kgg

Contributing Member-

Posts

3,372 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by kgg

-

While doing a quick search on Alibaba for a drop feed cylinder arm sewing machine similar to the Seiko TF-6 I found an interesting yet concerning link. Link: " BRAND NEW Techsew 5100 5200 ALL MODEL Fully Loaded Package 16 Cylinder Heavy Duty Compound Feed Industrial Sewing Machine " ( https://www.alibaba.com/product-detail/BRAND-NEW-Techsew-5100-5200-ALL_11000016761112.html?spm=a2700.galleryofferlist.normal_offer.d_title.6d9266556GfEav ) Supplier: Rising Star Productions out of Nassau, Bahamas ( https://bs29080611782rwqr.trustpass.alibaba.com/index.html?spm=a2700.details.0.0.6a006370bQzG2H&from=detail&productId=11000016761112 ). On the Rising Star Productions page they also listed Techsew 4800, 2600, 2750, 810, 830 and SK-4 @Techsew Ron this maybe of interested to you. kgg

-

The Seiko TF - 6 was a left handed machine drop feed machine using a max thread size of V92. I think this series has been dropped and now the right handed drop feed machines are the only ones available now in the TE series which also have a thread max of V92. Have you considered maybe a post bed machine????? I did a very quick search on Alibaba and could not find a drop feed cylinder arm. kgg

-

Most all of us are subject to some form of legal system not a justice system. You are lucky up here in Canada we have two legal systems that try and co-exist as we have two official languages (English and French) common law and civil law that try to co-exist together. About all you can really do is keep your individual data footprint / exposure to a minimum, like social media platforms. There's always going to be bad actors out there. kgg

-

Good info. Lucky you did spray that through the gun. kgg

-

Go with the info in the original post or contact Tecmic ( https://www.tecmic.co.jp/en/ ) directly about the age and spec for this particular model. Personally when you consider the cost I wouldn't bother, machine $600 USD which is about $825 CAD plus a servo motor at about $200 CAD plus another $200 for a table / operating pedals / miscellanenous parts/ etc you would be over $1200 CAD. Why not contact companies that do repairs to industrial sewing machines like Manson in Vancover ( https://www.masonsewingmachine.com/ ). Most upholstery class machines machines can do 3/8" of material. Since you are looking at a cylinder arm style Tecmic you really I think should be looking at machines like Juki LS-341 / LS-1341 and clones. What is you budget as there maybe other options that would suite you needs like a one armed bandit. kgg

-

No longer available. kgg

-

The Juki LS-341 takes a "M" style bobbin and the Cobra takes a "U" style bobbin. To that end there are differences which maybe minor but the OP did mention that he was told by LMC it was a hybrid of Juki and PFAFF. I don't know of any PFAFF's that take a "U" Style Bobbin while the Juki LS-341 and 1341 take the "M" style bobbins. kgg

-

A couple of questions: i) does your machine have a speed reducer or just one belt from the head directly to the motor?? ii) does your machine have a clutch motor or a brush servo motor or brushless electronic servo motor??? iii) what size of motor? A couple of photo's would help clear up your particular setup and narrow down possible solutions. kgg

-

The Tandy Outlaw is a re-badged Cowboy Outlaw done for Tandy. Within the one arm bandits you also have the Tippmann Boss which maybe a consideration for you. For holsters you need a class 4 by rights similar to the manual Cowboy Outlaw or motorized Cowboy 3500/4500 machines but the other items you could more then likely get away with a Class 341simialr to the Cowboy CB341 machine. Then there is the used market for both the manual and the motorized machines. Maybe there is something in the used section of the forum. kgg

-

Since you mentioned a class 341 clone, Cobra Class 26, I would suggest looking for a used Juki LS-341 / Juki LS-1341 or clone. It really boils down to determining: i) what do you want to sew ii) your budget. From those and your location machine recommendation could be suggested. kgg

-

I have not used that particular one the Consew 206RL. It is a portable walking foot machine the same or similar to all the other Sailrite type clones. Like the others in this class of machine it has a small Singer Class 15 bobbin, the amount of material you can fit up the presser foot is very limited, stitch length consistency will depend on the thickness of material being sewn and typically a thread size maximum of V92. I think you would be much better of getting either a good used or new industrial sewing machine. These machines are better suited to doing repairs on sail material. Whether you go with a cylinder arm or flatbed will depend on what you want to sew. kgg

-

Great Info. kgg

-

My thought is that's probably a good idea. kgg

-

Excellent point. kgg

-

That is too bad at least you got a few good deals before they closed. Did they give a reason for the closure or any news about the other two stores? kgg

-

I have seen too many client dogs over the years that died a horrible death as a result of them ingesting stuff like hand towels, ladies stockings, socks, human incontinence pads, pet incontinence pads, rubber toys, rope, rocks. Some dogs can expel some items with no problems while others can't and by the time you figure out that they can't it's sadly already to late. Just my experience, kgg

-

You need to look at this thread chart to needle size ( https://www.tolindsewmach.com/thread-chart.html ) V69 use #16 or #18 V138 use #22 or #23 V207 use #24 The Singer 211G156 can handle a #22 needle so it can do up to V138. When sewing in fabric use 135 x 17 needles for the leather straps probably best to use 135 x 16 needles. kgg Singer_211G155,_211G156_Service_Manual-1.pdf

-

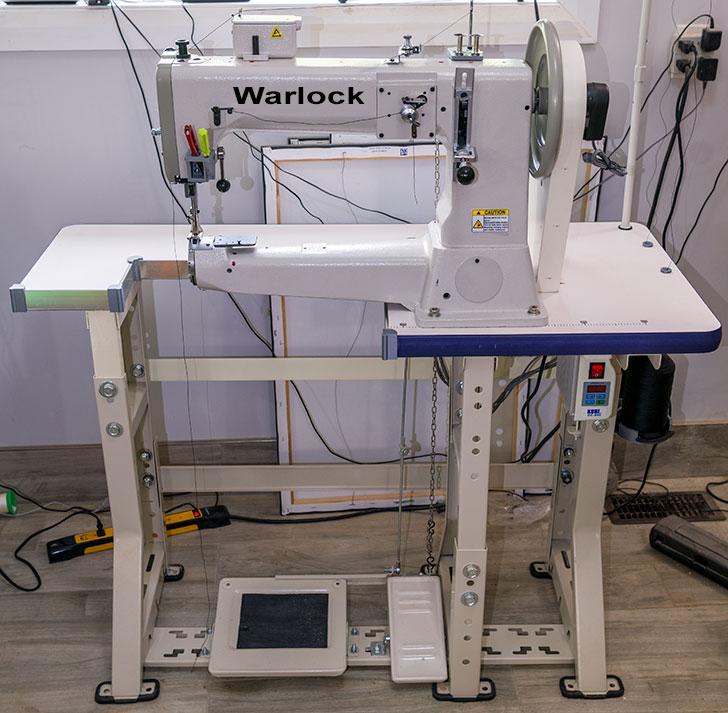

If you really need the ability to move the table up and down I think the only real option would be some form of hydraulic lift, mechanical hand pump, air over hydraulic or electric over hydraulic. The down side to being able to move the machine up and down at will is you will have to come up with a method for activating the foot pedals rather then the typical mechanical method ( rod or chain ), maybe using electric controls. Also: i) If you are going to cut the table top it will reduce the max capacity of 300 lb down so you would need to do the calculations to figure out by how much. ii) Looking at the spec for the table top on the homedepot table, the top is only 1.2" thick. It really should be 1.5" min. iii) Another option for making your own table would be go to a sewing machine repair shop and see what if they have a used table frame. When I need one I usually pay about $60 CAD for the complete frame. kgg

-

Call your vet. The dog probably will require surgery depending on what an Xray shows. One of my guys had to this type of surgery. kgg

-

Yes and they wonder why a lot of car sales people and dealerships are not respected. Wish they got rid of the stealerships all to together and let the customer deal directly with the manufacturers and have factory approved service centers. It would be more profitable for the manufacturer, less cost for the customer and no stealership markups for BS items or market adjustments. What this stealership didn't realize they not only lost out on a rental, no big deal just a couple hundred bucks, they lost out on a new car sale as well. I am planning on purchasing one within the next year. Now I am wondering whether I am even going to buy one of that manufacturers vehicles. kgg

-

I needed to rent a cargo van like as I needed to pickup 9 sheets of 4' x 8' HDPE. I figured I would rent one from a local stealership who over the years sold me two new cars. They had one, price was OK and offered full coverage so if anything happen all I needed to do was pass the keys back if anything happened to the vehicle. So far things sound good. The dirtbag said the truck is out front, I've check and noted the couple of scratches on the form. Give me your license, credit card and sign here. Hold on now, lets see the truck first. He noted maybe three dings on the form while I noted at least 20 with my cell phone. He was not a happy camper to see me haul out the cell phone nor I. I said lets see the rental form. The two copies were different. One form had me responsible for the full value of the truck should something happen and the other form noted $5,000. Neither was what I wanted. I said this is wrong so fix it as I wanted full coverage. The dirtbag said this is what we offer. I said "Have a nice day and this will be the last time I ever come to this stealership." There was a couple of colorful words added to that sentence. I would not want to be a buyer if they pull $$$$ like this on a rental. I drove up the road and rented a cargo van from UHaul who were very professional. If you ever need to rent a vehicle always check and note with your cell phone anything wrong on the vehicle both inside and outside but most importantly check the paperwork. That's my rant for today. kgg

-

From the info, last photo, I have seen your machine is going to be about the same weight as the Juki TSC-441 and clones around the 125 lb range. Base on the weight I would not go with the "U" style table unless you brace the machine with a third "K" leg right under the machine. For my machine I did sort of a hybrid of the "U" . What I done that may give you some ideas: i) I used a standard industrial "K" frame and table top then I added a third "K" but turned the third "K" leg backwards and placed it directly under the center of the machine. The third "K" leg ensures no possibility of the table top warping / bending and gives better stability. ii) Then I cutout a section of the table top and made other mods like extra cross bracing and relocating the thread spools to underneath the table top. Like @bruce johnson I like sewing being sat down whether using a flatbed or a cylinder arm machine as I find it more comfortable and better foot control of the "go pedal". kgg