Search the Community

Showing results for tags 'servo motor'.

-

Option A: Digital Servo Motor See the parent article: Choosing a Motor While lots of motors are sold under the moniker “Servo motor”, the most obvious way to recognize a digital servo motor is that it has an LCD on the front of the panel. Note on this forum you will hear people talking about “brushless” servo motors. In theory, a digital servo can be brushed or brushless, but all the digital servos I’ve seen are brushless. So you can assume when folks are talking about a “brushless” motor on the forum, they mean a digital servo. 1. What does “servo” really imply A true servo motor is one that has a feedback loop. You ask it to go 500rpm, and it has an encoder or some other feedback mechanism that it uses to go exactly 500rpm. Whether stitching through thick leather or thin fabric, it keeps going exactly the speed you asked for. 2. Is a Digital Servo the Right Motor for Me? Choose a digital servo if: - you want to use a needle position sensor - you’re OK with doing some basic setup in the LCD menu, - If you want the consistency of the needle always penetrating the fabric, without need to “get a run at it” - you want a motor that does exactly what you tell it - you don’t mind the surprise of instant start. (digital servos have a minimum speed) - you can find one with a minimum speed of 100rpm or lower 3. What is a Needle Position Sensor? A needle position sensor allows a digital servo to stop at the same position every time you let off the gas. I like my needle position sensor configured to stop in the needle-down position. That is the position I use most often, since it allows me to turn corners while stopped in needle-down. So when I let off the gas, instead of stopping immediately, the motor actually proceeds to the needle down position and stops there. 3.1 Positioner: Heel Tap When you have a needle position sensor, it will typically have heel-tap functionality. That is, when configured to always stop in the needle-down position, after it comes to a stop in the needle-down position, you can press the other end of the treadle (the end close to you) and the machine will move approximately a little more than half a rotation and stop in needle-up position. Now you don’t have to do nearly as much hankerin' with the handwheel, because the needle already knows how to stop in your two most desirable positions. 3.2 Positioner: One Stitch Stopped prematurely? A little tap on the pedal and it will give you one more stitch and stop again in your preferred stop position. 3.3 Positioner: Reverse Magic Reverse is convenient with needle positioners too, since you typically want to start reverse from the needle down position. Just allow the machine to stop before you move the stitch lever, and you’ll automatically be starting your reverse stitches in that “reverse magic” position (needle down) where moving the stitch lever does not move the feed dog at all. 4. What’s the Big Deal about Minimum Speed? When looking for a servo motor, the most important feature you should be looking for is a slow minimum speed. When the digital servo motor starts turning, it immediately goes from 0 to whatever the minimum speed is. Meanwhile you’ll be be holding the threads down so your seam locks, and trying to steer at the same time The lower the minimum speed, the less jarring this all will be when the motor starts. 4.1 Examples with 100rpm minimum speed As of August 2025, the lowest minimum speed I’m aware of in a Currently Available Inexpensive Digital Servo Motor (CAIDSM) is 100rpm, and it costs a little more than a hundred dollars. You will need to buy the needle positioner separately, which will cost you another 30. (Will post link as soon as mine arrives and I’ve tested it) 4.2 Examples with 200rpm minimum speed Previously I used these two models which have 200rpm minimum speed. I’ll put air quotes around the brands, since these are just labels and you can buy the same motor with a variety of labels on it. “Stitchman”: https://www.alibaba.com/product-detail/Energy-Saving-Servo-Motor-Industrial-Thick_60477748373.html “Consew C1000”: https://www.amazon.com/dp/B01N6IYMCZ 4.3 Gear Reduction You can lessen the minimum speed that your digital servo offers by gearing it down. The simplest way to gear it down is to buy the smallest motor pulley (the pulley that goes on the end of the motor) that you can. Ideally your digital servo will use a 15mm cylindrical-shaped shaft (no taper), because aftermarket pulleys are readily available in 45mm O.D. for about ten dollars. 3:1 belt reduction is commonly available and costs about $110. You may or may not decide you need that much. There are also examples here on the forum of custom built gear reducers using pulleys and pillow blocks. 6. What’s already Working Well Since this article does set out to name certain deficiencies in the CAIDSMs, I thought I would also give praise to the things that have already been ironed out, and are much appreciated! 6.1. The maximum speed can be set to something approachable instead of the default 3500rpm. 6.1. Setting the maximum and minimum speeds is a repeatable process. That is, if you want max speed for one project to be 1200 rpm (at the motor) and for another project you only want 700 rpm, you can select exactly those values in the menu. 6.1. The digital servo already runs well at consistent speed with great penetration power. 6.1. Needle position sensor has basic functionality. 6.1. The power switch is usually in easy reach of the operator. 6.1. The power switch lights up so we can see it’s powered on. 6.1. Digital servo motors are quiet! You won’t know it’s on if you’re not on the gas. 6.1. Digital servo motors come with an adjustable bracket for setting belt tension. 6.1. Digital servo motors come with a V-pulley. (I can’t believe I’m listing this as a feature!) It’s just a larger-than-ideal diameter. 6.1. Electric braking: When you let off the gas, the digital servo motor applies electric braking until the motor comes to a stop. (After coming to a stop, the brake is released so you can easily move the handwheel) 7. The Ideal Digital Servo Motor For those whose ambition it is to built better Digital Servo Motors, here are several categories that could use improvement. 7.1 Ideal Needle Positioner 7.1.1. When you tap the gas pedal to ask for one stitch, you should ALWAYS get exactly one stitch. If you give two stitches instead of one now there’s an extra hole in the leather that I hadn’t planned on. Also, giving more stitches than asked seems like a safety issue. 7.1.2. When you heel-tap to ask for the needle to come up, the needle should come up. It must not do a full turn and then come up. A full turn would put unwanted holes in the leather and is a safety issue. 7.1.3. Distance in degrees between needle-down and needle-up should be configurable. (My preference would be to set the needle-down position using the set screws on the needle positioner, and then have a single setting “distance from needle-down to needle-up” in the menu that has a range from 1 degree to 359 degrees (degrees of handwheel, not motor pulley), with a default of about 200 degrees. 7.1.4. If the belt slips such that the motor has to turn farther than it expected for the needle position sensor to register one complete cycle, the motor should stay in needle detection mode. 7.1.5. Ideally, the needle position sensor should have an LED that lights up when the positioner is in the needle-down position. (Makes for easier setup) One of my CAIDSMs has this, one does not. 7.1.6. Assuming this unit comes with a needle position sensor, the controller should have needle positioning enabled by default. 7.1.7. Needle positioner should work even if using considerable gear reduction, such as 3:1, 4:1, or 5:1. 7.1.8. Ideally, allow the user to easily toggle between stopping at needle-up, stopping at needle-down, or disabling the needle positioner. (One of my systems has this option, the other does not) 7.1.9. Ideally, after letting off of the treadle as the motor continues to turn to come into the desired position, this speed of this motion would be configurable. Some users will want this motion to happen at the minimum speed. Some users may want it to be somewhat faster than the minimum speed. (Of my two digital servos, both of which have 200rpm minimum speed, one comes to final position at 200rpm and the other comes to final position at about 250rpm. I did not see any way to adjust either.) 7.2 Ideal Included Pulley 7.2.1. Motor should come stock with a small motor pulley (35mm-45mm) to lessen the effects of the minimum speed. 7.2.2. If motor does not already come with a small motor pulley, motor should use standard 15mm cylindrical shafts with a key hole. After market pulleys are available for these shafts down to 45mm for about ten dollars. (In a pinch you can 3D print a small pulley for any style shaft, but it may not grip as well as the metal ones.) 7.3 Ideal Minimum Speed 7.3.1. Ideally, the minimum speed would be 30rpm. This would alleviate the need for a gear reducer for many people. If you’re going to tell me that you can’t keep the motor cool at 30rpm, then put a temperature sensor on the motor and let us run at 30rpm until the motor gets too hot, and then make us take a break. When I’m sewing, most of my time is spent getting the next seam ready, and not that much time actually stitching. So there’s little chance of me overheating a motor. 7.3.2. If you can’t offer a minimum speed of 30rpm, perhaps you can build in true soft-start functionality. By this I mean when you first press the treadle the motor would start at something very slow (like 10rpm) and would ramp up to the minimum speed over the course of say one second. This would give us more reaction time during that first stitch when we are both holding down the top thread and guiding the material and keeping our fingers out of the way. (By the way, the only feature similar to soft-start I have actually seen on CAIDSMs would be better described as “how long to wait before full speed is allowed” and was not a soft start the way I am imagining it.) 7.4 Ideal Gas Pedal 7.4.1. There should be a long range of travel in the foot pedal between slow and fast. CAIDSMs have a range of travel of less than one inch. If you can only offer one inch of travel, then how about providing instructions for drilling alternate holes in the treadle so that the amount of treadle rotation required for full actuation is still large (30-40 degrees). 7.4.2. When the maximum speed is set to something slow such as “900 rpm”, the range of pedal travel should be spread across the entire usable range. Meaning you should have to push the pedal all the way to get to 900rpm if 900 rpm is your max. 7.4.3. If the gas pedal is pressed down while the power button is turned on, the motor should not start. (Safety) Rather, the motor should wait until the gas pedal is released and then pressed anew before motor starting. 7.5 Ideal Physical Layout 7.5.1. The menu should be accessible from the standard seated user position. (Some CAIDSMs have the menu hard-mounted with the motor, which is hard to reach, hard to see.) 7.6 Ideal Safety 7.6.1. Pressing the gas pedal after the power switch has been turned off should have no effect. CAIDSMs do not have this yet. Rather, it takes about 12 seconds after turning off the power switch before the LCD goes blank. And until the LCD goes blank, the motor has full power. This is a safety issue because it takes patience to turn off the motor and then wait for the LCD to go blank before performing maintenance issues like threading the needle, replacing the bobbin, replacing the needle, etc. And we want to make sure users can perform maintenance without the risk of accidentally engaging the motor. 7.6.2. When the power switch is turned off, the motor should immediately stop. CAIDSMs currently keep running after power is switched off, until they bleed off the internal capacitors. 7.6.3. Ideally one could limit the amount of torque through the control settings. Another way to limit torque is to run your belt on the loose side. One of my CAIDSMs shows an option to limit torque, but the option doesn’t actually work. 7.7 Ideal Menu Design and Factory Defaults 7.7.1. There should be no settings visible in the menus that don’t do anything. 7.7.2. The settings in the menu should be numbered incrementally. No skipping numbers, as this is confusing. 7.7.3. Instructions for operating the manual should be provided in clear language. 7.7.4. The factory default maximum speed should be something medium slow like 1000rpm. Let the user increase it through the menu if they need it faster. 7.7.5. Ideally the documentation would include an email address or website where users can ask questions and get clarifications about features. (CAIDSMs don’t even say who the actual manufacturer is.)

-

- servo motor settings

- servo motor

-

(and 2 more)

Tagged with:

-

We are trying to delvelop excellent servo motor for leather sewing machine, by now we have reach below features/functions: 1. Low speed: minimum speed 50 RPM only 2. High torque: an awesome 8.6 Nm of torque 3. Soft Start: make the machine far more manageable 4. “Jog-Dial” (suggested by Italian dealer): ectronical needle positioning 5. Speed Controller: allow you to adjust sewing speed in a second 6. Half Stitch (suggested y Sweden dealer) : micro-adjustment stitch length 7. Needle UP/DOWN position Any requirement else?

-

Please contribute recommendations to the best currently available servo motors to slow down Juki LU563 (or other machines) for Leather Sewing. What is the best quality, reliability, and longevity for servo motor and is it worth having a needle positioning mechanism? I have a head injury and seem to have forgotten a lot of what I knew and greatly appreciate your help with this!

- 19 replies

-

- servo motor

- slow down machines

-

(and 2 more)

Tagged with:

-

This has been mentioned a few times in various message threads regarding the Enduro motors that were/are sold on Ebay. But I just wanted to put this down as a topic for you guys out there who grabbed some dirt cheap Enduro motors as I did a few years ago. I have a few Enduro 1050-2PF, 220 volts, servo motors that I bought off Ebay a while ago. They were dirt cheap on one point. Like $35 each or so?? I have 240 volts in my shop so it was no big deal to run some cords to feed these motors. However some folks have mentioned that these can run ok on 120 AC. I'm setting up a new to me Pfaff Chainstitch machine so I dug out one of the 1050-2PF units and hooked it up. I had to put a plug on the end, so why not try out 120 VAC? It works fine. I tried a wooden hammer handle torque test ( start the motor with a wooden hammer handle forced onto the edge of the V belt pulley ). The motor has plenty of torque at 120 VAC to grind grooves into the hammer handle from a dead start. I belted the machine to the motor and it all works fine at 120 VAC. The display and control buttons are working just fine as well. I have not tried hooking up the needle positioner sensor. That is next. This unit also has a 24 volt solenoid output for a foot lifter. But I probably won't use that. Obviously these motors were designed to operate on a range of input voltages. Why these don't show that on the boxes? I have no idea. Note that I cannot find any laboratory testing approval of any kind (UL, etc) on these motors, the boxes or the paperwork, so make sure you turn them off when you are done sewing. I'm ok with that myself.

-

Hi all, I feel like I have been given a bit more than I can chew. I ordered a Seiko CW8B2 cylinder arm machine. The supplier provided it with a Ho Hsing i90M. Clearly it was my own stupidity assuming the controller would be basic and simple. This is my first industrial machine and the controller is way too complicated (to be fair, I live in Hong Kong and communicating with the seller was not that easy). First off, the controller is mounted to the motor and away from the user so you need to go around the table to make changes - I didn't expect that and I would have thought the large controller could be turned to face me but it seems that it cannot. It would be great if I understood how to make adjustments on the controller (the manual is quite complicated). Right now I set it for a very low speed - like 2spm (getting to that setting was a miracle). However, all I really want to set it to do is set it for slow for light depression of the treadle and increasingly fast for increasingly heavy depression of the treadle. Does anyone have a clue how to set this controller for this? Does anyone else have this motor and controller or a similar Ho Hsing model? The manual is here: https://www.hohsing.com/wp-content/uploads/download/i90m-manual-tw-en.pdf Many thanks in advance for any assistance in plain English.

- 3 replies

-

- ho hsing i90m

- servo motor

-

(and 1 more)

Tagged with:

-

Hello! I recently bought an industrial Juki that came with this servo motor. I was under the impression that the dial in the front would adjust the speed, however nothing changes when I turn it. Does anyone have this motor? Is there a way to change the speed? Photos of the motor are attached. Thank you!

- 5 replies

-

- sewing machine

- servo motor

-

(and 1 more)

Tagged with:

-

Hi folks and good morning from Australia I have a slight problem with my Cowboy CB4500 and servo motor The machine is 10yr old but has done very little work and most of that is 8/9oz.Today I have gone to sew and switch the power on everything lights up as per normal the LED on the front has these little [ ] things that just revolve around the screen as per normal no noise at all, have pulled all power connections (plugs) out put them back in switched power off for a while switched it back on again I am at a loss as I only used it a month ago and it was perfect. The only thing I have put it down to is we did loose power for about 2 days due to flooding in the north of the country and I did hook up a generator for that time and the machine was plugged in to the wall maybe a power spike from the generator, but then it should not switch the LED screen on.I DON’T KNOW

- 3 replies

-

- servo motor

- cowboy cb4500

-

(and 2 more)

Tagged with:

-

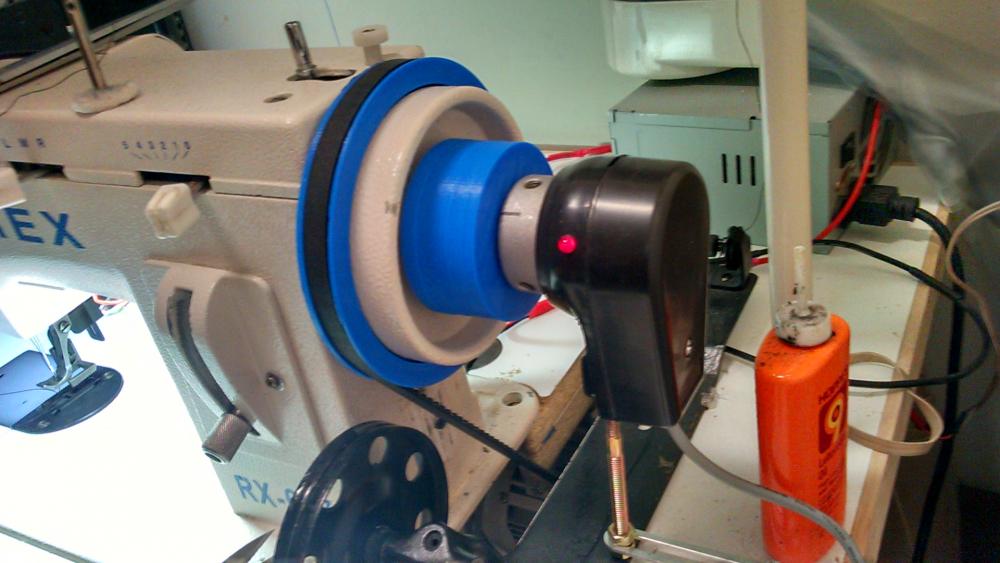

servo motor Servo motor with syncro and speed reducer

Reacher10 posted a topic in Leather Sewing Machines

I have a REX 607Z setup in a custom table (had my friend CNC the top) so I could hook it up to a servo motor with a Syncronizer. The servo motor is brushless and has four buttons on the control unit, Consew CSM-1001. The machine is working absolutely great with the servo motor and syncro...it took the machine to a higher plane. Now this machine is very good for what it is however it will struggle power wise with the 550 watt motor, nothing major for the work I'm doing and nothing that bothers me...it is still light years better than the little motor it comes with. I picked up a JUKI 55 with the table and a clutch motor in good condition for $125. With how well the REX responded with the servo motor it was a no brainer to use the same brushless setup on the JUKI. Knowing that the 550 watt motor wouldn't have the same power as the clutch motor I bought pillow blocks and a shaft to make a speed reducer, I had a 2" and 6" pulley. My initial thinking was to use the 3:1 reducer with the clutch motor just to see if perhaps I could stick with the clutch motor if I indeed had better control. Well trying to deal with that giant motor just flat out got on my nerves so I said screw this, I'll just get the brushless/syncro setup for it as it would be much easier to deal with and in the mean time put the reducer on the REX. It would give me some extra torque and I could get the reducer up and running and get any kinks worked out. I did have to make a timing pulley for the brushless motor since the REX uses a timing belt. This was simple enough to do, I modeled up 30 tooth pulley for the motor and an adapter to increase the fly wheel to 5 inches...same deal as the power wheel sailrite sells. I made these on my 3D printer and away I went. Since I had the 30 tooth modeled for the motor shaft I just had to change the model to fit the 3/4" shaft for the reducer. Printed it out and boom, had me a nice reducer. It turns out I got it up and running in no time. Here is where the problem came in. The syncro was no longer working as it should. I have read reports of the syncro not working when a speed reducer was installed as well as reports of the syncro setup working fine. My initial thinking was that it SHOULD work correctly, thinking that the needle would go where it's supposed to based on the syncro. The total reduction ended up to be 6:1 and the servo setup doesn't know or care how this is achieved, like a 1" pulley on the motor and a 6" flywheel pulley. ...right?...wrong! I was perplexed by this. Well lets take a look at the numbers and I admit they are kind of all over the place. I put the original 70mm v-belt pulley back on the servo motor because the 6" pulley going on the reducer shaft was for a V-belt. The 30 tooth timing pulley I made for the reducer is 1 1/4" dia. What I discovered is that even though from the motor to the flywheel is a 6:1 ratio there seems to be a direct correlation between the revolutions that the motor turns and where the revolution on the syncro is. So the motor is spinning a 2.75" (70mm) pulley and turning a 6" pulley, that is a 2.18:1 ratio. Then on top of that I'm going from a 1.25" pulley on the reducer shaft to a 5" flywheel pulley which is a 4:1 ratio. So as I was about looking the positions of the drive pulley and the flywheel I realized the servo motor was turning a certain amount of degrees compared to how many degrees the syncro was reporting and they didn't add up! So if the needle position was simply based on the syncro postion then Bobs your uncle but because what the syncro reports and what motor reports don't jive, it ain't gonna work. So I'm not sure it will work even if I get the drive pulley diameters in line. A 2" on the motor to a 6" on the reducer and then from a 2" on the reducer to a 6" on the flywheel. The motor would be reporting 2 times the amount of rpm's than the syncro is reporting it should have....who the hell knows? I think I'll model and print the pulleys and flywheel adapter to those diameters and see what happens. Lets face it with the hodge podge of diameters I'm using now, yeah, that would throw anything out of sync...lol. As a test I made an adapter for the syncro to go right on the 3/4" reducer shaft and it worked perfectly. If anyone has any thoughts on this please feel free to chime in. For those that report no problems, my guess is that relationship between motor and flywheel rpm's does not apply on there control units. I'll post some pics of my reducer but right now it looks like 3 kids and dog had a wrestling match in there. Here's an FYI. On my unit, if I set it up for needle down I can additionally press the back of the treadle and the needle will raise. However if I set it for needle up, when I release the treadle. that's it, needle up, no needle down option. So what I do is set the control unit for needle down but the needle is up and the syncro is set to report that it's in the needle down postion. When I release the treadle the needle goes to the up position but then if I want the needle down i just press on the back of the treadle....it works great. Stay tuned... BTW...first post...I've learned A LOT form this forum...THANKS! -

I was using a 550 brush servo motor on a post bed with a standard speed reducer pulley (cream colored) that is being sold around. At lower speed this motor... well... So I moved to brushless. Amazon sells a "genuine" Consew 550 / 3/4 horse power, and then there is another option 750 / 1 hp version. Will the extra horse power make any difference, in torque??? - I think with the extra pulley (also motor pulley changed to 45 from 75) more torque is needed? Also, I already have the Consew brushless on one machine sans speed reducing pulley, it pulls hard (lot of torque as opposed to a brushed). And am also using a 750 / 1 hp on a second machine sans speed reducing pulley that can run super smooth at 200. The build quality of the Consew is better, however. If I don't really need that extra 1/4, I would go with the 3/4 hp.

-

I’ve been looking at servo motors on Amazon. I see conflicting statements in the reviews. Some seem to indicate that the servo speed jumps from 0rpm up to the setting on the servo control. Or, the speed jumps from 0 to 400rpm (for example) then is variable up to the set point on the controller. Meaning there is no option to run the servo at slow speeds – IE just a few RPMs. Others seem to indicate that the serve will run from 0rpm variable up to the speed set on the controller. I realize that most Amazon reviews are to be taken with a huge lump of salt… Which is correct? The Mophorn brand seems to offer quite a few options at very reasonable prices. For example: Amazon Morphon Servo Any of you have any experience with this brand? Thanks for the help, All the Best, Jeff

-

First of all I am a new member to this site so, Hi to everyone. I am new to leatherwork and I was thinking.....has anybody ever put a servo motor and speed reduction pulley system on a vintage domestic sewing machine. I obtained a 1954 Necchi Mira machine that runs like a champ, but is lacking in power that is needed. I will just be using it for maybe a couple of pieces of 4-5 oz and less. I can now work through a piece of 4-5 pull up chrome tan and apiece of 4-5 oz veg tan if I put flesh side of chrome tan to the feed dogs. Should I just save this money and apply it to a walking foot machine? ....any thoughts ,suggestions and experience would be greatly appreciated. Thanks NOTE: I know this is a domestic machine but it seems to be well built and no plastic except for on the light bulb holder. It will sew through much heavier pieces but I don't want to abuse this machine. Thanks again, Mike. I posted this in how do I do that but figured it was the wrong place.

-

Great machine if you can’t afford to spend thousands on a leather sewing machine. I’m starting nursing school and won’t have the time for it and I need money. https://redding.craigslist.org/for/d/igo-pfaff-545-walking-foot-industrial/7216319921.html

-

ABOUT ME: Hi there! I am searching for someone who might need a great INDUSTRIAL sewing machine Check this out please and see if it could be of any use... I was going to create leather belts and gun holsters in Texas, but I changed my mind once I returned to Alabama...I am an aerialist and I would like to sell my machine to invest in my dream...If you're not interested PLEASE share with someone you think may be interested. The Lord works in mysterious ways, #GodBless ABOUT THE MACHINE: The Techsew 5100 Special Edition is the ultimate sewing machine designed for a wide range of leather work projects. Light range leather work: Purses, handbags, pouches, wallets, notebook covers, vests Medium range leather work: Belts, knife sheaths, scabbards, quivers, horse blankets Heavy range leather work: Saddles, gun holsters, knife sheaths, harnesses, horse tack Additionally it is also great for non-leather work applications such as tie down straps, boat/car covers, orthopaedics, thick paper binding, parachute harnesses, tarps, vinyl, canvas, synthetics, heavy webbing and more. What makes the Techsew 5100 Special Edition so special? Techsew SmartServo-NP Needle Position Motor The Techsew SmartServo-NP is an automatic needle positioning motor which saves you tons of time and effort while sewing. This powerful and versatile motor will automatically lift the needle at the end of a seam, or automatically leave it in the bottom position. This will eliminate the need to constantly turn your handwheel to position your needle. At 1HP and 800W, The SmartServo-NP will help your machine power through thick leather at any of the 16 adjustable speed settings. Additionally, a speed reducer is used in combination with the SmartServo-NP motor for added power and speed control. This system is ideal for beginner, intermediate and expert sewers as well. ALL EXCLUSIVE TO THE TECHSEW 5100 SPECIAL EDITION! Features: Triple Feed - Walking Foot (needle feed + alternating presser feet + bottom feed) 1" Presser foot clearance Sews from 6oz all the way up to 7/8" thick 16.5" Cylinder bed Equipped with Techsew SmartServo-NP motor and speed reducer to sew at slow & controlled speeds - great for novice, intermediate and professional sewers Reverse stitch - for reinforcing stitches 12 inch heavy duty flywheel Reinforced steel pedestal style table with adjustable height (sew standing up or sitting down) Includes: Complete table with casters, SmartServo-NP motor, speed reducer,TS-28 LED lamp, TS-5 LED stitch light, TLG laser guide, swing down roller guide, flatbed table attachment, 3 pkgs of Organ diamond point needles,8 bobbins, thread lube pot, left toe foot, double toe foot, center foot, smooth blanket foot set, 1 lb. (16oz) cone of thread, oiler, instruction manual, repair tools, thread clipper. Stitch length adjustment up to 11mm (7/16") Uses thread sizes 69 to 415 Uses needle sizes 18 to 27 FREE setup & instructional DVD included! Includes Limited Lifetime Warranty and FREE technical support for the life of your machine Machine comes pre-threaded, oiled, adjusted and READY TO SEW Specifications: Needle sizes: 18 to 27 Thread sizes: 69 to 415 Presser foot clearance: 1" Sewing capacity: 6oz to 7/8" thick Cylinder bed length: 16.5" Maximum stitch length: 11mm Techsew SmartServo-NP motor: 800W, 1HP, 110V, 300 to 1800RPM, 16 speed settings with bright LED display, completely silent when idle and reduced noise during operation. The most POWERFUL servo motor in the industry.

- 6 replies

-

- leather

- sewing machine

- (and 10 more)

-

Selling my trusty Juki 563, I have installed a servo motor last year. Its a great work horse. I've been using it for sewing leather and heavy duty canvas. Finally upgraded to a cylinder arm machine and need to make some space.. I am asking for $999 - local pick up only please, I can't even think of shipping this thing.

-

I have made a demonstration video on my simple machine. It do have got a simple universal motor, a speed reducer, and I made some electronics for it that make the system act as a servo motor. The speeds demonstrated in the video are from 8 stitches/min to 540 stitches/min - a factor 68. The response to load changes and small moves are shown as well: What is your controlable speed range of your sewing machine with servo motor? Can you do better or worse? I have seen some recent demonstrations on youtube of industrial sewing machines with servo motors. And I am not that impressed of the speed control I see. For most of them, I see them jump start to a quite high low speed, and I do not like that. I did see this video from 2012 showing a resonable good low speed control, but I am not sure about the max speed and speed range: https://youtu.be/-h5U32SDZ38 Back in year 2012, several servo motor types had an issue, that they were hard to control. These issues were discussed in this forum, and I shall like to link to the four threads I just read about it: https://leatherworker.net/forum/topic/40034-question-about-servo-motors/ https://leatherworker.net/forum/topic/40168-cobra-class-4/ https://leatherworker.net/forum/topic/41483-servo-motor-mod-diy-easier-speed-control/ https://leatherworker.net/forum/topic/41916-having-problems-with-servo-motor-speed-control/ At that time a simple modification to some servo motors was introduced. More US suppliers of servo motors tried to make improvements and contacted their suppliers and manufacturers. I am however not sure, how much change to the designs that were later introduced. Electronic designers of servo motors may have limited knowledge of the needs of a sewing machine operator. Of cause an electronics designer can be incompetent aswell. The discussions here back then indicated, that many leatherworkers like to be able to sew very slow and also fast with the same set up. I think a factor 100 between lowest speed and highest controlable speed should be easy to make for servo motors. It could be from 45 RPM to 4500 RPM. However It seems to me, that most of the servo motors for sewing machines have a range with a factor about 30 only. The pedal construction can also be a limitation. However many leatherworkers were also happy with the motors they had. Others wrote, that they were not aware before the change, that they should like the better control they were able to get.

- 11 replies

-

- pedal

- speed control

-

(and 1 more)

Tagged with:

-

I have just purchased a Juki DU-1181-N industrial sewing machine from Meissner Sewing in Sacramento. I have replaced the servo motor that it came with and replaced it with another that I already had. I am offering it for sale for $100 plus freight. Brand new. FSM-550 Servo Motor, POW 550W, 110V. RPM 0-3300 See all three photos here: http://tombanwell.com/servo-motor

-

Hi all, I was doing some spring cleaning/maintenance on my Cowboy 4500 today. I got everything dusted and cleaned, back on, put together, and oiled. I turned it on to test without a needle/thread installed and it ran great, the only problem is it runs so great that it runs even when I'm NOT pressing on the foot pedal. I don't think I changed anything, but I suppose it's possible I may have bumped or adjusted something unknowingly while moving the machine. -I can push lightly (about half way) on the pedal and the machine will work normally with the speed reducer function. When I let off the foot pedal, the machine will stop as expected. ***The problem comes when I push all the way down on the foot pedal and then let off, the machine keeps running (needle, feed dogs, foot moving etc.) like it's on the slowest setting. It also makes a fairly obnoxious squealing noise while moving very slowly. I tried moving the link on the chain up and down to change the amount of slack and tension- that doesn't seem to be it. If it's too tight it will run too fast and I don't get the speed reduction. Too loose and it doesn't matter. I even had the chain completely unhooked from the pedal and it kept running. I've narrowed it down (I think) to the black plastic arm on the servo motor that is attached to the foot pedal by the chain. It's not going all the way back up to stop the movement of the machine. I can gently push up on it momentarily with a finger and the machine will stop normally. If I let off the pressure with my finger, it will keep running. I also can apply a little more pressure and the whole black plastic arm will "click" or "snap" back up to a locked position and the machine will remain off. It will start up and run normally when I press the foot pedal, but again when I put it all the way down and release it will not stop completely. I have to manually push this arm up to stop it completely. Again, that's why I thought it might be the chain tension, but had not luck when moving the link and tension. Is there anything you can think of that would fix this? What could I have done to cause it? Could the problem be coming from something else? This machine is only 2 years old, hasn't seen excessive use, and it is well taken care of. I bought it from Toledo Sewing Machine and have never had any problems with it before. I'm really hoping I don't have to replace the motor since it's so new. I took the cover off the servo motor to see if there was anything obviously wrong and couldn't see anything. I'm not super mechanically inclined, so I thought I'd start here with the experts before doing anything. I didn't want to start chasing one problem and create a handful of others. Any help you all could provide would be greatly appreciated. Fingers crossed it is something simple and I can get it back to normal. Thanks in advance, -Hannah

- 13 replies

-

- cowboy 4500

- cb4500

-

(and 3 more)

Tagged with:

-

i feel like I am in the twilight zone. when I took off the simple nut and the lockwasher washer kind of thing, the consew 50 mm pulley didn't fit on the machine. I took a picture of the way it was before I touched it for reference and the when I revoved the wheel, there were only 3 things. the new wheel is maybe a sixteenth thicker than the 55mm. couldn't fit on the new one so tried to re-install the original and ot it is like the shaft shortened. before and after and there is no way to get the nut on it even with the original on it....I am trippin first picture is before I touched it. second picture is with the original wheel back on it and same hardware. 2nd picture the wheel is against the servo motor housing and I don't think it will turn

- 9 replies

-

- consew 205rb

- servo motor

-

(and 1 more)

Tagged with:

-

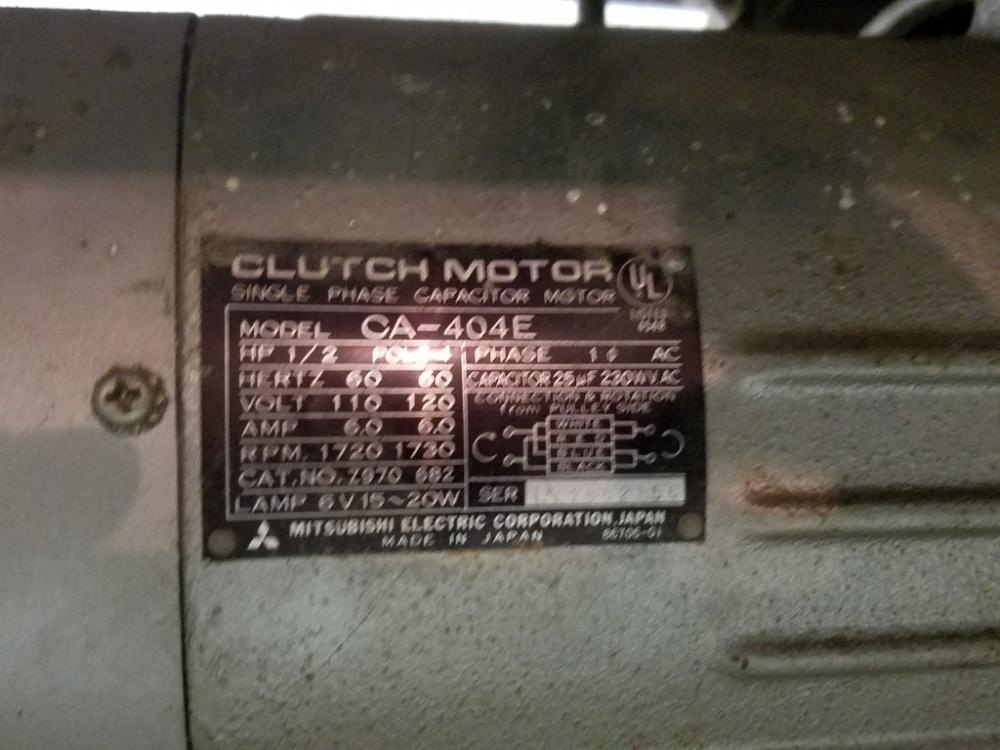

Hey Everybody, I've been a 'lurker' in the shadows here for a few years and have learned a ton of stuff. The openness & generosity of you folks is amazing. I have a Pfaff 145 (high lift version) flat bed sewing machine I got from my Dad. Try as I might I just could not master the clutch motor when sewing thicker leather. I would try to feather the clutch to slow things down and it wouldn't punch through the leather, or I'd engage the clutch enough to punch through & it'd be a runaway train. I changed pulleys on the motor (3.5" to 1.5") and on the head unit (3.5" to 5.5") to try to slow things down & increase torque but the change was negligible to me. This was probably more of an operator issue than a machine issue but the result was still a machine I could only use on thin materials. What prompted me out of the shadows was my experience with Bob & Toledo Industrial Sewing Machines.After searching threads here about Pfaff & servo motors, I called Bob at Toledo Industrial Sewing Machines. He talked me through all of the features & benefits of servo motors, installation tips, etc. He answered all of my questions and took quite a bit of time with me. I ended up ordering the Family Sew FL-550 motor and received it in Atlanta in 2 days! Man, what a difference! Power to spare and I can now sew 3/8" thick leather with complete control! I can stitch sooooo slow too! I keep finding myself sewing stuff just to sew stuff (I have burned through a good share of my scraps). Major props to Bob & Toledo Industrial Sewing Machines!!

- 4 replies

-

- pfaff 145

- servo motor

-

(and 1 more)

Tagged with:

-

Hello all, just wanted to say hello and see what suggestions people have on some thoughts of mine. I just got into sewing and purchased a 111w155 in good shape for $250. Has a good clutch motor on it. I will be using this machine for knife sheaths and some upholstery work. However, I got lucky at an auction and got an Imperial zigzag (not much info online but its identical to the singer 143 models) with a Quick Rotan setup for $70. Also got a Brother MA4-V61-98-5 serger for $25. I think I got a pretty good deal. Anyway, im thinking of switching the quick rotan setup to the singer 111w. Primarily for slower control and the needle up and down options that the rotan controls offer. Do you guys think this will do well on the 111w? It took me 3 days of scouring the web but managed to find pdf manuals for the quick rotan setup. Not sure what the pulley ratio would be but I can machine a correct pulley if needed. Appreciate any thoughts. Didn't find any topics with anyone doing this on an old singer 111w. Thanks, Adam

- 12 replies

-

- 111w155

- quick rotan

-

(and 1 more)

Tagged with:

-

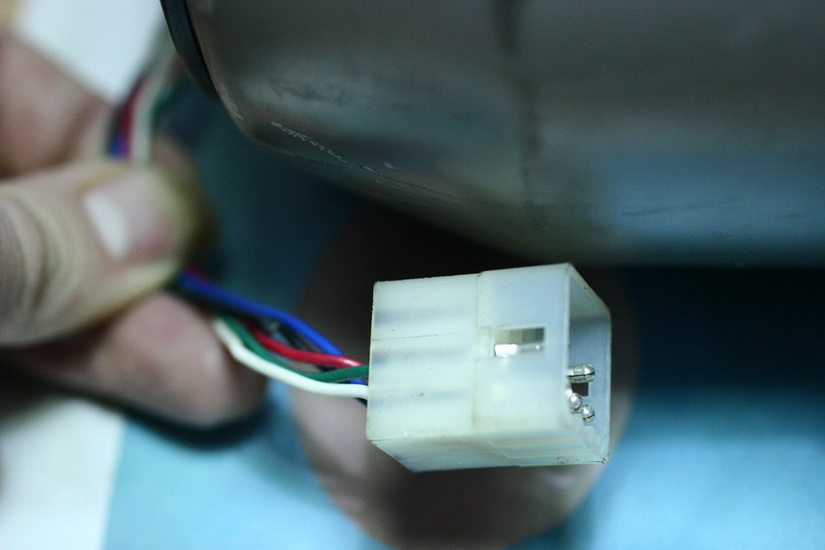

Hi to everyone,just bought a few days ago a Juki ACNP-MOO2 550W servo motor.Found it on an online market and the seller was very poor with the details.Beeing a cheap deal (35$ including postage) I had bought it,thinking that I'll manage with it somehow.Only after its arrival realised that there isn't the regular small weight servo motor I know from my sewing machine.It's a 30 pounds beast.It's the motor only,no controll box or an on/off box.It has 3 cables coming out of it but I can't tell which one is which.I would like to try to see if it's working but I can only guees which are the power wires,so I better leave it alone.Can anyone tell more about this motor,anyone used this model before?What do I need to test it,or to make it run again.What control box do I need to look for?If I can't use it on a sewing machine can be used as it is,without the controller,for something else like a homemade polishing machine or belt sander?Thank you.

- 6 replies

-

- juki ac motor

- acnp-moo2

-

(and 1 more)

Tagged with:

-

Hey to all! Thanks for accepting here I would like to ask about the servo motor. I have JUKI 1811 with clutch motor, which is super fast - it is hard for me to work with leather, speacially for me as I am beginner. Could You tell me what kind of servo motor would fit my JUKI DU-1811N and also be the slow one? I have googled and searched this forum, I havent found that specific answer, but I guess I know that I need the small one - as it has advantage with slow type leather work? Any additional suggestions maybe. Thanks again, Niklas, CLIQ.

- 4 replies

-

- servo motor

- 1811

-

(and 1 more)

Tagged with:

-

After much debate I have decided to try and sell my Ludwig 205-370 heavy duty cylinder arm leather stitcher. Due to time constraints from my job I am just not doing enough leather work anymore to justify keeping it and I could really use the room in my shop, so I will sadly let it go. This machine is an exact copy of the Adler 205-370 and operates just as smoothly as the actual Adler I tried at Weaver Leather. It is in fantastic condition and has no issues. If you're not familiar with this model, they will do everything one of the 441 / "Class 4" machines will do and run smoother while doing it. The machine includes a swing-away edge guide, an adjustable height table/stand, auto-bobbin winder, speed reducer, and a quality servo motor. I have a few different presser feet and feed dogs for it, several packages of needles, a few spools of bonded nylon thread, and several bobbins. I also have the Weaver timing device and digital copies of the Adler manuals. I am asking $1,500.00 for the machine and all the accessories I have for it. It would be a tremendous effort to break this thing down and crate it to ship because it's HEAVY and BIG, so I would really prefer local pickup. However, if someone is willing to pay for the effort required to ship it I am willing to do the work as a last resort. I am located near Huntington, WV. Feel free to ask any questions you have about it or if you'd like to see any other pictures. I am not in a bind or "needing" to sell it in any way, so I'm not going to accept any low-ball offers. If I can't get within reason of what it is worth for it, I'll just cover it up and keep it. If interested you can message me here, email me at evandailey@suddenlink dot net, or call or text at 304-six33-489two.

-

We purchased this Consew Double Needle Post Machine recently. It was purchased brand new from the manufacturer. We thought it would work for our business, but instead it has sat unused in our art studio. We tried using it once or twice, but discovered that it is most definitely the wrong machine for our needs. It is technically in Like NEW condition, with no signs of wear. We've proactively serviced it to ensure that it is ready for the new owner. This machine would be better suited for a saddle maker or a company specializing in leather/upholstery fabric furniture, please see Full Specs below. This machine comes with the table and a servo motor. We are selling it for a few thousand less than what we paid in hopes it will sell quickly. Willing to accept reasonable offers. We are asking $3800 for this machine, actually selling it for a few thousand dollars less than what we paid in hopes it will sell quickly. Willing to accept reasonable offers only. We are unable to ship, due to its weight and size. Instead we are willing to deliver it anywhere within California for an additional $200. California buyers only. Local pick up is also acceptable. This machine is currently listed on EBAY, but I can pull auction if someone on this forum is interested. FULL SPECIFICATIONS: Model # 369RB-2 Double Needle, 1/4" Gauge- 135x17 Walking Foot Speed, Max (S.P.M)- 2200 Clearance Under Pressure Foot- 11/32" (8.5mm) Stitch Length- 5 s.p.i (5mm) Bed Size- 7"x20 3/8" (177mm x 518mm) APPLICATIONS: For sewing medium to medium heavy-weight fabrics. Leather, canvas, vinyl, synthetics, and various coated and laminated materials Designed for sewing operations which require decorative or functional angular stitching such as collars, pockets, shoe uppers, auto, boat and furniture upholstery, slacks, shirts, etc... Designed for stitching such products as overalls, raincoats, luggage, travelware accessories, bags, umbrella's, awnings, covers, tarpaulins, tents, wearing apparel, outdoor clothing, underwear, etc. General/parallel two-needle stitching with split bar for making even angle turns. Suitable for stitching uneven, hollow, tubular and curved articles FEATURES: Compound feed, walking foot mechanism assures perfect feeding of sewing material Large hooks and bobbin cases with their own thread take-up mechanism assure uniform and perfect stitching with minimum bobbin changes Easy operation of disengage able right and left needle bars by use of finger-touch lever Centra-Lube, semi-automatic lubrication system Oil fed take-up Stitches per minute 2200 Reverse Stitching Various gauge sets available Safety clutch protects the hooks from being damaged

- 4 replies

-

- servo motor

- shoemaking

- (and 6 more)

-

Hi all, this is my first post on the leatherworker.net forums, though I've been an anonymous reader for quite a while. Finally I have a question that I can't find an answer to: I purchased my first walking foot machine, an Adler 69, a few months ago. I'm pleased with how it sews but there are a few things about it I would change if I could, now having used it a little bit. If anyone out there knows City Sewing in NYC, they're great but can also be a pain to get information out of and sometimes I doubt their opinions and expertise when it comes to these types of machines. Anyway, here's what I'm looking for: 1. The table is too high. It appears that it could be lowered, but when I loosen the bolts nothing happens. ...? 2. The table design makes it difficult to build/install a removable flat working surface. Ideally I want to be able to 'convert' the working area to a flat bed when needed. Although not impossible with this table, it would be a lot less cumbersome with an alternate table design that includes some sort of surface on the left as well as the right that the removable work surface could then bridge (see attached photo). Also, this table is supposedly called the 'space saver table' but really it's about the most space-wasting I could think of! If I could design & build my own table, that would be awesome. 3. The servo motor speed cannot be adjusted. I've been reading on this website a bit about this. I guess it means I have a 'brushless' motor? Would I be sacrificing torque or anything else if I sought out a motor that is speed-adjustable? I've also been reading about EPS. I'd love to have that feature, too, if possible. Given the wish list above, do you think it makes sense to try to kit out my purchase or attempt to sell this machine and re-buy another package that has more of the features I'm looking for? Also, should it be better to stick with what I have, does anyone have any mechanic contacts in the NYC area who would be willing to help with the work? I'm always willing to learn, but I have to admit that I know nearly nothing about how to lower the table height, let alone install a new motor! Thanks a lot, Lauren

- 23 replies

-

- adler 69

- sewing machine table

-

(and 4 more)

Tagged with: