SilverForgeStudio

Members-

Posts

180 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by SilverForgeStudio

-

I am in the same research and recon position you are right now for my leather working and have a series of items I am looking at/working on in various weights. I have had the luxury of demo-work on several Adler and Consew models. All have trade offs. Its not buying... its feeding, caring and servicing the thing you need to bring into the picture as well. One thing to consider that has not been put out there for you is this- its not what you are currently sewing but what is your next level of products to consider. For production runs and "stable" product lines you may consider a flat bed all you will ever need- These machines are work-horses and can have good resale value if maintained. If you want to try larger mil-spec threads and kevlar items that may need a heavier needle consider the next level of machine you will need. As well consider parts/service/maintenance and warranty- you buy a "new" machine- is your warranty service center 75 miles away? Where is your closest spare parts guy? I am lucky to have both an Adler and Consew certified tech business near me (He also does older Pfaff as well- awesome dude). My local Juki service center is a quilting place that has NO CLUE about leather- but can take in warranty work no issue. Just my two cents here... Consider a cylinder-arm with a bed-attachment. Walking foot or compound walking foot machine and just go from there- These machines can go UP in thickness from where you are and although they can be fussy/finicky with the thinner items- once dialed in can do good work. Learn your machine inside and out. Get the SERVO upgrades- the control is vastly better for folks like me (fumble fingers who need the slowness and precision). TRY before you buy- take several thicknesses or projects and GO SEW with any machine you are thinking about look at the top and BOTTOM stitch lines when you sew Dont look at price of the machine- look at Value to you, the resale and functionality (Is it obsolete? Will it grow with your skill level or will you OUT-grow it) Compare- if someone says a price is only for right now- then walk away- they are trying to move something fast (Ask why?) Can a heavy domestic like a Singer 4411 do your work? May be an option (I use it for 2-3 oz liners) For that matter you could buy one of the "Hand-crank Shoe-Patchers" relatively cheap and learn on it while speeding up production- There are multiple videos on Youtube regarding these from setting up to Q/A to troubleshooting- Here is one to consider: Let us know what you decide and please have a great day!

-

Looking for help with a nicked V gouge

SilverForgeStudio replied to SilverForgeStudio's topic in How Do I Do That?

No- I bought it from Springfield- but its way out of any 30 day return (bought it last October)- But it was my first "batch of tools" so Im trying to get a handle on the lower end expectations of things. Good thoughts UK- thanks for the suggestions- Ive got the tools to do it- but Im just belly-aching about not being able to use it straight-away. Seems several of my purchases in tooling have this affliction... it has put me off finishing a couple of layouts. Yeah JD- I do have a metal working tool shed- but kinda like the "Use it out of the box" for my fun, relaxing stuff... I expected to polish hone and strop the edge- not RE-build the working pointy end! Ive ordered some O-1 drill rod to fab another... had to order another V gouge to use in the meantime though. Lesson learned- Buy better the first time! -

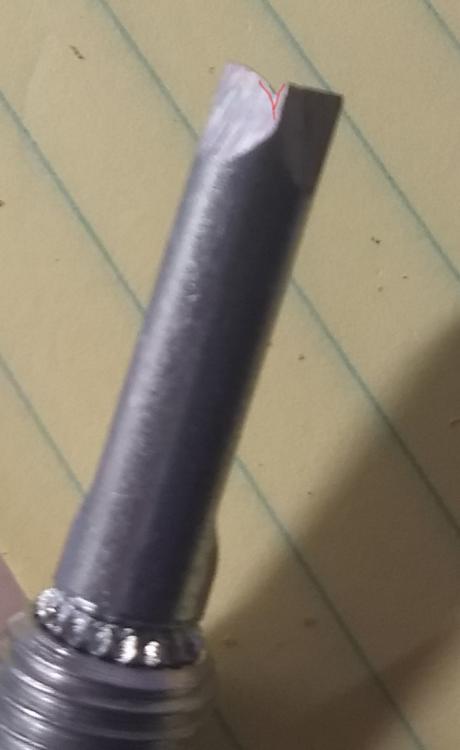

Being new- Ive been laying down some hand stitches and trying to get a firm grasp on the basics of this process. I had purchased a series of "must haves" for when I get to that point- one tool being a V Gouge (the screw-type adjustable one) So I never really got it out of the pretty plasti-dip covering... till I needed it. And I found a fairly un-useable tool with a nasty nick along the leading edge. Is this common with the "bargain tools"??? The red "V" is the nick off the center-line... no damage to the plasti dip or any other part of the "nose" of the tool

-

Is this to be used in a clicker press?

-

Including Care Cards?

SilverForgeStudio replied to ajones17's topic in Collars, Cuffs, Leashes and Leads

"Care" is a contentious issue in some circles- depends on what level the customer "cares" about the product- is it a consumable or a luxury? Does the client need it long term or merely fashionable use? My suggestion is to include a thank you note in the box/bag/container- Mid way in the note (in less than 30 words) express "How to care for your new leash." Limit the wording so you dont create a zombie. No one reads care instructions- but a thank you is always welcome! I do this with all my knives- and it has been well received. My 0.02, your mileage may vary- some assembly required, batteries not included... call your mother... yadda yadda yadda... you get the idea. Kerri -

Singer 111W153 & table resto project

SilverForgeStudio replied to Sugarkryptonite's topic in Leather Sewing Machines

@Sugarkryptonite Thank you for this thread- Looks awesome and you really need to get a design etched into that foot-plate- the machine NEEDS some pin-striping hot rod details after you have finished with it! Seriously- looks great. Love the South Bend Heavy- not too many of those workhorses kept that well these days! (I have an old Rockwell just as loved) -

@bikermutt07 - Im a newbie still... Im in transition to the all-leather items from my original canvas/leather and learning sewing... This is a concept I respect and will definitely see this in my future learning... and the upshot is if you make and learn in batches... and sell- you are automatically "training" yourself to do production work- because with repetition and practice come speed and efficiency. Thank you for sharing!

-

Landis D Leather Splitter Refurb.

SilverForgeStudio replied to LeatherworkingNovice's topic in Leather Machinery

If you have a higher end woodworking store like Woodcraft near you I would suggest asking them for sharpening service suggestions- Splitter blades are very similar in construction to wood planer blades. Once they are sharp- keep a leather board strop/hone charged with your compound of choice and after every few uses just strop the edge a bit. Also if you have a Makerspace, Metalshop school (High school) or machine shop near you find out if someone there would be willing to take the job on as a trade for leather goods. With my local Machine shop(s) they will not want to make ONE of any item (not worth it- very $$$$) but they allow their guys to do small jobs in off hours. I have horse-traded for welding jobs, a few odd thread screws and in one case milling a casting to make it fit an antique fire extinguisher... Your mileage may vary but this may give you some ideas- Best of luck and cool deal on the tools! -

It is rather therapeutic to say the least for now... And by the way- no such thing as "Junior" medic... Don't sell yourself short- you gotta know what I have to know- I just know the "cheat codes" and shortcuts... Its not the years- its the mileage that will grind you. Good to meet another in EMS in the ranks of these guys! HA! So far my adventure has been well met- and warm-hearted with a ton of fellowship and good advice- This is not just a forum- it is a community. Nice to meet you Sceaden! If you ever get to Hampton Roads we will eat at Capt Groovys- on me!

-

Any DIY Splitters/skivvers out there?

SilverForgeStudio replied to SilverForgeStudio's topic in Leather Machinery

Thanks Matt! I think a band knife would be the goal of a new build- but a simple hard-knife skivver is probably where I am headed with the blade- My ignorance in using the machinery is partly to blame- as is the excitement of a new hobby on all the excess "stuff" to tinker with- I can see a porta-band being converted to a band-knife in the future potentially... Understood- even the Cremonas and other band knives on youtube I have watched only have a sheet metal cap/guard over the band- More thinking then some doing in the new year! -

Any DIY Splitters/skivvers out there?

SilverForgeStudio replied to SilverForgeStudio's topic in Leather Machinery

HA! Ok.. well it will be after the spring when I get my foundry back out and set up the forge proper (garage is holding the contents of a friends house for now). But stay tuned! As I get ideas or if others have ideas please feel free to dump them here- Generating a plan is the first step! -

Any DIY Splitters/skivvers out there?

SilverForgeStudio replied to SilverForgeStudio's topic in Leather Machinery

OK so to make math easy I took a nod from another thread about TPI on the adjustment and 16 TPI would give easier adjusting math As well will be looking to reduce flex in the blade center with a hardened piece of 1075 ground to butt join and provide an attachment. Lower rollers out of some 304 Stainless stock with pressed bearing ends. If I leave the thickness adjustment on a ball swivel it can be tapered end to end as well. Max working width looks to be about 14.5-15 inches with grub screws and brass gibs for levelling. Yes I have a bit more time and useless scrap lying about than most... but its fun to build. @Rockoboy Waiting for a response or to see the build? Hope to get some others interested- maybe cobble up a home-brew shed-shop tool kit -

Most folks to gain a BASE understanding of a trade are required to put the time in- like apprenticeship programs... the minumim is 4,000 hours of contact and area time to be a "bottom of the barrell" journeyman machinist- successful Machinists, violinists... even "good" poker players will all tell you you need about 10,000 hours to really "compete" in the big leagues. Fellowship is the basis for learning- if you want to learn from a group- you need to be a PART of that group. Ask for thoughts then TRY to do something and then ask about the results. I am in that category right now- I am doing what was suggested to start... and I will ask for feedback when I am done. << The idea here is to provide a one-stop place for beginners where they can better make a decision on leather purchase.>> There is NO one stop... to have one would be to generalize ALL aspects of why someone will get involved in leathercraft. <<A concise webpage where one can decide on the correct leather to project. If we all went back in time, we'd do right to recall the frustration of sorting this out.>> I'm pretty much an authority on "figuring it out" as I am a new guy- less than 6 months from ZERO knowledge starting this journey... Fine- you build the go-to hub on the net... I will enjoy the journey of this "learning" thing. Please do not forget- Informed is educated. And self-education is the foundation of all masters of any craft. <<There are videos, books, magazines, etc. But again, not concise.>> You learn a concept- that is generalized... you DO the concept on a project- that is application and education. Between the 2 think of them as a "deck of cards" if you will... the more concepts you know the bigger your deck... and when you pick a project- you can pull the concepts out of the deck that APPLY to your project... its a lifetime of learning, building, doing. Speaking of "not concise" you can not UNDERSTAND the concepts until you DO the concepts. This is a hands-on craft. <<Go to any FB group and read the comments and posts by beginners.>> They are NOT interested in learning. These folks want someone to spell it out- they are NOT interested in learning- just doing... You have to want to know the WHY you do something not just HOW to do something. Its not instant gratification "Look what I made" craft-time... ask them to do it again without the net, the cloud or on a trip without the phone/laptop or internet... and they can not. Etsy is full of these folks. No thanks- part of the pride in making leather-work is the fact that I learned it. And I can do it again and again- I got help here by COMMUNICATING and INTERACTION... Harsh? No... reality.

-

So I came into a few industrial planer blades- 18 inches long, a bit over 1/2 inch wide and about 1/4 inch thick (see pics) These are toss outs from an industrial lumber planer near me- I make knives out of them for the fellows in the lumber yard and use their wood scraps as handles... nice use of scrap and it is a good selling point when the salesman can pull out a sample of the wood and shows a customer how it ages "under the hand" for custom work. Anyway- Ive got 3 left from the last batch- and thought I would take a swing at making a splitter/skivver of sorts... Any homebrew DIY guys out there? What I am really looking for is pictures of an older hand splitter like an Osborne- Stay tuned next year for a potential build!

-

I am unable to move on this machine- the wife has relegated me to hand stitching for eternity... HA! If this is verboten on the forums I apologize- mea culpa and it wont happen again! (Didnt see it in the rules anywhere) Seriously- My local sewing machine repair guy punted me a link to a Maryland located Adler-105. I know nothing about the machine except the posting- and my local sewing repair guy saying it was in-line with what I am aiming to sew (2 layers of 9-10 oz or belts). Here is the link- https://easternshore.craigslist.org/art/d/adler-heavy-material-sewing/6740024712.html Hope someone gets this before I feed the wife some wine and she says yes (HIGHLY unlikely)... HA! Hope all are well and please have a great day! Kerri

-

It does! thanks- I appreciate the carving as well- but its the finish and the color blends I am impressed with most as that fade is something I want to attempt! Thanks again!

-

Very nice- saved to my inspiration folder for sure- very nice indeed. Did you use antiquing over the dye? Interested in the Shading in your stippled area and border!

-

Harry- give this a go- if you can extrapolate the patterns to leather its a ready made free resource- Caveat- I have not done any of these bags in leather... I have sewn several in canvas and quilted jaquards (upholstery weight)when I was starting to sew this summer. https://allcrafts.net/sewing/pursesew.htm This site as a whole has a load of "crafty" patterns- but I have only wandered this page or two. Hope it helps- be safe and as always- enjoy the days!

-

Here is a link to another thread- a lot of good info here! Lots of heads up info there... My suggestion is to look at your current expertise in nylon and the Sandbags and try to mix it up- I have seen some awesome custom leatherwork with a 1000 denier panel in a flex point (underarm panel) with venting- Its entirely up to you! Welcome from another newbie to leather! Hope all is well and enjoy the days! Silver

-

I know Im late to the game- apologies. One thing I have used in the past to assist me in another employment venture is looking around at a community college or university art program and having a chat with a photography instructor- We used students learning commercial photography for "test-product" shoots and the students worked free (for a project grade) and the caveat is their photography was used with their name citation for them to build a professional reference. Worked out well until the university started wanting to charge us for the studio/student time (But we were able to get 4 product runs and 2 catalogs of stock photos out of it FREE!) Just a thought if you have the ability to schmooze and the opportunity to be close enough to tap this as a resource.