-

Posts

794 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by DonInReno

-

Need Advice About Buying/Using A Pfaff 145 H4 6/01

DonInReno replied to TorqueMonster1's topic in Leather Sewing Machines

I'm not familiar with that machine at all, but others will chime in as to the availability of parts, etc. I'm guessing presser feet are more expensive for that make than one that takes Singer-style feet, but you won't need a lot of different ones. In a generic sense that's exactly the type of machine for what you're wanting to do. Get some 92 size bonded polyester in a half dozen colors, size 20 needles, and samples of various types of upholstery fabric to play with. My local fabric store that caters to the kinds of things you're interested in has a scrap bin for leather remnants and small yardage vinyl and fabrics that is sold by the pound for super cheap. Basic thread colors that always seem to get used are navy blue, black, white, creame, sage green, tan, medium milk chocolate brown, dark chocolate brown, medium gray. If I had to pic three colors to get started it would be white, black and a tan - simply order new colors as needed to match projects. Keep crappy colors for practicing. Simply practicing sewing seams will teach you a lot about your machine, the fabrics and what looks good and what doesn't. Most of it sews quite easily - it's the folded seams that will break thread and needles if you try to haul ass over them. Good upholstery require practice to get a good feel for it - just like turning wrenches teaches a feel for how tight is just right and all those other skills that build up good instincts. It's 100 percent guaranteed when you finish a project there are many things you'd change next time - so enjoy the small projects before taking on big expensive ones. In my 20's while running a fire crew I borrowed an old Singer from the smoke jumpers and we didn't make anything new, but everyone enjoyed learning how to sew modifying heavy duffel bags, repairing equipment and whatnot. Ive become a big fan of patterns when making covers for patio furniture or whatnot. Clear 10 mil poly is easy to cut and tape, as is ordinary construction paper. Some items just don't drape like it seems they should. have fun with it - make cool stuff! -

Personally I'd try to sort out the issues and not return the head unless absolutely necessary - the only person that wins is the shipper. Obviously either the fork is a little wide, the plate is somehow off kilter or the machining of the cam width is tight - I'd measure the fork and let the dealer check if it's in spec or if he needs to send a replacement. Heck maybe the best fix is a simple shim under the retaining plate. I'm sure they'll work with you to sort things out. These are a tremendous value once the kinks are worked out, which is why we're driving a lot of Cowbow, Artisan and Cobras rather than Juki's. I don't own a cowboy, but also live in Reno and you're welcome to look at my 8 yr old Artisan 3200 (roughly the same machine) to judge how stiff this type of sewer is - everything is quite a bit stiffer than any domestic or upholstery size commercial machine. The hand lever for the presser foot is so stiff it's a chore to cycle - it just is what it is. Your motor is different than the servo on mine but it does take some effort to overcome the resistance of that 3:1 reducer. On your edge guide, look closely at the threaded shaft the nut screws down on - at least with the one I have there are two flats that slide between the rails of the part screwed to the machine. If the flats aren't aligned with the grove it wouldn't clamp down fully and could rise up 1/16" to 1/8", but mainly it would be loosey goosey and not tighten down (the bolt is upside down in the pic). Hang in there - you're almost home free.

-

Pfaff 335 BB (older model) experience?

DonInReno replied to plinkercases's topic in Leather Sewing Machines

That's great news - sorting out tension release issues can be a challenge! Also keep in mind that with many makes & models with this type of tension release you can get additional foot lift without activating the pin by varying how far the tension assembly sits in or out. I'm not familiar with the bits the pin affects on the front side, but there is surely an adjustment like any Singer style. Normally the backside is adjusted to specs then the front side tension knob assembly is fine tuned to release properly, so we're talking about it somewhat backwards. -

Pfaff 335 BB (older model) experience?

DonInReno replied to plinkercases's topic in Leather Sewing Machines

During normal operation the presser foot shouldn't rise far enough for the sliding gizmo to engage the release pin - only when the foot is lifted beyond its normal range of motion by either hand lever or knee lifter. The large gap between the hand lever and sliding gizmo appears to show the sliding part is too high up on the shaft with presser foot down so it's engaging the pin as the foot rises when it shouldn't. -

The reducer is finally installed, but not in the way originally intended. Direct connection of the motor shaft to the input of the reducer seemed like a great idea, but it turns into a long awkward looking contraption. With the Consew CSM1000 the 111w155 with factory hand wheel will sew one stitch per second up to about 30 stitches per second - the speed range I was aiming for. The biggest downside to this arrangement is the force required to turn the hand wheel by hand - it would be much better to use a bigger hand wheel and bigger output pulley to reduce the reduction a bit. I wouldn't get another planetary reducer unless a servo with NEMA mounting arrangement could be used to cleanly directly mount the two. Compared to the typical 3:1 pulley reducer it is more compact, and different, but better I'm not so sure yet. :-)

-

finally Youtube video of a sewing machine setup

DonInReno replied to Gregg From Keystone Sewing's topic in Leather Sewing Machines

Thanks for the video - that's quite a zig zag.- 3 replies

-

- zig zag

- sewing machine

- (and 3 more)

-

In a production situation the cool feel of the table is probably a plus! ...I'm just relaxing messing around with small projects. The restaurant grill is a great idea!

-

Brazing won't be as strong as welding, but it's pretty quick and easy - much better than jb weld. Even silver brazed with the stuff used by hvac techs would look good, but be warned most hvac guys are not used to working with cast iron and it needs to be preheated to avoid cracks.

-

can old thread cause problems and just what

DonInReno replied to OLDNSLOW's topic in Leather Sewing Machines

...in a related direction - by lubing every new spool with a good dose of silicone spray will this speed up or slow down the problems with aging thread? My gut feeling is the silicone helps prevent dried out thread from sticking and causing tension issues, but I've never heard anyone with first hand knowledge of it. For now I'll keep spraying every spool as it's purchased - you can ask me in ten years how it's working out! Lol -

Gas pedal is two-thumbs-up! There is about a 4:1 ratio of pedal movement to shaft movement and most of the variability is in the first 1/2" of the 2-1/2" of pedal travel, which seems about right. Surprisingly, the amount of return spring pressure greatly affects the comfort of your foot. Too little is as bad as too much. With just the factory return spring the resistance is so light a single big toe can easily operate it. The bracket that uses factory motor mounting holes was tossed and the speed controller was mounted separately from the motor, which was flopped around and now runs in reverse - super simple - time to mount the planetary reducer. Tomorrow I'm grabbing another pedal and making it into the presser foot lifter!

-

A quick update - walking through a garage sale of sorts there was a large cast iron industrial machine table with nice legs so I grabbed it and plopped a 111w155 on it. Metal tops are simply cold and clammy feeling for a flatbed machine even if the room temp is in the low 70's! 5 minutes sewing on it made it obvious that a heater for the top would have to be used every time - that's a deal killer. Oh well, I have a nice metal table for a bench drill press. Lol

-

Gunsmiths deal with a lot of hardened screws and numerous sizes of slotted screws. Brownells and numerous others sell great sets with hard bits - no gunsmith stays in business if they don't have good screwdrivers that don't slip. Off the shelf at Home Depot or lowes Klien electrical screw drivers are pretty hard. Stanley bits appear hard, but it's overly hardened crappy steel - they cheapened the metal about a year ago and all the guys I know stopped using them. Bosch and Makita bits are ok, Milwakee is middle of the road and stay away from kobalt or Ryobi. I'm not a big fan of craftsman in general, but the little black handle ratchet for screw bits is inexpensive and works ok. A big step up is the Gearhead screw bit ratchet. I like these with an extension to break larger screws and without to break tight quarter screws. In super tight situations a bit can be cut almost in half or aviation suppliers seem to stock shorty bits. The little thumb wheel (this one is craftsman but available from others) gets used all the time with or without an extension. To me a dremel is essential to slightly thin a bit that is just a little too tight. Keep it handy and instead of messing up a screw head you'll have a perfect fit and not only do screw heads last longer, but the bit will as well. if you're a restorer or simply OCD there are screw slot files available from Brownells to either widen or deapen a screw slot.

-

If you enjoy tinkering I'd suggest thinking of an industrial set up in parts - the table, the motor and the sewing head. It seems servo motors are replacing clutch motors at an increasing rate and there are a lot of good usable clutch motors ending up in the landfill or selling for almost nothing. Good tables with homely laminate tops that remind you of the 70's are also free or nearly so. There are well used singer needle feed heads that might not be your first choice, but for $100 less than a similar walking foot machine may fit the budget better. It seems any walking foot head that sews will sell for at least $300 - older odd ball walking foot machines might be $200, but make sure parts are still available. Well worn needle feed heads like a 212g140 start at $200 and it's not uncommon for a light duty straight stitch to pop up for $100.

-

Thread trimming scissors for normal guy hands

DonInReno replied to DonInReno's topic in Leather Sewing Machines

i have yet to see any trimmers marketed to sewers that have tips as fine as the fly tying scissors. The thick tips in this photo are the little Ginghers. -

Now I'm not a production sewer so it's a given even how I'm trimming is not that fast. It's always been a surprise there aren't better scissor options with little pointy tips and sized for man hands. I trim close at every opportunity and like a thin sharp point. The little $35 Gingher feels clunky and heavy yet sized for an 8th grader's little fingers. Fly tying equipment is primarily sized for a normal pair of men's hands and the Dr Slick brand has a dozen variations and great quality. My first $20 pair from this company has been used for years with very little light sharpening keeping them clean cutting clear to the tip. It always felt just a little short - an extra inch would still allow precise trimming with less hand movement. Today while at the local Cabela's outdoor store this black handled pair was being clearanced for half price - just $14 - and the size was exactly what I was hoping for. Not only is the tip as sharp as the other model it has carbide edges so there will be a little more time between sharpenings. Perfect!

-

Very good video

-

Help with thread size understanding and selection

DonInReno replied to Mhicks's topic in Leather Sewing Machines

Lol - I looked up the seller and they are no longer as cheap as they were 6 months ago. I won't even mention the name because their thread today may be from a complete different manufacturer. Looking through Amazon and Craig's list there are still some deals out there - $12/lb delivered bonded nylon can be had, but pick carefully! Some great deals on American thread, but the born-on-dates are getting up there. My biggest disappointment is with Amazon and how their listings are so much pay-for-play that the best deals never show up on searches. It's like they strip keywords from sellers they don't like (aren't paying extra for placement) and even if you know a product is in there it can take some creative searches to find it. eBay has some sellers that once in a while sell a limited quantity of thread at a very low price to keep their name toward the top of the list on low price searches - it's more difficult to find these opportunities since some asshats list one or two yard samples in the same space as 1/4 lb spools - total bait and switch if you ask me! Searching closed transactions on eBay shows that some regular sources are selling significantly below the normal price - it never hurts to ask for a price break apparently! Finally I can't help but be intrigued by the random bags of partial spools in random sizes and colors at The Thread Exchange for cheap. -

Help with thread size understanding and selection

DonInReno replied to Mhicks's topic in Leather Sewing Machines

Although not for everyone since it's a bit of a gamble as to quality and delivery time, there are some thread sellers shipping from China with rediculously low prices and estimated delivery times in months rather than days that would be an inexpensive way to get a variety of sizes. I ordered a half dozen spools of seldomly used thread and to my surprise it arrived the next week and is above average quality. My guess is the thread is warehoused in the US in a Free Trade Zone so it technically hasn't been imported until it leaves the FTZ. -

Although not your machine, some Juki's with a pretentioner disk up top on the post only have the disk on the light and medium weight versions while the heavy thread model of the same machine only has the bare post.

-

I'm saving lunch money for a 7 class Singer. With all the machines I've been paying attention to $1,000 might be a great deal if everything is tight - few well sewing 7's sell that cheap. However it might be over priced - worn out in many areas, have cracked or poorly repaired parts, and may require $100's just to be a mediocre sewer. Not to kill your enthusiasm, but in some ways if you have to ask, then you might be better off learning about the various models and how to evaluate and value machines before feeling like you have to decide quickly on a machine you know little about. There will always be a deal just as good down the road. Unless a machine looks perfect when inspected closely and will sew perfectly the day I'm looking at it, it's worth no more than half of what the machine would normally sell for. At least that's my rule of thumb. Edit: The owner obviously doesn't think much of it since the table seems to be more of a work bench, and the weld on the hub of the pulley looks half ass. You are buying it from a photo so it's going to be boxed up by someone who I wouldn't trust knows how to do it properly so there's only a 50/50 chance it won't be damaged in shipping so in my mind that reduces the price in half again. Don't fall into the trap of relying on shipping insurance - you won't come out on top if the box its shipped in isn't rated for the weight, and/or cushioned properly, and especially if the seller requires you to arrange for shipping pickup/insurance while relying on his packaging skills. Good luck - if you get it hopefully it's a great machine!

-

Show & Tell: 3-D printed corner supports for sewing table

DonInReno replied to Uwe's topic in 3D Printers and Lasers

That's the coolest thing I've seen all week! -

Yes, I think some kind of extra hold on the bearings is a good idea. I'd like to still be able to pull the covers without having to heat them up to release something like loctite so....IDK. I'll probably peen the aluminum to close up the bearing recess a little to a stiff slip fit and not worry about it. As for the reducer I picked up, the next one will be a smaller size - the o75 size is rated for about 50 ft-lbs of output torque - much more than required. The ratios available are 1:3 to 1:100 and 1:5 is probably a better choice as well! Lol There are literally hundreds of variants of this reducer - many of which would be hard to retrofit, so it's pretty important to at least see the input and output.

-

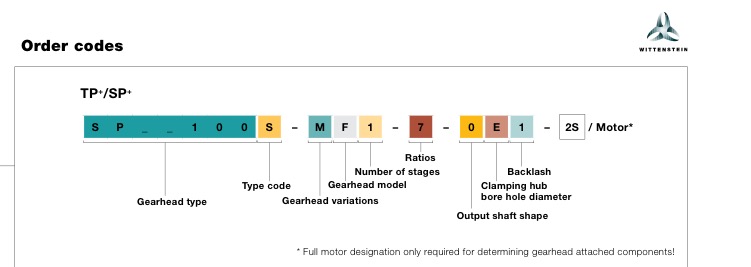

To make sense out of these reducers there is a lot of documentation in the 454 page catalog! Basically I picked up a rather ordinary middle of the road model.

-

A scrap of 1/4" aluminum large enough to mount to the motor that will in turn attach to the factory spacer on the reducer was a whopping $ .40 and a bronze sleeve that will be bored out and pressed on the motor shaft was another $3. This motor is not in any way bullet proof! Just looking at the thing cracked the fan shroud and the front cover that supports the input bearing is not confidence inspiring - definitely too thin to mount the spacer to, so the four screws holding the bearing retainer in place will also be the attachment points for the 1/4" aluminum plate. The bearing retainer bore must be cast .003" -.004" larger than the input bearing - at the slightest bearing roughness this is sure to be the end of the motor as the outer bearing race eats and wobbles out the retainer - hopefully it squeals a warning before spinning the bearing. Having said that there's no reason this motor can't run indefinitely as long as it's not overheated damaging the coils and the sealed ball bearings are replaced at the slightest sign of roughness. There are no brushes or other moving parts.

.jpg.d60258221c476480a6e073a8805645bb.jpg)