Search the Community

Showing results for tags 'boots'.

-

This is my fourth leather project and fourth pair of boots. Each time has incorporated new techniques and tweaks. So far, I’m the most pleased with these.

-

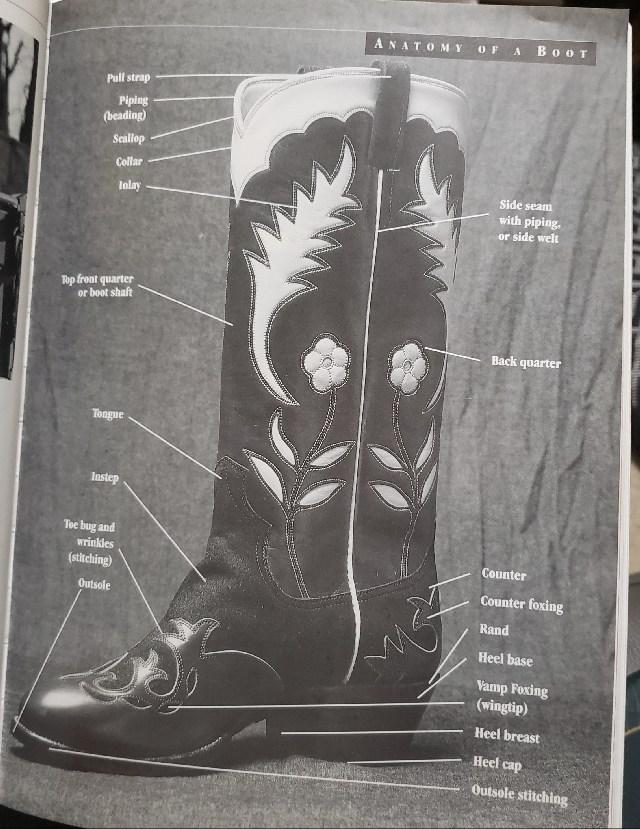

I picked up couple of books last week-end - both by Tyler Beard. One of them is a book about saddles and saddlery, and its makers and history. The other is about Cowboy Boots and everything about them. What I like in this book is the 'Anatomy of a boot', clearly shown. For those of use not used to using cowboy boots, this is new. It certainly is, to me. So I thought I would put up the photograph of that here, for anyone on this forum who, like me, does not have this information.

-

Hello all! Newbie here, with a question! Nothing overly involved or complicated here. I want to do something fairly basic, I think. I want to make these boots: ...look like this: These are the same type of boot: a WW2-era paratrooper 'jump' boot. The company that makes the new boot is the same company that made the original (Corcoran) and they are identical. I've read that I can get the 'creased' look by binding up the boots and soaking them in cold water for a day. Any advice on the coloring? Should I be dyeing, or using oils or waxes to tan the leather? Tips would be appreciated. Thanks!

-

Pit of despair. Sewing a zipper into the heel of a riding boot. First time installing a zipper. I welcome your tips and advice. My double stick tape didn't stick to the leather so I used a dab of Barge cement on the bottom and binder clips to hold the zipper for sewing. I hand sewed the zipper into the heel then used a machine for the rest.

-

Hello everyone, I need to know if a boot like this can be repaired? It's a large scratch and I'm not sure how to go about getting it fixed. I was thinking of sanding around the scratch, then trying to buff with either saddle soap or an oil? Any ideas??? Thanks

- 6 replies

-

- boots

- boot repair

-

(and 2 more)

Tagged with:

-

So, this is the fifth pair of boots I am making. The previous four pairs were an evolution of engineer boots and so I decided to make some harness boots this time. They are ready for the midsole, soles, and heels!

-

i hear at 19th century step in shotgun chaps were made bigger so they could fit over your boot's. does anyone know how much bigger.

-

18th-century leather boots (replica) for a bjd doll.

Svetliy Sudar posted a gallery image in Gallery- Our Leatherwork

From the album: Svetliy Sudar Leather Arts Workshop ©

This pair of boots was made as custom order for doll-maker from Sweden. You can read a detailed article about it in our blog - https://svetliysudarworkshop.wordpress.com/2020/02/09/18th-century-leather-boots-replica-for-a-bjd-doll/ These boots are a miniature replica of the 18th century boots. Made as real boots. It should be noted that the “source” we had was quite remarkable: about 42 boots, worn by King Charles XII in Frederick Hall on November 30, 1718. These boots are in the Livrustkammaren Museum (The Royal Armoury (Swedish: Livrustkammaren) is a museum in the Royal Palace in Stockholm, Sweden.). Upper and sole materials - genuine leather (hand and machine stitched). Spurs are titanium, fully functional. Instagram – https://www.instagram.com/svetliy_sudar/ Facebook – https://www.facebook.com/svetliysudarworkshop Twitter – twitter.com/SvetliySudar -

18th-century leather boots (replica) for a bjd doll.

Svetliy Sudar posted a gallery image in Gallery- Our Leatherwork

From the album: Svetliy Sudar Leather Arts Workshop ©

This pair of boots was made as custom order for doll-maker from Sweden. You can read a detailed article about it in our blog - https://svetliysudarworkshop.wordpress.com/2020/02/09/18th-century-leather-boots-replica-for-a-bjd-doll/ These boots are a miniature replica of the 18th century boots. Made as real boots. It should be noted that the “source” we had was quite remarkable: about 42 boots, worn by King Charles XII in Frederick Hall on November 30, 1718. These boots are in the Livrustkammaren Museum (The Royal Armoury (Swedish: Livrustkammaren) is a museum in the Royal Palace in Stockholm, Sweden.). Upper and sole materials - genuine leather (hand and machine stitched). Spurs are titanium, fully functional. Instagram – https://www.instagram.com/svetliy_sudar/ Facebook – https://www.facebook.com/svetliysudarworkshop Twitter – twitter.com/SvetliySudar -

18th-century leather boots (replica) for a bjd doll.

Svetliy Sudar posted a gallery image in Gallery- Our Leatherwork

From the album: Svetliy Sudar Leather Arts Workshop ©

This pair of boots was made as custom order for doll-maker from Sweden. You can read a detailed article about it in our blog - https://svetliysudarworkshop.wordpress.com/2020/02/09/18th-century-leather-boots-replica-for-a-bjd-doll/ These boots are a miniature replica of the 18th century boots. Made as real boots. It should be noted that the “source” we had was quite remarkable: about 42 boots, worn by King Charles XII in Frederick Hall on November 30, 1718. These boots are in the Livrustkammaren Museum (The Royal Armoury (Swedish: Livrustkammaren) is a museum in the Royal Palace in Stockholm, Sweden.). Upper and sole materials - genuine leather (hand and machine stitched). Spurs are titanium, fully functional. Instagram – https://www.instagram.com/svetliy_sudar/ Facebook – https://www.facebook.com/svetliysudarworkshop Twitter – twitter.com/SvetliySudar -

18th-century leather boots (replica) for a bjd doll.

Svetliy Sudar posted a gallery image in Gallery- Our Leatherwork

From the album: Svetliy Sudar Leather Arts Workshop ©

This pair of boots was made as custom order for doll-maker from Sweden. You can read a detailed article about it in our blog - https://svetliysudarworkshop.wordpress.com/2020/02/09/18th-century-leather-boots-replica-for-a-bjd-doll/ These boots are a miniature replica of the 18th century boots. Made as real boots. It should be noted that the “source” we had was quite remarkable: about 42 boots, worn by King Charles XII in Frederick Hall on November 30, 1718. These boots are in the Livrustkammaren Museum (The Royal Armoury (Swedish: Livrustkammaren) is a museum in the Royal Palace in Stockholm, Sweden.). Upper and sole materials - genuine leather (hand and machine stitched). Spurs are titanium, fully functional. Instagram – https://www.instagram.com/svetliy_sudar/ Facebook – https://www.facebook.com/svetliysudarworkshop Twitter – twitter.com/SvetliySudar -

18th-century leather boots (replica) for a bjd doll.

Svetliy Sudar posted a gallery image in Gallery- Our Leatherwork

From the album: Svetliy Sudar Leather Arts Workshop ©

This pair of boots was made as custom order for doll-maker from Sweden. You can read a detailed article about it in our blog - https://svetliysudarworkshop.wordpress.com/2020/02/09/18th-century-leather-boots-replica-for-a-bjd-doll/ These boots are a miniature replica of the 18th century boots. Made as real boots. It should be noted that the “source” we had was quite remarkable: about 42 boots, worn by King Charles XII in Frederick Hall on November 30, 1718. These boots are in the Livrustkammaren Museum (The Royal Armoury (Swedish: Livrustkammaren) is a museum in the Royal Palace in Stockholm, Sweden.). Upper and sole materials - genuine leather (hand and machine stitched). Spurs are titanium, fully functional. Instagram – https://www.instagram.com/svetliy_sudar/ Facebook – https://www.facebook.com/svetliysudarworkshop Twitter – twitter.com/SvetliySudar -

18th-century leather boots (replica) for a bjd doll.

Svetliy Sudar posted a gallery image in Gallery- Our Leatherwork

From the album: Svetliy Sudar Leather Arts Workshop ©

This pair of boots was made as custom order for doll-maker from Sweden. You can read a detailed article about it in our blog - https://svetliysudarworkshop.wordpress.com/2020/02/09/18th-century-leather-boots-replica-for-a-bjd-doll/ These boots are a miniature replica of the 18th century boots. Made as real boots. It should be noted that the “source” we had was quite remarkable: about 42 boots, worn by King Charles XII in Frederick Hall on November 30, 1718. These boots are in the Livrustkammaren Museum (The Royal Armoury (Swedish: Livrustkammaren) is a museum in the Royal Palace in Stockholm, Sweden.). Upper and sole materials - genuine leather (hand and machine stitched). Spurs are titanium, fully functional. Instagram – https://www.instagram.com/svetliy_sudar/ Facebook – https://www.facebook.com/svetliysudarworkshop Twitter – twitter.com/SvetliySudar -

18th-century leather boots (replica) for a bjd doll.

Svetliy Sudar posted a gallery image in Gallery- Our Leatherwork

From the album: Svetliy Sudar Leather Arts Workshop ©

This pair of boots was made as custom order for doll-maker from Sweden. You can read a detailed article about it in our blog - https://svetliysudarworkshop.wordpress.com/2020/02/09/18th-century-leather-boots-replica-for-a-bjd-doll/ These boots are a miniature replica of the 18th century boots. Made as real boots. It should be noted that the “source” we had was quite remarkable: about 42 boots, worn by King Charles XII in Frederick Hall on November 30, 1718. These boots are in the Livrustkammaren Museum (The Royal Armoury (Swedish: Livrustkammaren) is a museum in the Royal Palace in Stockholm, Sweden.). Upper and sole materials - genuine leather (hand and machine stitched). Spurs are titanium, fully functional. Instagram – https://www.instagram.com/svetliy_sudar/ Facebook – https://www.facebook.com/svetliysudarworkshop Twitter – twitter.com/SvetliySudar -

18th-century leather boots (replica) for a bjd doll.

Svetliy Sudar posted a gallery image in Gallery- Our Leatherwork

From the album: Svetliy Sudar Leather Arts Workshop ©

This pair of boots was made as custom order for doll-maker from Sweden. You can read a detailed article about it in our blog - https://svetliysudarworkshop.wordpress.com/2020/02/09/18th-century-leather-boots-replica-for-a-bjd-doll/ These boots are a miniature replica of the 18th century boots. Made as real boots. It should be noted that the “source” we had was quite remarkable: about 42 boots, worn by King Charles XII in Frederick Hall on November 30, 1718. These boots are in the Livrustkammaren Museum (The Royal Armoury (Swedish: Livrustkammaren) is a museum in the Royal Palace in Stockholm, Sweden.). Upper and sole materials - genuine leather (hand and machine stitched). Spurs are titanium, fully functional. Instagram – https://www.instagram.com/svetliy_sudar/ Facebook – https://www.facebook.com/svetliysudarworkshop Twitter – twitter.com/SvetliySudar -

So I don't know if this is the right place to ask for help but I have searched the entire internet for either similar boots or someone I could commission to make them for me. I'm looking for something based off of these: I wouldn't expect them to be exact because this is not a real picture but I really love these boots and I want something similar. If anyone could help with this or help me find someone who can that would be amazing. Price isn't an issue. My email is jacklynlemay (at) gmail.com Thank you!!

-

Hi All, I'm a newish shoe/boot maker in AZ, and I wanted to introduce myself and see who else out there is making footwear. My style is a moccasin style shoe/boot, that is patterned around making a cast of the person's foot. So, each one is built for the individual's foot. I'm in the process of working on some sandals, and little bags and wallets. I would love to connect with other shoe makers, especially if you're in the Southwest. Rai (like the bread)

-

I spray painted my boots but the paint keeps coming off when I wear them. Any ideas on what I could do?

- 4 replies

-

- equestrian

- silver

- (and 5 more)

-

So, 10 months ago, I posted my first leather project... a pair of engineer boots. I didn't expect to end up with something I could wear and didn't care about the mistakes in stitching, pattern, etc. However, the end result was something unexpected and so I decided to do it again, this time with better materials, more care, a better pattern, etc. So, here are the results. My engineers, version 2. Very happy with how they turned out. Brown Horween Chromexel Horsebutt Japanese buckles Neoprene soles with Catspaw heels Unstructured toe

-

My cousin wanted a wallet made from the tops of an old pair of work boots. He's a junkman that goes by the name "Junkman" and goes through work boots like crazy. The outer is from the boots and the inner is 2/3oz veg tan.

-

Hello all, First off, Ill start by pointing out that I am not a shoe/boot maker and have never made a pair. I have absolutely no experience in this field although I have been leather crafting accessories for a few years. That said; I'd like to take a stab at making a rough pair of boots. I'm not really interested in learning how to carve a pair of lasts out of wood at this point as it seems that this is an art of its own. Rather, I'd like a more simple way of making a pair of lasts. I've done a bit of reading about using a pair of old boots/shoes to pour some sort of resin/foam into to get a rough last shape out of, then shaping it. The problem is, the only information I've found about a substance which can be nailed into without cracking is this smooth-on foam #25. Which apparently is dense and rigid enough to put a nail into, but flexible enough to avoid cracking, according to a user in another thread. This foam used in combination with a thin layer of bondo apparently will do the job for a couple of pairs of boots/shoes. Problem is, this foam is $185 a gallon. This is completely unreasonable for me as I'm just doing this as a hobby. I also wonder if this foam would be rigid enough to stretch the leather over without altering the shape of the "last". Is there some other resin or plastic combo or otherwise I could use to achieve a "nail-able" and rigid material? Could I just melt some recyclable HDPE? Or would that deform the shoe I plan on using to pour the substance into? I need something that won't hurt my wallet, and is hard enough that I can form leather with it, but not so rigid that it would crack when nailed into. I really hope someone has some experience with this! Thanks again, Zayne

-

-

Hello all, First off, Ill start by pointing out that I am not a shoe/boot maker and have never made a pair. I have absolutely no experience in this field although I have been leather crafting accessories for a few years. That said; I'd like to take a stab at making a rough pair of boots. I'm not really interested in learning how to carve a pair of lasts out of wood at this point as it seems that this is an art of its own. Rather, I'd like a more simple way of making a pair of lasts. I've done a bit of reading about using a pair of old boots/shoes to pour some sort of resin/foam into to get a rough last shape out of, then shaping it. The problem is, the only information I've found about a substance which can be nailed into without cracking is this smooth-on foam #25. Which apparently is dense and rigid enough to put a nail into, but flexible enough to avoid cracking, according to a user in another thread. This foam used in combination with a thin layer of bondo apparently will do the job for a couple of pairs of boots/shoes. Problem is, this foam is $185 a gallon. This is completely unreasonable for me as I'm just doing this as a hobby. I also wonder if this foam would be rigid enough to stretch the leather over without altering the shape of the "last". Is there some other resin or plastic combo or otherwise I could use to achieve a "nail-able" and rigid material? Could I just melt some recyclable HDPE? Or would that deform the shoe I plan on using to pour the substance into? I need something that won't hurt my wallet, and is hard enough that I can form leather with it, but not so rigid that it would crack when nailed into. I really hope someone has some experience with this! Thanks again, Zayne

-

I thought it would be good to gather up a list of shoe making books with authors and ISBNs. We can do this as a running list of books. M. De Garsault's 1776 Art of the Shoemaker translated by D.A. Saguto ISBN 978-0-89672-650-5 The Art of Leather Inlay and Overlay by Lisa Sorrell ISBN 978-0-7643-5121-1 Bespoke Shoemaking by Tim Skyrme ISBN 0-9802937-0-7 The Make-it-Yourself Shoebook by Christine Lewis Clark no ISBN Make Your Own Shoes by Mary Wales Loomis. Book is available from her website. The Art of Boot and Shoemaking, A Practial Handbook by John B. Leno ISBN 978-1-57898-972-0 Handmade Shoes for Men by Konemann ISBN 3-89508-928-1 Pattern Cutting, Step by Step Patterns for Footwear Edited by Frank Jones ISBN 978-0-9554086-0-1 Last Designing & Making Manual (DVD sold separately) by George Koleff no ISBN Available from walrusshoe.com and Tim Skryme Shoes for Free People by David & Inger Runk ISBN 0-913300-44-6 Stepping Through Time, Archaeological Footwear from Prehistoric Time until 1800 by Olaf Goubitz Available from Oxbow Books Make Your Own Medieval Clothing, Shoes of the High and Late Middle Ages by Stefan von der Heide ISBN 978-3-938922-25-5 Shoes and Pattens by Frances McGrew and Margrethe De Meergaard ISBN 978-1-84383-238-6 DVDs The Art of Shoemaking featuring Glen Leasure available from healthyhandmakeshores.com Make Your Own Scandianavian Turnshoe with Jason Hovatter available from laughingcrowe.com