-

Posts

794 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by DonInReno

-

I’m a big fan of Douglas fir and framing lumber can be an inexpensive way to build all sorts of furniture, but it can’t be used right off the shelf. When framing lumber is kiln dried it’s moisture is in the 16% range. “Sun dried” is between 16% and 19% and “green” lumber is 19% or more. After Doug fir aclimates to your house it’s probably in the 9% to 12% range depending on how humid your particular house is. To get lumber that’s at equilibrium with your house you can simply buy lumber and store it for a number of months until it stops shrinking and you can cut and glue it nice and flat and it will stay that way. The easiest way I know to keep tabs on the wood is to simply measure once a week or month with a dial caliper on both ends and the middle. You’ll see the ends dry out much faster than the middle. If it dries out too fast the surface will develop checking (cracks) - if this is happening coating the ends with melted wax and maybe even loosely wrapping the boards in plastic. Eventually the boards will stop shrinking and they are ready to use. Another source of dry framing lumber is in the classifieds or at a surplus building supply store. Something that’s been around for at least a year is safe. More and more people are interested in recycling and there are great deals on some very nice wood. Edit: this 6’x6’ table is built with framing scraps and a couple layers of 5/4” ply as a base for a tile top. I selected straight grained scraps as they were available and coated them with a layer of varnish and simply set them inside the garage....about 9 months later they were stable and ready to be cut.

-

Even kiln dried framing lumber has much more moisture than it will have at equilibrium with the conditions in your house. It will shrink, twist and warp a considerable amount. If you stacked that same lumber under your bed or behind the couch for 6 months so it has a chance to dry out then cut and glued it up flat it would turn out just fine.

-

Yet another which machine to buy topic

DonInReno replied to katit's topic in Leather Sewing Machines

That’s a great first machine! -

The easiest and most expensive will be a place that sells rough sawn hardwood lumber to the public. Most towns of any size will have such a supplier. They might have a short piece with a little cup to it that’s essentially worthless as a countertop, but would be cheap - like $50. Normal price would be $100 for a top with short pieces glued end to end and probably $150 for all full length strips of wood. Walnut would be twice that. These hardwood suppliers, local cabinet shops, and even some tile stores that stock butcher block will buy from a regional mill that cuts and glues the tops. These mills will have a number of scratch and dent returns and tops that have cupped a little....many will simply get thrown away especially if they have any kind of customer applied finish. These places will have multiple wood species and in addition to counter tops they’ll make butcher block game tops, bowling alley lanes, prison beds, etc. Looking for deals if someone doesn’t have anything for you always ask if they have any advice for who might.

-

V belt or the link belt for servo motor?

DonInReno replied to myjtp's topic in Leather Sewing Machines

The belts used for most industrials is a “3L” type. The 3 means it’s 3/8” wide and the L stands for light duty. At a hardware store, auto parts, or even online the 3L will be followed by a number which is the length in inches. So a 3L320 is 32” long. 3L325 is 32-1/2” long. Some brands are quite smooth and some have a lump or two if that’s an issue for you. -

Do you have a picture of your table? What kind of budget do you have? There’s a thread that’s not too old down on the list that has a lot of custom tables. There’s nothing wrong with refinishing a top if that’s the look you’re going for. A plywood top with a little finish is functional, but it looks like a plywood top. If you keep your eyes open for second hand butcher block it can be cheap for a 4’ section - or even free. My day job involves remodeling a lot of kitchens and clients seem to think there is a lot of value in the old butcher block, until it sits in their garage for a week and none of their friends want it then it seems to go into the dumpster or one of our guys use some of it for a work table top. Heck, if you lived closer I have a piece I’d give you. New maple butcher block can probably be had for $100 or so - maybe even less if it’s a scratch and dent piece. I’d try to find a regional supplier and simply stop by the shop where they glue it up and ask if they have any 4’ chunks you could buy for cheap.

-

Good to know....it’s addd to the list to Santa. :-)

-

COBRA class 26 sewing machine.

DonInReno replied to ComputerDoctor's topic in Leather Sewing Machines

It sounds like you’re sorting through a lot of information and gaining a better appreciation for the capabilities and limitations of various machines. The downside to trying to find an all around machine is that it’s not great at either extreme and no one machine can do it all. Even trying to use a machine at the ends of its capabilities often requires more than a few minutes of readjustment or replacing feed dogs, needle plates, presser feet, etc... The bright side is you almost can’t go wrong. No matter what your first machine is, after a few months you’ll know exactly where it comes up short and what the next machine should be. -

I’d have to have some sort of speed reducer - perhaps something compact like on a Sailrite, or a well thought out compact 2:1 model with a largish 1000w servo.

-

What size needle?

-

Thanks guys!

-

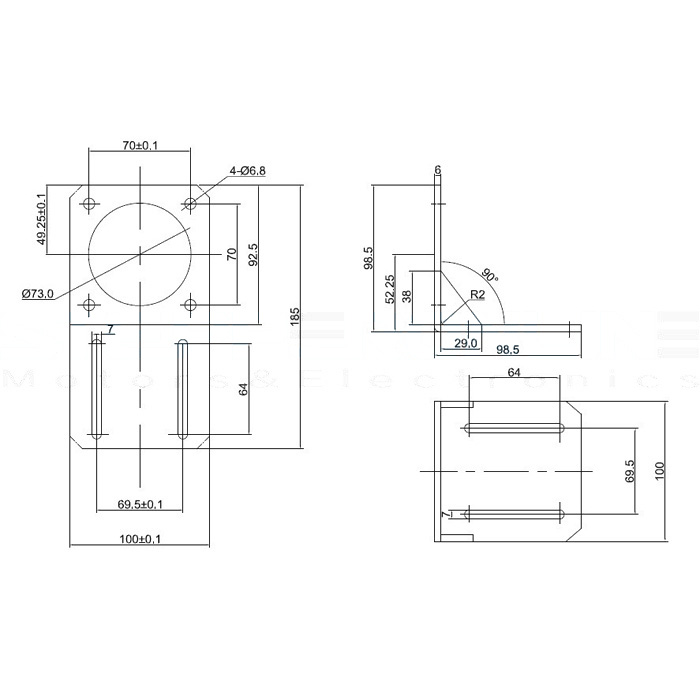

I’d love it if there’s enough room on the front cover to match a NEMA 27 or 34 hole pattern. The distance between the mounting holes is....wait for it.....2.7” or 3.4”! Lol this looks like a nema 27 bracket and the other is a planetary reducer that fits a NEMA size servo motor

-

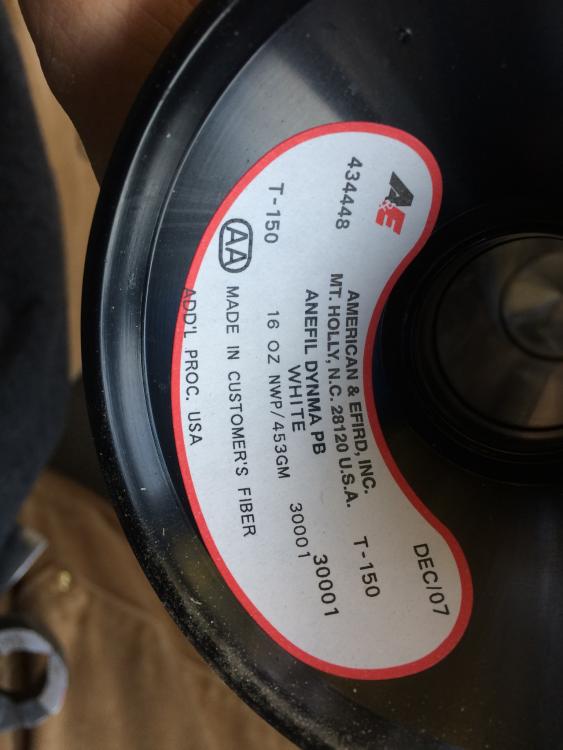

At the local industrial fabric store I spotted a new case of thread labeled “Kevlar $24/lb”, so it peaked my interest enough to grab a spool. Well, looking at it closer at home it’s obviously Dyneema, which I knew nothing about. Turns out it’s the same as Spectra and is the fiber used for winch cable replacement ropes. Super tough. Also super slick - knot strength is a problem and much more back tacking is required to secure a stitch. Some claim a lot of UV resistance, but destructive testing of climbing gear at Black Diamond shows it looses strength about as fast as Nylon. Then I’m imagining using it in some application a larger thread is normally used....and an article comes up saying it’s extra strength doesn’t do a lot of good because the Dyneema cuts through Nylon fabric before the thread breaks so it’s best use is when sewing Dyneema fabric or webbing. Well crap. Lol It melts at 300 degrees F so it’s nothing special in that regard. It’s also hard on scissors - this is what many cut-resistant gloves are made from - one drawback to being very abrasion resistant! Breaking strength seems to be somewhat mysterious - a few sources claimed breaking strength is low because it’s down rated to reflect knot strenth. Others claimed it’s twice as strong as nylon. Well my Dyneema Tex-150 breaks at 50 lbs. and on the same scale a good quality 138 bonded nylon breaks at 40 lbs - not as big a difference as expected. It’s still cool - maybe someday it will have a good use.

-

At least with guitars and dial micrometers, not everything shipped from China have tags that say made in China. Lol I’m sure if someone buys enough machines they will put whatever you want on the tag :-)

-

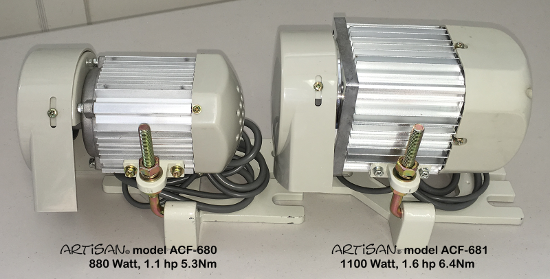

I’m kind of excited about this servo - is it just me or does it appear to have a squarish body as if it or a variant using the same form factor is perhaps NEMA sized to directly bolt up to a geared reducer?

-

Are expensive whet stones worth it?

DonInReno replied to Artificial Intelligence's topic in Sharpen it!

A few years ago I ran into some images taken with an electron microscope showing what’s going on when we sharpen a knife blade and it really changed my perspective. This is just an example of some of those - the factory new Victorinox edges are pretty sharp in use, but the edge sharpened by a professional knife sharpener on stones is even better. The scalpel blades are interesting https://scienceofsharp.wordpress.com/tag/knives/page/3/ check out how the removal rate of different stones and how coarse stones need additional pressure or they don’t take off more metal than finer ones! https://scienceofsharp.wordpress.com/2016/12/21/abrasion-rate-vs-grit/ -

Of course an ideal fix is to strip it and braze or hard silver solder the part back on, but you will have to repaint the bed. As a quick fix to get it up and sewing I’d pull the bushing, degrease the bushing bore and outer part of the bushing and use a good quality epoxy to glue in the bushing and the loose part. There appears to be fairly good surface area and a high strength epoxy would hold quite well if you can get the oil impregnated bushing clean enough to bond. As with super oily wood, a final degreasing wipe with accitone immediately prior to assembly is your best bet.

-

singer 111G156 removing the handwheel

DonInReno replied to davemac2's topic in Leather Sewing Machines

Awesome! -

Very nice!

-

Great pictures - very nice indeed

-

Got a Pearson #6!!!! wee hooo!!!

DonInReno replied to plinkercases's topic in Leather Sewing Machines

Very nice machine - a lot of history there! If anyone hasn’t walked through a well stocked motorcycle shop, there are now synthetic lubes of all kinds available there from thick and sticky to thin and runny - even packaged in rather small quantities. Reading a few packages it appears each is a miracle cure for something.... -

singer 111G156 removing the handwheel

DonInReno replied to davemac2's topic in Leather Sewing Machines

This normally works best with replaceable screwdriver bits, but with the deep hole if you have a second well fitting screwdriver you don’t mind sacrificing, by cutting off the handle, placing it correctly on the screw slot and giving it a moderate hammer love tap, it will most likely free up the screw. It has to be metal on metal to shock the screw - hitting a plastic handle doesn’t do much. I’m trying to think of an example of how much force to strike it with....breaking open a walnut is too much and cracking the shell of a peanut is too little.... This technique is used a lot by gunsmiths. As for heat -if you don’t have a torch even heating the entire handwheel with a blow drier until it’s too hot to touch will slightly expand it and take a little pressure off the screw. -

Do all Singer 111W155 machines have a walking needle?

DonInReno replied to CEA's topic in Leather Sewing Machines

It may have been repainted once or 10 times - safe to say it’s somewhere between in good shape and worn out. Multiple tapped holes are most likely left over from its previous life in a factory setting where these machines are run all day year after year and many parts are most likely not original. The modified presser feet setup may be nothing hard to fix or it may be a result of a broken part - you definitely want to make sure everything is intact at that price. Basically I’d say the table and motor are worth no more than $50. The machine may very well be worth the asking price, but it’s a matter of wear at all the metal to metal parts and the condition of hook and tension assembly in addition to any broken or missing parts. Personally I’d think it’s worth no more than half the asking price since you don’t aren’t in a position to assess level of wear unless someone can convince you otherwise.- 21 replies

-

- 111w155

- needle feed

-

(and 1 more)

Tagged with: