nylonRigging

Members-

Posts

478 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by nylonRigging

-

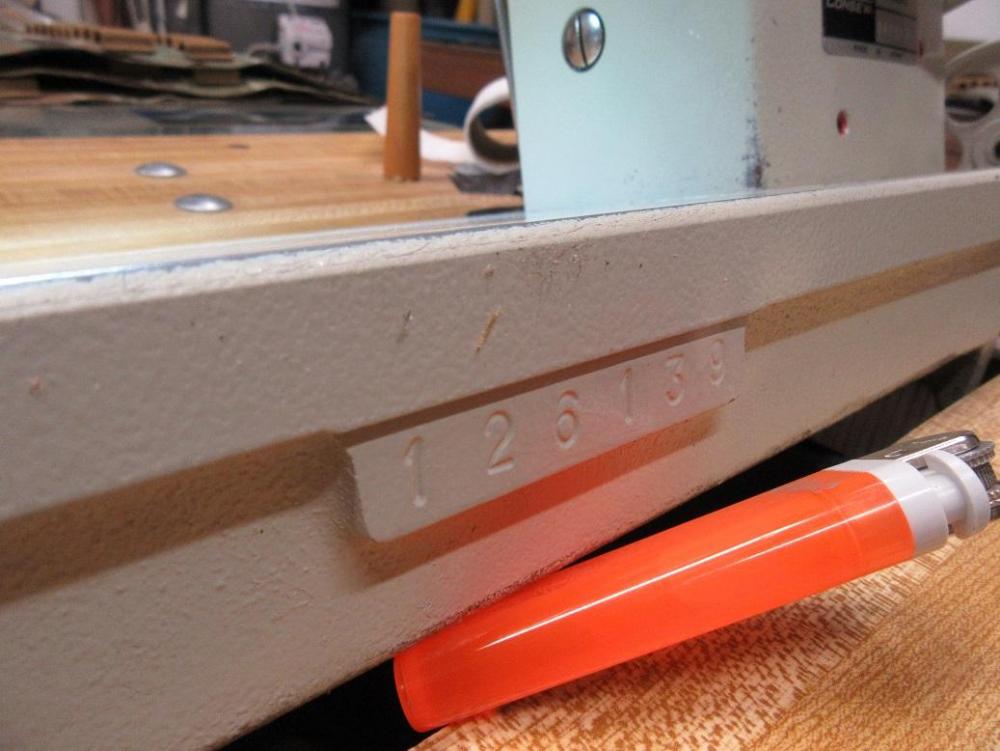

How to identify when my consew was made

nylonRigging replied to Don Ayres's topic in Leather Sewing Machines

I have never seen an on-line Consew serial#'s and date of manufacture archive to look that up, Like you can easy do with Singer manufactured machines with factory serial#'s cross reference open direct to the public. Does your Consew machine have the serial# cast on the underside front of the machine ? . You might give call or email Consew, and ask if there is a way, or if they even do publish there date of manufacture info . . -

Your choice of course but I would have the turn on the inside. Yes that a great looking Bag . I like that cut and look. It just that people with years experienced and with ( Ego Eye ) ...LOL . there eye is drawn instantly to, ( proper Aesthetics ) , and the strap fold-seam not being presented for forward view . .

- 9 replies

-

- shoulder bag

- cross body bag

-

(and 1 more)

Tagged with:

-

What Uwe is saying . looks like a Binder for floating on cylinder bed . Flatbed set-up is a different animal , but No reason why you cant put together a Binder to do what you want on a Flatbed if that what machine you going for, and material you edge binding . But.. ( All I know, is what I do ) , and for advice, all related mostly to the materials/items I design, sew and sell, doing the same sewing for quit some time . My personal Binding knowledge is deep, but narrow niche . All my sew/Binding knowledge is tuned around set-ups on the Flatbed, and for single and double needle, and I personally prefer ( Needle Feeds ), with usually using different 3/4" to 1" width Binding . - I put this Pic. up here once (for an example ) for slide-plate mounts with binders sometime back . This Pic. is flat bed, right angle, R-side slide-plate mount for double needle. That thick heavy binder throat in the Pic. , I had Tenn. attachment solder up . But I put adjustments in the swing arm for some height and angle . Also 3/32" raised Dog and Throat plate work with the Binder for added adjustment . - -

-

you don't have any adjustable play for height and angle in that Binder setup, on the flatbed . looks to be that the throat is screwed down to side-plate, with limited only a In-Out play for how close you want to the foot/needle . also maybe put a picture up with a more top view of your attachment . what exactly is your machine ? .

-

Correct ... but only 13" on the length of workspace . and not 16" like a full 441/4200 model clone . ( TerminusEST ) ... very Nice .. I never seen that ( table top mount before ) on the Artisan/toro 3200 model . That Pic. explains a lot also with power controls, motor, foot, hand . . You got a Sweet factory set-up for a more portable/confined working space, while still keeping-up on the punching power with that model head . Someone will be getting a nice low hour set-up with your sale. - I Have/been working that 3200 model Artisan for a while now. but It mounted steel stand/castor wheels, and UWE flat-table top . and it sews thread cord pretty well , and surprising it still Very easy to dumb it down to using #138 if you want to go that small also. .

-

I think ? , that be called ... " using your Artistic interpretation". . in 5000 years of history gone by, today finding truly unique one of a kind ideas/patterns are going to be few . .

-

Bernina 217 crankshaft end-screw for needle positioner

nylonRigging replied to jfhspike's topic in Leather Sewing Machines

Thanks... for future reference , will write that down and throw in the drawer on the old 217 . . -

Consew 206rb tension problems

nylonRigging replied to LisaGingerbreadJane's topic in Leather Sewing Machines

Only time I ever had a problem with the Bobbin Case, and sporadic uneven/high thread tension, was really pissing me off for a couple days, but I had a spare bobbin case and I threw that in, and it all went GTG after that . Turned out when I closely examined the old bobbin case, I could feel and see it happen, and was original factory bobbin case that worked for years perfect, The Bobbin Case went 'out of round'. ( I must have) dropped it on the concrete floor of shop when it slipped out of my hand and the metal Case must have hit on the edge and bounced just right . That made the bobbin case bad in one spot, that gave bad clearance for the bobbin when spinning to rub/hit when sewing. . -

If ? .. in the end, you cant find a replacement screw with compatible Singer Co. thread pitch and proper length . You could just 'slightly' over-bore the original inside Diam. of the hole . and then just ( hand Tap with T-handle ) . Tap/cut the thread pitch to more common and easy to find thread size . Hand Tap is very easy to do, if the hole is easy accessible, or just remove the part and put in a vice to hold and drill and Tap . If the hole is a real small Diam. Just take it slow and easy, use plenty of fluid and keep cleaning Tap and chips out, so to not snap a tiny Tap off in the hole. .

-

I want to Bump Up this thread on 'snips ' . If you do go to the goldstartool website and buy snip. ( don't mistake ) those 'GS' house branded snips, for the Touro Tesoura snips . They look the same on the webpages, same price, But they NOT even the same quality of snips ....LOL They sell ( 2 ) brands of 4-1/2" snips . the Touro are 'GOOD' deal/good quality . Those 'GS' house branded snips are a BIG Step down below there quality . Using the two brands sideXside in the hand cutting and visually, those Touro Tesoura snips have better looking blade grind, better finish and obviously better quality control over those GS snips sold there. .

-

That is the main reason in getting delays on orders being put in . One person test positive, That person goes home for 14 days, and then everyone else that 'thinks' they had 'possible' contact can go home for 14 days. Seems like everyone is waiting for something that is not getting filled on-time with making an order. I been waiting since Nov. for an order of 1-k buckles from distributor, and they finally got they order going out to me ups today . From what they are saying to me on phone calls , It's just the normal quantity demand for the items, but Both, them/distributor and the manufacture have been running shorthanded on staff/employees from all the covid horseshit that is still going on. .

-

That machine has been sewing for how many years without having it ? ... So (IMHO ) you just over thinking it . Just Sew with it . It probably has no reverse lever, still it is a really good all-around machine to have in your stable. Easy to work on, and easy find and inexpensive parts also . .

-

Mitsubishi question to the vendors of this forum

nylonRigging replied to DrmCa's topic in Leather Sewing Machines

I was going to say but forgot . are you using 135x5 needles ? . I think you can just set-up your machine with 135x17 no problem with raising the needle bar a tad bit to compensate for the little longer needle . Also .. ( if you don't already know ? ) . you can also throw a 'roller foot' on that bottom feed of yours with that presser rod and common high-shank split toe foot, and set it up in 20-30 minutes, and they really sew great. Those roller foot aftermarket kits for your Mitsu. and a Ton of other similar models are mass produced and dirt cheep . Come in small/medium/large rollers . The kits come with all parts dogs/needle plate/flip-up roller foot. all for less than 20-$ - - -

Hey .. Thanks for the Post of the Link I do own good gingher and mundial's sheers as well as using the cheap snips , and these are good Snip's . I bought 4 of them to check out and use, and these snips are really good quality . ( just a heads-up ) The sale price right now probably not going on past the new year, but these snips are going for only $-9 .99 apiece . I do love the cheep eagle disposable snips, and I been buying them for Years, but a guy could get spoiled using good snips ....LOL . . Only 'time' will tell the true quality of the stainless blades, but they handle nice, the tooling and grind look GTG and they snip in close and tight on the smaller #69 as well as the heavier thread cord #277 and 346 . .

-

Understanding Bonded Nylon and Bonded Polyester Thread

nylonRigging replied to Trouthunter's topic in Leather Sewing Machines

Poly. thread does stretch, it just that Nylon thread stretches more than Poly. like ( DoninReno ) saying, the general 'rule of thumb' is that Poly.thread tends to be more UV resistant and hold dye color better when getting a beating by UV . Nylon is better for holding up for abrasion and a little higher tensile strength over Poly. Nylon and Poly. thread both start melt right around the same Temp. , When burning each they also smell totally different . When melting thread tails, the Nylon thread melt a lot nicer than Poly thread . I like the way Nylon thread tails makes a nice little puddle. Poly. thread tends to just Flame-on pretty intense and quick . You also notice when hot knifing/cutting Nylon thread weave of webbing's and nylon fabrics, that it's a lot cleaner/nicer melt with Nylon. . -

If you like a thread feeding hole on the sides of the barrel to poke the thread tail threw on the rewind , Don't order those China heavy steel chrome plated 441 bobbins off ebay/amazon . Good price, but they only notch them for the pin to set, but they don't drill a hole. You can drill your own holes in the sides, but I had to make a jig to secure them on the drill press because of bobbins shape . I bought a dozen of them and the shaft holes are hit and miss for constancy on size, some loose but some you can Not slide shaft into it. The lightweight Aluminum barrels work great, if you can find them ? , and when sewing, there the 1st one's I grab . .

-

That is it . I figured it at least was minimum of 25 year old machine ... ( shoepatcher ) said it looks mid 80's) Seller looks like they also bought it used over 10 years, and just been sitting neglected for several years, So it going to be dry/oil and filthy . All depends on how hard it looks like it was worked over it life, Bed looks pretty worn showing many years of materials run across it . Needs a good looking over before considering spending any money for it and a scrubbing, oiling then going threw and eye-balling the mechanics for possible problems. Also if buying, Needs a new good Servo motor ( another 200-$ ) Adler a good name, but Reality is 'maybe' offer 500-$ at the most, because it is a small project to make it even respectable enough, to set in with my other machines . .

-

1st I heard of this . Was sitting at machine tonight and was going to toss snips in trash . Tried it tonight on a dull Eagle .99 cent snips . Ran the channel side of old needle back-forth over edge and they Snipping Again . learn something new everyday ....thanks .

-

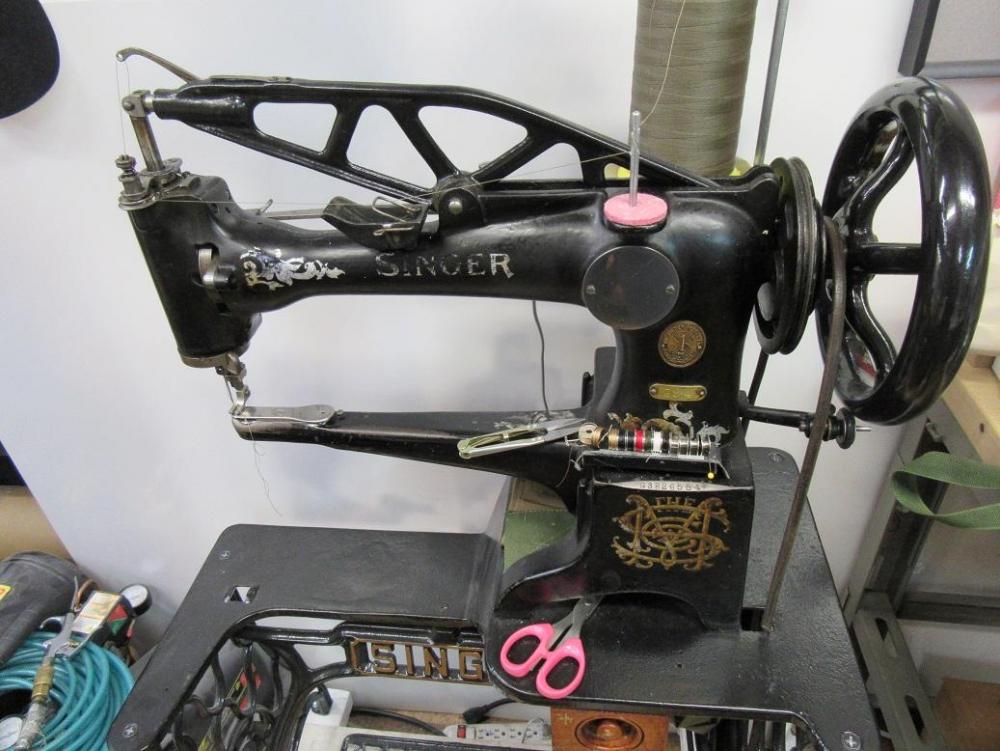

-

What am I looking at here ??? . I not really a follower of Adler machines, because of the extra expense of buying parts here in the US. , but this one popped-up here Locally, so I looking for some Adler fanboy advice. Any guess of Model, and year of production ?? I have minimal information given. ( Just this crappy Pic.) . and say's ..." it been in storage for the last 4 or 5 years " . .....thanks - -

-

Mitsubishi question to the vendors of this forum

nylonRigging replied to DrmCa's topic in Leather Sewing Machines

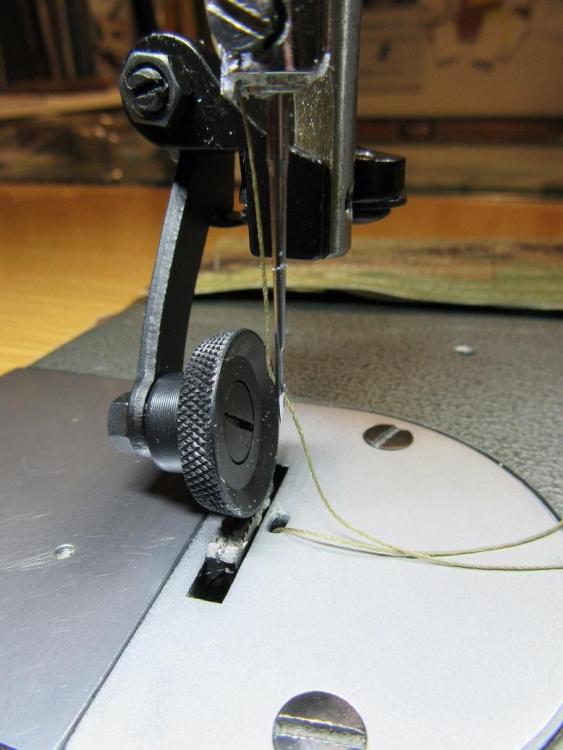

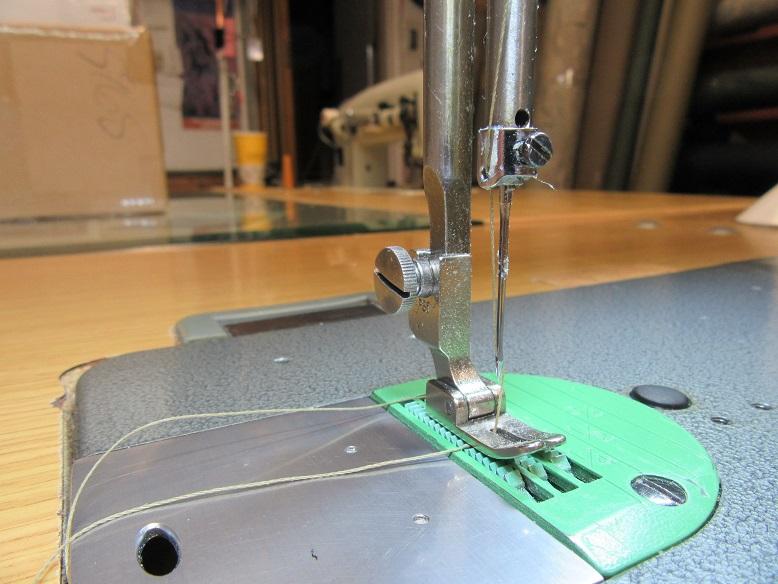

this one a DB170 .. the green color is just a Teflon coating . The only bitch I have about the old Mitsubishi's are the smaller bobbins . . -

Mitsubishi question to the vendors of this forum

nylonRigging replied to DrmCa's topic in Leather Sewing Machines

I would not know as this particular machine has never sewn leather, but if It was sewing thin leather I am positive the dogs would leave deep track marks on the underside . This machine is tuned for heavy nylon with the extra heavy set of feed dogs with raised needle plate and 135x17 needle . It also servo has a extra small pulley wheel and speed control, if needing it can punch real slow RPM . For these Mitsu DB's and other similar builds, there is a 'fine' tooth dog set that you can get also for delicate items . There are a lot of easy common obtainable parts and these parts like DB mitsu. bottom feeds and there parts cross over to a boatload of other machines under many names. Also the OP stated that , ..." It stitches perfectly on a broad range of fabrics, and I am happy with this. But there is still a problem! " He might or might not be using on leather or not ??? . he probably using mostly on synthetics . But if the OP was using on thin leather and that leather panel was getting a lining to hide the tracks. then would not be a problem. some Bottom feeds can actually lay down some nice stitching when you tune them for a specific need. also they can get into really tight places with using and narrow feet . . -

Mitsubishi question to the vendors of this forum

nylonRigging replied to DrmCa's topic in Leather Sewing Machines

I not a subscribing vendor of the site, but your DB bottom feed should look all trim like this Mitsu. DB . that looks really Macgyver'ed-up for sure . This one, I turned the needle bar 45 deg. to put the set screw in foreword position, from it being on the R-side . - - -

Those are meant to be disposable, so the Riveting is always cheaply done. Snip until there dull and just toss in the can and grab another sharp snip . There not made to resharpen, but lightweight and fast, and if you have a bunch of machines, then it easy way to got, just throw one of them on every machine . I always buy couple dozen a year of ( eagle Brand ) snip's . Buy them bulk-packs off Ebay and there only 1-$ each & free shipping . The Snip's link that ( joon1911 ) posted, from goldstartool , right now are the Best bang for the buck-$ .

-

What type of stitch gives the greatest pull strength?

nylonRigging replied to lod's topic in How Do I Do That?

exactly what ( chuck123wapati ) is saying. the seam for your application is major consideration . Just running a straight double-needle run on a double felled seam, is strongest for your description . on the opposite end of the spectrum for weakest seam, it would be a butt seam It also Not the ..." pull strength". like in your thread title. You are dealing more with a ' shear loading ' and not a straight pull, for the breaking point on the thread type strength rating . Shear Loading multiples 'greatly' the structural breaking point on thread, because the greater force on the Seam sewn is pulling lateral on both sides of the thread and seam . .