All Activity

- Past hour

-

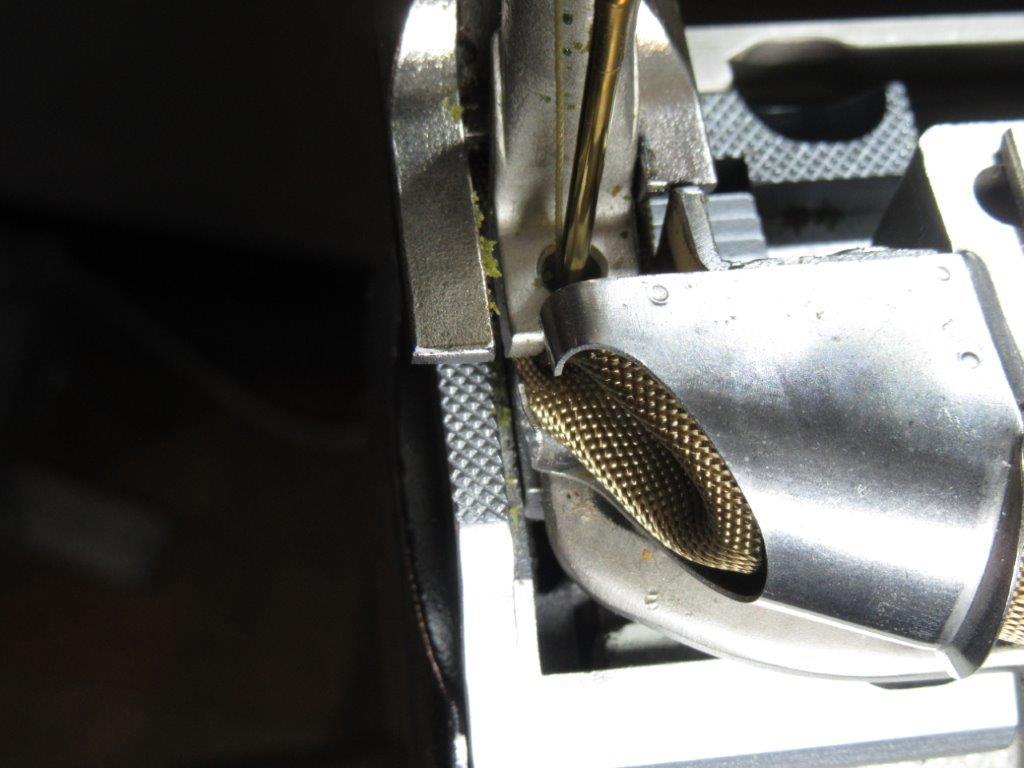

This is just suggestion, and everybody different in their setups and their techniques. This just my technique that been using for long time setting up and binding. and just my opinio for your binding using Cylinder Bed and compound feed, with syncro-move with your feed movement. Don't be intimidated by cutting and shaping both Inner and Outer Feet to make things work , Also Cut/trim that push-stop plate that leads out from the binder throat that you pushing your material up against on the Feed. Your length of that push-plate really does not have to be run out past the needle plunge to do it job with you pushing material against it. Leaving it long, is just working against you on your final results . Also, Your outer-press foot . Your inner R-side toe. ( me ) I like to 'leave it there' . but trim it off and shape it . Your outer L-side toe, just leave or trim to suit the need. Rather than just using only the L-side toe and foot-Heel . Keeping a little of that R-side foot ( even small ) is to your advantage in press/hold down and feed of binding and material. Very Rarely do I ever keep the outer press-Foot that is sold to me with binder kit. I end-up making my own off generic stock Press Foot. And, your inner Foot. I like to trim/shorten and shape the toe of it also . Needs to end-up as tight as possible, and trimming the inner foot and shaping toe let's the binder in more tighter/closer . Also when your holding and feeding your material into the binder and sewing with cylinder bed, make habit of, Don't let it sag lower than the binder. I like to hold and feed material into, on a little higher angle than a flat level feed to binder. Surprising how even angle of material feed can change the binding tracking on the cylinder bed. -- Not same cylinder bed machine as yours, but here in this Pic. this just my technique . In the Pic. The needle is just coming 'out' of it's plunge and just on the rise. Where everything is at it's tightest in it's syncro-feed movement . You can see where the outer press-foot R-toe just shy of touching/meeting the Press-plate tip/ending. With the press-plate length cut just a tad past the needle . Binding system, all has to end-up tight and smooth, movement back and forth. - - -

-

I've gone through this recently with raw edge 90* binders and it wasn't long before I realized the above to be all correct and very important. Also, practice (PRACTICE? we talkin' bout PRACTICE!?!) how you are feeding the material into the binder. I went through a lot of tape, material, and time before I figured things out. I worked with a few different over the counter binders and ended up modifying my binding foot, throat plate, AND binder brackets to get my desired results. Now it works every time on smaller radius curves. This is with a synchronized Juki 246 cylinder arm.

-

Before you know it, youll be on you 10th attempt and still going till it becomes a fever. I think I have about 20 holsters laying around my house. I guess its obvious why Im single?

- Today

-

I'd say you were right about the tension, the holster is 10 oz with an additional 2 oz liner. But the loop is just 10 oz, so it may be that very slight different causing the issue occasionally. I'll have to double check that before I go for the second attempt.

-

This is the penultimate report on Test Pieces Group 1 This Group has mainly been kept in a south facing car windshield. During the test time each piece was re-oiled once #1. Baby Oil; Flex - the same as Control #1, Smell - Slight smell of leather, Colour - Dark Brown, darker on front than rear, No fungus or rot #2. Cooking oil (rape seed oil); Flex - the same as Control #1, Smell - Slight smell of cooking oil, Colour - Dark Brown, same on front and rear, No fungus or rot #3. Lard (pork fats); Flex - about the same as Control #1, maybe slightly better, Smell - No smell, Colour - Light Tan, Same on front and rear, No fungus or rot #4. NFO Compound; Flex - about the same as Control #1, Smell - Very slight smell of leather, Colour - Dark Tan, Same on front and rear, No fungus or rot #5. Olive Oil (extra virgin / pure); Flex - about the same as Control #1, Smell - Very slight smell of leather, Colour - Dark Tan, Same on front and rear, No fungus or rot #6. 3-in-1 oil (contains benzine); Flex - slightly stiffer than Control #1, Smell - Very slight smell oil, Colour - Dark Tan, Same on front and rear, No fungus or rot #7. Vaseline (petroleum based); Flex - stiffer than Control #1, Smell - No smell, Colour - Nearly the same as Control, (which is like slightly darkened raw leather), Same on front and rear, No fungus or rot I'll try to do a report on Group 2, the pieces hanging outside This will be the penultimate report on that group as well as I'm thinking of ending this at the end of September or so 2 years, and we / I have discovered that a lot of these products can be used on leather without harm, all they may do is darken undyed leather

-

Well, that worked ! Thanks @CowboyBob He stitches now 🤩, just to have to regulate the tension now. Thanks for your help.

-

Groove is facing left 😬 ... changing that right now ! No manual ... was rather hoping someone on here might have one 🙏🙏

-

OK, Im stumped. Need a snap or sam brown stud for a 16 oz. piece of saddle leather. Cant find anything longer than 3/8". Line 24's are way too short. Using it for a clients double headed axe sheath. Sheath is all 16 oz. Thoughts?

-

Sorry for my part. I had my jackass pants on that day. Jim

-

"made by sum yung gui hung lo". Made I larf that did. If I'd said it Tom would've told me off. (Just kidding Tom.) I've drooled over such set ups on YouTube Wiz. Don't get me wrong Wiz, I'm not shy when it comes to spending money when it's right and if I had such contracts I would do the same. I've no doubt that eventually I'll end up with something decent and by the time I've learned what I need to know and enjoyed playing I'll be able to do it with a flourish. Here's todays effort. The red is just over 1mm, the veg tan is 2.5 and 1mm. The red is 18mm

-

I spent good money on a binding setup for my Adler 69 and got nowhere with it, probably my fault but there you are. I bought one folder from JL but it's too small. Maybe it'll come good later. Don't give up.

-

Way back in the late 1980s, I had a job setting up a sewing operation that required applying edge binding to the items being sewn. I started out with an over-the-counter folder and some bias tape in 3 foot lengths from a store. The results were a disaster! I called my industrial sewing machines dealer and he recommended that I contact a guy who custom built folders and other sewing machine attachments.I got together with that fellow, showing him a sample of the material I was working with. He designed and built a double folder attachment that fitted onto or across the bed of the Juki LU-563 that I was going to use. The folder was made to double fold bias tape that was sold on huge rolls. It was 1.25 inches wide and I believe was polyester material. The roll sat on top of a platter that was mounted onto the right-rear end of the table. The platter rotated freely under adjustable spring tension. I set it to prevent the roll from free-wheeling when I sewed fast. This setup worked flawlessly. The edges were about 5/16 inch down from the top and were sewn a little over 1/16 inch above their bottom folded edge. The material being covered measured about 1/16 inch thick along the edges. It was an orange honeycomb material that I made into safety vests worn by road workers when they were on the job on highways and byways. I also 2" wide sewed yellow Reflexite strips across the front and back, plus sewed a patch on the back identifying who they worked for. This eventually morphed into reflective vests for transit works and Police officers. The bottom line here is that if you need to sew edge binding onto goods for sale, go the extra mile and have one made or modified to work with your preferred edge tape and sewing machine. A fully matched set of parts will work more reliably than miscellaneous parts from hither and thence, made by sum yung gui hung lo.

-

I spent a day with a binder on my pfaff-545 and could not get the bottom and top sides to be even. I conjectured that to get them even the entrance runway (the zig zag of wire) would need to be horizontal, whereas mine was canted upwards to clear the flatbed. My best plan at the time was to stitch from the wrong side of the fabric, since the bottom of the binder always had less coverage than the top. That way the stitches on the right side of the fabric could be close and tidy to the edge of the binding. I bought two binding attachments with my JL 341, but have not used them. When I ordered them they were specific about asking what kind of tape I wanted to use---both its width and its thickness.

-

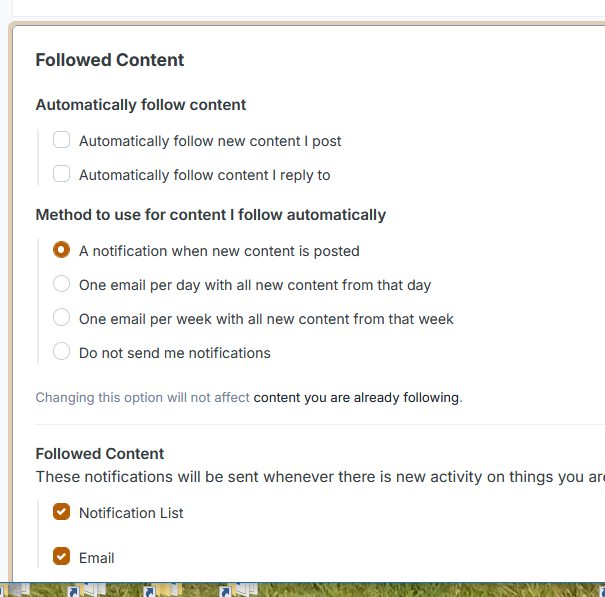

How to Subscribe to Everything in a Single Forum

friquant replied to friquant's topic in Computer Help

That does seem to be the pattern for the other missing notifications as well. I'll figure out a game plan for those 🍹 -

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)

Thinking of making my own tack (questions)

Northmount replied to RestlessHands's topic in Saddle and Tack Accessory Items

I moved your post to Saddle and Tack Accessory Items. There are other related sub-forums here as well. Have a look through them and you may find some of the answers that you are looking for. Did you know that you can edit your posts? The time window for editing is about 2 hours. Look for the 3 dots at the top right of a post, pick it, then pick edit. This way, you can add info, fix typos, correct statements, etc.- 2 replies

-

- treeless saddle

- painting

-

(and 1 more)

Tagged with:

-

Thinking of making my own tack (questions)

RestlessHands replied to RestlessHands's topic in Saddle and Tack Accessory Items

Ah and, completely forgot. I need tips on painting/decorating leather that actually is resistant to light wear (skirting, fenders, back of cantle) as well as where people get their sale hardware from. Sorry for the inconvenience, thanks- 2 replies

-

- treeless saddle

- painting

-

(and 1 more)

Tagged with:

-

I have made various things from leather and I feel like tackling a larger project. Whether that's me making tack to sell or making tack for me, I'm interested in how the complexity of certain things work. I'm vaguely aware of how to create a treed saddle, but what I'm really interested in is treeless (seems like a "horse girl" thing so maybe lucrative lol) and so now I'm trying to figure out how to make treeless saddles that aren't shit, with proper wither clearance. Also, instead of asking The Google I was wondering what your favorite measurements for things like headstalls and breastcollars are. Thanks!

- 2 replies

-

- treeless saddle

- painting

-

(and 1 more)

Tagged with:

-

The place to sell items is in the Marketplace. Moved your detailed post there.

-

SGG84 joined the community

-

I have bought sample cowhide skins from mainly Samanta and Opera over the past few years, that I have then decided not to include in the range, and so would like to sell. They are lovely quality and would all have cost me approx £65 - £80 per m2 - I would sell those that are up to 1.5m for £50 a skin, and for above that size at £100 - plus shipping. If you would like more information / pictures etc, please reply to this post. sale leathers .pdf

-

New pistol, new holster

Samalan replied to Thadrick's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Wow, that's a beauty! -

Boss says I might get a promotion before they put me in the old folks home. I trained for years at a desk job shoveling horse sh*t, never dreaming that I'd make the big show shoveling the real thing. This is better. Thanks, Jonas. The harness leather burnishes more easily than the HO bridle. I guess the waxes in the leather help the process. I can only blame myself for my previous stretchy belt. It was not heavy enough to stand up to the heat and humidity - was always damp. Thank you. I am all about sewing fixed loops and buckles on bridles, but I did manage to get some uneven stitches on this belt.