nylonRigging

Members-

Posts

477 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by nylonRigging

-

also.. Running different sizes of thread on your Nylon webbing for a Belt, is going make it less stiff or make more ridged depending on thread size. When your wearing and breaking the belt in to you body. Running heavy thicker thread and highs tension over time It will stay stiff ridged longer . I just did up a new 1.75" wide, 2-layers of type-13 a couple days ago for myself . Nylon heavy square weave webbing for belt, I usually just use 69 for just putting it together . If it a Belt for daily carry and adding stiffness rigidness. I run #207 or 277 down both side and two straight runs down the inside . For making less ridged and more softer after the break-in wear, then use 138 or go smaller size thread . Instead of just straight runs, you can trick it up a little bit also and do things like Diamond pattern and things down the center area in different color tones. .

-

90% of all Internet reviews ( like that ) are worthless and Shilled ...LOL .. also Every machine Links straight back to Amazon Sales . yes, was Rated 'Best' internet Shoe Cobbler by using intense research consisting of: ..." it has a high-gloss paint, with all metal construction ". .

-

Tough Neighborhood ??? ... LOL -

-

Ya the 269's cam 'fly wheel' underside horizontal is some type of lightweight composite, ( not sure exact materials ? ) .. but I been told a few times by tech's that Singer was Way Ahead of there time back then when designing that lightweight wheel . People don't think much these days on all the high-tech. lightweight composites out in year 2020 at there fingertip's for prefabbing an idea . from Poly's, Ti , carbon fiber ...etc. ' . but back then It must have been a huge hurtle to get over with a wheel that large diameter and weight, spinning that fast on the stitch cycle, and then trying to stop the weight inertia . That is what Singer came up with and a huge % of them are still spinning and stitching today 60-70 years latter. .

-

There are several of old 269's sitting around here in the NW. US. area . so parts are not to hard source. the NW was a pretty big outdoor gear, clothing manufacturing area at one time, we are blessed with a lot of old machines around and some good repair Tech's that are still breathing. the old 269 run fast and 'loud' , I don't think you can get them to cycle the stitch run slower ( guessing 1700 rpm ? ) I think that what factory recommends. my 269w is a ( 28 stitch) . the pneumatic set-up on it is pretty standard simple also. it just a single peddle, with heal-Down for pressfoot Up, and then tap the toe to top of peddle to start the cycle . Has good high lift on foot . and mine is using 135x5 needle, with 69E . Good machine is you not doing high volume production. The only pain in the ass with it I ever had, was always the thread cutter and it always was giving me fits. So it is No More and parts are laying in the drawer . .

-

Sewing thread polyester vs bonded nylon

nylonRigging replied to kgg's topic in Leather Sewing Machines

I used to buy a lot of Nylon #69 and some #227 off Superior Thread Co. . I liked the quality of there nylon they sold, it was always nice and smooth thread and came of the rolls nice to. They used to have and mail-out, a specific color sample and thread size chart/card, they would send you for only Nylon/poly thread buying. Nylon is strong good for abrasion, and also in the terms of for specific application of static and dynamic, stretch is specified as very good thing. Looks like in this Vid. , Dr. Bob is a pedaling his goods for sale, to the neighborhood Quilting Bee . but.. Not making fun of quilting, as my Mom can kick my ass when sewing Quilts and crochet an Afghan. . -

Confused about binding attachments

nylonRigging replied to Rylando's topic in Leather Sewing Machines

Raised feed dog and Raised needle plates, My go to, would be Tennessee Attachment, If anyone has them prefabbed.and in-stock for your model and all same design heads they would . I would just call and ask one of the Binder tech's there. . not something you going to find in a general internet sales search . Unless it for like a common singer 111-211 design head, and they are easy getting on ebay and amazon . . -

Beginning Sewer looking for general advice

nylonRigging replied to MtlBiker's topic in Leather Sewing Machines

'Cordura' and they will legally vigorously protect their trademark . I think the name Cordura, people just thrown that out there generically for description, even though it might not be . Kenyon mill also makes good 1000 den. and heavy weight weave nylon fabric . They use the name 'K-kote' as the trademark . Their also Berry compliant, eastern mill US made good quality stuff, but I never found any of there 1000 den. that is supple/flexible as the Cordura brand can make. But thicker stiffer weave 1000 Den. nylon is good for a lot of things . Kenyon also has quality back coatings also like Cordura . I try to buy Cordura and Kenyon nylons for quality side of things, but I used to buy some imports like 'Kodra' brand . Ya, you definitely in a tight position for High-$ shipping up from US. to Montreal. As 'rule of thumb' good heavy weave 1000 Den. with heavy backcoat will weigh close to 1 Lb. per yard . Shipping-$$ always suck for fabric or leather also , This year alone 2020, I have probably have picked up close to 800 yrds of nylon and had it truck/shipped for pick up. . -

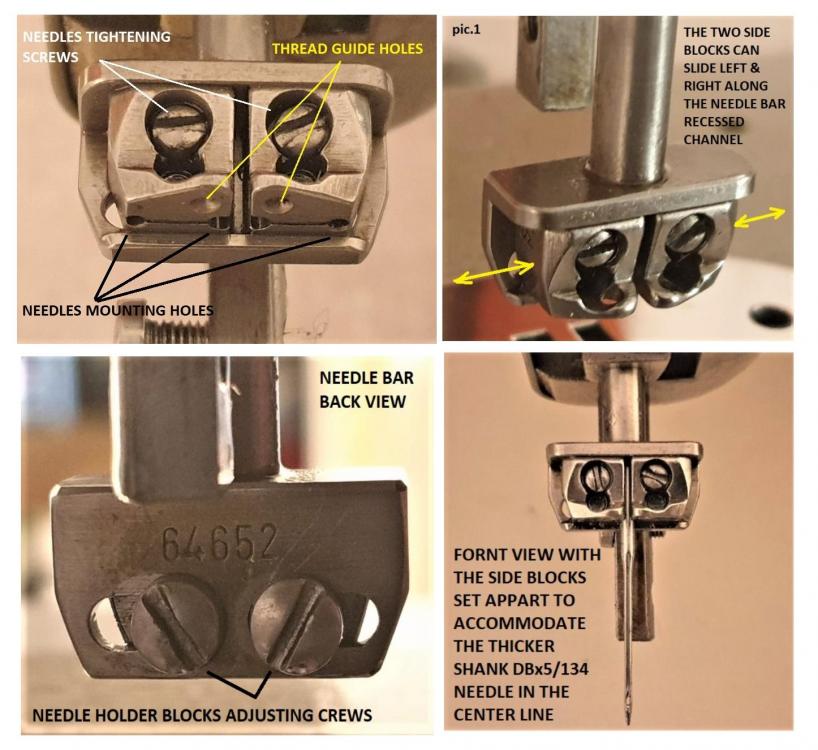

- - Might have your machine model have come with ( 2 ) factory needle clamp setups ? , single and a double . My Bernina 217 straight/zigzag combo machine as 2 thread tension assembly setup like your Pfaff model . and also the Bernina offered 2 different factory needle clamp setup's to quick change out for single/double needle stitching . ( I don't think ? ) that ( D 1 ) slot in the center of the Needle clamp is for a needle . space ( wide gap ) in between the 2 needle hole, It In No Way resembles a hole to place a machine needle into . That needle clamp in your Pic. looks like a double-needle clamp only . -

- 19 replies

-

- double needle holder

- needle type

-

(and 1 more)

Tagged with:

-

Confused about binding attachments

nylonRigging replied to Rylando's topic in Leather Sewing Machines

Not discussing 'brands' of binders or straight or 90 deg. . but on your Flatbed machine, you will want to ( really consider ) a raised dog and raised needle plate, for a better (full) adjustment range for getting your tape/binding to fold and flow . You will find that all binding will never track the same threw the throat, likewise when switching materials you are binding on. The increased adj. range that raised Dog/plate will give you is a HUGE advantage for getting that binder throat down low and into the Feet and material . . -

I got a old 1957 , 269W141 that is tuned nice and a solid tacker. I originally bought it for doing line-sets and bar-tacking the finger traps on Para gear . I picked it up about 15 years ago from a outdoor gear shop going out of business ( machine was bad Out of tune ) not finishing it's stitch cycle, but owner swore it was all complete and was still solid machine . So I took a gamble because the price was right . Had it worked over by a local Tech. and he went threw it and got it running like a top, and it still running strong today. They are handy machine to have when yo0u need it . Tackers are pretty intimidating 'to me' and they are a different animal for sure with flywheel and and timing stitch cycles, I NEVER would have jumped on buying the used Bar Tack if I did not have a good sew repair tech. at hand to set me straight. .

-

THIS.. keep them both . It nice ( never hurts ) to have 2 heads set-up with different gauge needle sets ready to go . and I keep two double needle setup just for outside and inside seam-bind . I still have an old 112 140 head that runs great and keeps on rolling, They almost run forever just keep them oiled good and clean, and they probably out-live you in life span . the Most you are going to have to do with those old 112's to keep them going is change about the bobbin assembly and shafts when the Hooks get so worn and you cant get anymore adjustment left, and 'maybe' change a belt. .

-

Beginning Sewer looking for general advice

nylonRigging replied to MtlBiker's topic in Leather Sewing Machines

Not familiar with the Name of 'tanker fabric' ? You want a heavy denier weight, heavy weave nylon or poly for those wood totes, but Cordura is way to nice to use for Firewood tote bags ....LOL like ( JJN ) say's above post. you should bump-up to at least a bonded 69 nylon or poly thread. Cordura is more expensive because, it trademark owned name. US milled. To say that Cordura is 'Good fabric'. is also an understatement . Their proprietary formula on the Urethane backing is outstanding quality also, and puts all the import 'faux' copies to shame. Sometimes I can't believe how supple the invista Brookwood 1000 den.nylon is when it comes off the roll and with sewing it. . -

I don't know about 500-$ ....LOL, I think your just being polite. is that 111 a needle feed or walk foot ? I myself like the old 111 needle feeds, .. walk foot is little more desirable to people for project machine. But the needle feeds can lay down some Nice stitching. I don't think he can get 500-$ for that set-up . . Not the way it looks in that Pic. ( my honest 1st impression ) that just pop in my head from looking at the Pics. of the machine , is Head, table top and frame, motor, thread stand, wiring...etc all looks ' pretty Rough '. looks to been abandoned and not used for many years. .. maybe ( 150-$ ) would be a good starting price if you were selling it on craiglist. That machine as it sits, is a Fixer-up project. maybe 150-$ if the Head sews and hook, bobbin assembly, dogs ..etc still solid shape. (for example) local here, I see a ( nice clean table set-up ) 111-W, the guy has been trying to sell, sitting here 2 years in Portland for 350-$ .. and it wont sell . and it is clean working set-up and 5x nicer shape than that machine Pic. .

-

One knob has to be the foot pressure + / - .. and the other ( i don't have that model juki ? ) . but could be foot height Adjust ? maybe remove front cover and look to see if obvious adj. something ? or look in the manual ? that another thing is ? have you adjusted your foot stepping height at all to step easily to negotiate the higher seams . Deflection . is when your needle is punching threw multiple layer, and it will plunge going off center slightly. It makes your bottom stitch look like crap and if bad enough deflection you can strike the needle plate . that's why needle plates are sold cheap and needle are sold by box's of 100 ....LOL Keep the needle sharp, and also you might want to bump up a size maybe at least a 135x17 ( 20 ) . You might be sewing great with a thinner blade and smaller eye . But when you jumping on top a seam that is 3X thicker than what you were just sewing. -

-

Also Add ; I was just back sewing and something else did just pop into my head . ( slight chance? ) maybe worth checking ? , that when you raise your foot to a height to engage that large step-up . maybe ? , your Tension Disk push-Pin, is just cut a little long, and you just barely tapping it on the high lift, and loosing a bit your top thread tension setting . It Something you Maybe ? not noticing till you pushing the upper end of you Foot lift. .

-

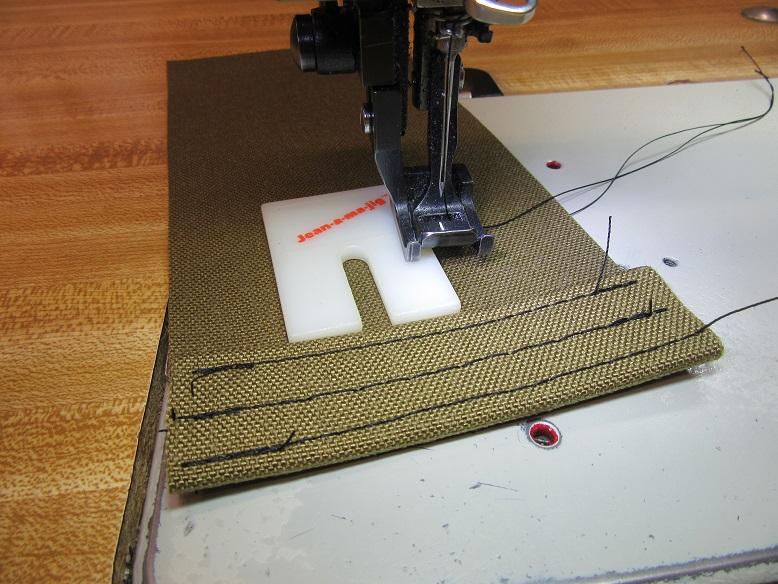

that machine is walk foot and use a 135x17 needle ? . also assuming your using 69E thread ? could be not enough thread tension, and presser foot tension ? or when your step-up on top the stack folds of the thicker seam, you might be getting some needle deflection ? if your satisfied with your machine setup, but not satisfied with the bottom stitch looks. You might also try a ( height shim ) . placed for the foot and dogs to all level out on level plain , just at the point you walk/step-up on the thick seam stack. Your sewing a folded seam/hem, that is ( 3 piece ) thick , and then your machine has to negotiate a side-seam that is rolled out of Hem. that is a good jump and the shim really helps to give machine a easy road to lay nice better stitch. you are barely getting the foots toe on top of the high seam stack, but now the thinner fabric below is suddenly unsupported. Same stepping off the high stack, your foot is running off but thinner material below is unsupported until the Heal drops off the edge. I have a few I keep in machines drawers and they come in handy from time to time. I also make my own, and in different heights, for running feet/dogs parallel on different height material. But common sold nylon/plastic ones for a straight stitch jump / they look like this . and you just slide (open needle slot ) in-front of stacked seam to jump down big, and then remove when the foot just clears the stack . . Or slide Shim in from behind to jump up big, when your needle is on the down stroke sitting in-front of the stacked seam - -

-

what . pintodeluxe ... say's . I think it mostly depends on the what bobbin assembly the machine has. some machines design are 1st stroke thread-tail grab magnets if you don't hold, and then some type machines don't grab but rarely. On the machines I have a couple of them are real grabby and you cant ever forget to hold the thread tails on the 1st stroke ever. Then on a couple machines, they rarely will ever grab and tangle on the 1st stroke. I think the most forgiving machines I have for not holding thread tails on the start stroke is a old Jap Consew walkfoot, and Mitsubishi. The very WORST 1st stroke grabber for machine I have, is the old Swiss Bernina 217. and you 'can't ever not once' forget with that machine. -

-

Bell Crank Lever . If you only getting 12 spi for your stitch adjustment like you said, then that is where you need to concentrate for starting to stretch them back out longer . https://leatherworker.net/forum/topic/87846-recondition-a-29-4-bell-crank-lever/ .

-

Messed up my machine (juki 441 clone), advice appreciated.

nylonRigging replied to Ysalex's topic in Leather Sewing Machines

You live over in Bend OR. , Don't know any sew Tech. there, but there is hand's-on Tech./repair in Salem, Portland, and across Br. in Vancouver . In the end it might have been the better choice for perfect timing job . You can still take it to qualified people for a repair on the broken set-screw, and get it set-up/timed properly to the the requirements you want the machine to work at . It 150+ miles from Bend to Salem and a Tech. there can drill that set-screw out, dissemble that part and re-Tap for using a little larger size set-screw . It a lot of driving for you, but you will end-up with the job being done correct. . . -

Routing your top thread . Your not routing threw both the Tension assemblies are you ? . you only use one of them for single needle . the 217 offered a double needle attachment and that is reason for there being 2 tensions . You said .." top thread feels real tight, but stitch still seems loose ". maybe you running to much bobbin tension ? . Or what 'Constabulary' said .. Double the layers, if only testing on a single layer. For the fraying thread on the Needle . start by checking for burr on the Hook . Or a burr on needle plate or feed dog . Or maybe you got to small a needle hole for thread size . Or using to much tension and causing to much friction . - -

-

Was going threw hardware box and seen I had 2 of these . CS Oborne . ( #217 set ) made USA . . #0 (1/4" hole) . . Spur Grommet Set . 30-$ \ plus shipping . Payment is .. Paypal , or Postal .. PM me for info . ...thanks .

-

Bernina 217n-8 adding roller puller

nylonRigging replied to Josacraw's topic in Leather Sewing Machines

I got Swiss.217 also, and the factory Cam box's and Puller set-ups are real hard to run into . The 217 is a quality gem, but rarely have I seen anyone selling used puller and cam box for them . I would love to score on an old cam box . Global also ( has or had ? ) a clone also . Looks exact copy to mine, with straight-stitch and ZZ, and needle position slide . The only thing they did not remake with there copy, is they left-off the top on-board bobbin winder . they look to have a internet page/linking 217 with advertising there puller and Cam Box . https://youtu.be/uRP4EXWJe3M https://globalsew.com/product/zz-217-series/ - -

So you did Not have skipped stitches, before you changed needle and thread size . ? Can be timing with Hook and needle . or, Distance from Hook to Needle scarf on the pass-threw . also in relation to small or large size threads being used . also, take a look and make sure your Scarf presents a nice flat 90deg to the Hook, and you not tweaked left or right. .

-

Brother PQ1500SL , That to bad it sold, ... ' The Quilting Marine ' , had a really high praise of the machine . https://youtu.be/GRxuqaJCZL4 -