Search the Community

Showing results for tags '29k'.

-

Hi everyone, I'm new to this forum and although i've been reading it frequently over the last two years this is my first post. After much hand-sewing of leather items, i've taken the plunge and bought last month a singer 29K3 dating back from 1905. The machine was quite rusty and battered but I didn't pay much for it either. I have to mention this is my first sewing machine ever. I've been looking for replacement parts but although they are plenty for later models, I can't seem to find stuff for older machines and am not sure whether the newer parts are compatible. I have successfully cleaned, repaired, adjusted, soldered a number of things and the machine will now stitch more or less consistently. I am however left with three issues and am happy to collect guidance from the educated on these : 1. On the back of the slide part of the "round ring" is a small roller. This one is worn (faceted), and the groove in the drive pulley may be worn as well. I can drill out the roller and replace it with a custom machined one of suitable diameter. How much play between the roller and the groove is acceptable? Would a replacement part be compatible with this machine? 2. The needle isn't perfectly aligned with the hole in the shuttle cover plate. the needle is a little bit to the left, as if the lower arm of the machine was too long. If the leather is thick and causes the needle to deflect a little bit under load, it can hit the plate and break the needle. A previous owner has chamfered the hole on one side of the plate, in order for the needle to get back in the hole. Is there any adjustment I can make to correct this? 3. The shuttle was missing when I got the machine, I had to source one but am not perfectly happy with the result. I may or not have the correct part, but there is some play around the shuttle, even if the small spring in the shuttle carrier is present. As a result, a clacking noise is sometimes heard from that area, and I wonder if any replacement part better suited to my machine would be availables. I welcome any advice on these topics, with many thanks in advance.

- 11 replies

-

- restoration

- singer

-

(and 3 more)

Tagged with:

-

I have an old Singer 29K57 patching machine. It was in a barn for over 2 decades and I have been fixing it up to use. I replaced several parts, cleaned and oiled it all up and got everything running smoothly, with one exception... the bobbin keeps jamming. I have been a professional sewer for many years (although new to this kind of machine). I've switched needles (different sizes, etc.), switched threads (including different weights), purchased new (used) shuttle carriers and tension springs and new shuttle bodies. The timing is right. The shuttle is picking up the thread with every loop. For some reason, however, the thread slips under the shuttle carrier and gets jammed (see image). I watch it very slowly and still can't figure out why it's doing it. The first loop through, up to about 2-3 stitches, seems to go smoothly but then it jams again. Any thoughts? I almost threw the whole thing out the door today!

- 7 replies

-

- singer 29k57

- singer29k

-

(and 2 more)

Tagged with:

-

Howdy all, I’m new to leatherwork and very new to sewing machines. I recently bought a cobra/singer patcher clone from Amazon (INTBUYING Industrial Leather... https://www.amazon.com/dp/B08HRLS3B7?ref=ppx_pop_mob_ap_share ) I got the thing all dialed in last week and sewed a belt with it. Seemed to work well and everything but when I got to the end it kept breaking thread. Thought maybe I over-tightened the top tension so I loosened it but it still keeps breaking. Now it seems that it’s missing the bobbin thread altogether. However when I don’t have material on the machine and I have the cover open I can watch the shuttle catch the thread but as soon as I slap some leather down it won’t. Can’t think of why it won’t work for the life of me and I can’t find any answers anywhere. Any help greatly appreciated, thanks in advance. Chase

-

hello, I just joined since i found so many great tips and tricks here. I am currently rebuilding a Singer 29K51 from 1928. i can post pics if wanted i need help with the gearbox though; i can not get the cogwheel of the axle comming down from the shuttle carrier. it is screwed on and i can not reach it with a screwdriver to unscrew. anyone able to help me out? thank you very much

-

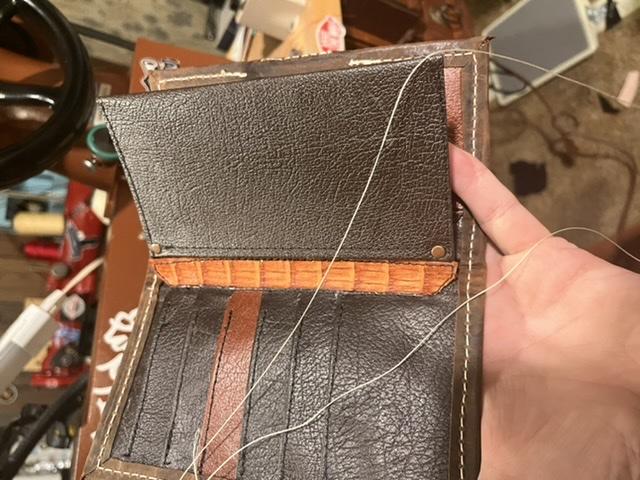

Clutch purse pattern I made ‘bout 35 years ago. Done it so long I don’t even have the pattern. I just do it. Change it up to fit the here and now… women seem to dig it…

-

Made this holster with turtle tail. Had to do quite a bit of fleshing to get maximum use from it. 6 sq inches of useable leather is hard to stretch. A 1” belt sander w/120 grit and a feel for what you’re doing and you can make use of the rock hard 1/2” thick outer edges. Turtle puts off more dust than any other leather I’ve used so it’s best done outside. It takes more work than other exotics, but it’s definitely an attention getter. Sewing it together was easy peazy on the 29k except in one area where I could’ve skived it thinner, but the China patcher handled that like it should’ve. Customer loves it and that’s all that matters. Be great to make a costume out of, And what I’ve been told they’re tasty too. I dunno about that, but I’ll eat anything with gravy…

-

This has a rebuilt needle head with good regular 5 stitch per inch (you can adjust it for less). It has a new bobbin winder. It is running very smoothly and consistently. I am asking $1300 for it. It is in Aspen Colorado. I can make a crate for it and ship it for cost: shipping, time and materials. I have a balance wheel handle and hardware ordered from England. It should be here soon. It comes with 10 new bobbins and some needles, extra feet, etc. Thank you.

- 2 replies

-

- sewing machine

- boot patcher

-

(and 4 more)

Tagged with:

-

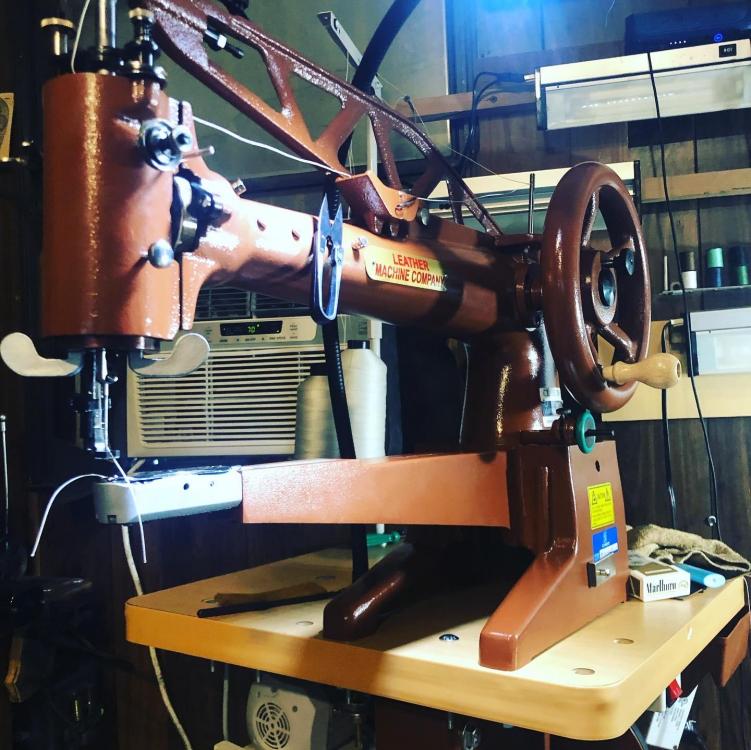

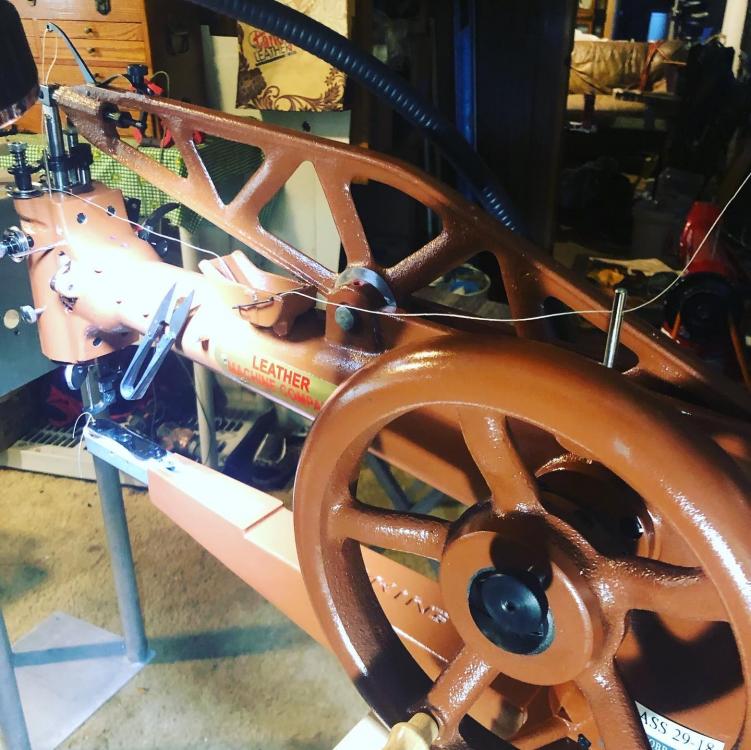

Picked up a cobra 29-18 from LMC. Couldn’t be happier with the machine or the service throughout the sale. Delivered without a scratch…

-

looking for any hands on experience with the cobra class 29-18. I know of no one who’s purchased one. For what it cost, it should come with a real live cobra too.

-

Looking for some help please. I have bought an old Singer 29K171 and is busy taking it apart and cleaning it. Replacing parts and bringing it back to life. But I have hit a snag. How do I remove the pin which holds the shuttle driving cam gear. All parts of the machine is badly funked up. Wd40 has helped and all other pins slipped out. But this one is stuck and I am not sure if it is meant to release to one side only.

-

I find it amazing how things come in waves. I am still getting my 45k in order when an opportunity to buy a 29K58 showed up at what I thought was an irresistible price. So here it is. It runs very smoothly and came with a stack of leather point needles.

-

For various complicated reasons we are ceasing to do boot work and so we will be selling our Singer 29K60 machine. This is a long arm treadle model with the "splittable" arm ( there are similar machine out there with a one-piece arm which are virtually impossible to service). It has been drilled to accept a motor at some stage but we have used it as a treadle machine for the last 12 years or so. We are open to reasonable offers or would swap for a Singer 46K49 / Allbrook & Hashfield / Techsew 402 or similar. Posting here before posting anywhere else. This is a very nice, working machine. The table hardware is included but will need a new top making as it is for a short arm machine. By all means contact us for further information.

-

Looking in the UK for a singer 29K table without paying silly money like on Ebay

-

I'm looking at purchasing a Singer 29k and the shop that closed has 2 for sale. A 29k71 for $150 and a 29k58 for $200 both work well. I've researched the best I can on them both and read through various threads here on them most were from a few years ago so thought I'd ask as well. From what I can tell they seem pretty equal or am I missing something? I'm contemplating just offering them $300 for both, worst case one could always be used for parts. Any thoughts on this - get both or get one - if so which one? Appreciate the guidance/input.

-

Hello Anyone knows anhthing about this machine? Is fully working and the prize that is asked is 200$ Is it only a cobbler machine or can it be used as at ordinary leather sewing machine? Best regards Johan

-

I've been wondering if anyone in the combined brain trust might know how much in U.S. Dollars the different models of Singer 29 series shoe patchers sold for when they were new? Such as a 29-4 made around the beginning of the last century, and still commonly used by many folks today. Or, in my particular case I have a Singer 29K58. Now, I roughly know how much I've seen them selling for used, but have no idea, how much they sold for new. I'm also searching for a Singer 29K72, or 73 whichever is the long arm version, but again without knowing what the new price was, I can't judge what a fair used price might be? Thanks.

- 11 replies

-

- singer shoe patch

- 29k

-

(and 1 more)

Tagged with:

-

I've acquired a 29K-30 Patcher. Works okay but I found a flat worn on the cam follower roller mounted at the end of the needle bar lever. Ordered and received a new roller and pivot assembly from Pilgrim (p/n 1801) but the drive shaft is so worbled up at the end I can't pull/hammer the cam/pulley off. I can pull it back enough to free the roller but don't see how to pull the pivot. The original roller appears to be peened or swedged onto the pivot shaft so I can't just replace the roller. Any advice? I'm taking a couple wheel pullers to the shop today to remove the pulley but there's no place I can see to clamp onto the worn part.

-

Hi folks I've just bought a singer 29k 15 machine with stand. Its been stood for a good few year and needs a total refurbishment. Before I have the downloaded manual for it but it doesn't show all the parts. So it's there a manual for dismantling this machine? I've looked and can't find one. Or is there someone online that has recorded how to do it. The main problem I have is that it looks like there are some pins rather than bolts holding some of the bits together, rear pulleys, top rocker arm. They look original as they are nearly perfect. But I Need to know about them before I try to knock them out only to find out they were threaded and ive knackered the whole job. Advice please people. I'm very mechanically minded and it's good honest Victorian/Edwardian engineering! Cheers folks

-

Hey all! This is my first post here, after searching for similar threads and coming up relatively empty. I just started out as a hobbyist shoemaker/wanna-be cordwainer a few months ago, and as such I eventually had to get an appropriate leather sewing machine, after using a Singer 99K for my first pair of boots and finding it troublesome to not be able to sew three-dimensional shapes. I recently acquired a Singer 29K72 for a measly $200, and it is in remarkable condition. The previous owner seems to have taken good care of it and oiled/cleaned it regularly. Nevertheless I also did so as soon as I’d brought it home and it operates smoothly. It will gladly make stitches as long as 4 mm, although I operate with a much higher SPI for shoemaking. However, I have run into a couple of small issues and was wondering if any of you have any suggestions as to how to rectify them. 1) The leading edge of the shuttle carrier is worn down a little bit. I have purchased a new shuttle carrier (and driving pinion) from College Sewing to replace it. The problem is the tiny set screw that holds the driving pinion and shuttle carrier in place: it just will not come loose. I have tried a variety of different flathead drivers, but none of them give me enough momentum to get the screw lose without stripping the very fragile slot in the screw head; since it is so small. It is also already slightly stripped from the previous owner fidgeting with it. I have applied oil directly to the screw, but it will not budge. Suggestions? 2) The user manual says the leading edge of the shuttle carrier should travel 1/3 of the way across the slot where the needle reaches its deepest point at each oscillation of the carrier. I have made this adjustment to the eccentric stud, but it seems to not want to stay adjusted to that point. After sewing for a few minutes, the shuttle carrier starts coming short of the slot for about 5 mm. The machine will still stitch, but gets prone to skipping stitches. Then I’ll have to adjust the eccentric stud again, but it will soon revert back to an incorrect position. Does anyone know why this is and how I can remedy it? When I first adjusted the eccentric stud, it was stuck, but some oil to the adjustment screw loosened it up and made it possible to adjust. Is it possible I have damaged something when adjusting it the first time, perhaps? There is some very minor slack to the shuttle carrier, but not so much that it would move that far on its own without the eccentric stud being adjusted. 3) The needle clamp position adjustment is stuck also. Loosening the screw does nothing. I have oiled it, but it won’t budge. This is the smallest issue so far since the needle is still centered nicely above the needle plate hole, but I’m dreading the day I have to actually adjust it and won’t be able to. The two first issues combined leads to the machine skipping stitches every 10-15 stitches or so, which is very annoying. When it skips one stitch, it will also skip the next…and the next, so I have to stop what I am doing, lift the presser foot and move the material back to where it first skipped a stitch before I can continue sewing. Mind you, I am making shoes where a lot of the stitching is decorative and therefore needs to be impeccable, which is difficult when you have to remove the material and move it around a lot.

- 18 replies

-

- singer

- singer 29k72

-

(and 4 more)

Tagged with:

-

These are pretty basic but they do the job. http://www.ebay.com.au/itm/New-Clamp-on-Fabric-Guide-to-Suit-Singer-29k-ABLE290-ADLER30-etc-/221657043168?ssPageName=STRK:MESE:IT I have a range of other 29k parts listed on evilbay.

-

I purchased a Singer 29K51 but haven't located a really good manual on operation,maintainance,parts or specs on what this machine can actually sew or thread size to use. Does someone have a link where I can buy a manual described above? Maybe someone can tell me if this machine is worth using or should I use it as a paper weight and purchase an electric leather sewing machine? I'm a novice leathercrafter, making belts,wallets,checkbooks for now, I do plan on making motorcycle seats, chaps and asscessories later on and repairing horse tack, maybe harness rigging but no saddle work. It looks like the Techsew 2700 would be the perfect all around machine, but to expensive for this novice What other used machines would qualify equally or close to the Techsew 2700 for around $800-$1000 ?? I did read all the info posted by Wizcraft on leather machines. Very interesting and informative.

-

http://minneapolis.craigslist.org/dak/atq/4446860042.html Above is my CL ad for a 29K51. I am selling this working and in good condition beauty for $500 firm. It is available only to people who can pick it up in Hastings, MN