kgg

Contributing Member-

Posts

3,344 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by kgg

-

I would either i) go to their ebay store and contact them from there and see if they still can supply. ( https://www.ebay.com/usr/duckcreektraders ) ii) find someone with a 3D printer and have it replicated. kgg

-

Weird and frustrating obstacle Setting up shoe patcher

kgg replied to Annikita's topic in Leather Sewing Machines

That is why I fondly refer to them as a " Tinkers Delight ". They do have their place but you need to be willing to put the effort into getting them running right and presentable. kgg -

Why not build your own and save a further couple hundred dollars??? Example: Bench Grinder $139 at https://www.harborfreight.com/power-tools/grinders/bench-grinders/8-in-variable-speed-bench-grinder-with-led-work-light-59300.html Stand: $49 at https://www.harborfreight.com/universal-bench-grinder-stand-59196.html or $59 for a pedestal at https://www.harborfreight.com/bench-grinder-pedestal-68321.html Sanding wheel and burnisher can also be purchased just depends on the diameter of the shaft of the bench grinder. kgg

-

Enduro Servo Motor voltage requirements, 220v not required !?!

kgg replied to Dave9111's topic in Leather Sewing Machines

My suggestion is that you unplug them. If they are not plugged in there is no potential of a fire hazard. If they are not ULC or CSA approved and should something happen you may run into a problem with your insurance company. kgg -

You forgot to mention what size of needle you are using. You should be probably using a #25 or #26 needle depending on how thick and tough the leather is. Also another alternative is rather then starting at the very beginning of where you would normally drop in the first stitch is to move forward about three stitches and reverse back to the normal starting point then start your forward stitches. That way you reduce the amount of thread (stitches) in the holes down from three to two yet the stitches are locked. At the other end just back stitch three stitches and end there. kgg

-

@dikman nicely done. Necessity is the mother of invention. kgg

-

Thank you for the comparison it is helpful and shows it pays to shop around. You maybe a "broke dude" but I'm a cheap "old geezer". Why pay more for the same item particularly these days. kgg

-

It is a quick cross reference of the more popular machines that are or have similar operating specifications. If I'm not mistaken your Pfaff 145 is an older version of the 545 and the latest version being a Pfaff 1245. Thanks for sharing the quick cross reference. kgg

-

Sorry to hear that but she should really like the dragon. Nice work, great detail. kgg

-

I haven't tried this myself but maybe an old fashion Singer 15 might be able to sew the wrench rolls if you use V92 and a basic sewing design. They can be had for very cheap might be worth a try. kgg

-

I would suggest it would be easier to do on a flatbed like @Wizcrafts noted. I use my Juki 118n for 20 oz canvas. I would also suggest using V138 rather then V92 also the hole that the needle of your 441 makes maybe is going to be more noticeable then that of 135x 17 needle. kgg

-

In Ontario a 22kw(propane)/ 19kw (LG) Generac is about $7500 at Homedepot but...then it will cost another 10-12k for installation (site location /preparation) / approvals (electrical / propane / township / protected lands / insurance) / inspections (electrical / site / propane) for it to be allowed. Other then the site preparation most people are at the mercy of the certified electrical / propane contractors that will be needed. A neighbor last summer had one installed and said by the time it was all said and done you couldn't buy a pack of smokes out of the what was left over from 20K. The way around this for a lot of us is a portable 10kw multi fuel generator (gasoline/propane/LG) for about $2500 installed in a prefab 100 square foot shed for about $1000. The drawback is you don't get auto start / auto transfer. kgg

-

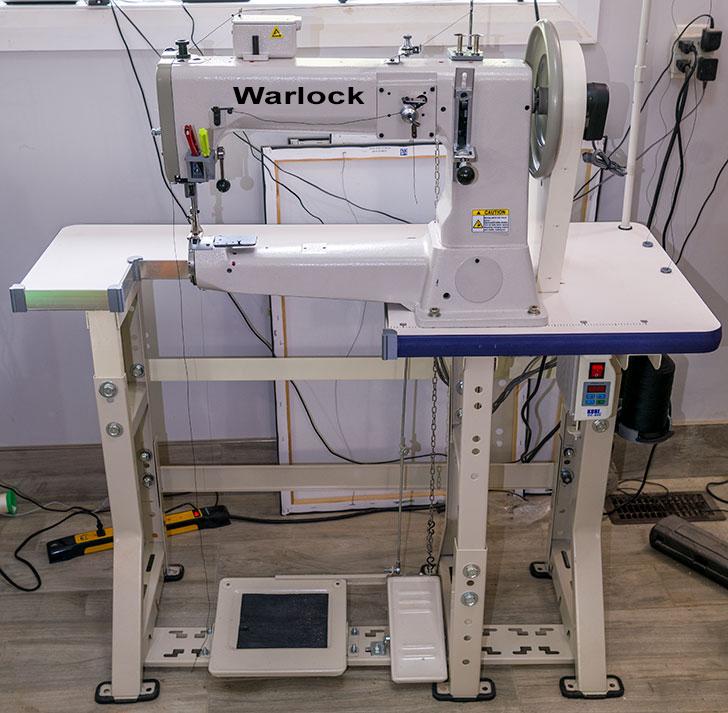

This is a high speed machine made for sewing fabric and is only a drop feed with a max thread size of V92. It may very well sew very very thin leather but I wouldn't bother. The price is OK but adding a servo motor to get good speed control is going to add another $200 CAD which could go towards another machine made for leather. How thick of leather are you planning on sewing and in what thread size?? kgg

-

Having a generator is a must when living out in a rural area. Last summer I had to replace my Briggs 10,000 watt whole house generator. I did look at the Generac generators but $20,000 wasn't in the cards. The old generator finally gave up the ghost and to repair it would have cost more then a brand new unit. The old one had 930 hours run time on it so I didn't feel to bad. This time I got smart and built a generator house with AC lighting, DC lighting and with my batteries on flood charge all the time. No more standing outside during a snow storm, wind storm or pouring rain. Open the shed door, turn the DC lights on, start the generator and way to go, comfort. kgg

-

Well that was a waste of time mostly for you. Sounds like great consumer service, NOT. kgg

-

I should clarify my suggestion on the front edge angle iron. I am assuming you are planning on cutting out a fairly large section with the base of the machine sat on the front to back edge just under the machine. That would mean the edge of the plywood would be unsupported. That is where I have seen sagging. I solved that potential problem when I moved to the 441 by adding a extra leg directly under the center of the machine. If possible go to a industrial sewing machine repair shop as they typically have old table setups. They usually sell the bits and pieces like the complete frame or individual parts like the pedal and cross member pretty cheap. I usually pay about $50 CAD for a complete frame. kgg

- 181 replies

-

- diy sewing table

- industrial sewing table

-

(and 3 more)

Tagged with:

-

I would suggest that before you go installing another shuttle assembly first make sure the original setup sews properly first. When in the reverse the needle drops down into the same holes made in the forward motion. The best and simplest way is with a sheet of heavy paper and without the needle threaded. kgg

-

The metal frame looks really good. A couple of things to keep in mind: i) Why are you installing casters?? Unless you are going to be moving it around a lot they maybe a waste of effort and if you decide to install them install the lockable style. ii) The table top needs to be 1.5 inches thick so I would suggest doing your cutout for the machine base first in the top 3/4" piece of plywood then glue the bottom layer of 3/4" to the top layer. Remember the grain of the mating surfaces of the 3/4" plywood have to be 90 degrees to one and another to get max strength. iii) You may want to consider welding a 3/4" x 1/8" tick angle iron stiffer across the front to prevent any table top sage along the front edge. I have see some tables that had a bow in the front. kgg

- 181 replies

-

- diy sewing table

- industrial sewing table

-

(and 3 more)

Tagged with:

-

I’m losing hope with my consew 206RB-5 and I need advice.

kgg replied to Tsiatko's topic in Leather Sewing Machines

A couple of questions: i) What size of thread are you using?? ii) What size of needle are you using?? iii) How thick is the leather??? iv) Are you using an edge guide?? If I'm not mistake the Consew 206 RB has similar specs as the Juki 1541S (compound feed). My 1541S hates anything under say 4mm particularly soft items that can be pushed down into the needle plate opening. For those type of items I use my Juki 1181N (walking foot) but on occasion have placed a sheet of paper on the needle plate side of the item to help stiffen things up. kgg -

Cobra class 4 foot pedal: Thread Release

kgg replied to DieselTech's topic in Leather Sewing Machines

I would try handwheeling so the thread arm is at the top of it's cycle. Looking at your photo I am thinking that some of your problem maybe the thread is not seated properly between the top tension discs. I would suggest looking at this video on threading a Cobra 4 ( https://www.youtube.com/watch?v=6tCzNuj4bvQ Notice the difference in your thread in the top tension discs, yours is the first photo. kgg -

#25 narrow needle plate & feed dog install/adjustment

kgg replied to DieselTech's topic in Leather Sewing Machines

I would suggest checking the engineering manuals that came with your machine. If none were supplied I would suggest 1) call Leather Machine Co. 2) refer to the Juki TSC-441 Engineering manuals or call the supplier of the needle plate / feed dog. kgg -

I would email the company and ask for instruction. kgg

-

Have considered using Velcro rather then the snap??? kgg

-

I can see a die cutter would be faster but like @AlZillaI also don't see how that will eliminated the stretch problem. Have you tried a slightly larger hole for the ring snaps and using a lever press???? What are the items going to be used??? kgg