All Activity

- Past hour

- Today

-

susiesmooth joined the community

-

Im wondering if my problem is a safety clutch as since having a minor sewing problem(though there were about 4 rotations worth of thread caught up under the bobbin holder) the hook & needle timing appears to be waaaay out now, about half a rotation away from meeting . I've never heard of a safety clutch. Does anyone know whether an old 291 would have one?

-

Awww! Woman Repurposes Mom's Singer in Her Memory

fredk replied to Sheilajeanne's topic in All About Us and Off Topic

Just got a delivery of my latest one see it here; https://leatherworker.net/forum/topic/102026-freds-ramblings/page/12/ -

I just took delivery of my latest purchase Another sewing machine. Purchased off ebay. I couldn't resist the 'bling'. Its a domestic, possibly German and uses a shuttle. I'll check it out fully later. I doubt I'll put it to use though and it has a nice wood case 4 Singers, 1 Singer clone, 1 Tippmann Boss, 1 New Home & 1 (unknown)

-

friquant started following Stitchman Servo Motor (The Missing Manual) and Stitchman servo motor.

-

I have the same servo motor. The paper manual shows the wrong values for the P15 settings. On mine P15 actually needs to be set to "0" to enable the needle position sensor. Here are my notes on this servo motor, which may reasonably constitute an English user manual, with some missing pieces.

-

Here is my attempt at documenting the settings for the Stitchman servo motor. After some trial and error, the needle position sensor is working. My setup has 2.2:1 gear reduction by way of an extra small (35mm) motor pulley, and the needle position sensor still knows what to do. If anyone has figured out the slow start settings for this motor, I'd like to hear about it. Normal Mode ### P Switches between three needle stop modes. Notice there are two green LEDS next to this button. TOP_LED: Stop with the needle UP BOTTOM_LED: Stop with the needle DOWN (position affected by P-03), and enable heel-tap NO_LEDS: Stop as soon as you let off the gas ### S This turns the lamp on/off. (untested) ### + Increases the max speed. default: 4500 range: 200-6500 (Note you can also increase max speed using P16 in programming mode) ### - Decreases the max speed default: 4500 range: 200-6500 (Note you can also decrease max speed using P16 in programming mode) Programming Mode Most settings are changed from inside programming mode. ### Enter Programming Mode - While holding down "P", press "+" - The screen will display "P-00" ### Save and Exit Programming Mode while in programming mode: Press "S" This saves whatever changes you've made and exits out of program mode ### Restore Factory Settings while in programming mode: - Hold "S" key for 3 seconds Table of Parameters These parameters are accessible from programming mode ### P-00 (apparently not adjustable) ### P-02 (Motor Direction) default: 1 range: 0-1 ### P-03 (UNDocumented Needle DOWN Position) (The needle UP position seems to remain the same. So to change your needle UP position, loosen the screws on the needle positioner.) But setting the needle DOWN position effectively lets you specify how much rotation between needle up and needle down. Note this setting only comes into play when the green "lower" LED (next to the P button) is lit and when P-15 (Needle Detection Mode) is set to "0". (When the green "upper" LED (next to the P button) is lit, heel-tap does nothing.) (Note P-15 is mis-documented in paper handout) default: ? range: 6-18 6: needle-up + 30 deg 7: needle-up + 35 deg 8: needle-up + 40 deg 9: needle-up + 45 deg 10: needle-up + 50 deg 11: needle-up + 55 deg 12: needle-up + 60 deg 13: needle-up + 65 deg 14: needle-up + 70 deg 15: needle-up + 75 deg 16: needle-up + 80 deg 17: needle-up + 85 deg 18: needle-up + 90 deg ### P-04 (Minimum Speed) default: 250 range: 200-800 ### P-05 ("Speed up and Slow") default: 3000 range: 500-4000 (This setting does not do anything on my machine. My machine can go full speed from the beginning.) ### P-06 ("Set the seam") default: 0 range: 0-999 (I do not know what this means or what it does.) ### P-10 (Automatic clearance run) 0: disabled (default) 1: automatic clearance run NOT SAFE!!!! This bypasses the gas pedal and starts a routine of "speed up, slow down, stop, repeat" mode. ### P-11 ("Presser foot ascend starting time") default: 0 range: 0-2000 (milliseconds) (I do not know what this does.) ### P-12 ("Ascend presser foot keeptime") default: 5 (seconds) (I do not know what this does.) ### P-14 (Max Current) Woah this would be cool if it worked default: 300 max: 50-450 (I would love to use this feature. But it is only in the paper manual...it does not show up as an option on my machine) ### P-15 (Needle Detection Mode) THIS IS BACKWARDS/WRONG IN THE PAPER MANUAL 0: use needle detection 1: ignore needle (default) ### P-16 (Max Speed) This is shown in the paper manual as P-01 default: 0900 range: 0200 - 4500 ### P-19 (Unknown) Not listed in paper manual default: 00 range: 0-15 ### P-20 (Unknown) Not listed in paper manual default: 0800 range: 200-3500 Photos Including images of the manual, the controller, the motor shaft (tapered!), and the motor pulley to help you determine whether this is the servo motor that you have. I conjecture that "Stitchman" is just a label applied, and that the actual manufacturer supplies these same motors and controllers under various names. Mine came with the purchase of a Jiang Long 341.

-

Daddy can you do your frog impression? Why? Because mummy says when you croak we can all go to Disneyland

-

Help!!Trouble Uploading Photos - "Upload Failed" Error (Error Code -200)

Jazz_M replied to Jazz_M's topic in Member Gallery

Thanks a ton! You’re too kind. -

SheRa1983 started following mrdabeetle

-

SheRa1983 joined the community

-

TommyG started following Sweatband shape

-

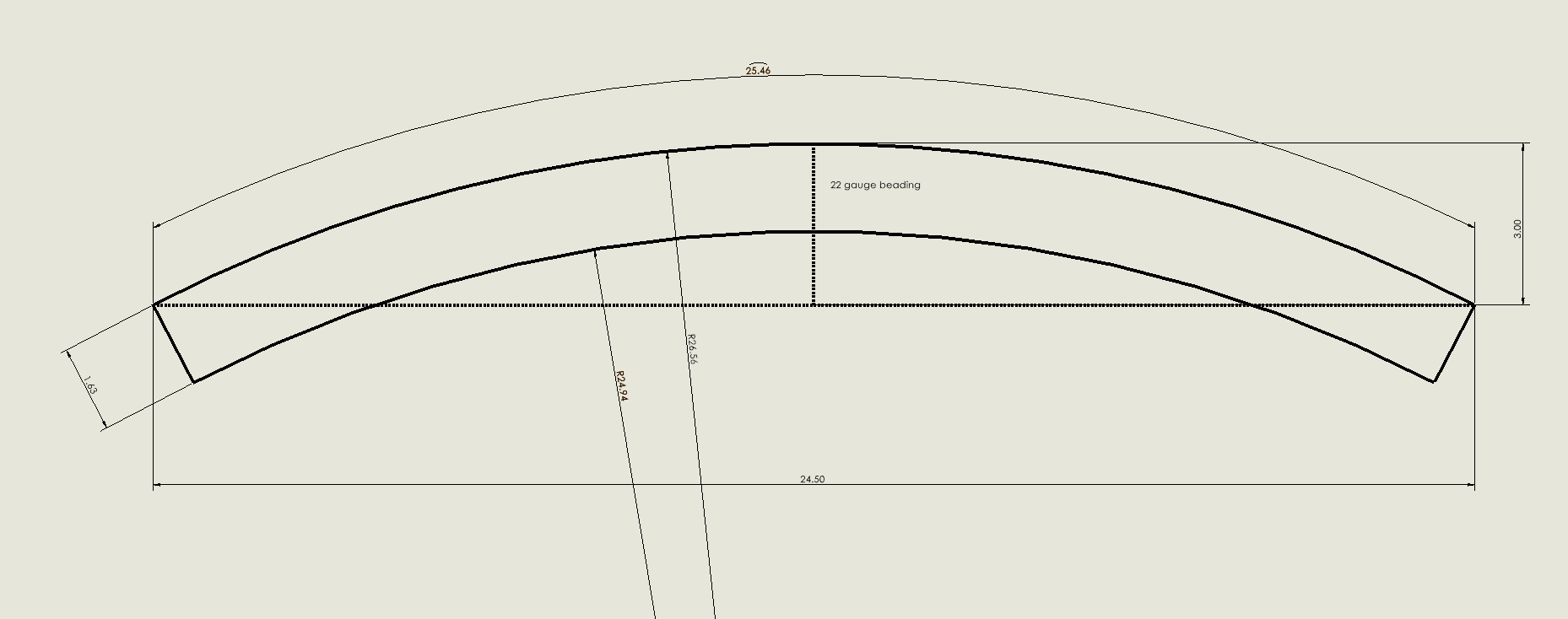

Just recently took up the hobby of custom hat making....so I figured on making my own sweat bands as $10 (+ shipping )a pop for premade is quite a high perceantage on the cost of creating a costume hat...so after some reasearch I drafted a template for the leather section out aluminum, just a big curved ruler if you will. So, its big enough to cater for size 6 thru 8...so the top arc would be the circumference..i might scribe mine with sizes measured out on the right side (length of arc=circumference) I know they use a plastic reeding now but I went old school and use 22 gauge spring stainless steel wire (source Amazon) to insert in the bias binding edge added.I hope this helps someone, the question on dimensions and a template seems to pop up on various forums. Oh...mine is based on 1 5/8" wide sweatband btw. I also used Sheep Leather as my material.

-

Help!!Trouble Uploading Photos - "Upload Failed" Error (Error Code -200)

Dwight replied to Jazz_M's topic in Member Gallery

Get a simple program . . . put it on your computer Adobe photo shop elements 2.0 is a really good one . . . it's 5 bucks on Ebay . . . comes with a disc . . . don't buy one that is a down load as you will forever be plagued with ads and adware Use it to size the photos to 800 by 600 pixels . . . and an overall size of 500 kb or so. Then use the choose files below . . . go to your file on your computer . . . choose the pic . . . and it'll load. You can do a lot with that little photoshop program afterwards as well. May God bless, Dwight -

Very true. Maybe this and similar posts could be pinned in 'Getting Started' for beginners. Nothing is more encouraging than seeing beautiful work done with a minimum number of tools! I wish I had seen all this when I first started 2 1/2 years ago. Very nice @WalterF, Thank you for showing how much can be achieved with simple tools, skill and imagination. I should have said that first.🙂

-

Looking for silver hardware for breast collar

rktaylor replied to DS-Leather's topic in Saddle and Tack Accessory Items

Hansen Western Gear has some options. I've been pleased with their buckles and conchos, but haven't bought anything like this from them. https://hansenwesterngear.com/ Randy -

Romar joined the community

-

orcoporco89 joined the community

-

Hi everyone, I'm trying to create a new post, but I keep running into an issue when I try to upload photos. Every time I select an image, it just shows "upload failed" and I'm seeing an error code -200. Has anyone else experienced this, or does anyone know what might be causing it? Any suggestions on how to fix this would be greatly appreciated! Thanks in advance for your help.

-

yashpatel10 joined the community

-

Gilbey817 joined the community

-

I recall a while ago reading a user question on this topic, and am just getting around to adding my two cents worth. Rivets using plain stems cut just "long" of the "clench washer", then peened round to assure a permanent "set" can be challenging. The length above the washer is critical, and MOST easily attained with a compound diagonal cutter (colloquially a "compound dike") Using a "compound diagonal cutter" for these little wonders has been the only time-after-time reliable means I've found of quickly and accurately getting the post clipped off at the correct place without negative effect on my/your carpel tunnel. Got my most recent pair form Walmart for about $9.50. Amazon's got a DeWalt version for about $17.00, Just trying to help. Sorry about the delay in posting.

-

AlZilla started following Springfield Armory 9mm Echelon w/ Sharps Bro. frame.

- Yesterday

-

I have made several holsters for this young man. I am flattered that he likes my work. 2 chest rigs, one leg drop, one for a silenced 22, and others. This is a Springfield Armory Echelon 9mm on a Sharps Brothers aluminum frame with a Holosun red dot. Another dang nice gun. I'm jealous! Hermann Oaks 8/9 oz Fiebings light brown pro dye Resolene 50/50 with water with a 100 % resolene top coat 207 bonded nylon top and bottom Sewn on a Cobra class 3 Dang i like making holsters!

-

Well done Walter. I had the opportunity to show my work at a Boys and Girls club. I enjoyed their enthusiasm very much. While my work is mainly holsters, i was able to show them key rings, ear rings, cattle tags, and many variations of leatherworks. I still get emails from them....

-

Nice big oak leaf... I often associate that sort of leaf of chipster99's with more Northern areas, but then I think I saw some similar to this changing colors on a different road about 10 minutes from here. Cool that you showcased the dried leaf with the good carving

-

EmmaRose joined the community

-

Landis 3 Needle and Awl machine not stitching correctly

Goldshot Ron replied to knotzo's topic in Leather Sewing Machines

I just saw this thread. The one thing that I think I see, is that the bobbin is threaded incorrectly in the shuttle. Sewing with the cover off will also affect how it sews. I have messed with my Landis 3 for almost 7 years, and I still do not have faith in it nor myself to tackle a real project. -

Scoutmom103 started following PFAFF 145 Top Tension Issue

-

AlZilla started following 3 Knife Sheath Examples for Class.

-

Simple, minimalist design and skillfully executed. This is at least your 3rd post showing the importance of practice with minimal tools and skill building over a shop full of the latest big name tooling. Every beginner should read these few posts before they start filling that Amazon cart. Thank you for posting these.

-

Made 3 different knife sheath styles for a class I have the opportunity to teach in Birmingham, AL on 19 July. Love being able to show a way of designing and making these with minimal tools and expense. Used clearance bellies, contact cement, wax, glycerin soap, thread, and neets foot oil.

-

Landis 3 Needle and Awl machine not stitching correctly

dozernmike replied to knotzo's topic in Leather Sewing Machines

Did you get this working? -

I am looking for a landis 3 loop thrower. The little finger with a hole in it that moves the thread in front of the needle. I have tried the landis number for a few months but I'm not getting an answer. I thought I would see if anyone has one before attempting to make one out of a 5/32 aircraft drill bit.

-

As far as it's backed off I really doubt the tension is the problem,my guess is look for it to be binding ( or getting caught) somewhere between the spool & machine.

-

Smg joined the community

-

RobynR changed their profile photo

-

The servo motor worked fine with no positioner system prior to transporting to a new location....so thinking it might have to do with some internal misalignment as Constabulary stated.