All Activity

- Past hour

-

spring flowers and good food

Handstitched replied to chuck123wapati's topic in All About Us and Off Topic

Beautiful pics Well , things are progressing . Dads op site is pretty much healed up. No more dressing changes. Yey ! Just some lanolin to maintain the area. Just his skin graft area on his thigh is taking a bit longer to heal, i have to change that dressing every 2 days now, makes a change from visiting the local hospital every 2 days. We know nearly all the staff now by name , been there that many times. Still have the occasional video conference with major hospital in Perth. Hope all is well with your daughter and recovering well , and you're looking after yourself as well, taking care of our loved ones can be 'challenging ' . Take care friend HS - Today

-

97-10 Resources, Singer Class 97

Cumberland Highpower replied to Grigg's topic in Leather Sewing Machines

I have only a little experience with the 97. I think they were primarily used to sew heavy rigging back in the day, that was something hook and awl machines couldn't do. Should be able to simply adjust the needle bar up or down to compensate for the long needles? Those singer needles are longer because there's more stuff it has to clear. Guide/foot wise. You could probably use a shorter needle with good results if you ran it without the needle guide. That would depend on what you're planning to sew most likely. Seems like the old 97's have gone down the obsolescence path much like old Landis 1 and Champion Stitchers? -

"G" machines were made in Germany,W -USA,U-Japan

-

Alan P joined the community

-

Dear All I like to know what's the diffrent in the letter (g) this sewing machine have diffrent letteres when i search for parts W-G-U-A I have seen it on: https://www.industrialsewingmachineparts.co.uk/parts212.htm Thanks in advance

-

It took me a while to spot it too. Only a leather worker would pick it up, but I 'd think the average person wouldn't see it. But as suggested, antiquing might do the trick . HS Nice work BTW

-

Thanks for your help I will remember that including photo size

-

When you do make the jump into sewing machines, if you have any technical or operational questions, head over to our Leather Sewing Machines section of the forums. When you do get to try using his Juki, hold back the starting threads so that the top thread doesn't get pulled into the shuttle and jams the machine. Holding at least to top thread, back and to one side, keeps it from getting drawn down unexpectedly. You can let go after either backtacking, or sewing all the way around and overlapping the first 5 to 10 stitches. Your master should teach you that, but it becomes a subconscious operation that one might fail to pass along.

-

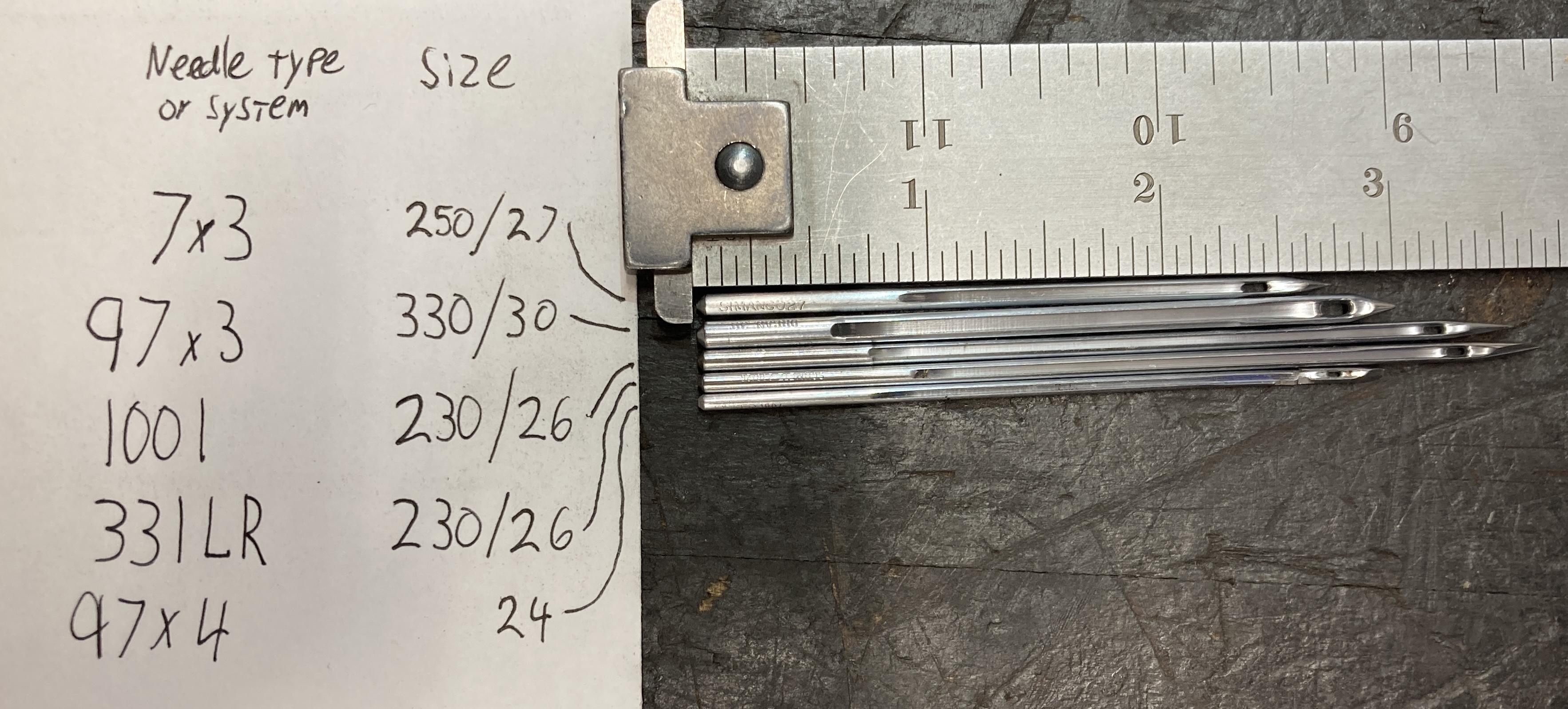

I recently picked up a 97-10 Singer harness sewing machine and have found some info and I'm still looking for more information. There is also much to read in older threads. The Army technical manual TM 10-3530-202-24 might have the most useful info in one place, and includes info on several other Singer machines. https://archive.org/details/TM10-3530-202-24/page/n1/mode/2up Includes instructions on how to disassemble a lot of things, unfortunately the "Assembly and Installation" that follows is simply "Reverse procedures above". No real adjustments or timing info that I've found yet, though I haven't read it all word for word. The corresponding parts manual TM 10-3530-202-24P (I've ordered but haven't yet seen inside this manual) Singer Parts list Form 18301 Revised (640) https://site.singeronline.com/ssl/instructions/SINGER_97-10.pdf or https://www.supsew.com/download/Singer/Singer 97-1, -10.pdf I have a similar original Singer paper parts list that came with my machine. It has the same form and revision numbers but is only the pictures (no list or text) from the above PDF list, and the pictures appear to have been copied a time or two, a little less clear. I also have an original Singer "Instructions For Using singer Sewing Machines of Class 97" Form 8348 Revised (139) It is helpful but very limited; descriptions of the different models of 97, how to thread it, basic operation, and oiling, nothing more. I'd like to find an adjusters manual, does anyone have one, know of a PDF, or even what form number it is? Needles are kind of hard to find. 97x3 (round point) and 97x4 (leather point) I have one original Singer (now broken) 97x4 size 24 that was 3.000" long and about 2.8" from top end to bottom of eye. I was able to find new Organ brand 97x3 size 30 which is 3.030" overall, and same 2.8" from top end to bottom of eye. I believe the original needles did not have a scarf but a long and a short groove. The new Organ 97x3 size 30 also includes a scarf. From previous threads people mention using the shorter 7x3 or 7x4 needles from the Class 7 by lowering the needle bar and settling for reduced foot lift and sewing capacity. I already have a 7 class and the attraction of the 97-10 is it's larger sewing capacity, thus I'm not interested in using shorter needles. 7x3 needles however are readily available, also as type 794 H. Also mentioned were 1000, 1000H, 1001, and 331LR needles, all longer than necessary, so they would be cut shorter. They all also have a longer point to eye length than the original 97x3 or 97x4, may or may not need to grind the shuttle for clearance, I'm unsure if any other issues arise because of this. All of these needles are also hard to find, can be expensive, and I was only able to find a couple sizes I've purchased some 1001 and 331LR needles and will try shorting and using them. Needle guides, one each upper and lower, are an issue too. I haven't found any anywhere, and they ought to be changed to suit each needles size you use. Mine came with size 28 upper and 27 lower, and they can be used with that size needle and smaller, but obviously doesn't support a smaller needle as well. The parts manuals I've browsed do not show needle guides large enough for size 30 needles, which is the only size of 97x3 needle I have found to buy. So without making or modifying guides, or removing them, those needles aren't very useable. Also looking for a few used parts, does anyone know of someone with one of these 97 machines for parts, or perhaps a source of new parts?

-

were to buy woolie material in canada

halt replied to halt's topic in Clothing, Jackets, Vests and Chaps

Thankyou -

It might not be as hard as it sounds? 25 years ago when I was first getting into leatherwork I set up for snaps/etc. I bought some surplus arbor presses (US made) and bought snap setting tools from DOT. I bought a variety of the tools, some for the hand squeezy deal, some for other machines. It wasn't hard to work out how to use them on arbor presses. Most US tooling of this type has a shank that is on some kind of standard. 5/16 7/16,3/8 1/2" I don't know what the shank diameter of your riveter is, but it's probably one of those. You might just get lucky and buy setters that bolt right up. I feel like DOT brand setters for snaps are 3/8" as I sit here, I'll have to check later if I remember. Weaver tends to just copy what's industry standard, or whatever was most popular/common.. For example I have a big foot powered Judson Thompson loop stapler that's 100 years old and I Bought a Weaver anvil for one of their machines and it dropped right in and fit perfectly. If not, how hard can it be? You can work out sleeve bushings from the hardware store if your new tooling is for example 3/8" and your tool takes 1/2" shanks. I kinda don't see a need to hire a machinist to make adapters. --I just watched a min of a video on YouTube showcasing a Stimson 405 out of curiosity, looks like the lower tool is a 1/2" shank, the top looks pretty slender, maybe 5/16"? You could probably just bore the ram out to the standard of whatever tooling you wanted to switch to, if you actually wanted to do that. It also appears that 405 tooling is readily available, snaps, eyelets, gromets, etc. Seems like you likely have a non-problem? Grommet Setting Tools Grommet Installation Machinery |Stimpson Web Store

-

were to buy woolie material in canada

AlZilla replied to halt's topic in Clothing, Jackets, Vests and Chaps

Moved this to the sub-forum where they talk about chaps. Let's see if you can get some help. -

Stagesmith joined the community

- Yesterday

-

Thanks for the comments. I have a local machinist who works for beer so the adapters should be easy (at least for me). I currently don't have dies, so I was wondering if anyone has made a similar adaptation. The Weaver dies seem affordable, but I haven't priced others. I want to make use of the tool, but I don't know much about it and want to invest wisely. Randy

-

Development of best servo motor for leather sewing machine

dikman replied to CowBoyOUTLAW's topic in Leather Sewing Machines

Yep, that's not a "modern" clutch motor, which Wiz is likely referring to, it's what Singer fitted to their older industrial machines. It's a separate motor connected by a belt to a pulley stack with a clutch in it. -

I agree with @DieselTech talk to someone that does basic machinist work and have a couple adapters made. Pretty simple stuff. Also get them to make an adapter with 8mm internal threads in the top adapter so you even use the inexpensive dies that the Chinese type presses use like punches, etc. kgg

-

Two things arrived in the post today 1. From Temu this hole punch sharpener. The outside cone to sharpen the inside edge of punches and the tool has a hollow part to help sharpen the outside edge. Comes in a protective plastic box. This should help me keep my punches sharp 2. From texasleathertools a handled stamp. He took one of my Viking eagles and made a stamp. And is it tiny! Only 12mm (1/2 inch) across the base. Made in machined brass with a steel handle. First class workmanship. It came with its own plastic protective case. Now I need to find a project I can use it on I put some paint on the design so you could see it clearly - remember this only 12mm across the base

-

I think that would be the best way and maybe add a couple more to give it a little extra character. kgg

-

Try, very, very carefully, dabbing and rubbing the spot with cellulose thinners

-

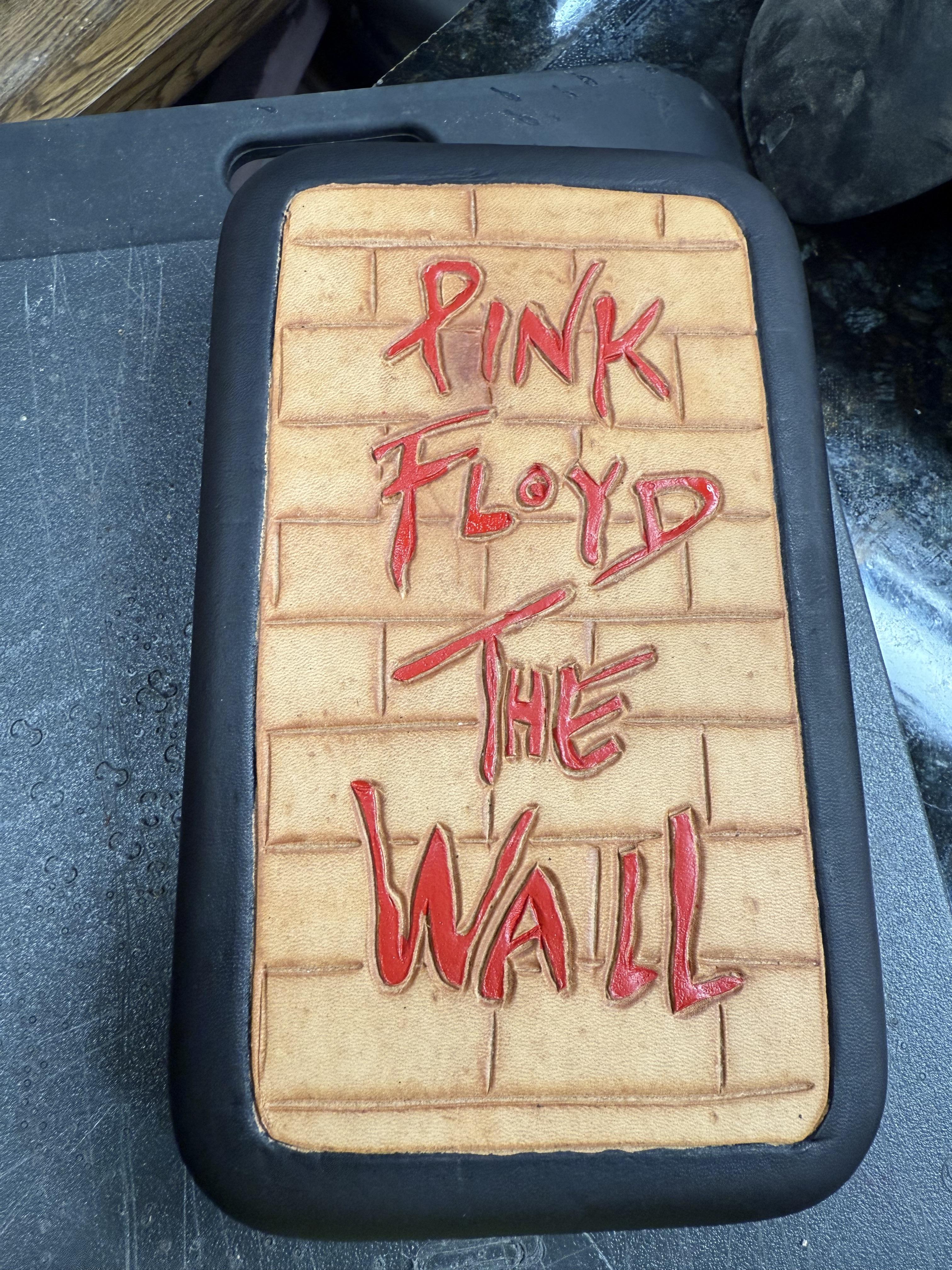

Yes. Between the P and the I. It’s such an eyesore. I’m hoping once the drop of oil soaks in overnight and it is what it will be I can then scrape it maybe and re-oil??? Maybe? It’s a diabetic test kit for my brother. I’m hoping to remove it but if not, well, it’s my brother. lol.

-

Is it the area in between the P and I? Antiquing may hide it. It looks like it got a little burnished so if it doesnt work the first time try slightly roughing up that area and try antiquing again.

-

Thank you. No seriously. Lol. It’s a friggin pink spot in the word pink! Ra help me. Lol

-

Ah! I think i finally spied it. I think if you antique it, then top coat it. It will no longer be visible.

-

Lol is this a joke? Cause I am not seeing the bad spot you mentioned. BTW that looks great! Nice work.

-

How do I remove this spot? I got a bit of paint on it and I tried acetone. Then I added a drop of oil. Now it looks pink. What do I do? I also plan on antiquing this. Maybe it will cover it up a bit???

-

Not sure if anything is available off the shelf, but bear in mind that Stimpson didn't sell hardware generically. In other words, you couldn't just buy dies and than fit them to any machine. They had different die systems for different machines, and each application had a different stroke, arm configuration, pocket mechanism, etc. 3/8" diameter hardware is more common though. At least if it was for the regular C-1 series rivet machines and for the 489 and similar series grommet machines (which were the foot and electric powered versions of that hand operated press). It wouldn't be a hard job for someone with a metal lathe to make an adapter to at least get the hardware to fit in the hole. You'll also need to consider how you'll hold your fasteners in place. Most of these machines relied on special pockets to do so which the driver would push the rivet or grommet through and they are really not meant to have the hardware swapped out frequently. You'd set it up for one job and a different machine/press for another job. Some drivers have a rubber sleeve or a magnet to help hold the fastener in place, but you'll need to consider it when choosing your hardware. Because it's a hand operated press, you only have one hand to hold the material and fastener in place as you set it. Grommets are often pre-punched, so you can set the fastener in the hole and then crimp it without any pockets, which is likely how that press was made to work, so I think it would do better sticking with grommets.

-

Don Hendricks joined the community

-

If adapters are not available. Then talk with a machinist to make you adapters for whatever brand dies you got or want.