All Activity

- Today

-

Lovely work, I have yet to master doing horses. On one occasion I can do a nice job, but other times they are a complete flop no matter how many times i've done them , lol 😆 HS

-

Great work 👍 acorns and oaks leaves are some of my fave patterns, that and roses. HS

-

It's been some time. How has this machine worked out?

-

Veli joined the community

-

-

Eli Schlabach (217) 543-3464. Landis Sales & Service is located at 115 E CR 500 N, Arthur, IL 61911. This location is in Douglas County.

-

-

jleaf joined the community

-

Opinions on the Cowboy cb3200 sewing machines? I found one for sale fairly close to me. I make quite a variety of things and realize one machine won't do everything but if I could mostly use it for sewing tack and heavy stuff and sew everything else by hand. Thanks

-

caustic_cowpoke joined the community

- Yesterday

-

Outstanding. Thank you for the tutorial. I bought a dozen caiman tails cheap from Buckle Guy, I think, and have been looking for a use. DAve

- 24 replies

-

- rifle sling making

- rifle sling measurements

- (and 1 more)

-

Dye woes

Yellowhousejake replied to Yellowhousejake's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Interesting idea. I have done that with NFO, but results vary depending on the leather. DAve -

I know this is an old thread but I noticed someone was visiting this thread so here is what I found earlier this year on evilbay in Jan 2025. They are for 1/4" piping. This set is not a plug and play set as I needed to adjust the height of the bars to which they mount as the length of this set is shorter than the "standard" 441 feet set. They do work when the machine is adjusted but I have as of yet have had no need for these.

-

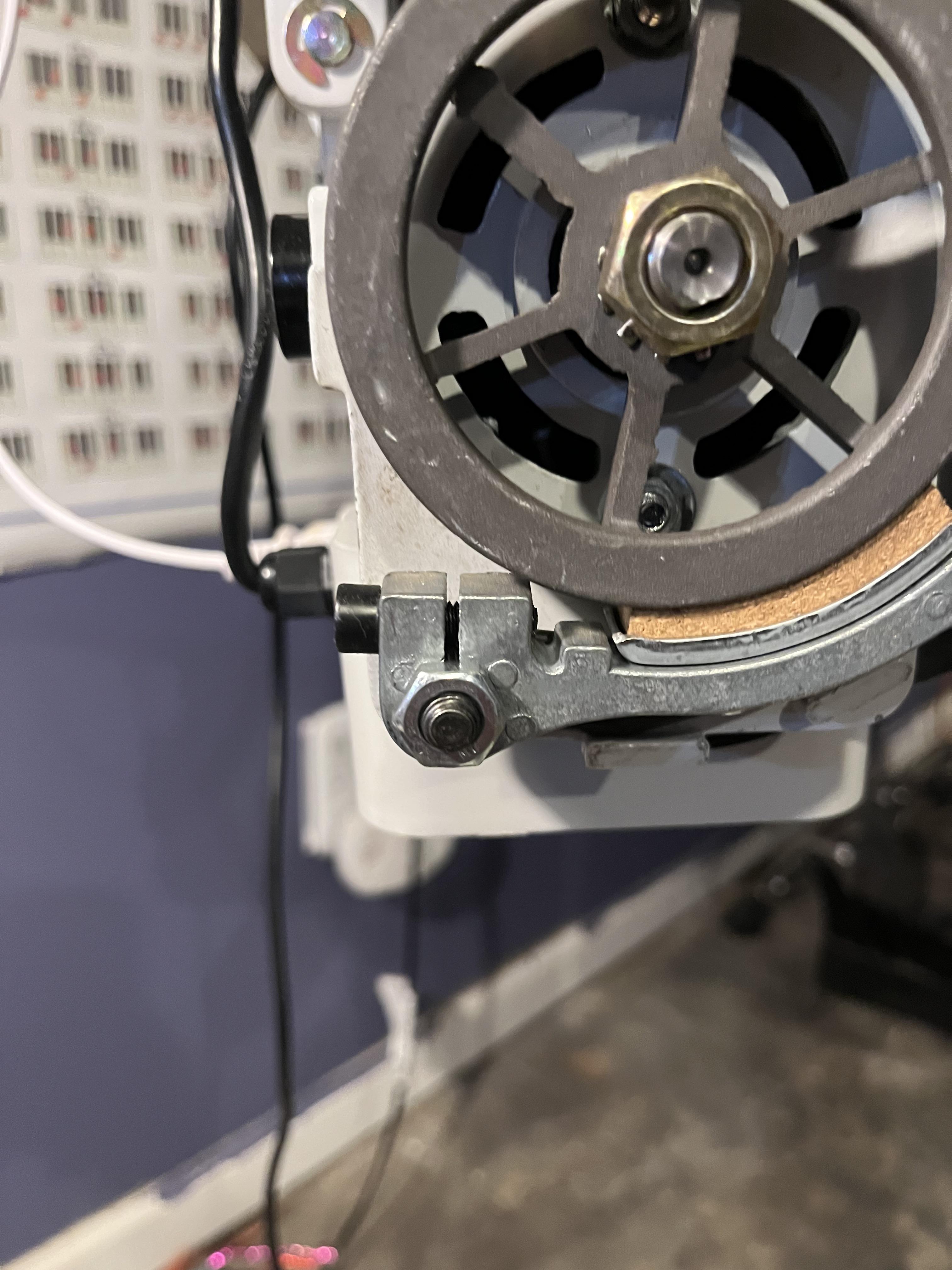

The more the slack, the better. Do whatever it takes to move the brake pad away from the clutch drive plate. If it's already on the verge of engaging, back off the screw to give it more hold vs motion time. Somebody with a shop should come up with an adjustable clutch/brake pad accessory for these motors.

-

I may need to adjust my clutch brake b/c I barely have to tuck the gas and it’s moving. It’s a fine line between releasing the brake and the machine stitching.

-

Very impressive, first time I've seen the pattern extended right to the end with the buckle tongue holes through it.

-

JohnnyLeather joined the community

-

Hi everyone, I own MuseLeather.com and wanted to offer it to the leather community before listing it publicly. Why this domain works for leather businesses: ✓ Memorable & Professional - "Muse" implies artistry and inspiration (perfect for handcrafted leather) ✓ Clean .com - Instant credibility with customers ✓ Brandable - Works for wallets, bags, belts, journals, furniture, apparel ✓ Available social handles - @museleather likely available on Instagram/Facebook Use cases: Leather goods brand (handbags, wallets, accessories) Custom leather workshop Leather furniture company E-commerce store Leather craft education/courses Why .com matters: Customers default to .com when searching. It ranks better in Google and looks more professional than .net, .co, or other extensions. Price: $1,200 If you're serious about building a leather business and want a strong domain foundation, this could be it. DM me if interested.

-

This is your first time tooling? Fantastic work!

-

Sounds like allot of the neatsfoot oil I've used. I remember everyone swearing by "Sheps" here in the USA. It was identical to what you describe, stench and all. I used a fair amount over some years. If you heat it up it will loose the cloudiness. Don't use it to lube machinery, it's not suitable for such use unless you're in a Post Apocalypse Zombie-Walking World. (I guess would be ok at that point).

-

I don't have a Landis 3 to compare to....Although I'd gamble they might be similar to what's in a Landis 16? The Landis Amishman in McCleansboro IL has strippers for the 16. I think the're kinda pricey for what they are. Long ago I was cheap and just made my own from blocks of rubber. I got the best results from just taking a block of 1/2" 40 durometer rubber and greasing it up real good and using a punch of the right diameter. one good whack and a cylinder shaped piece pops right out. Put in the wax pot and just lightly tighten it down. Use a small awl or really thin/fine nail sharpened real sharp to poke a hole while it's in the guide.

-

georpano joined the community

-

Yup. shure can

-

Tandy gun holster pattern wanted

Wildwest2029leathercraft replied to Wildwest2029leathercraft's topic in Resources

Can u share -

-

Run on is the reason for leaing the brake on. But, open the motor housing where the lever comes out and look to see is there is a screw adjustment to preposition the lever downward, or to move the brake pad outward. If so, you can move the lever down to a point where the cork just engages, then fine tune it so it to minimize the free play before it engages with the motor. Some folks have actually sanded down the cork brake pad to get more movement before it hits the metal drive plate. That's the ideal situation. Clutch motors have an adjustment for free play that most servo motors lack.

-

You can measure the width of the needle just above the scarf. That will tell you the metric needle size. (1.4mm, for example is 140Nm)

-

I removed the brake from my brushed motor, and preferred it that way. I didn't like having to press on the treadle in order to move the handwheel freely. Try removing it, and see how many revolutions it takes for it to stop from the speeds you sew at. Then you can decide what you like.

-

Great job! that looks fantastic. I also like the patterns going over the edge. Makes it look like it is sitting on top of the belt.

-

Lots of those specialized presser feet have been around for over a century. There's a reason they endure. A zipper foot definitely lets a person stitch extremely close. In the case of a zipper foot (say on a domestic machine especially) you're well off to pair it with a needle plate that has a close fitting needle hole instead of a zig zag plate. The larger needle hole can let your sewn goods push through and mess up your stitch. You'll run into a lot of these little issues as you expand your sewing skills.