-

Posts

604 -

Joined

-

Last visited

Contact Methods

-

Website URL

https://aaleatherbigbookcovers.com/wp/

Profile Information

-

Gender

Male

-

Location

Richland, WA

-

Interests

Books, Bookbinding, Book covers, Guitars

LW Info

-

Leatherwork Specialty

Leather Book Cover

-

Interested in learning about

Leathercrafting

-

How did you find leatherworker.net?

Followed Johanna

Recent Profile Visitors

24,238 profile views

stelmackr's Achievements

Leatherworker (3/4)

-

Found a file that shows how I made the leather binder, over 20-years ago. We were living in Wellingore, England so measurements and sourcing materials were always a challenge. I always felt like I was in a country divided by a common language. ;-) 3-ring_binder.pdf

-

Thanks, great ideas. Currently they are in 3-ring binders, inside Office Depot® Brand Multi-Page Capacity Sheet Protectors, 50-Sheet Capacity, 8-1/2" x 11", Clear, Pack Of 25. The whole leather magazine fits inside and are in various 3-ring or adjustable 3 post binders. Some are in binders I designed and tooled with designs on front and back along with embossed contents on the spine. There is something about the paper magazine the appeals to me. And the ability to tool designs on the covers. Thanks again for the ideas for the electronic storage. I'm closing in on 80-years old and not sure I have the time to scan all the magazines ;-)

-

Thanks, great ideas. Currently they are in 3-ring binders, inside Office Depot® Brand Multi-Page Capacity Sheet Protectors, 50-Sheet Capacity, 8-1/2" x 11", Clear, Pack Of 25. The whole leather magazine fits inside and are in various 3-ring or adjustable 3 post binders. Some are in binders I designed and tooled with designs on front and back along with embossed contents on the spine. There is something about the paper magazine the appeals to me. And the ability to tool designs on the covers. Thanks again for the ideas for the electronic storage. I'm closing in on 80-years old and not sure I have the time to scan all the magazines ;-)

-

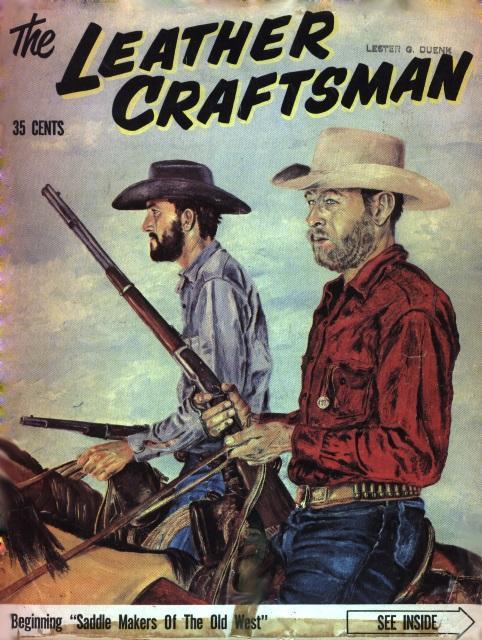

Over the years I have collected the Leather magazines from the first issue to the current Leather Crafter's Journal Jan/Feb 2025 (most all retained their Pattern Pull-Out section). My question is, do other leathercrafters collect them and how do you store them?

-

This: https://www.ebay.com/itm/225185301503

-

Google says: https://archive.org/details/TM10-3530-202-24/page/n7/mode/2up

-

Greetings, Here is what I use to emboss words, letters into Veg Tanned leather. I use this method because a LOT of my work involves letters: https://drive.google.com/file/d/1GLfvsGGEUyjaOgc1dJr75GgUTDiegBah/view ...and an older version https://drive.google.com/file/d/1qgV6aH_FkHa5lBX_kNceroW2elQju_XW/view?usp=sharing Hope this helps

-

I have similar Christmas story. About 35-years ago, I thought a Leather Bowling Bag, for the wife, with those fancy scrolls and lettering would be just the right ticket. I went to all the bowling establishments and all the sporting goods stores around and all they had vinyl or canvas bags and none looked like what I had seen at some bowling tournaments. How was I to know that all those Leather Bowling Bags were all handmade So, I I went a Tandy store near Mountlake Terrace, WA, just north of Seattle to see if they could direct somewhere to find them. Low and behold, as I walked in I saw a bowling bag kit on sale for $25 (or $50, I forget) that I figured I could put together. How hard could this be for a Software Programmer? Anyway, after purchasing the basic beginners kit (basic 7 stamping tools, including a Stohlman basic leather book, wooden mallet and a swivel knife. Some odds and ends, rounder and key fob and some antique dye). I walked out with a lot more money out of my pocket. Read the book, experimented on the rounders and key fob. Made lots of mistakes, but Christmas was rushing towards me. Re-read the book and directions and say maybe the leather was too wet or dry. Casing it was called. I cased (in my case drowned the front of the bag) and it took so long to trace the pattern that the leather must have dried to the right wetness because the swivel knife worked a little bit better. Long story, short: I finished, tooling dyeing and assembling the bag and she loved it. I’ll try to post some pictures—this is my first project. My wife let me take pictures of it a few years ago. (Sadly the Leather Bowling Bag lasted longer then that marriage). Over the many years I needed to replace the plastic ball internal holder with a wooden frame.

-

Tooling picture

stelmackr replied to Joshstrange's topic in Gun Holsters, Rifle Slings and Knife Sheathes

The Stohlman "The Art of Making Leather Cases vol 3" has several pictures of rifle scabbards. Here is one sample: -

Very nice. Pictures were a little small to see details, but still a nice job.

-

Wish I had this advice 30-years ago. ;-)

-

I have the DVD that was produced from VHS tapes when George Hurst turned the videos over to Jim Linnell, but the color is was washed out. That makes for a poor teaching video teaching aid. Does any old-timer (like me) have a VCR tape of the Robb Barr Rainbow Trout lesson I could buy, borrow?

-

Techsew sk-4 Skiver blowing fuses

stelmackr replied to JonesCoLeatherworks's topic in Leather Machinery

If you have a shop air compressor, bring it in and blow out the inside of the unit and pay attention to the motor. Grinding does send a lot of metal fragments around. Just a thought, since it worked right up to the sharpening. -

Check this needle type chart and see if you are using the needle for the effect you want: https://www.groz-beckert.com/mm/media/en/web/pdf/Sewing_machine_needles_for_leather_and_technical_textiles.pdf Because some needles deliberately slice the top leather to sink the thread into the leather. And needle size and thread size also make a difference.

.thumb.jpg.4ed1dbae8dada980d06392d599329b6e.jpg)

.jpg.84c253100c48818ea5128ca72236e518.jpg)