kgg

Contributing Member-

Posts

3,352 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by kgg

-

Manual Strap Cutter Machine: Opinions/Recommendations

kgg replied to DieselTech's topic in Leather Machinery

Looks like it does a nice job. All you need to do now is change the hand crank to a pulley and strap a servo motor on. kgg -

I use a 3" round sanding disc and a wooden burnisher disc on a viable speed bench mounted buffer I got from Princess Auto. Works decent enough for my needs. kgg

-

Like @northmount said you should checkout that link and NO the groove side of the needle needs to be on the Left. You never said what type or size of needle you were using with what size thread in how thick of material, leather or fabric. If you are sewing leather you need the correct size of needle a 135 X16 in the correct size and for fabric you use 135 x 17 needles. There are a lot of other factors that can cause a machine to not sew or sew properly, top threading path to the needle, thread tension, how the thread comes off the bobbin, incorrect needle installation to name a few. It would be nice to see some photo's of how you threaded the machine from the thread spool holder to the tip of the needle. Chances are this is a simple problem that you should be able to solve yourself with the help / suggestions of members here. You should download a copy of the JUKI LS-341 engineering manual as the Techsew 2750 is a clone of the Juki LS-341. kgg

-

Definitely not right. Couple of suggestions: i) Remove the belt from the motor and remove the knee lift. Then hand-wheel it. If the noise is eliminated the drive belt was installed to tightly and or the knee lift installed incorrectly. ii) Re-oil the machine putting oil directly into the bearings and any place the metal touches. When oiling like a bearing move the hand-wheel so that you turn the part you are oiling a quarter turn and re-oil until you make a complete revolution. iii) Check for signs of rubbing of metal parts. iv) I would use synthetic transmission oil around the bearings as it will get into the bearing and provide better lubrication then sewing machine oil. v) Was this machine store for a long time or dropped?? kgg

-

My suggestion would be to remove the thread from the needle and lock the presser foot up. Then give it run to see if the noise disappears. Also have you oiled the head recently??? kgg

-

This link isn't working and here is the message I get when I click on the link: " This content isn't available right now When this happens, it's usually because the owner only shared it with a small group of people, changed who can see it or it's been deleted." Maybe try putting the link on youtube. kgg

-

Time is just a relative thing. Just a little longer for some. Not a pet peeve but more of a chuckle and a half. I sold my Sailrite Ultrafeed LSZ-1 the other day to a guy who drove 5 hours arriving on time. The guy brought his wife along which was fine by me. I had the Sailrite setup alongside the Consew 206RB-5, which is also for sale, in the basement. So off all three of us toddle to the basement door. Both of them liked the Sailrite Ultrafeed LSZ-1 but he really, really liked the Consew 206RB-5. His wife asked what I thought was a simple question "where are you planning on putting the Consew". Without as much as cracking a smile he said "Our bedroom". Well off to the races the misses went, like a firecracker. It got so nasty I backed up to get out of the way. It got so heated he finally ask her in no uncertain terms to go sit in the "xxxxx" truck. The only reason I didn't throw the two of them out was I figured I would sell one of the two machines to him. He bought the Sailrite Ultrafeed lSZ-1. I can only imagine what it must be like in private when the two of them get going based on what they acted like in someone else house they never meet before. I would have liked to have been be a fly on the wall for that 5 hour drive home. You just don't know how people are going to act. kgg

-

Lets have a look at a "Genuine Leather" belt???

kgg replied to kgg's topic in Leatherwork Conversation

Why that doesn't surprise me. I guess they got sucker once or twice. kgg -

If your machine is a Model C or D machine it has a safety clutch. Try resetting the safety clutch. Another problem could be the screws came loose and it put the bobbin gear messing off or a broken tooth. kgg

-

Are you planning on using 90 degree or inline binders??? kgg

-

When it comes to table top attachments I have couple of questions: 1. How deep does the table top really need to be from the front edge to the rear edge? 2. How wide does it really need to be from the needle to the left outside edge? 3. What do you use the table top for? 4. What accessories like guides / binders / etc if any do you use with the table top? 5. What class of machine do you use it on Class 341, Class 441? Hoping for some good discussion / experience. kgg

-

What is your price range???? For holsters you need a Class 441 capable machine like say a Cowboy 3200 or 3500 or 4500. Another option would be a manual machine like a Tippman Boss or a Cowboy Outlaw. kgg

-

Advice on purchasing an Adler 069-373 (used)

kgg replied to Aetolian's topic in Leather Sewing Machines

Good advice. kgg -

Nicely done. Your friend should really like it. kgg

-

Lets have a look at a "Genuine Leather" belt???

kgg replied to kgg's topic in Leatherwork Conversation

Very good advice, thanks. How true. kgg -

Lets have a look at a "Genuine Leather" belt???

kgg replied to kgg's topic in Leatherwork Conversation

I like that. Keep the hardware and throw out the rest. kgg -

Lets have a look at a "Genuine Leather" belt???

kgg replied to kgg's topic in Leatherwork Conversation

And I thought the various sewing thread standards weren't confusing enough. I wonder which marketing genius came up with those misleading terms. To me "genuine" meant authentic and "real" meant actual. I also wonder how many people buy genuine leather and think they are getting decent leather? kgg -

Lets have a look at a "Genuine Leather" belt???

kgg replied to kgg's topic in Leatherwork Conversation

I think around 3 or so months. Which means he would spend about $80 a year for belts. kgg -

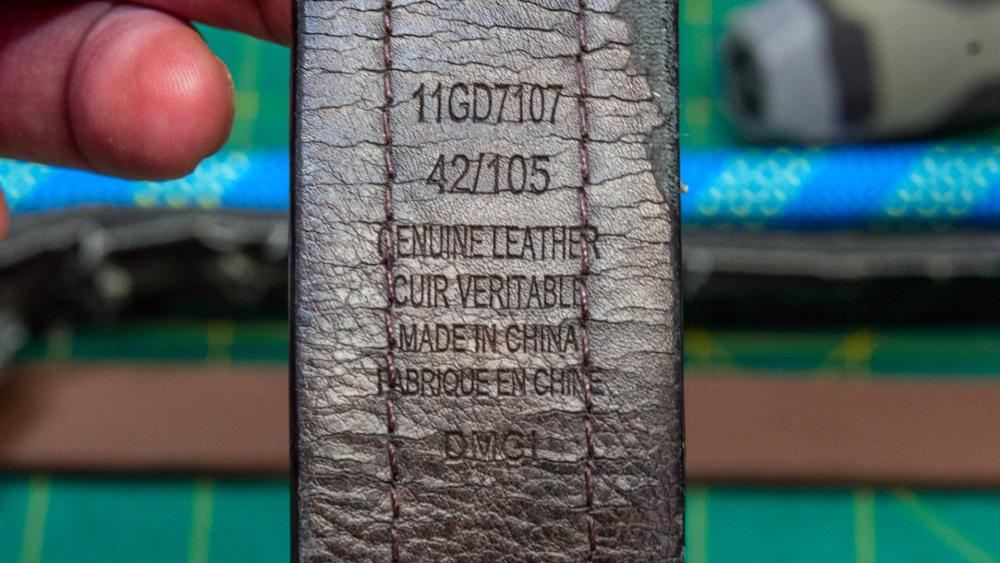

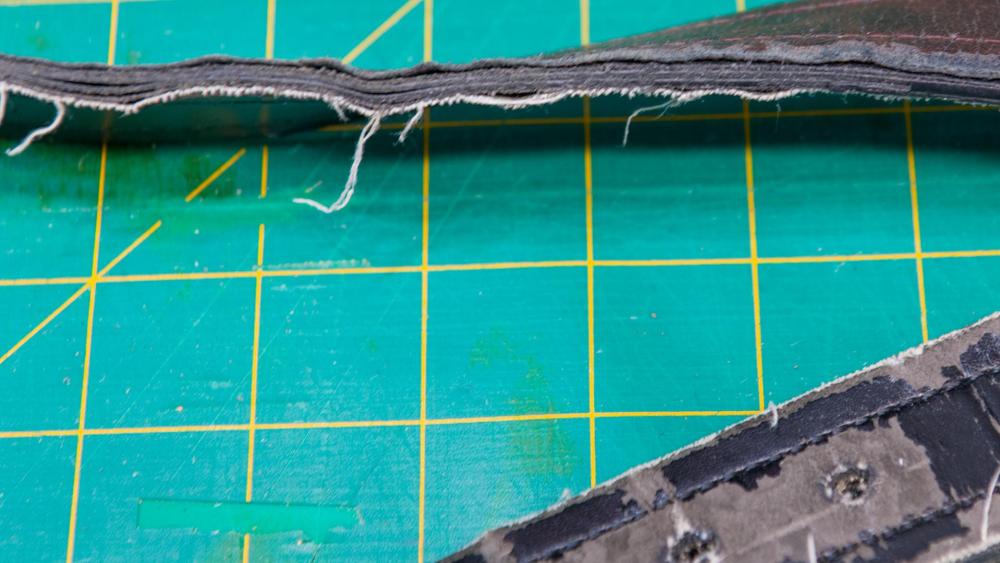

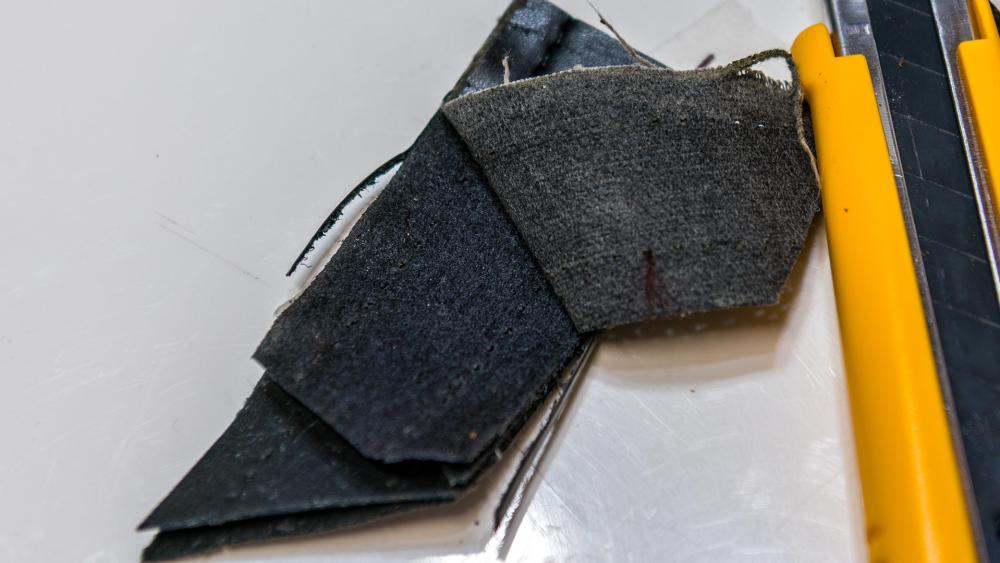

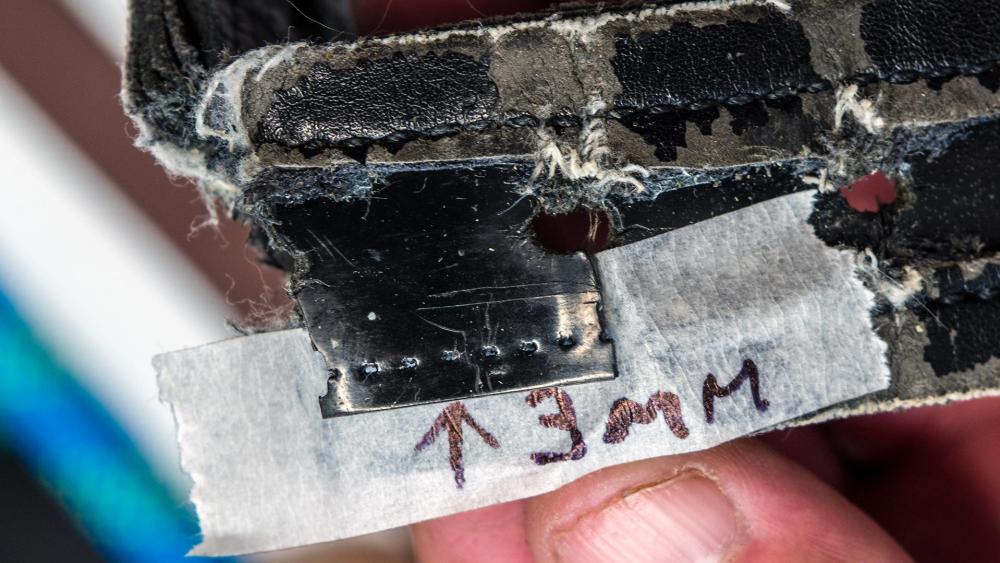

This belt is a "Genuine Dickies" belt made in China with "Genuine Leather". This belt was owned, used and abused on a daily bases by my brother. Lets be kind saying it has seen better days and he got every cents worth of value out of the belt that probably cost about $20 CAD. Needles to say I'm in the process of making him a new belt made out of "real" leather. The only piece that can be salvaged is the belt buckle which is actually pretty sturdy. Now me being me I hated to just throw the belt in the garbage bucket. I first just had to dissect the belt to see how this inexpensive Chinese "Genuine Leather" belt was constructed. i) The belt is 36mm wide and has a thickness of 4.96 mm, according to my mic. ii) The edges are finished with some pliable plastic / rubber substance. iii) The prong holes of the belt are spaced 24mm center to center, according to my mic. iv) The belt did not have a loop keeper. v) There is some form of 3mm thick plastic strip that was sewn in the middle of the layers, probably for stability and longevity of the belt holes, that was installed 18 mm before the first prong hole and extended 18mm after the last prong hole. These measurements were according to my mic. vi) The body of the belt is made up of 6 layers of some form of fabric with the both sides being finished with what appears to me to be some form of fake leather. Each layer was stuck together along with the edge being stitched with V46 or maybe V69 thread. I could not find anything that to me would resembled some form of real leather, chrome tan or veg tan, in the construction of the belt. I guess the bottom line is you get what you pay for. kgg

-

@AlZilla sounds a little suspicious as the owner of equipment is in British Colombia, the OP is another province, phone number is for a cell phone in Calgary, Alberta, not wanting to post photo's and second topic post with same heading. Hum. I could be wrong but.... kgg

-

Things happen on a dime and you don't mind as they are being honest. kgg

-

Ordered a Cobra Class 26 : Couple questions

kgg replied to DieselTech's topic in Leather Sewing Machines

That shouldn't be a problem to do as the hole to put the chain through is already drilled in the table top but you may have to extend the point of contact on the Presser foot lift pedal. kgg -

Ordered a Cobra Class 26 : Couple questions

kgg replied to DieselTech's topic in Leather Sewing Machines

Yes this is a presser foot lever extension to provide more leverage so the effort to rise the presser foot up is reduced. As with all levers the longer the lever is from the pivot point the effort to lift the load which in this case is the presser foot will be less. On most Juki Class 341 clones that don't use the pedestal stand the Presser Foot Lift and Go pedals are or can be adjusted farther back at the base of the stand to take full advantage of the extra leverage the extension bracket provides. The other Class 341clones can also be setup like the Cobra with the Lift Cable / Chain connected inside the base of the machine. The Cobra setup on a pedestal stand will require a little more effort to raise the presser foot. kgg -

Appears to be a Consew 206RB-5. Here is a link to help you: ( https://www.tolindsewmach.com/consew-206rb.html ) kgg

-

The needle is really made for V69. My thoughts: When you made the turn in the top left of your photo the stitch changed from good to bad. When you turn 90 degrees you need to move the leather when the needle is just starting on it's upward movement. Also since the needle is undersized there isn't any room to allow turning without the leather grabbing / twisting the thread and being tight in the needle which then probably throws off the thread tension. The bottom thread knot in the lightest dark color leather if it is 1.2 probably just hasn't got enough thickness to hide the V138 bobbin thread coupled with thread tension going off on the turn. My suggestions: Do a test run with the lightest color leather, I'm assuming it is the thinnest and see if V138 works properly in that thickness of leather. Do a test run with the lightest color leather, I'm assuming it is the thinnest and see if V69 works properly in that thickness of leather. Use a larger needle, #21 or #22 for V138. kgg