experiences and knowledge are not only entertaining, but help paint a much more realistic picture. -

Sewing Machines Question and Recommendation

DonInReno replied to pepeunidos's topic in Leather Sewing Machines

Any first time user of an industrial machine could do much worse than one of the mainstay upholstery walking foot machines like a singer 111w155, consew 206, Juki lu562, etc. These are relatively cheap, readily available, well supported/documented, and would sew the majority of what you’re building. You will always have a use for the good old flatbed walking foot. somewhere there’s a write up of a guy who simply cut a disk out of plywood, clamped it to the handwheel, and added a swiveling hand knob for sewing by hand -

What an iconic piece of American history. If you understand the limitations of the machine and choose to use it over a more versatile modern option such as one of the 441 class machines then I say more power to you. As to the value of one of these I tend to see two scenarios. The saddle guy or person who sews or fixes things for a living has one and they picked it up early in their career because it was an affordable way to speed up some tasks - it had to be reliable to pay for itself so it’s always been kept in good shape. These machines tend to sell for the most money because they are complete enough to sew reliably - I’d expect to pay at least $1,000. Today that same type of person starting out in a leather career would be purchasing a 441 or similar modern design because it’s the most bang for the buck - productivity, ease of use, flexibility, parts & accessories availability, and service. The second tier of machines have been enherited, or gifted, or it was just so outdated 50 years ago it was sold off for something more modernized, or any number of other strange reasons industrial machines make it into the hands of people who let them fall into deeper states of disrepair. These machines barely sew if at all - they might not have sewn correctly the past 50 years ever since great great uncle Dirk got drunk and dropped it off the tailgate of his pickup. Maybe they just need a good cleaning and correct adjustment, maybe it will never function correctly. $500 is my personal cap for these rode hard and put away wet machines and that’s only if all the parts are there.

-

A 95-10 has been on my wish list for a while and every six months or so one pops up for around $1,500 on the west coast, which seems like the low end for one of these - at least what I’ve seen. It looked like the budget would allow for a new toy like this, but I committed to some sidewalk pavers for the front yard so I’m tapped out this month. This pair of machines is in the middle of wine country so it’s not a bad road trip if someone else is looking for one. https://sfbay.craigslist.org/nby/hsh/d/real-leather-sewing-machine/6686176875.html

-

Filson Factory Auction Dozens of 211W151 Starting at $20

DonInReno replied to JJN's topic in Leather Sewing Machines

That big 7-31 has my attention, but that would be two really long days driving to get it. I’m not super familiar with that part of Idaho/western Washington, but there are enough 7 collectors in that neck of the woods to keep the price up. It’s a nice resource when there is a chance to share something like this - thanks for thinking of the rest of us. -

The cutting board is a great idea and the results are very good. The machine turned out exceptionally well - I like how you went about it all.

-

Are sewing machines worth the money

DonInReno replied to Horsewhishper's topic in Leather Sewing Machines

There’s a 4500 on eBay for $1,500 ... but they won’t ship it.....these deals are out there if you’re lucky enough to be within driving distance. -

That’s awesome - hopefully it does get paired with the head!

-

Good call Wiz

-

That’s cool!

-

It amazes me that this rather simple design is so old and has touched so many people over the years.

-

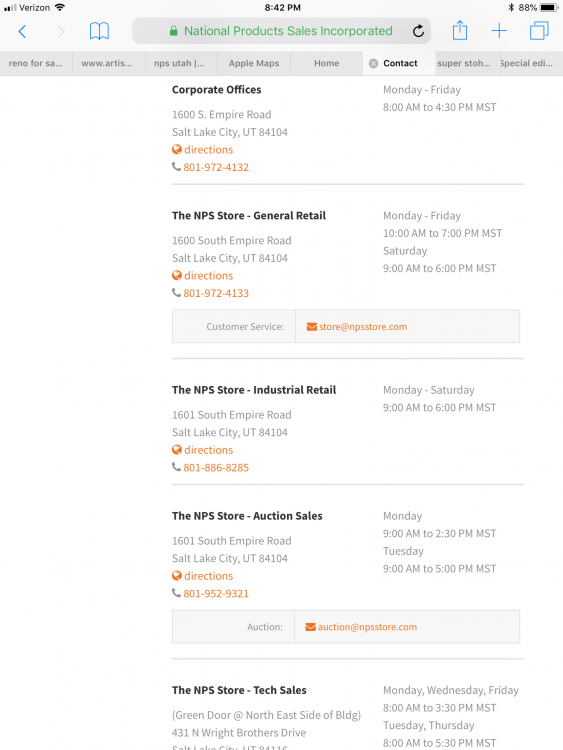

There are numerous phone numbers and emails, but I think the industrial store is what you want. I have zero use for a second big stitcher, so hopefully this will be a good machine for you. If the shipping cost turns out to be crazy high and is a deal breaker for you let me know and I’ll still drive over and buy it - I’m a sucker for a good deal. :-)

-

SInger 95K51 finally with reducer and...WOW

DonInReno replied to plinkercases's topic in Leather Sewing Machines

Good job - it’s hard to get too much reduction for many things! -

You need at least a walking foot machine - that’s what I’d be looking for. The 29-4 patcher shouldn’t be your primary.

-

Keep your eyes open and don’t get discouraged - I’ve seen a lot of good deals on walking foot machines of all sorts pop up in Washington over the past few years.

-

Juki Machine Identification and Tips for Buying Used

DonInReno replied to Askal's topic in Leather Sewing Machines

To give you an idea for what a lu-562 sells for on eBay - on the low end for just the head and a sewing sample so it is at least capable of sewing - I can’t remember seeing one for less than $400US plus another $90US to $125US for shipping. You will want to look it over closely for cracks - it’s not a big stretch of the imagination that someone brought it in to see if a cracked frame can be repaired and either balked at the repair cost after the repair and didn’t pick it up, or balked at the repair cost up front and just left it with them as scrap. In the few dozen welding shops I’ve visited over the years I’ve never seen one with an industrial machine, although making custom rain or dust covers for equipment isn’t uncommon so it’s not out of the question it was actually used at the shop. How fun - it is a great machine. -

Thanks - it sounds like an interesting store.

-

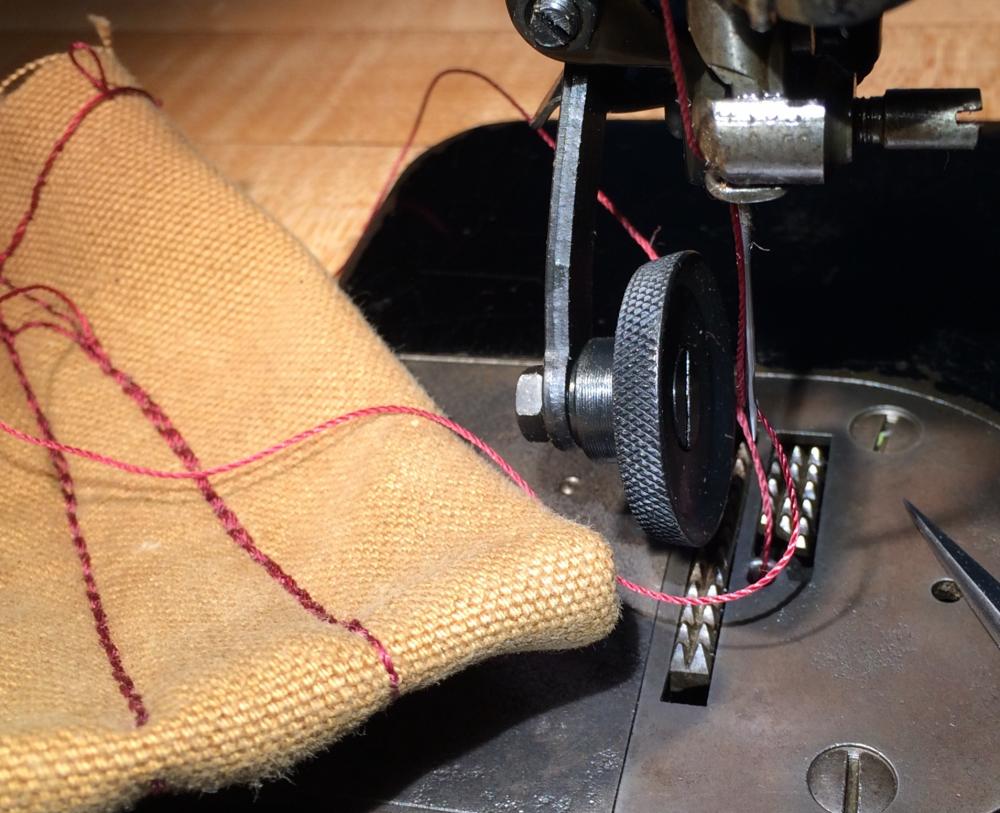

In the past I’ve suggested a machine like this, even used this exact machine as an example, to someone interested in the cheapest way humanly possible to sew 138 weight thread. I didn’t want to wrap up any more $$ in this machine than absolutely nessessary so the bobbins, bobbin holder and roller foot were ordered and shipped from China - they estimated delivery in 4-5 weeks which is about right. At half price of similar cheap parts shipped from a US location it’s simply amazing that there’s any margin left for the seller. The bobbin cases came in a two pack, which is good because one had a snag that made it useless until I feel motivated to take it apart and modify the catch. The bobbins are nicely machined and could easily be confused for others costing 5x as much. The roller feet are interesting - crude in some respects, but with nicely machined wheels. At first it looked like the body that attaches to the presser foot bar was injection molded powdered steel, but it’s just a steel looking finish on an aluminum part. Still, for something like $5 each they are fun to play with without breaking the bank. Keeping in mind I had no idea how it sewed before being shelved and the hook is less than perfect with a point that’s been filed down just to the point of being sharp and recontured, it’s a little bit of a crapshoot as to what’s going to happen when the needle is first threaded. With 138 nylon top and bottom and a #23 fabric needle it sews canvas quite well. I sewed 8 layers (1/4” compressed) of Carhartt canvas straight, hard right, hard left, all without a skipped stitch so the hook is doing pretty good. While a roller foot is a small improvement, it’s still worlds away from a good triple feed machine.

-

That’s a good deal then. What part of Utah - or even better do you have the contact info on the place that is selling it? I’ll buy it.

-

Look closely with a bright flashlight at the entire machine - every inch - there may be a crack in the cast iron or smashed bits somewhere. Hard contact will show a scuff, dent, crack or something along those lines. $600 may be too much if the frame is cracked.

-

Other than the handwheel what’s missing off the head? Edit: If you basically have a head minus handwheel it’s still worth $1000....replacement handwheel is something close to $200. More than one person here would buy a working 4500 head for $1500.

-

Sales has been and always will be like fishing - if big fish are thought of like big profit margins you can’t catch big fish in streams that only have small ones. If big fish in your creek only bite a certain bait or lure it doesn’t matter how good YOUR bait is it isn’t going to change the fish’s preferences. Fish are not evenly distributed in any lake or stream, and every body of water is slightly different - successful trophy fishermen look for pockets and in any industry there are pockets of money. And just like fishing the best pockets of money require work and skills to tap into and not everyone is cut out for every niche - if it were easy everyone would be there.

- 22 replies

-

Singer Age by Serial Numbers Slide Chart

DonInReno replied to Gregg From Keystone Sewing's topic in Leather Sewing Machines

A great nugget! -

My suggestion to a friend who has never owned a commercial machine was to get an old $500 triple feed, walking foot, flat bed from singer, consew, Juki, or whoever - half worn out and needing minor adjustment is about right. This machine will not be ideal for leather bags, it’s not as sexy as a fancy new machine, you’ll have to learn how to fix it, in the end it may not be liked and will gather dust on a back shelf, but no other machine will teach as much about the capabilities and limitations for such a low price. If it’s used for a month or year it’ll be worth as much as you paid for it so the freakin’ machine has almost ZERO cost other than the time invested, which I would consider an education expense. It will be the machine you’d lend to a friend in your same position. Everything learned will transfer to a cylinder bed machine either larger or smaller.