Search the Community

Showing results for tags 'motor'.

-

Dear all, I have got my hands on a pfaff 561 with an efka variostop motor. I'm a true newbie with (industrial) sewing machines and I really didn't know much about the machine before purchasing and how to value it. I've come across the problem that the machine shuts off when I decrease the pressure on the footpedal (from fast to slow stitching). I don't know what happens, I can only explain it as the experience of lowering the speed in a (clutch) car and the speed becomes too low for the gear and the car finally shuts off. The efka motor of the sewing machine "stutters" and then finally shuts off as if it has short-circuit. I can't restart the motor up until (over) a minute later, before it starts and shuts off again. The seller told me the machine works on 220 Volt, but maybe not? Are the settings not compatible? I would really appreciate it if someone with the knowledge can give me an update on the do's and don'ts with the efka motor! Was this purchase a mistake? In the meantime I got my eyes on an Adler 67-73 L with a servo motor, though it is double the price. Would it make more sense to return the pfaff and invest in the Adler? I am situated in the Netherlands and don't work with leather but I make bags and wallets with waste tarpaulin.

- 9 replies

-

- steppermotor

- variostop

-

(and 3 more)

Tagged with:

-

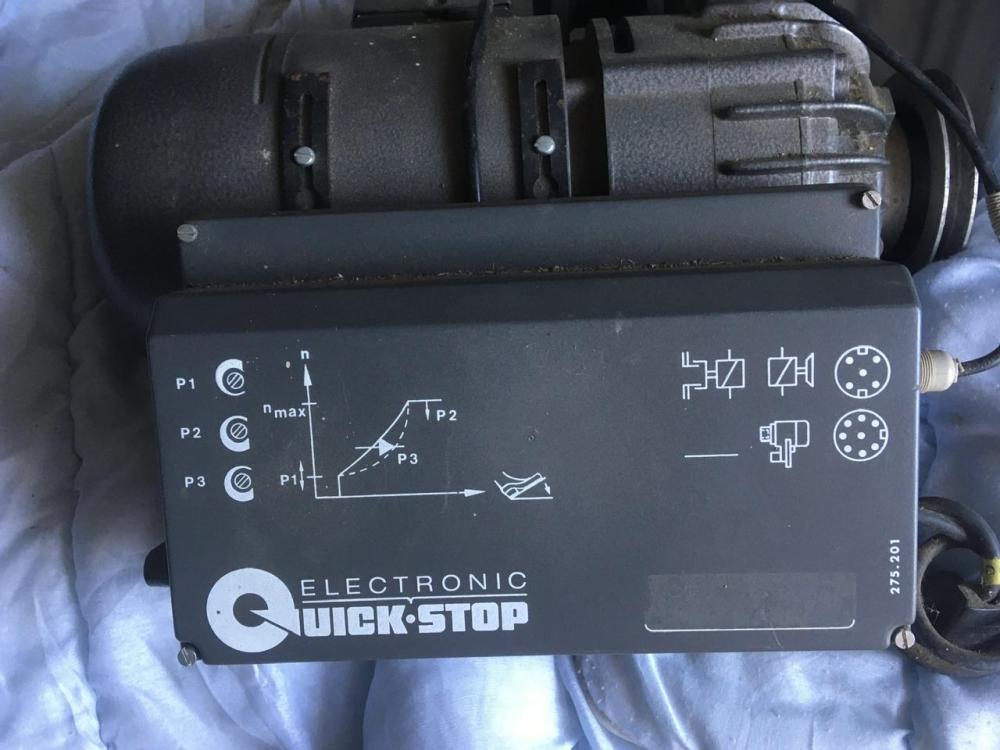

Hi everyone, Im new here and want to start learning about leather works and sewing in general, the forum seems already full of great advices and experiences but I still can’t find any info on the motor of my machine. I inherited an Adler 69-373 that came with a Quick Rotan NDK 880 M/14 motor that I’d like to know a bit more about but I can’t find any information online. It’s mounted with a Quick Stop 275.201 control box and a needle positionner. Would anyone here have the manuals or some kind of useful info about this motor and control box ? Thank you much kind regards, Jerome

-

I have a Singer 66-18 with the Simanco BA motor. I know it is not a heavy leather machine but want to use it for lightweight garment leather. The motor runs at high speed BUT has no power. Without the belt, I can easily stop the motor with my fingers. On the machine, the motor can barely run, even without thread or material under the presser foot. I can hand turn the balance wheel easily and I have cleaned and oiled the machine. The motor works better when the belt is tensioned too loose. I have replaced the drive belt. I don’t feel like the problem is the machine but don’t know what to try next. Thanks in advance! Ken

-

Hello, I recently posted about choosing my first industrial machine - thanks to everyone who chimed in to help there. I am going with the Juki 1541S and wanted to discuss the pros and cons of the motor setups I'm looking at to make a more educated purchasing decision. Cost difference: $10 - negligible. Typical use case: Sewing through 8-10 oz bridle + two layers of 4 oz soft leather. Would like headroom to ensure power isn't an issue if I need to use heavier material for some projects. These pros and cons are based on my research so far, including reading a lot of threads here, not actual experience. Please feel free to correct me if something seems off and/or add your own experiences. FESM-550S w/ reducer - PROS Gold standard - used by lots of people, known to work well. Very slow speeds possible. Maximum controllability. Reducer can be used with a variety of motors. Easy/cheaper to replace motor if it poops out. FESM-550S w/ reducer - CONS Reducer is a heavy cast iron wheel that might introduce some additional momentum into the system that the motor has to brake. Anyone have issues with this in reality? Might not be an issue at low speeds anyway. Reducer makes for a more mechanically complex setup compared to other methods of slowing things down (smaller output wheel, larger hand wheel, motor that supports very low speed/high torque out of the gate). Less powerful motor for the money (reducer itself costs more than the motor), though still plenty to do the job. SP-1100-NPFL - PROS Every account I've read so far has described this as a torque monster even at low speeds. Probably overkill for me, but nice to know I'd never want for power. Simpler setup with detached control box in easy reach. Comes with the needle positioner, which seems cool, but might not be needed at slow speeds anyway, and could just be another gizmo to break. SP-1100-NPFL - CONS Expensive - if this motor poops out, high replacement cost since I can't just slap a $150 servo on it and call it good without a reducer. Not as time-tested as the 550S/reducer setup. Perhaps not able to reach the low speed/high torque abilities you can get with a reducer (without aftermarket mods)? Can anyone chime in on this? Question: Which of these setups would you choose to power your new machine if you were buying today, new to using a sewing machine, and wanted a reliable low speed setup that has room to grow for the future? Or should I just toss a coin because they're both pretty darn good?

-

I need a replacement motor for my Adler 30-15 post machine. The motor I had was a Westinghouse, 1/6 hp, 1725 rpm, Frame 145, style 1177109-C, open, AC motor type FH. (placard of motor attached). Please call or email me a price. Demps Bannerman demps@criticalpowersystemsinc.tech 662-401-8831

-

I own Juki 1508s . GOLDSTAR GSM550 will not let me go lower than 1600 RPM. I have speed reducer installed. This model uses a needle positioner that I like. Question- need a new motor that allows RPM 500- 3500 but also has needle positioner that fits Juki AMCO shaft. ( see picture of needle positioner) Or how do I tell the servo to go slower from computer module...Any opinions?

-

My JUKI came with a Goldstar GBSM 500 servo motor. I lost the instructions of what the buttons do. One is speed, one says allows you to switch between P1 and P2 ?? I thought that was part of the positioned mechanism but nothing changers when I use it, third but allows change from F1,F2,F3. I don’t know about this. help if you can

-

Hi all, I have a consew 226R and I'm ready to put a servo motor on it for more control. My problem is that most of the recommended motors on leather forums, like the Reliable motors (which seem reasonable for well under $200au), are all for sale overseas or on ebay. Whilst some of them look like they have the voltage option for Australia, which is 220v, I can't tell if they would then have an Australian plug. The motors that are for sale from Australian vendors all look extremely expensive to me by comparison, around $400au. I'd really appreciate any info from fellow Aussie leather workers who have been down this path. And from anyone else too of course, if you have seen this type of question before. Regards, Carrie.

-

Hello, I bought my Cobra Class 26 3 week ago (NEW). It´s really nice machine, and I like it a lot. But I have problems with servo motor and controlling the sewing speed. When i set speed on for example 15. I cannot sew slowly. When I press foot pedal, just a little bit it, sews immediately fast. And when i set speed on 5, it sews slow, but sometime accelerates for few stitches (like on number 10), and than slow again. But my foot pedal is still. Maybe you have some suggestions what can i do? I tried a lot, but probably not everything. Thanks a lot and have a nice day

-

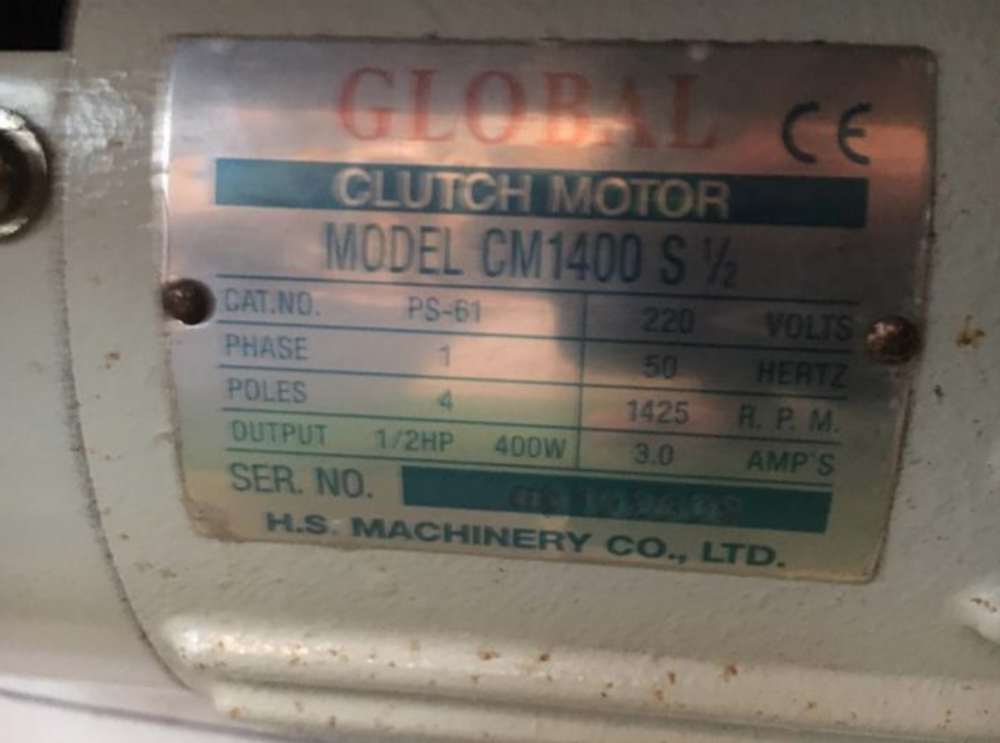

I'm in need of a 'slow' sewingmachine for precision and control stitching and found a good deal now. The advertiser send me this photo of the motor; it's a clutch motor, he called it a 'leather motor' since it goes at about 1425 r.p.m. I have no experience with motors/electronics and could use some advice regarding this offer, or deciding to upgrade to a servo. I made the agreement that I can either buy the machine without the motor (and order a servo elsewhere) or buy it with, but it will have an impact on my budget. Will this motor be slow enough for my needs? I would like it to go stitch by stitch at times, I'm not at all interested in 'fast' options. Also I prefer the machine to be quiet, which I know a clutch is not. What is the aprox. value of this clutch motor (without machine)? Thanks !

-

Hi everyone new here and just became a proud owner of a consew 206! i quickly found out that it vibrates my entire apartment though, which isn’t great for neighbors. Im wondering if there are any servo motors with speed variability in the $100 range that would serve me well. Is that cheap not worth doing, are they fine, is $200 night-and-day. Any advice is appreciated. Thank you!

-

I recently purchased a juki lu563. It came with an extra motor, a enduro pro sm645-1p. It was missing the fuse cap and fuse. I contacted enduro and they can’t tell me what amp fuse is used with this motor. Does anyone know what amp buss fuse is used with this motor? I’d like to get it running. thanks

-

I recently purchased a juki lu563. It CSM with an extra motor, a enduro pro sm645-1p. It was missing the fuse cap and fuse. I contacted enduro and they can’t tell me what amp fuse is used with this motor. Does anyone know what amp buss fuse is used with this motor? I’d like to get it running. thanks

-

- sewing machine

- servomotor

-

(and 3 more)

Tagged with:

-

Hello, everyone! I recently bought myself a Pfaff 345 cylinder bed industrial sewing machine. I would like to swap the fast 3F clutch motor with a more controllable servo motor. I live in Europe (Slovenia) and as far as I know I can't get my hands on a Family sew or Hightex motor here. My options are 750W Jack servo motors and Zoje servo motors (although not much is written about them on the internet), maybe 550W Sailrite Workhorse or any other good quality motor brand I am not familiar with. I would appreciate any advice on which servo motor to buy. My budget is in 200-300€ range. I mostly do leather bags, purses, belts, wallets from veg-tan (not more than 6mm/0.3 in thick) and crome-tanned leather. Kind regards, Gregor

-

Hi guys- i need some recommendations on a servo motor for my DA 269-373. I have an Enduro Pro 5000rpm on my Consew 206rb, along with a speed reducer. It's a 110v motor, and I'd really like to do something similar on my other machine as well. However, I'm having trouble locating another motor like the one I currently have, so I'm wondering if anyone would recommend others. Or at least which ones to stay away from. I see several models with brakes (as far as I know) floating around eBay for around $100-130, but I'm not sure what to make of them. I also see several that look smaller and have a digital control on the control box that is separate from the motor itself (Iike the Consew CSM1000). Any help on this would be appreciated. Thanks!

-

From the album: My Trade Crafts

biker wallet with a lady riding a moon too -

Hi there, I have a flatbed heavy-duty Sailrite LSZ-1 that I've been playing with and I've found the speed very difficult to control solely by the foot pedal. Looking at videos on youtube, I learned that Servo motors can be bought to retrofit old sewing machines, I wonder if I can do the same with the Sailrite LSZ-1. How would I go about this to figure out if it is possible? The motor on this LSZ-1 is attached to the sewing machine. Another idea I read somewhere is to add a voltage regulator kinda thing that can more precisely control the speed compared to using a foot pedal...no idea how to do this though please help...thank you all!

-

I had a vintage Fortuna s50v that was set up in a particular way: when the ON switch was turned on, the bell knife rotated at constant high speed. The feed roller variable speed was controlled with the foot pedal (a light press on the foot pedal would ensure a slow feed; flooring the foot pedal made the feed roller rotate at top speed). This setup was perfect for the types of leathers I skive. When moved abroad I sold the Fortuna, and am now looking at a Japan-made Nippy NP-202 or NP-2 or skiver (essentially same-same parts as that old Fortuna). Local skiver vendors say to set a skiver up that way two motors are needed. One underneath and an additional motor mounted to the table behind the skiver (back right). I am not very mechanical, but not inclined to want to mount a motor on the table behind the skiver. The Fortuna v50s seemed to have only one motor. Enclosing photo and have many more photos of the guts & back of the skiver if helpful. Question: In order to run bell knife at constant speed and control feed roller at variable speed, are two motors necessary? What is the best optimized way to set up the skiver? Specific suggestions would be appreciated.

-

Anyone have any experience with the Zero-Max E1 Adjustable Speed Drive or anything like it? It says it uses a series of 4 clutches to reduce the input from anywhere between 0 - 1/4 of its original speed. It's rated for an input of up to 2000 rpm, and it seems to be fairly well made. That's just a general observation though...it seems fairly beefy. I'm not sure what it does to the power/torque of the output though. I don't know if using the clutches as opposed to gears or pulleys means that the speed reduction is achieved by pulling power out of the system as opposed to just simply trading decreased speed for increased torque. I'm not super knowledgeable of how clutches work, but I'm wondering if it basically transfers X % of the power to achieve the decreased speed. If not then it looks really awesome, and like something I'd like to pick up if I can find a good deal on one somewhere. I've found a couple for around $225, the same price I've been finding on the nice reducer pulley setups, but I also found a used one for $150. Who knows how good the clutches are still though. It might be worth the extra $75 to get one that hasn't been used. I'm assuming the clutches on these would eventually wear out just like the clutch on a motor or in a car. I've done just enough transmission work to know I don't like doing it, and I've only worked on the valve bodies...never made it into the clutch packs. Although, that could partly be due to having to do it stuck under a 2-ton vehicle with about 24" of space between the ground and the bottom of the car. Man I wish the concrete in my garage was thick enough to support a 2-post vehicle lift. Enough rambling...any thoughts people?

-

My Consew 206RB-2 with clutch motor seems to have too much play in the clutch before engaging. I'd like to shorten the movement required to engage the clutch, and I'm pretty sure that is something that is possible. I'm just not sure how to do it. I seem to remember reading something about just adjusting a bolt on the motor, and I even see a bolt below & to the left of the pulley that seems like a likely candidate. I'm just not sure though, and I don't want to mess something up if I'm wrong. Hopefully someone here could give me some help with this?

- 3 replies

-

- adjustment

- motor

-

(and 2 more)

Tagged with:

-

My Consew 206RB-2 with clutch motor seems to have too much play in the clutch before engaging. I'd like to shorten the movement required to engage the clutch, and I'm pretty sure that is something that is possible. I'm just not sure how to do it. I seem to remember reading something about just adjusting a bolt on the motor, and I even see a bolt below & to the left of the pulley that seems like a likely candidate. I'm just not sure though, and I don't want to mess something up if I'm wrong. Hopefully someone here could give me some help with this?

-

I'm a newbie to Industrial sewing machines and need to slow the brute down. I have just fitted a Jack JK 563A Motor to my Brother LS2 B837 and even at the slowest speed it is running to quickly. Is it possible to fit a smaller pulley to the motor and what is the size of the shaft? Any advice would be most welcome. Cheers Richard

-

Ok, I got a Pfaff 545-H4-6/01. I know this is a really good machine but now I am trying to learn it and I could really use some help. I am very new to sewing machines but I am going to do what it takes to learn them. The first thing I need help on is the motor, I want to put a servo motor on it for better efficiency and being able to sew at slower speeds etc. but this machine has a lot of extras I have not seen on a machine and I do not know what exactly changing out the motor would involve. I am attaching a lot of pics to show what is on this Pfaff. I cannot even turn the motor on yet because the power cord is a 2nd phase cord (I think) and I only have the standard outlets in my shop. Anyways the motor is a Quick Rotan Synchro 6040. One thing that has me kind of baffled, the guy who I got the machine from said something about needing an air compressor hooked up to raise the walking foot. I think that is what he said but I am not sure if that is exactly what he was talking about. So this is a clutch motor right? Can I change the motor out and put a servo motor on the Pfaff? And what are all of the extra hookups on the back of the machine head? Thank you in advance. I can also take pictures of any specific part of the machine if someone needs to see it. the first 9 pics are of the motor and the last 3 are pics of the attachments on the back of the head of the sewing machine. Thanks a lot!

-

Hi. Prior to buying my machine (Consew 226R), I did a lot of reading here so I just want to start by saying I really appreciate this forum. While everything worked just fine when I bought it, and loaded it in my truck, I'm afraid the 100+ miles of driving may have jarred something loose. Now, whenever I press the START button, the motor accelerates and reaches full RPM w/o any problems. But as soon as I release the button, it starts winding its way back down. So my first thought is it's a switch problem, but before I start fiddling with it, I wanted to see if anyone else has experienced this? Thanks! Salvisa

-

Has anyone tried one of these motors. How about a review? One thing I like is the dial instead of that LED race track thingy for speed control. Art

.thumb.jpg.b3b038d95f8d29d7583c901a4df11280.jpg)