-

Posts

1,292 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by TomE

-

The bar was low. The old strap was considerably lighter color than the chapes, and it was dry rotted. I'm thinking it wasn't original equipment. The client bought the purse used as a Christmas present. He was happy with the color. Thank you, Jonas. I did sew by hand to complete both ends of the stitch lines. I will look into the Serabraid.

-

Thank you, gents! I will admit that this was the third try matching the color. I am woefully deficient in dyeing techniques bc I mostly use drum dyed leather. Ended up dip dyeing in 10% Fiebings dark brown Pro Dye.

-

Happy with Amann Serafil thread from @CowboyBob at Toledo Industrial Sewing Machine. It feeds well through my Cobra Class 26 and is a good color match (color #7766) for this vintage Louis Vuitton purse. Lots of colors to choose from besides my usual brown and black thread for horse tack. Made a new shoulder strap for this old purse and considering making other items in a brown/yellow color scheme.

-

Wholesale hardware suppliers beyond Buckleguy, Tandy, Weaver, Ohio etc.

TomE replied to PheesOriginal's topic in Suppliers

Beiler's Manufacturing and Supply in Ronks PA has quality brass and stainless buckles, snaps, rings, fasteners, etc. with good prices and service. Quantity discounts when ordering 100 or more pieces. They are geared towards the harness and tack trade. Amish company with no website. Call for a catalog. -

Cobra NP4 Leather Skiving Machine - bad presser foot mechanism?

TomE replied to NeilMott's topic in Leather Machinery

Hard to know what's wrong with the foot lifting mechanism without taking it apart. LMC is generally very helpful with advising, sending parts, etc. In my limited experience skiver feet typically need polishing for best results. I have a Techsew SK4 and some additional FAV feet that I polished on a buffing wheel. -

To sand the edges or not to sand

TomE replied to ThisIsMyFirstRodeo's topic in Leatherwork Conversation

Reasons to sand edges include leveling multiple layers, removing excess glue before finishing the edge, and smoothing the fibers as part of the burnishing process. What are you trying to achieve? I routinely sand to level an edge or remove glue, and I avoid it when burnishing. If my regular burnishing methods don't produce a smooth enough edge then I'll sand and do more burnishing. Depends on the tannage, moisture content, the part of the hide I'm working with, thickness, etc. -

Turned out nice. I like how you laced the brow band on the crown.

-

That's a beauty! What caught my eye immediately is the way the vine is woven around the flowers to create a criss-cross appearance, and how you decreased the size of the letters to complement the shape of the point. Lots of neat details. Thanks for sharing.

-

For tack repairs I match colors by trial and error, testing dye mixtures on a scrap of the same leather I'm using for the repair. I am usually adding a small amount of Fiebings brown dye to their English bridle (yellow-tan) or mahogany (red-brown) dye as a base. The Fiebings brown dyes I've used are, from lightest to darkest, are light/medium/dark brown, show brown, chocolate, and dark chocolate. To my eye, the show brown has a bit more reddish hue than the others. To simplify, I'd get show brown (dark red-brown) and chocolate (dark brown with a black tone) and dilute them in a tan or mahogany base. Based on the picture of your saddle I'd guess that a pinch of show brown in mahogany dye would be an acceptable match. My go-to dye for dark brown Asian tack is 7% show brown in mahogany dye. Your saddle is not that dark. As others have said, oiling and sunlight will also darken the leather to improve the match.

-

I'm no expert but I would sharpen the knife, working slowly/gradually to avoid overheating. Use a marker on the bevel to see that the stone is creating a uniform bevel. I would also polish the foot to reduce drag - use a buffing wheel if you have access to one. Check that the drive roller is round and without gouges/flat spots by shining a bright light to visualize the gap between the roller and the knife.

-

A gum eraser or "plastic" eraser does a pretty good job of removing excess contact cement. I apply cement sparingly, let dry for 5-10 min then warm it with a heat gun to "activate" the adhesive before assembly. Heating produces a strong bond with less cement.

-

Here's the bitless bridle/halter that I mentioned. As noted in the thread below the rolled leather noseband was swapped out for a soft polyester rope noseband, matching the original. The client's trainer felt that the leather noseband didn't release properly. wa

-

The knot on the Weaver bitless bridle looks like a double overhand knot. This video shows how it is tied. I learned to tie rope halters from this author's 3 part Youtube video. She also has useful videos on eye splices and butt splices for lead ropes. I don't have much experience with bitless bridles but I made one for a client, patterned after the Monty Roberts "Dually" training bridle. She wanted a leather version of his nylon halter for every day use with her older dressage horse. I'll look for pictures of it after chores today.

-

I have a similar challenge sewing next to raised leather features on horse tack. I've used the inline presser feet from Toledo Industrial machine and the narrow presser feet from Hennigan Engineering and Precision. Both foot sets can do a good job. The inline feet require backing out of square corners, in order to give the rear foot a place to land. The narrow presser foot set is a bit wider but easier to maneuver. Another strategy is to leave a wider margin around your raised piece, use a conventional foot set then trim the edge after sewing. I don't like doing this for long stitch lines, like sewing reins with a raised feature in the middle of the length, because it's a lot of trimming and waste. Think it would work fine for smaller items. Here's a video of the inline presser feet. https://www.facebook.com/share/v/18w1DUTZzc/ Here's a video of the narrow presser feet. https://www.facebook.com/share/v/1787akb5As/

-

In this short video Tim Alden of Alden Leather Supply shares a neat trick for sewing next to hardware. Wish I'd thought of this. He makes sewing sideways look easy. I've used hand sewing, different presser feet, and backing up towards the hardware to get the hardware sewn in tight. Any other tips to share? https://www.facebook.com/share/r/1Bcjp74xtc/

-

The narrow groove of a power bunisher works well, or using canvas with the leather lying flat on a smooth/slick surface and working the edge.

-

Thank you, @PastorBob. Clearing the cache may have completely solved the problem. Pages are loading faster now. I use Chrome on multiple devices and hadn't considered that the shared cache might be slowing them all for this site. Other sites that I frequent aren't showing a lag but maybe they will be even quicker now that I've cleaned up the cache.

-

Thanks for your replies, @fredk and @AlZilla. We have fiber optic internet (a miracle, considering we’re in the boondocks) and no other issues with slow service. Occasionally this site loads quickly, but usually it’s a wait. Wasn’t the case until the last few months.

-

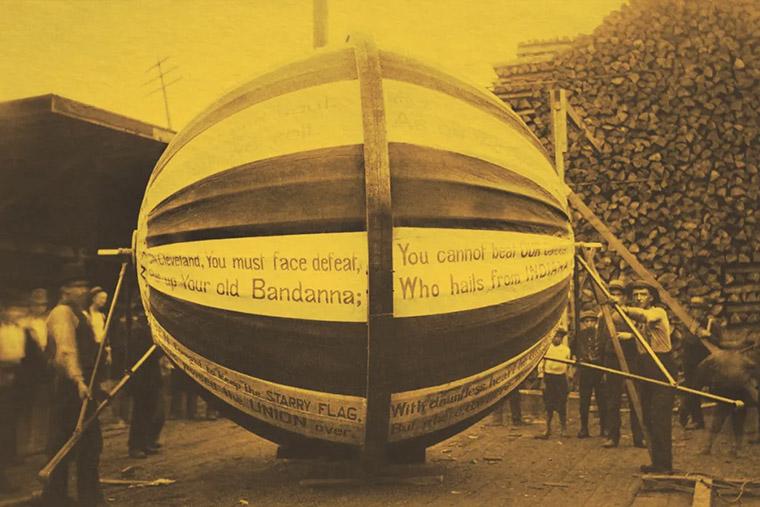

Here's a project that I haven't seen discussed before. President William Harrison's leather and tin ball, which apparently is the origin for the phrase "keep the ball rolling." https://wordsmarts.com/keep-the-ball-rolling/?lctg=3e121733-b5b4-47ec-a793-21d132d067fc. Now that I have your attention, my real reason for posting is to ask does anyone else have trouble with the leatherworker.net site loading slowly? For the past ~3 months, most pages of this site require about 20-30 seconds to load. It is a slow process to use the site. Is there a workaround? Thanks for your input.

-

Reommendations for Getting into Saddle Repair

TomE replied to Samer's topic in Saddle Supplies, Tools & Trees

As you no doubt know, English saddles and western saddles are 2 completely different items in terms of materials and construction. There are a lot of resources and classes for western saddle making, which will show construction methods that are relevant for repairs. I'd start with the Stohlman's Encyclopedia of Saddle Making from Tandy and also check out books and DVDs at the Leather Crafters Journal online store. Fewer resources available for English saddles. Robert Steinke's books on repairing harness and saddlery are good if you can find/afford them. Joshua Siegel is a skilled saddler in western MA who might be a resource for you. Also, the Facebook Saddle Restoration group includes some skilled saddlers (scattered among many saddle cleaners/flippers). Jack Stewart does saddle repairs for Stubben North America and is a helpful member of the restoration group. -

Welcome! There's a wealth of knowledge among current participants and in the archived posts. A tip that I regularly use is to search the site with Google using the syntax: site leatherworker.net your key words here Look forward to seeing your work.

-

Tutorial, replacing zippers in riding boots.

TomE replied to Mulesaw's topic in Shoes, Boots, Sandals and Moccassins

Here's the original link. https://ykk.meclib.jp/library/books/Zippers_101/book/#target/page_no=1 -

Tutorial, replacing zippers in riding boots.

TomE replied to Mulesaw's topic in Shoes, Boots, Sandals and Moccassins

This YKK Zippers 101 document has some useful information and styles I hadn't seen before. 0001.pdf -

Thank you for the explanation. A different type of layer loop than what I see in the Beiler's catalog. I am working my way through Preston's book - finally located a used copy - and enjoying learning about the terminology and construction methods. Thank you. That is some nice looking hardware. I'll probably wait until our trade wars subside to inquire about their US sales.