Search the Community

Showing results for tags 'holster'.

-

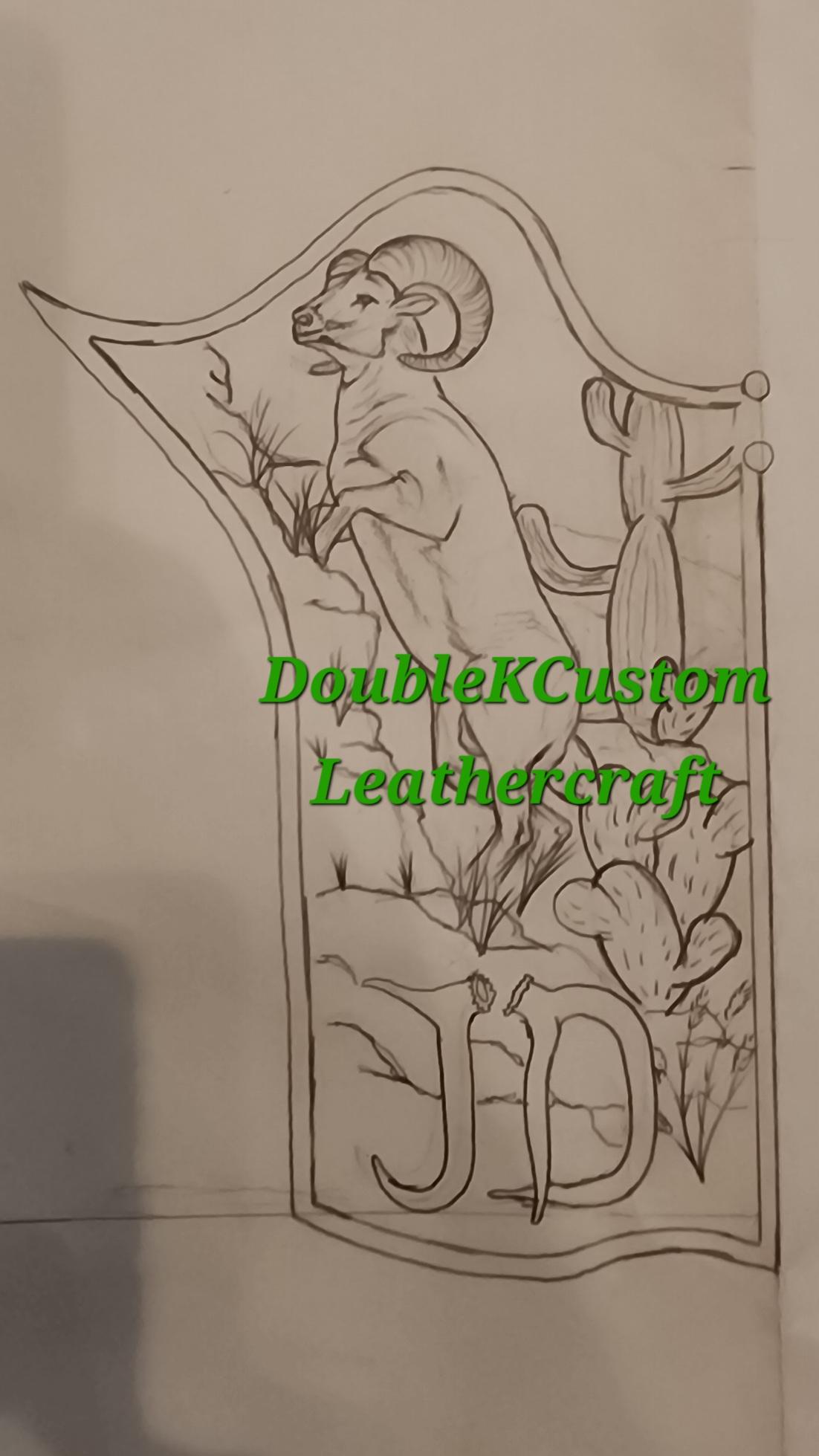

This is a follow up to my previous post explaining how I drew the pattern for this carving. And a few other things. I did add a toe plug on this to help retain its shape for years. My client specifically said, "I would like you to have artistic freedom on this, and I would like to be surprised" direct quote. I chose the bighorn because of their resilience and strength. They live a rugged lifestyle that represents the wild west. I chose the desert bighorn because it's headed to CA and they're one of two native species too the state. Hermann oak holster tan 9/10 from weaver. Feibings pro dye light brown Feibings antique finish dark brown, with no resist to darken the leather a bit for a more medium brown Feibings leather balm atom wax finish Ritza tiger thread 1.0 cream saddle stitched Tokenol edge burnish Weaver's Water Buffalo lining, and hammer spur strap (for strand round braid)

- 15 replies

-

- desert bighorn

- holster

-

(and 1 more)

Tagged with:

-

I'm not finished yet but I'm close. I just need to same the edges and finish. I'll update this as I go. I just wanted to share the process of making unique patterns to carve. First, it took me some time to find the right picture. I knew what i wanted and could've easily just drawn out, but i wanted to see the muscle structure of the sheep climbing. And not just climbing, but climbing steep country with the right angle to flow with the holster shape. I use an app on my phone that's called tracing paper. It allows my to zoom in or out and lock the screen so I can trace the outline to make the photo a line art pattern to work from. I can do things freehand, but sometimes it's just quicker this way. This is how I started the pattern. I traced the sheep first, then added to the background and foreground. After that it's just business as usual. Case the leather, transfer the pattern and go to town. I'm stoked at how well this has turned out. It will be dyed light brown with a dark brown antique. Hermann oak holster tan from weaver. This is the last holster from that side and had a severe taper in thickness from 10 oz to 7 oz. I evened out the thickness to the bend of the belt loop and left the loop at 10oz. Feibings pro dye and antique finish Ritza tiger thread 1mm cream Leather balm to finish Lined with 3/4 oz Water Buffalo to make up the lost weight and bring it back near 10oz overall. I'll post more pics after I finish everything

-

While working a commission for a company, one of the employees asked if I could do holsters. I had never made one so I did my best to find out if I could. I see many mistakes in my part, especially messing up the last bit of stitching of the entire piece. But for a first try im pretty pleased with myself. I'll have to use it for awhile before I'd be comfortable trusting one I made enough to sell though.

-

This is my first IWB appendix carry holster. Sig P365 X Macro with a foxtrot 2R light. In the three years of don't business here in Montana, this is only the second IWB holster I've been commissioned to make. The first one was a beautiful single clip for a fullsize browning high power to carry in the 4 o'clock position. This one came out looking great, but.... IT'S A FAILURE. Yes I'm posting my fail in showoff to make a point. The gun, and light combo fits great. The holster is comfortable except for the left side (right side in picture). Apparently I make the corner a bit too sharp. That's not where the real failure is though. Today I got a dreaded text. The magazine button gets pushed and his magazine popped out in front of customers. He works behind the gun counter at a big retailer. There's two things wrong here. First, that's definitely something you don't want to happen in front of someone, especially in a retail setting. It not only tells everyone "Hey, I'm carrying a concealed weapon!" but it also looks bad on the company that employs him and the maker of the holster (me) Secondly, and this is the most important part of being a holster maker, failure such as this cannot be tolerated. That could end up extremely bad in a situation where he may actually have to protect himself. The mag could be in the gun, but not in battery and if he had to defend himself, it could be a death sentence. As a holster maker I have to take into consideration that this holster may have to save a life, it must function 100% correctly. It's a crushing feeling, but a good lesson. I'm glad it's only been a day and he figured it out before he actually needed his firearm. I will be making adjustments to the pattern and of course making him a new holster. Its unfortunate that this does happen occasionally. Especially when is outside my specialty. I'm not experienced in IWB holster design. 65% of my business is shoulder and chest holsters, with 20% pancake style holsters and the last 15% misc holsters, knife sheaths and other projects. I'm sharing my failure for others to understand. We're not perfect all the time and we have to fail to learn. I have about 4 or 5 holsters that were just not the right fit, either too tight for the weapon, or the wrong balance. This though, is my first actual failed design. I've already discussed with him where the flaws are. I'll make it work right, and I won't be charging anything extra. This is 100% on me and not the customer's crazy ideas.

-

Here's one of my latest holsters. Its a chest holster that rides like the doc holiday, low and cross draw. I used a Gormley hand of God pattern for the holster, modified a bit to ride on the harness instead of a belt. This one is for the 1858 Remington. The rope border is stamps using a triangle bevel. Time consuming but it comes out much better than the rope stamp the customer originally wanted. He was very pleased with this one. I pad and line the shoulder strap with water Buffalo. The rest is Hermann Oak "holster" veg tan. The holster is 9/10oz and the strapping and shoulder strap is skived down to around 6oz. I hand skive with the good 'ol safety skife, then come back through with my finger plane to even out the surface.

-

- 5 replies

-

- flatback holster

- holster

-

(and 1 more)

Tagged with:

-

I finished my customer's order with the moose carved holsterthat I posted about a week ago. I ended up having to make the elk holster a second time because I forgot to adjust my pattern for the suede lining. I figured it out right away, and the entire time I was making it i thought something was off. The phone case was my first that I've been commissioned to make. My customer was absolutely ecstatic about it. Mainly I think he was more excited about the grizzly. The knife sheath is for a little damascus pattern skinner. We decided to go with the snapping turtle leather inlay because it's such a small window to carve on. I still have some of the leg leather left from a couple of tail inputs inlaid orders. Elk holster- Ruger P85 Moose holster- SCCY CPX2 Grizzly- Galaxy S+ series/size phone Snapping turtle inlay- unknown knife maker, small skinner

- 4 replies

-

- snapping turtle

- figure carving

-

(and 2 more)

Tagged with:

-

Made with W&C 10oz tooling leather. Primary pistol is a Cimarron/Uberti 1875 Outlaw, 7.5" barrel, .45 Colt. Cross draw is a my father's Ruger New Model single six, 5.5" barrel, .22LR

-

So... I'm hoping this isn't too much of a daft question after the lengthy back story... But... I've had a friend of mine ask me to push my still fairly limited skillset and build them a holster and drop gun belt for a replica Colt .45 SAA single action pistol (his description based on the replica he has provided me to work with, looks like a cowboy gun to me as i'm not a pistol person). I have followed a couple of very detailed descriptions on how to template and assemble the holster and have been somewhat successful... however, with both methods used after some gentle wet forming around the replica firearms the pistol is rather firm to both insert and remove from the holster unlike what I see in movie magic or the youtube gunslingers. I can hold the holster upside down and shake it quite vigorously without the pistol coming out. I will be remodelling the template anyway as it looks a little wobbly in places and I am planning on lining the holster for the final build so will require a touch more space. My question is this, how tight is too tight for a holster?

-

It's been well over a year since I made this holster for a customer that wanted something unique and flashy at the same time. It's definitely up the in the top 3 favorite holsters I've made. Any critiques are helpful.

- 7 replies

-

- 1911

- skull carving

-

(and 1 more)

Tagged with:

-

I haven't been around here in a while...just wanted to share my latest work, a holster I'm making for a friend. The resist totally failed, but I think I like the finish so far. Not sure if I'll send it out this way but I'll wait until it's stitched up and edged properly and all before I decide. As an aside, I haven't been doing much leather lately...I've been having problems with my hands for a couple of years now. Last year it got so I couldn't really hold small tools for more very long, much less gripping them while I whack em. Docs don't know what's wrong yet, sooooooo....anybody have any tips for controlling hand pain so's I can stick with this a while longer? Thanks all...happy pounding!

-

Tried my hand at a revolver holster. Seems to fit a large N-Frame just fine. Open to suggestions, comments, critique, etc.!

-

My dad has been going to Lithuania for last 6 or 7 years on mission trips with his church. One of the guys they met this past summer who was helping them get supplies and help translate and other stuff is military/police officer as well. Him and my dad was talking about guns and such and my dad was showing him my website and some other pics of work I've done. He mentioned how he would love to have a custom holster for off duty use for his glock 17. So I built him one and the preachers wife is taken it over to him as a gift when she goes next week to deliver a Christmas care package to the families they help. I didn't go to over the top decided to keep it classic with a nice 2 tone black and brown. 7/8oz for main body. 6/7oz for the decorative stiffner/belt loop. And it's lined with some thin pig I had laying round.

-

Beautiful little pew pew remington 44 mag with a Burris 2x7x hand gun scope I happened to have a lg frame pistol pattern. All that was required was cut the pattern in half and add the leather for the scope add straps add a 6 oz veg tan linerI m

-

From the album: Primo

I had no idea what the line I drew over in Red sharpie was supposed to be for until much later in this project! lol© 2023

- 2 comments

-

- holster kit

- holsterglock

-

(and 3 more)

Tagged with:

-

Large collection of aluminum dummy guns for sale. Used for holster making, nothing wrong with them just no longer use them. 238 aluminum, 14 plastic semi-auto 130 magazines $15,500 plus shipping OBO

-

From the album: Primo

I searched and searched on this forum, and I think I found ONE person who was doing this. This was the BEST part! As you can see in other pics, I added a layer of black leather (pre-dyed) with leather glue and then when that had set up for about 5min, I started molding my holster around the gun (which was saran wrapped and rods added for sight clearance) and when I put it in the vacuum mold, every little detail of the gun started showing up. It was very exciting to watch, lol© 2023

- 1 comment

-

- holsterglock

- holster kit

-

(and 3 more)

Tagged with:

-

From the album: Primo

I love the feel and warmth of leather, but kydex just has that "click!" This is a different version of SafariLand's "Quick Lock System." I fits every width of belt, at any hip position, at any cant position. THEY'RE FREAKIN' AMAZING!© 2023

-

From the album: Primo

Freshly oiled after the vacuum was held for 48hrs, That is an 1881 Morgan Silver Dollar for anyone who is a coin connoisseur. I had two matching coins, both 1881 MSD. One is in my holster, as you see here, and the other is in the holster I made for my dad while I was finishing up this one.© 2023

-

Flat and you can see every mistake!

Lifesaver3123 posted a gallery image in Gallery- Our Leatherwork

From the album: Primo

If you can't already tell by the brand of pattern and the shape, I'm using a holster kit I found at Hobby Lobby after a few too many edibles.© 2023

-

- holstersmolding

- holster kit

-

(and 3 more)

Tagged with:

-

Below is my take on Will Ghormley's 3 Persons 1911 holster, from the 1911 100th anniversary pattern pack. I modified it (very slightly) for a Springfield EMP4 (soon to be mine .) Tooling pattern is Al Stohlman; Angelus light brown, ecoflo tan antique gel, wax finished edges. This was only my second attempt to use a toe plug (last time was about 15 years ago,) so the stitching on the bottom of the toe is iffy, but I'm happy with it.

-

I have a few bundles of DVDs for sale through a couple of eBay auctions (Ending 11/15/22. in the evening): - 6 DVDs on leather carving, Sheridan style and more: https://www.ebay.com/itm/255810778928 - 9 DVDs on how to make various knife sheaths : https://www.ebay.com/itm/255810991680 - 5 DVDs on bag making, carving and construction: https://www.ebay.com/itm/255812182660 - 6 DVDs on How to make Holsters including the John Bianchi set: https://www.ebay.com/itm/255812221084 - Full DVD set of Leather Holster Making by the American Gunsmithing Institute taught by the talented Chris Andre: https://www.ebay.com/itm/255812206122 - 5 DVDs on leather lacing, turks head, etc..: https://www.ebay.com/itm/255812236482 - 6 DVDs on Dyeing, Assembly, Tool care: https://www.ebay.com/itm/255810974935

.thumb.jpg.327685d8c1787fa894323fed9a6b2dac.jpg)

.jpg.66a3d1aab4701b2cca2157c76b80ab93.jpg)

.jpg.daaaf2a8ad2966160cb9a081070fcf57.jpg)

_sm.thumb.jpg.a9dd9457707d124e04cfdb79fe76fec2.jpg)

_sm.thumb.jpg.716255b42b3df831e75686201e6da3a6.jpg)

_sm.thumb.jpg.034aefebad379058322f706e6c5ad387.jpg)